Snap-on Equipment EELR501A User manual

1 of 73

Snap-on Equipment

INSTALLATION AND OPERATING MANUAL

READ THOROUGHLY BEFORE INSTALLING, SERVICING

OR MAINTAINING THE

LIFT.

SAVE THIS MANUAL

INSTALLATION and OPERATION MANUAL

12K SCISSOR LIFT

EELR501A, EELR525A

EELR709A, EELR724A

Nov. 2019 REV.F

309 EXCHANGE AVENUE, CONWAY, ARKANSAS, 72032

TEL: 501-450-1500 FAX: 501-450-1585

EAZ0080V44A

2 of 73

TABLE OF CONTENTS

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................... 4

2.0 SAFETY WARNING DECALS ....................................................................... 6

3.0 SPECIFICATIONS ......................................................................................... 7

4.0 CONTENTS .................................................................................................... 9

5.0 TOOLS REQUIRED FOR INSTALLATION OF LIFT ..................................... 9

6.0 INSTALLATION OVERVIEW ....................................................................... 10

7.0

INSTALLATION INSTRUCTIONS ............................................................... 10

7.1

Surface Mount Bay Layout ................................................................ 11

7.2

Baseframe Location ........................................................................... 12

7.3

Flush Mount Bay Layout (Rear Mount Console) .............................. 13

7.4

Flush Mount Bay Layout (Front Mount Console) ............................. 14

7.5

Unpacking the Lift .............................................................................. 15

7.6

Hydraulic Connections ...................................................................... 16

7.7

Air Safety and Auxiliary Air connections.......................................... 19

7.8

Electrical Connections ....................................................................... 22

7.9

Initial Operation .................................................................................. 23

7.10

Bleed The Hydraulic System ........................................................... 24

7.11

Level and Support ............................................................................ 25

7.12

Anchoring Procedure ....................................................................... 26

7.13

Grouting Procedure (Optional) ........................................................ 27

8.0

ACCESSORY INSTALLATION .................................................................... 28

8.1

Installation of Wheel Stops ................................................................ 28

8.2

Installation of Rear Bolster Bar ......................................................... 29

8.3

Installation of Transition Ramps ....................................................... 29

8.4

Position of Approaching ramps ........................................................ 30

8.5

Position of Jack Beams ..................................................................... 32

8.6

Installation of Line Covers ................................................................. 34

8.7

Installation of Extension Line Covers ............................................... 35

9.0

INSTALL FRONT TURNTABLES ................................................................ 36

9.1

Installation of Front Turntables ......................................................... 36

9.2

Moving and Locking the Rear Slip Plate........................................... 36

10.0

FINAL PROCEDURES ............................................................................... 38

10.1

Check of Assembled Lift .................................................................. 38

10.2

Operation Test with Vehicle ............................................................. 38

11.0

LIFT OPERATION ...................................................................................... 39

11.1

Raising the Lift .................................................................................. 39

11.2

Lowering the Lift ............................................................................... 39

11.3

Approaching Ramp Operation ......................................................... 40

12.0

RECOMMENDED INSPECTION AND MAINTENANCE ............................ 42

3 of 73

12.1

Lubrication SPECS ........................................................................... 42

12.2

Mechanical Safety Locks ................................................................. 43

12.3

Air Cylinders, Air Lines, Valve and Fittings .................................... 44

12.4

Hydraulic Power Pack and Hose ..................................................... 44

12.5

Hydraulic Cylinders .......................................................................... 45

12.6

Check Base Frames and Approach Ramps .................................... 45

12.7

Fasteners ........................................................................................... 45

12.8

Transition Ramps, Chocks, Front Wheel Stops ............................. 45

12.9

Runways ............................................................................................ 46

12.10

Front and Rear Steer Plates ........................................................... 46

12.11

Rolling Air Jacks ............................................................................. 46

12.12

Entire Lift ......................................................................................... 46

12.13

Lubrication of Pivot Point and Sliders .......................................... 47

12.14

Lock Out and Tag Out Instructions ............................................... 50

12.15

Emergency Operation .................................................................... 52

13.0 TROUBLE SHOOTING .............................................................................. 54

14.0 RECORD OF MAINTENANCE / TRAINING .............................................. 55

15.0

LIFT PARTS LIST ...................................................................................... 57

15.1

Lift Parts List ..................................................................................... 58

15.2

Ramp Parts List ................................................................................ 59

16.0

HYDRAULIC AND AIR LINE ASSEMBLY ................................................ 61

16.1

Hydraulic Line Routing Map ............................................................ 61

16.2

Hydraulic Line Routing Parts List ................................................... 62

16.3

Hydraulic Circuit Map ....................................................................... 62

16.4

Hydraulic Circuit Parts List .............................................................. 63

16.5

Air Line Routing Part List ................................................................ 63

16.6

Air Line Routing Map ........................................................................ 64

