Snap-on Equipment EELR591A User manual

1 of 84

EAZ0080V42A

Snap-on Equipment

INSTALLATION AND OPERATING MANUAL

READ THOROUGHLY BEFORE INSTALLING,

SERVICING OR MAINTAINING THE

LIFT.

SAVE THIS MANUAL

INSTALLATION and OPERATION MANUAL

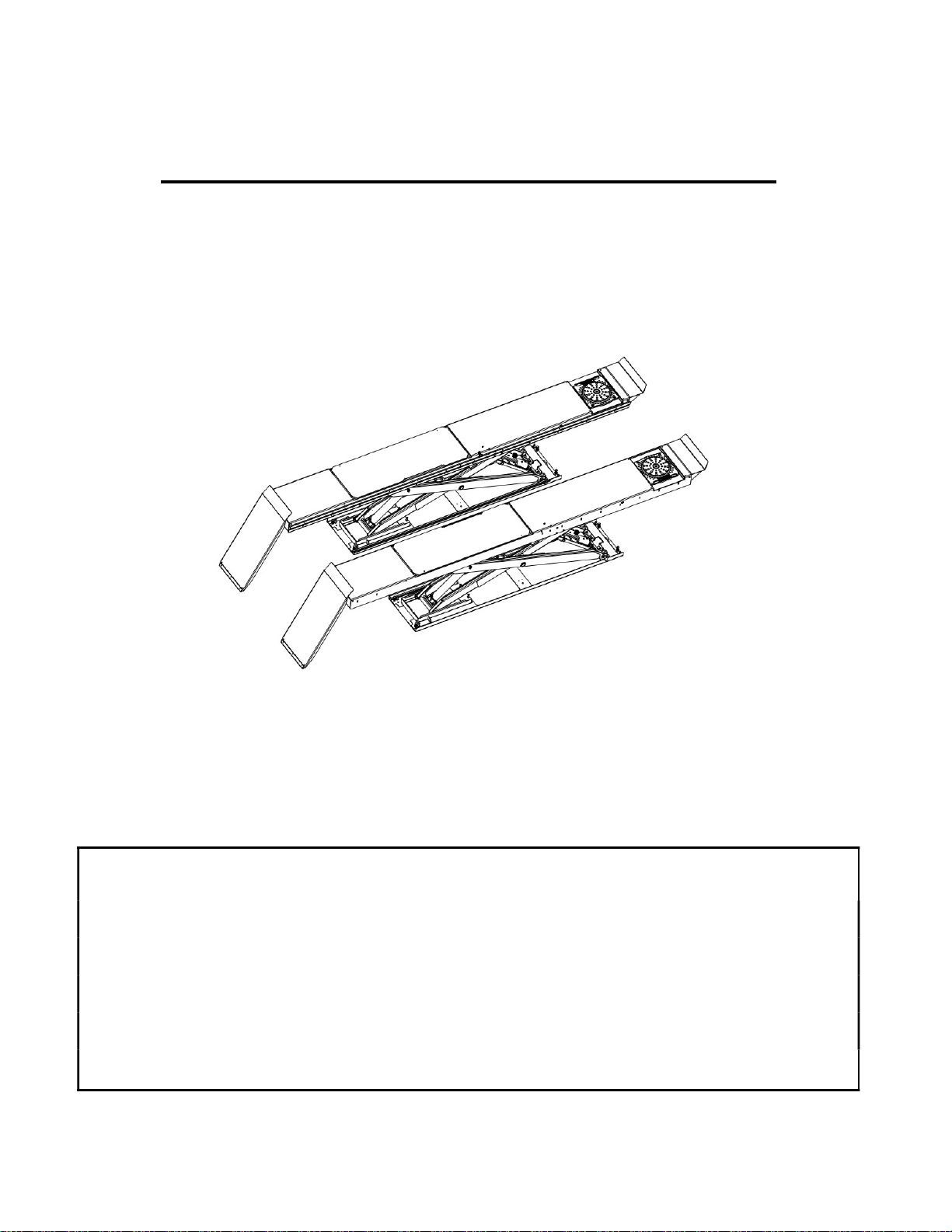

14K SCISSOR LIFT

Standard Models:

EELR591A, EELR592A, EELR593A, EELR594A

EELR787A, EELR788A, EELR789A, EELR790A

Short Models:

