Snelflight 2.4GHz RC System User manual

1

Snelflight 2.4GHz RC System

Thank you for purchasing the Snelflight 2.4GHz RC system. Comprising the T4EU 5-channel

transmitter and the R7F full-range receiver, the system is extremely easy to use and excellent value

for money. It is suitable for aeroplanes, many helicopters, and surface models. Binding is carried out

with a single push button, with no need for a special binding plug.

Features

1) Dual mode - Mode 2 transmitter may be easily changed to Mode 1

2) Four proportional joystick channels plus one switched channel

3) Elevon mixing switch

4) Frequency Hopping Spread Spectrum (FHSS) technology

5) Push-button binding

6) High interference rejection

7) 60 frequency channels

8) 60dB adjacent channel suppression

2

IMPORTANT SAFETY NOTICE

•Do not operate radio controlled models at night or in wet weather. Water can permanently damage

many of the components of the radio system, possibly causing loss of control.

•Only fly at designated RC flying fields. Fly at safe distances away from people, buildings, electrical

lines or other hazards. Failure to observe these precautions could result in injury and/or property

damage.

•During flight preparations, lie the transmitter on its back to prevent it from falling over and pushing up

the throttle stick. This is a surprisingly common accident.

•Do not allow fuel or oil to contact plastic parts. They may melt when exposed to such materials.

•Before turning on the transmitter, adjust the throttle stick to minimum. When turning off the system,

turn off the receiver first.

•Do not make adjustments to the radio system while the engine is running, unless absolutely necessary.

•Check transmitter and receiver batteries frequently. Land immediately if the transmitter power LED

starts to flash, or if erratic reception is experienced.

•Radio controlled models are not toys. Never leave models or related equipment within reach of

children.

•ALWAYS REMEMBER THAT YOU ARE RESPONSIBLE FOR THE SAFE ASSEMBLY AND

OPERATION OF YOUR RADIO CONTROLLED MODEL.

1) Transmitter

The diagram below shows the key features of the transmitter. These are labelled for aeroplane use:

3

Aileron Control (CH1): When the aileron stick is moved to the right, the right aileron is raised and the left

one lowered, and the aircraft rolls to the right. When the aileron stick is moved to the left, the ailerons

move in the opposite directions and the aircraft rolls to the left.

Elevator Control (CH2): When the elevator stick is pulled back, the tail elevator is raised and the aircraft

pitches up. When the elevator stick is pushed forwards the elevator is lowered and the aircraft pitches

down.

Throttle Control (CH3): When the throttle stick is pushed forward, the engine power increases. When the

stick is pulled back, the engine power decreases.

Rudder Control (CH4): When the rudder stick is moved to the right, the rudder moves to the right and the

aircraft yaws to the right. When the rudder stick is moved to the left, the rudder moves to the left and the

aircraft yaws to the left.

Switch Control (CH5): When the switch is moved, the fifth channel changes from 100% to -100%, or

vice versa. This can be used to operate landing gear, lights etc.

Reverse Switches (all): These reverse the operating directions of the four joystick channels.

Trimmers (all): these adjust the neutral positions of the four joystick channels.

Power Switch: Push forwards to turn the transmitter ON.

Power LED: Indicates that the transmitter is ON. When the LED flashes, you should stop using the

transmitter and replace the batteries.

Elevon Mixing switch: Used to turn ON/OFF the elevon mixing function. This mixes CH1 (Aileron) and

CH2 (Elevator), operating them in unison (Elevator stick) or opposition (Aileron stick). Intended for delta-

wing aeroplanes, this function also allows quadcopters to be switched between “x” and “+” configurations.

The transmitter is powered by 8 x AA batteries. These should be installed according to the polarity

indications embossed inside the battery compartment. Alkaline batteries are recommended.

2) Receiver

The receiver has seven channels, the first five of which will operate with the T4EU transmitter. The

receiver may be powered via any of the channel output sockets. The antenna is short, as is typical in

2.4GHz systems. Please note that the silver tip section is the active part. This should be positioned

vertically in an exposed location within the model, away from carbon fibre components.

The receiver can operate on a supply of 4.5 – 6.5V. For reliable, safe operation it is important to ensure that

the voltage does not drop below 4.5V, even when the servos are loaded. For large models we recommend

using a voltmeter to check that the voltage remains above 4.5V even when all servos are heavily loaded by

manually applying back pressure against the control surfaces.