17.0

CONSOLE ASSEMBLY ............................................................................. 65

17.1

Electrical and Control Panel ............................................................ 65

17.2

Console: Pneumatic & Filtering System ......................................... 67

17.3

Console Box Assembly .................................................................... 68

17.4

Console Labeling .............................................................................. 69

17.5

Power Pack ....................................................................................... 70

18.0

ACCESSORY ............................................................................................. 71

18.1

Line Covers and Nails ...................................................................... 71

18.2

Wedge Anchors ................................................................................ 71

18.3

Turntables ......................................................................................... 71

18.4

Jackbeam and Accessory ................................................................ 71

18.5

Hose Extension Kit for Flush Mount - Front Console .................... 71

18.6

Shim kit .............................................................................................. 72

18.7

14L Tank kit ……………………………………………………………….72

APPENDIX FOUNDATION PLAN…………………………………………………….74

4 of 73

1.0 IMPORTANT SAFETY INSTRUCTIONS

When using this lift, basic safety precautions should always be followed, including the following:

1. Only trained and authorized personnel should operate the lift or rolling jacks. Do not allow

customers or bystanders to operate the lift or be in the shop area while lift is in use.

2. Read all instructions in this manual and on the lift thoroughly before installing, operating,

servicing or maintaining the lift. Thoroughly train all employees in the use and care of lift and

rolling jacks.

3. Inspect the lift DAILY. Do not operate if it malfunctions or problems have been encountered.

4. Ensure no one is standing in front or behind the lift while vehicle is being driven onto, or

backed off the lift.

5. Before driving vehicle on, make sure lift is in the fully down position.

6. Before removing vehicle from the lift, make sure lift is in the fully down position and ensure that

all tools have been removed from the deck surfaces.

7. Always raise the lift off safety locks before lowering.

8. Do not allow rear tires or portion of the vehicle to interfere with approach ramp.

9. Be sure front wheel stops are always installed on the lift.

10. Never allow front wheels to strike the front wheel stops.

11. Always use wheel chocks to keep the vehicle from rolling freely on the runways. Wheel chocks

should be used at front and back of the same wheel.

12. Never attempt to overload the lift. The manufacturer’s rated capacity is shown on the

identification label on side of the deck. Do not override the operating controls or safety

devices.

13. Do not permit employees or customers on lift when it is either being raised or lowered.

14. Never raise a vehicle with passengers inside.

15. Always stand clear of lift when raising or lowering and observe "Pinch Points" warning.

16. CAUTION! Never work under the lift unless mechanical safety locks are engaged.

17. Always use Personal Protective Equipment (PPE) when installing or servicing the lift.

18. Always keep the lift area free of obstruction and debris. Grease and oil spills should always be

cleaned up immediately.

19. Always chock vehicle wheels before raising or lowering the lift.

20. Before lowering check the area for any obstructions including people.

21. To protect against risk of fire, do not operate the lift in the vicinity of open containers of

flammable liquids.

22. Adequate ventilation should be provided when working on internal combustion engines.

23. Never open hydraulic lines under pressure.

24. Do not raise or lower the lift with the vehicle on the Jackbeam.

25. For Jackbeam Safety Instructions, see Jackbeam Installation, Operation Manual.

5 of 73

READ AND SAVE THESE INSTRUCTIONS

Installation shall be performed in accordance with ANSO/ALI ALIS, Safety Requirements for

Installation and Service of Automotive Lifts.

For additional safety instructions regarding lifting, lift types, warning labels, preparing to lift, vehicle

spotting, vehicle lifting, maintaining load stability, emergency procedures, vehicle lowering, lift

limitations, lift maintenance, good shop practices, installation, operator training and owner/employer

responsibilities, please refer to “Lifting It Right” (ALI/SM) and “Safety Tips” (ALI/ST).

For additional instruction on general requirements for lift operation, please refer to “Automotive Lift-

Safety Requirements for Operation, Inspection and Maintenance” (ANSI/ALI ALOIM).

A qualified person should be consulted to address seismic loads and other local or state

requirements.

ATTENTION! This lift is intended for indoor installation only. It is prohibited to

install this product outdoors. Operating environment temperature range should

be 41 – 104 °F (5 – 40 °C). Failure to adhere will result in decertification, loss

of warranty, and possible damage to the equipment.