EELR587A, EELR588A, EELR589A, EELR590A

EELR783A, EELR784A, EELR785A, EELR786A

Apr 2020 REV. J

309 EXCHANGE AVENUE, CONWAY, ARKANSAS, 72032

TEL: 501-450-1500, FAX: 501-450-1585

2 of 84

TABLE OF CONTENTS

1.0 OWNER / EMPLOYER OBLIGATIONS ......................................................... 4

2.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................... 4

3.0 SAFETY WARNING DECALS ....................................................................... 7

4.0 SPECIFICATIONS ......................................................................................... 8

5.0 CONTENTS .................................................................................................. 10

6.0 TOOLS REQUIRED FOR INSTALLATION OF LIFT .................................. 10

7.0 INSTALLATION OVERVIEW ....................................................................... 11

8.0 INSTRUCTIONS ........................................................................................... 11

8.1 Flushmount Bay Layout ..................................................................... 12

8.2 Surfacemount Bay Layout ................................................................ 13

8.3 Baseframe Location ........................................................................... 14

8.4 Anchor Location ................................................................................. 15

8.5 Unpacking the Lift .............................................................................. 16

8.6 Hydraulic Connections....................................................................... 17

8.7 Air Safety and Auxiliary Air connections ........................................ 19

8.8 Pneumatic Sensor Connections ........................................................ 23

8.9 Electrical Connections ....................................................................... 25

8.10 Initial Operation ................................................................................ 27

8.11 Equalizing Function Check ............................................................. 28

8.12 Maximum Height Adjustment ......................................................... 29

8.13 Level and Support ............................................................................ 30

8.14 Anchoring Procedure ....................................................................... 31

8.15 Grouting Procedure (Optional) ........................................................ 32

9.0 ACCESSORY INSTALLATION .................................................................... 33

9.1 Installation of Line Covers ................................................................. 36

9.2 Installation of Extension Line Covers ............................................... 37

10.0 LOCKING FRONT TURNPLATES & REAR SLIP PLATES (OPTIONAL) 38

10.1 Installation of Front Turnplates ...................................................... 38

10.2 Console Connections for Locking & Lights .................................. 40

11.0 FINAL PROCEDURES ............................................................................... 42

11.1 Check of Assembled Lift .................................................................. 42

11.2 Operation Test with Vehicle ............................................................. 42

12.0 LIFT OPERATION ...................................................................................... 43

12.1 Raising the Lift .................................................................................. 43

12.2 Lowering the Lift ............................................................................... 43

13.0 RECOMMENDED MAINTENANCE ........................................................... 44

13.1 Checking Oil Level for Air Lubricator ............................................ 44

13.2 Maintenance of Turnplate & Slip Plate Locking System (Opt.) .... 45

14.0 LOCK OUT AND TAG OUT INSTRUCTIONS .......................................... 47

14.1 Isolation and Verification Procedure: ............................................ 48

3 of 84

14.2 Emergency Operation ...................................................................... 49

15.0 TROUBLE SHOOTING ............................................................................. 52

16.0 RECORD OF MAINTENANCE / TRAINING ............................................. 53

17.0 LIFT ASSEMBLY ....................................................................................... 55

17.1 Lift Assembly Parts List ................................................................... 55

18.0 REAR SLIP PLATE TRANSFER BALL ARRANGEMENT ....................... 60

19.0 HYDRAULIC & AIR ASSEMBLY ............................................................... 61

19.1 Hydraulic & Air Parts List ............................................................... 61

19.2 VARIOUS POLYTUBES .................................................................... 62

19.3 POLYTUBE PARTS LIST ................................................................. 62

19.4 OPTIONAL: LIGHT KIT SENSOR PARTS LIST ............................. 63

20.0 ACCESSORY ASSEMBLY ........................................................................ 64

20.1 Front Turnplate ................................................................................. 64

20.2 Rear Slip Plate Locking Mechanism .............................................. 66

20.3 Airline Routing for Locking Turnplates and Rear Slip Plates ...... 67

20.4 Rear LED Light Assembly: Exploded View ................................... 69

20.5 LED CONTROL BOX ......................................................................... 71

21.0 CONSOLE ASSEMBLY ............................................................................. 72

21.1 Electrical Panel ................................................................................. 72

21.2 Terminal Assembly for 14K ALI Console........................................ 73

21.3 Console: Pneumatic & Filtering System ........................................ 74

21.4 Console: Pneumatic & Filtering System -

Locking & Light System (Optional) ................................................ 75

21.5 Control Panel .................................................................................... 77

21.6 Console Panel Assembly ................................................................ 78

22.0 POWERPACK ASSEMBLY ....................................................................... 79

22.1 Powerpack and Manifold Assembly ................................................ 79

22.2 Powerpack Assembly ...................................................................... 81

22.3 Manifold Parts List ........................................................................... 82

APPENDIX FOUNDATION PLAN………………………………………………….. 83

4 of 84

1.0 OWNER / EMPLOYER OBLIGATIONS

1. The Owner/Employer shall ensure that lift operators are qualified and that they are trained in the safe

use and operation of the lift using the manufacturer’s operating instructions; ALI/SM 93-1, ALI Lifting it

Right safety manual; ALI/ST-90 ALI Safety Tips card; ANSI/ALI ALOIM-2008, American National

Standard for Automotive Lifts - Safety Requirements for Operation, Inspection and Maintenance;

ALI/WL Series, ALI Uniform Warning Label Decals/Placards; and in the case of frame engaging lifts,

ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference Guide for Frame Engaging Lifts.