6 of 73

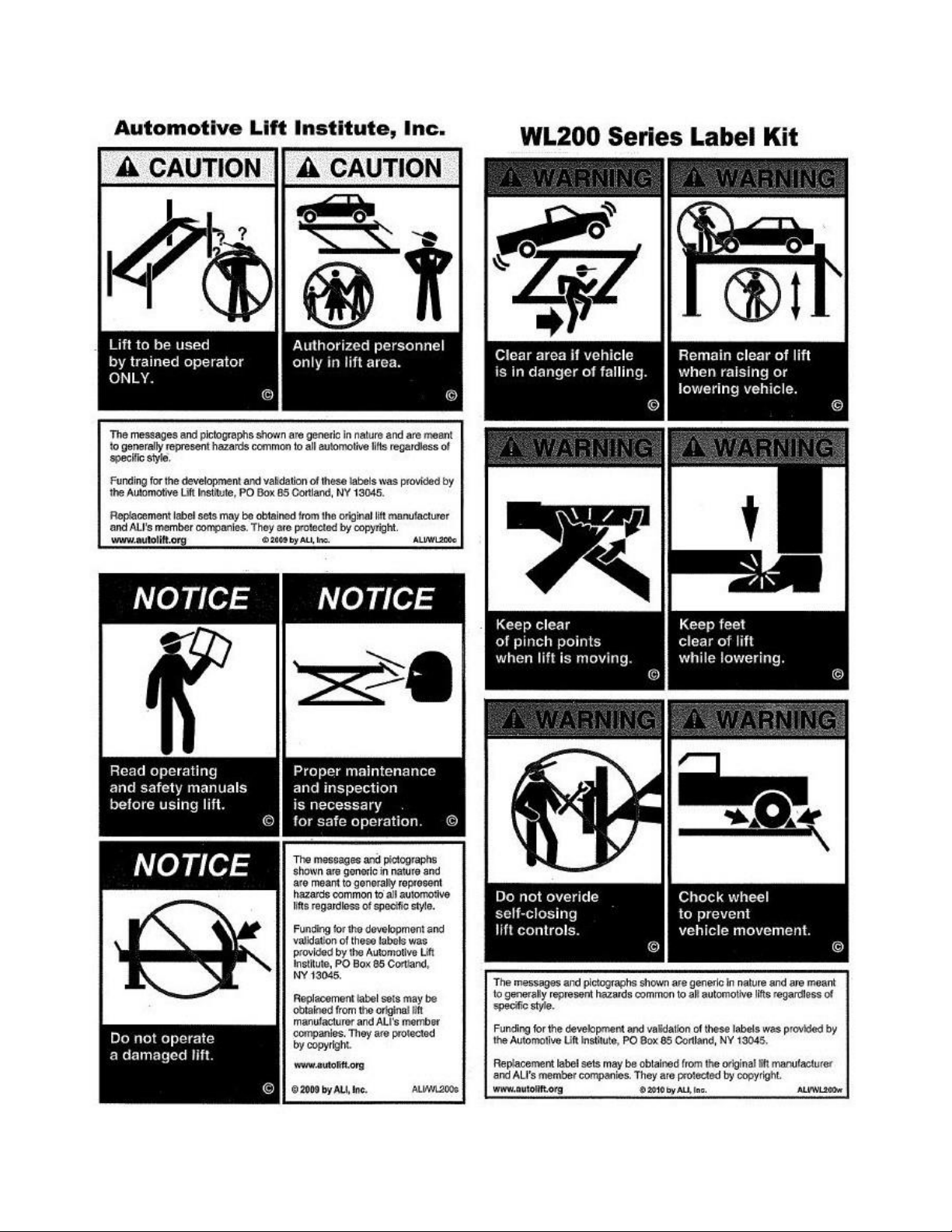

2.0 SAFETY WARNING DECALS

7 of 73

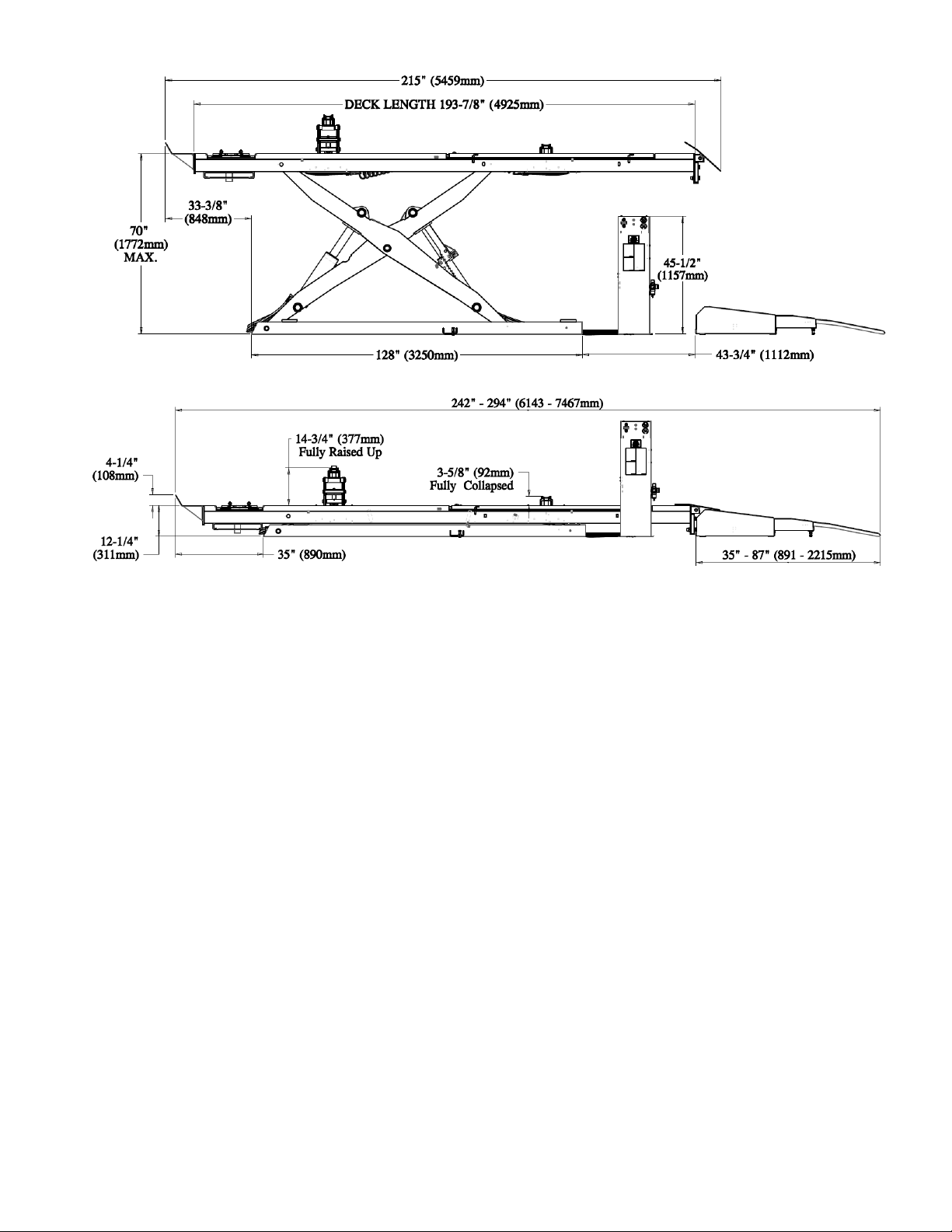

3.0 SPECIFICATIONS

Maximum Capacity:

12000 lbs

5443 kg

Overall Width:

90 Inches

2288 mm

Overall Length:

242 - 294 Inches

6143 - 7467 mm

Maximum Raised Height:

70 Inches

1772 mm

Minimum Lowered Height:

12-1/4 Inches

311 mm

Runway Width:

24 Inches

612 mm

Minimum 4 Wheel Alignment W/B:

89 Inches

2260 mm

Maximum 4 Wheel Alignment W/B:

158 Inches

4013 mm

Maximum 2 Wheel Alignment W/B:

165 Inches @Ø30" Tire OD

4190 mm

Maximum General Wheelbase:

179 Inches @Ø30" Tire OD

4546 mm

Raising/Lowering Time (approx.):

95 Seconds / 45 Seconds

Power Ratings:

230V, 1 Ph, 60Hz, 20A

Max. Operation Hydraulic Pressure:

2800 psi

Air Supply requirements:

90 to 140 PSI @5-10CFM

Pneumatic Lubrication Oil Type:

Snap-On #IM6 or Equivalent

Hydraulic Oil Capacity:

Tank size: 4.0 gal

Lift capacity: 6.0 gal

Hydraulic Oil Type:

ISO 32 (10 weight) hydraulic oil

Shipping Weight (Lift Only):

6614 lbs

3000 kg

Jack Beam Fully Raised Up

14-3/4 Inches

377 mm

Jack Beam Fully Collapsed

3-5/8 Inches

92 mm

Extension Adapter for Jack Beam

2-7/16 Inches

62 mm

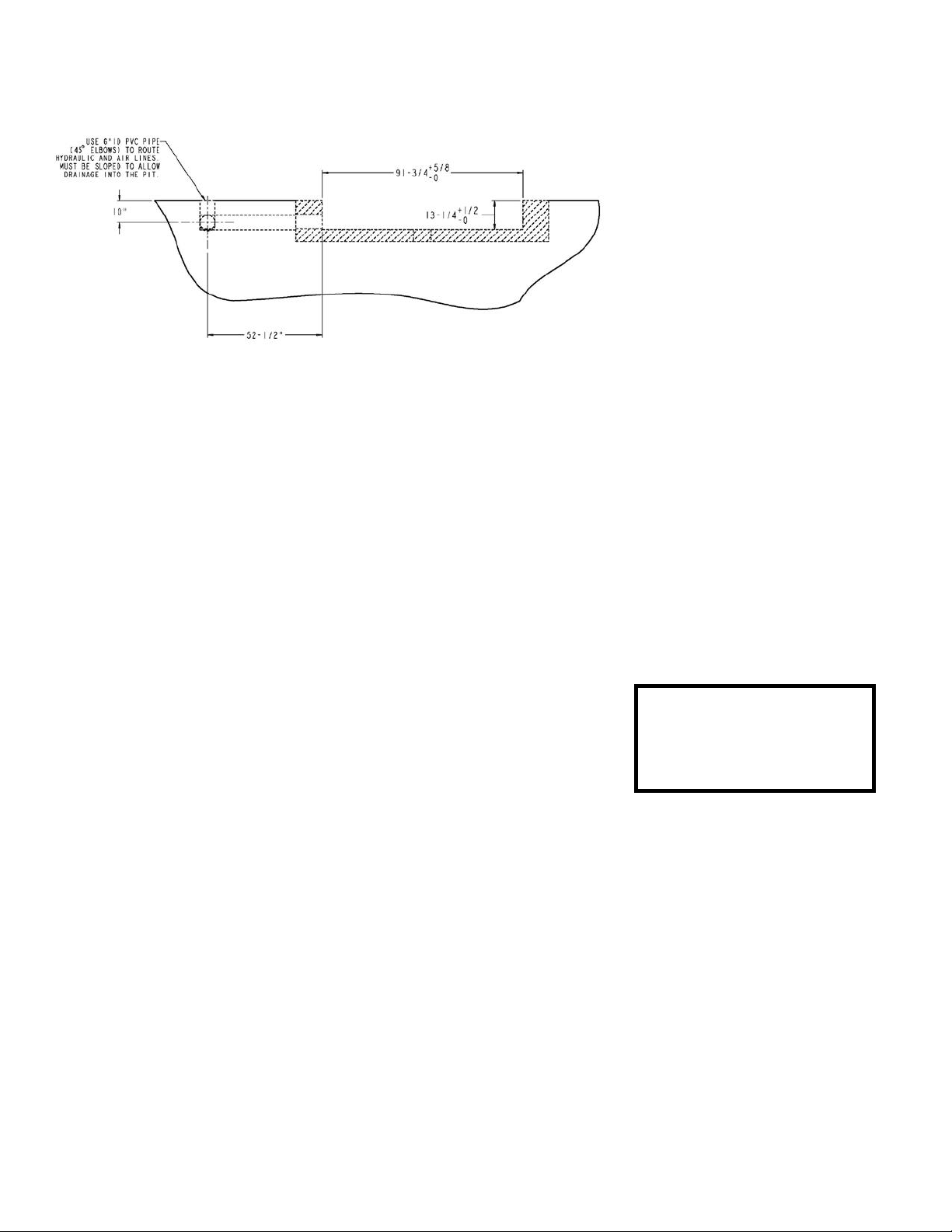

Figure 1 – Lift Dimension (Top View)

Figure 1 – Lift Dimension (Top View)

8 of 73

Figure 2 - Lift Dimensions (Side View)

Figure 3 - Lift Dimensions (Back View)