2. The Owner/Employer shall establish procedures to periodically inspect the lift in accordance with the lift

manufacturer’s instructions or ANSI/ALI ALOIM-2008, American National Standard for Automotive

Lifts - Safety Requirements for Operation, Inspection and Maintenance; and the Employer shall

ensure that the lift inspectors are qualified and that they are adequately trained in the inspection of the

lift.

3. The Owner/Employer shall establish procedures to periodically maintain the lift in accordance with the

lift manufacturer’s instructions or ANSI/ALI ALOIM-2008, American National Standard for Automotive

Lifts - Safety Requirements for Operation, Inspection and Maintenance; and the Employer shall

ensure that the lift maintenance personnel are qualified and that they are adequately trained in the

maintenance of the lift.

4. The Owner/Employer shall maintain the periodic inspection and maintenance records recommended by

the lift manufacturer’s instructions or ANSI/ALI ALOIM-2008, American National Standard for

Automotive Lifts - Safety Requirements for Operation, Inspection and Maintenance.

5. The Owner/Employer shall display the lift manufacturer’s operating instructions; ALI/SM 93-1, ALI

Lifting it Right safety manual; ALI/ST-90 ALI Safety Tips card; ANSI/ALI ALOIM-2008, American

National Standard for Automotive Lifts - Safety Requirements for Operation, Inspection and

Maintenance; ALI/WL Series, ALI Uniform Warning Label Decals/Placards; and in the case of frame

engaging lifts, ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference Guide for Frame Engaging

Lifts in a conspicuous location in the lift area convenient to the operator.

6. The Owner/Operator shall provide necessary lockout/tagout means for energy sources per ANSI

Z244.1-1982 (R1993), Safety Requirements for the Lockout/Tagout of Energy Sources, before

beginning any lift repairs and maintenance.

2.0 IMPORTANT SAFETY INSTRUCTIONS

When using this lift, basic safety precautions should always be followed, including the following:

1. Only trained and authorized personnel should operate the lift or rolling jacks. Do not allow

customers or bystanders to operate the lift or be in the shop area while lift is in use.

2. Read all instructions in this manual and on the lift thoroughly before installing, operating,

servicing or maintaining the lift. Thoroughly train all employees in the use and care of lift and

rolling jacks.

3. Inspect the lift DAILY. Do not operate if it malfunctions or problems have been encountered.

4. Ensure no one is standing in front or behind the lift while vehicle is being driven onto, or

backed off the lift.

5 of 84

5. Before driving vehicle on, make sure lift is in the fully down position.

6. Before removing vehicle from the lift, make sure lift is in the fully down position and ensure that all

tools have been removed from the deck surfaces.

7. Always raise the lift off safety locks before lowering.

8. Do not allow rear tires or portion of the vehicle to interfere with approach ramp.

9. Be sure front wheel stops are always installed on the lift.

10. Never allow front wheels to strike the front wheel stops.

11. Always use wheel chocks to keep the vehicle from rolling freely on the runways. Wheel chocks

should be used at front and back of the same wheel.

12. Never attempt to overload the lift. The manufacturer’s rated capacity is shown on the

identification label on side of the deck. Do not override the operating controls or safety

devices.

13. Do not permit employees or customers on lift when it is either being raised or lowered.

14. Never raise a vehicle with passengers inside.

15. Always stand clear of lift when raising or lowering and observe “Pinch Points" warning.

16. CAUTION! Never work under the lift unless mechanical safety locks are engaged.

17. Always use Personal Protective Equipment (PPE) when installing or servicing the lift.

18. Always keep the lift area free of obstruction and debris. Grease and oil spills should always be

cleaned up immediately.

19. Always chock vehicle wheels before raising or lowering the lift.

20. Before lowering check the area for any obstructions including people.

21. To protect against risk of fire, do not operate the lift in the vicinity of open containers of

flammable liquids.

22. Adequate ventilation should be provided when working on internal combustion engines.

23. Never open hydraulic lines under pressure.

24. Do not raise or lower the lift with the vehicle on the Jackbeam.

25. For Jackbeam Safety Instructions, see Jackbeam Installation, Operation Manual.

This manual suits for next models

15

Table of contents

Other Snap-on Equipment Scissor Lift manuals