9 of 73

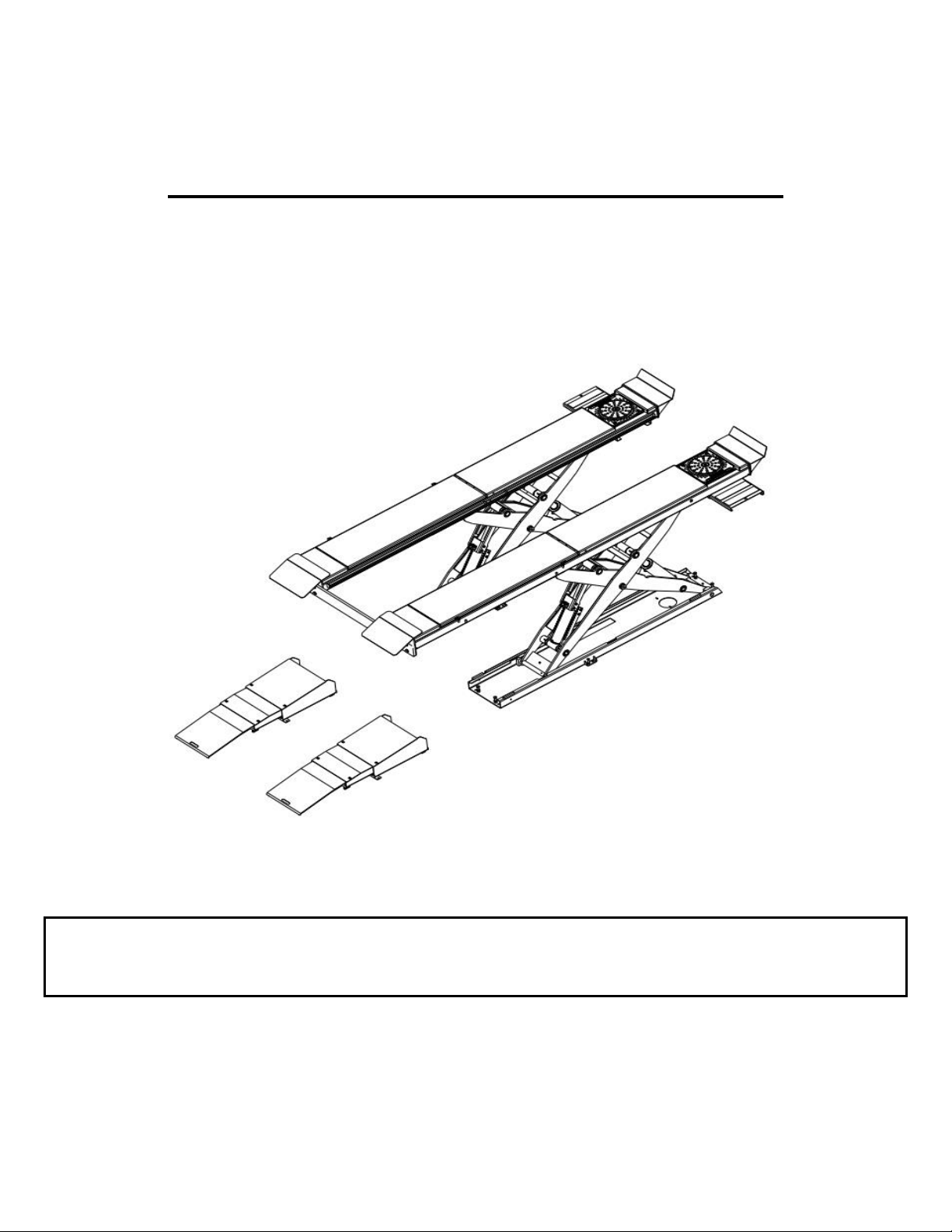

4.0 CONTENTS

The complete lift is contained in two (2) packages:

1. The main structural components are pre-assembled and packaged on top of each other.

2. The remaining parts are packed in a console/accessory box. Refer to the packing slip inside the

accessory box for a list contents.

Components include:

1pc. – Left Side Assembly

1pc. – Right Side Assembly

2pc. – Jack beams (If ordered)

2pc. – Approaching Ramps

1pc. – Console and Accessory box. (See accessory box list for contents)

1pc. – Grout container

1pc. – Customer care kit including manuals

5.0 TOOLS REQUIRED FOR INSTALLATION OF LIFT

Hammer Drill or similar, 1/4”, 1/2” and 3/4" Concrete Drill Bits

4’ Level

Metric and SAE Wrenches and Sockets

Hammer

Pry Bar – 5’ Long

Chalk Line

Tape Measure

Side Cutters

Screw Drivers

Funnel

Utility Knife

Torque Wrench

Recommended:

Self-leveling laser level

Plumb Bob

Impact Gun

Boom with appropriate capacity, see weight in specification section

Sling and rigging as needed to lift and place structure

Note: Apply LOCTITE #242 on required fasteners where symbol is shown.

If fasteners are removed reapply LOCTITE before re-installing.

10 of 73

6.0 INSTALLATION OVERVIEW

This is the order in which this installation is to take place:

1. Layout the Bay

2. Unpacking the Lift

3. Inspect the Lift

4. Connect Hydraulic Lines

5. Connect Air Lines

6. Connect Electrical

7. Initial Run of Lift

8. Level, Shim and Anchor

9. Install Accessories

10. Install Front Turnplates

11. Final Check

12. Clean

13. Train Customer on Operation of the Lift

IMPORTANT: Shop air must be connected to the inlet port at the FRL unit on the console.

7.0 INSTALLATION INSTRUCTIONS

When the lift arrives on site please read the owner’s installation and operation manual completely.

Check the contents to make sure no parts are missing before starting installation. Gather all of the

tools listed and make sure that the instructions are fully understood before commencing with the

installation.

IMPORTANT: It is the user’s responsibility to provide a satisfactory installation area for

the lift. Lifts should only be installed on a level concrete floor with a minimum thickness

of four and a quarter (4¼) inches or 108 mm. Concrete must have a minimum strength

of 3000 psi or 21 MPa and should be aged thirty (30) days prior to installation. Please

consult the architect, contractor or engineer if doubt exists as to the strength and

feasibility of the floor to enable proper lift installation and operation.

IMPORTANT: It is the user’s responsibility to provide all wiring for electrical hook-up

prior to installation and to ensure that the electrical installation conforms to local

building codes. Where required, it is the user’s responsibility to provide an electrical

isolation switch located in close proximity to the lift that will enable emergency stop

capability and isolate electrical power from the lift for any servicing requirements.

A qualified person should be consulted to address seismic loads and other local or state

requirements.

11 of 73

7.1 Surface Mount Bay Layout

NOTE: Leave any additional room for

any desired aisle or work area.

Recommended clearance around the lift

is a minimum of three (3) feet. Ensure

clearance conforms to local building and

fire codes.

Recommended overhead

clearance is a minimum of twelve (12)

foot ceiling providing 6 feet for the

maximum lift height and 6 feet for the

supported vehicle. For vehicles taller

than 6 feet it is recommended that the

user provides additional overhead

clearance or a shut off mechanism to

stop the lift from raising the vehicle too

high.

Please contact customer service for

latest installation diagram as it may

change without notice.

Note:

Console could

be placed on left

or right of lift.

Figure 4 - Typical Bay Layout

12 of 73

7.2 Base frame Location

Figure 5 – Base frame Locations

IMPORTANT: DO NOT CUT THE SHIPPING

STRAPS HOLDING EACH SCISSOR

ASSEMBLY TOGETHER UNTIL

INSTRUCTED TO DO SO.

1. With reference to Figure 4, the installer

should determine the most suitable

location in the bay for the lift.

2. Snap a chalk line for the centerline of the

lift ensuring that it matches the centerline

of the bay door.

3. Measure and snap two (2) parallel chalk

lines on either side of the centerline for the

inside edges of the base frames. Refer to

Figure 5 for the dimensions necessary to

provide the desired width between the two

runways. A distance of 42-1/4" (1073mm)

between the inside edges of the base

frames will provide the standard width of

40-1/2” (1028mm) between the inside of

the runways, shown on Figure 4.

4. Measure and snap a chalk line parallel to

the shop door for the front of the base

frames, a minimum distance of 262- 3/8"

(6675mm) is recommended.

5. Before proceeding, ensure that once the

runways are installed adequate workspace

will remain in front of the lift. Refer to the

minimum requirements listed in the

installation and operation manual of any

alignment equipment as needed.

Note:

The chalk lines are for reference only.

Refer to the minimum requirements listed in the installation and operation manual

of any alignment equipment as needed.

13 of 73

7.3 Flush Mount Bay Layout (Rear Mount Console)

NOTE: Leave any additional

room for any desired aisle or work

area. Recommended clearance

around the lift is a minimum of

three (3) feet. Ensure clearance

conforms to local building and fire

codes.

Recommended overhead

clearance is a minimum of twelve

(12) foot ceiling providing 6 feet

for the maximum lift height and 6

feet for the supported vehicle.

For vehicles taller than 6 feet it is

recommended that the user

provides additional overhead

clearance or a shut off

mechanism to stop the lift from

raising the vehicle too high.

Please contact customer

service for latest installation

diagram as it may change

without notice.

Figure 6 - Typical Flush Mount

Bay Layout

(Console in Back)

Note:

Console could be placed on

left or right of lift.

14 of 73

7.4 Flush Mount Bay Layout (Front Mount Console)

NOTE: Leave any additional

room for any desired aisle or

work area. Recommended

clearance around the lift is a

minimum of three (3) feet.

Ensure clearance conforms to

local building and fire codes.

Recommended overhead

clearance is a minimum of

twelve (12) foot ceiling

providing 6 feet for the

maximum lift height and 6 feet

for the supported vehicle. For

vehicles taller than 6 feet it is

recommended that the user

provides additional overhead

clearance or a shut off

mechanism to stop the lift

from raising the vehicle too

high.

Please contact customer

service for latest

installation diagram as it

may change without notice.

Figure 7 - Typical Flush

Mount Bay Layout

(Console in Front)

Note:

Console could be placed

on left or right of lift.

Hose Extension Kit

EAK0299T19A

must be ordered for

this routing option.

15 of 73

7.5 Unpacking the Lift

1. Unpack the console and place it in the desired location at the rear of the lift, see Figure 1 and

Figure 4. The console can be placed on either the left or right hand side of the lift.

2. Unpack the runways and lay each base frame along the chalk lines. See Figure 8.

Do not remove the individual strapping on the runways until they have been positioned

on the chalk lines.

3. Position the inside edge of the base frames along chalk lines, and ensure that the runways

are parallel. Ensure that both the inside dimensions (front and back) of the runways as well

the diagonal distances are equal. Refer to Figure 4 for runways dimension, Chalk lines are

for reference only. If minor adjustments are needed to make the runways parallel, this should

be performed.

4. Remove the remaining packing straps, and remove the hydraulic hoses, polytubes air hoses from

under the deck. Hoses are located under the rear portion of the runway and are factory pre-

installed.

5. Inspect lift for damage or any irregularities. If any are found, please contact customer service

before proceeding.

Note: Do not pull excessively on the hoses as it may strain the connections to the base frame.

Ensure that the turntable pockets are at the front, and that Jack Beam rails for each

runway face each other.

Figure 8 – Locate the Lift

Note:

Chalk lines are for reference only.

Runways must be made parallel by measurement.

16 of 73

7.6 Hydraulic Connections

1.

Install Hydraulic Equalization Circuit

Open the rear access cover of the console. Install the hydraulic equalization circuit on the right

side wall of console by using provided hard wares. See Figure 9.

Figure 9 – Hydraulic Circuit Installation

2.

Connect Hydraulic Hose to Power unit

Find the short hydraulic hose (9-0601)

from accessory box, one elbow end

connect to the straight fitting on power

unit, and connect the straight end to the

top elbow of the hydraulic equalization

circuit. See Figure 10.

Figure 10 – Hydraulic Hose Installation

17 of 73

3.

Connect Hydraulic Hoses From Console to Lift

The hydraulic equalization circuit orientation and ports layout refers to Figure 11.

The primary supply lines and equalizing lines from each runway are:

Left Side (L): Right Side (R):

CL CR

EQL EQR

(“C” for “Cylinder” and “EQ” for “Equalize”)

Figure 11 Hydraulic Equalization Circuit

- Unravel all hydraulic hoses and air lines from each runway, and connect each hydraulic lines as

shown in Figure 11 and Figure 12.

- Check the return lines are located beside the base frame slider and tied with other

hydraulic hose, reference to Section 16.1 item #9 in Figure 50.

•

Always make sure that the connections are clean to avoid contaminating the

hydraulic system.

•

Do not kink hydraulic hoses or air lines.

•

Do not remove hydraulic fittings while under pressure

For a flush mount installation with a front mount console requiring a hose extension,

refer to installation instructions 6-4189 provided with kit EAK0299T19A

18 of 73

Figure 12 - Hydraulic Connections

19 of 73

7.7 Air Safety and Auxiliary Air connections

WEAR SAFETY GOGGLES AND PRACTICE CAUTION WHILE

WORKINGWITH COMPRESSED AIR.

1.

Install FRL and Swivel Tee

Find the FRL (Filter/Regulator/Lubricator) assembly

with elbow and Swivel Tee poly from accessory box,

see Figure 13 a).

- Mount FRL assembly on the right side of the console

by using provided hard wares, see Figure 13 b).

Note: do not tighten the nuts at this time.

- Install the Swivel Tee from inside of console through

the big hole on console box to the elbow on the FRL,

see Figure 13 c)

a)

c)

b)

Figure 13 – FRL and Swivel Tee Installation

2.

Install Air Control Valve and Air Lines

Find the air fittings such as Swivel elbow (9-0619), Adapter (9-0620), Reducer (9-0617),

Union Y (9-0618), Ø6mm air hose (9-0622) and Ø6mm air hose (EAH0069V14A) from

accessory box.

- Open the top cover of the console, install the swivel elbow and the adapter onto the air valve

that mounted on console panel as show on Figure 14.

- Insert the reducer into the Swivel Tee, route air hoses and connect to the air fittings on air

control valve, reducer and union Y as show on Figure 14.

20 of 73

Figure 14 – Air Control Valve and Air lines

3.

Connect Air Hoses and Run Testing

- Uncoil the polytubes under each runway that is connected to the safety lock release air cylinder

shown on Figure 15. Route these two lines from base frames to the union ‘Y’ connector in the

console. See Figure 14.

- Uncoil the polytube that one end is connected to the Terminal bolt for Jackbeam on the driver

side runway, shown on Figure 15. Connect other end to the Swivel Tee in the console, See

Figure 14.

IMPORTANT: Use one 1/4" NPT cap to plug terminal bolt before connect to air supply.

- Mount a 1/4” NPT fitting (not supplied) to the inlet port at FRL unit. Connect the shop air supply

line to this fitting. IMPORTANT: Shop air must be connected to the inlet port at the FRL unit

on the console, in order for lift to operate.

- Remove the black hex socket cap on the top of Lubricator, Fill the Lubricator Reservoir with

Snap-On Air Motor Oil #IM6 or Equivalent up to 4/5 of oil reservoir height, re-install the cap.

How to fill oil and adjustment reference to Section 12.3.

- After connecting the main air line, check the air system for any leaks.

Note: The console is equipped with an air Filter/Regulator/Lubricator to ensure a clean air

supply is provided to the safety release cylinders, Jackbeams, The Air Regulator should

be set between 0.62 - 0.83Mpa (90-120psi).

This manual suits for next models

3

Table of contents

Other Snap-on Equipment Scissor Lift manuals

Popular Scissor Lift manuals by other brands

Skyjack

Skyjack SJ6826 RT Operation manual

DINGLI

DINGLI JCPT0607DCS Operator's manual

JLG

JLG 2032E2 Operator's and safety manual

Total Automotive Lifting Solutions Inc.

Total Automotive Lifting Solutions Inc. TLSS14ALOFRR1 Installation, operation & service parts manual

Bend-Pak

Bend-Pak MDS-6 Series Installation and operation manual

Bend-Pak

Bend-Pak SP-7XL Service manual