3) Binding the Receiver to the Transmitter

To establish a link when using the system for the first time, the transmitter and receiver need to be bound

together. After this, the receiver will not respond to another transmitter unless re-bound. Binding is carried

out as follows:

1) Switch on the transmitter, and lower the throttle.

2) Connect power to the receiver and wait for the green light to glow solidly.

3) Press and hold the bind button (in a recess at the end of the receiver) for about 2 seconds, until the

green light starts to flash, then release. After about 5 seconds the light will glow solidly again, and the

model’s servos will twitch or its control circuitry will indicate a signal received. The system is now

ready to use.

4

V 2.0 Revised 09-03-2014

4) Failsafe System

When the receiver is switched on, it will not output any channel position pulses until a radio signal is first

received. If the radio signal is subsequently lost, the receiver will continue to output channel pulses, but

their positions will revert to neutral. In the case of the throttle, the position will revert to minimum, which

means minimum pulse width. This will cause the vast majority of electronic motor speed controllers to go

to zero output. For glow-powered models, it is important to arrange the servo mechanics so that minimum

throttle corresponds to minimum control pulse width; do not use the throttle reverse switch in such cases,

otherwise the throttle will go to maximum in the event of failsafe activation. Please note that the receiver

does not learn new failsafe positions during binding – the failsafe positions are fixed. Always test the

failsafe behaviour carefully after setting up a model.

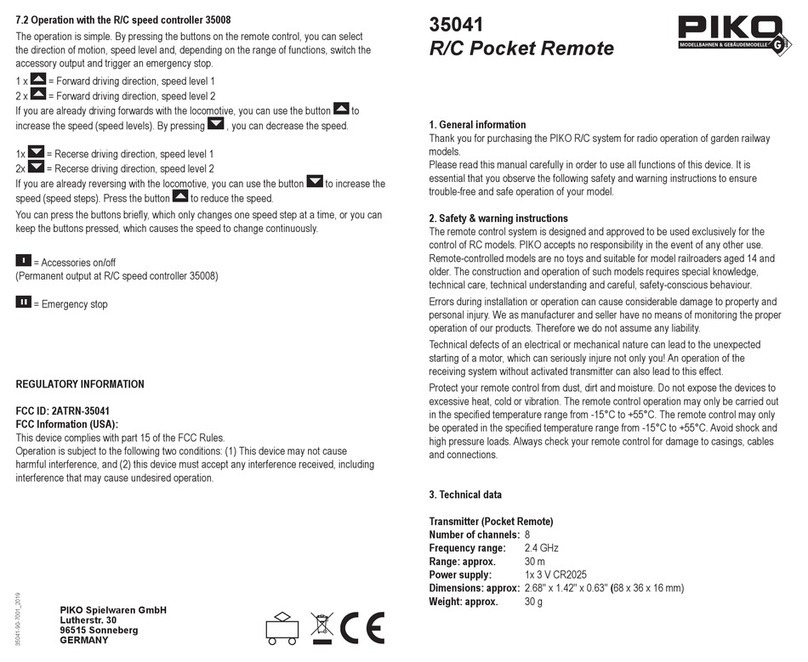

5) Transmitter Mode Conversion

Changing from Mode 2 to Mode 1 is a two-step process. Firstly a switch is used to make the electrical

change, swapping the throttle and elevator controls to the opposite sides. Secondly, the elevator return

spring (together with the associated spring-return lever) and the throttle ratchet spring must be swapped

over, so that the new elevator control self-centres and the new throttle control has a “notched” feel.

To make these changes, the back of the transmitter must be removed by releasing its four screws. The back

section is connected to the front by a number of wires, so it should be folded downwards and placed on the

table in front of the main section. The photo below shows the location of the parts – the operations are self-

explanatory. A pair of fine tweezers will be very helpful for manipulating the return spring.

6) Specifications

Snelflight Ltd, 48 Chalfont Way, Meadowfield, DH7 8XA, United Kingdom.

Web: www.snelflight.co.uk Email: support@snelflight.co.uk

Transmitter T4EU

Channels 5

Transmitting frequency 2.4GHz

Modulation type FHSS

Nominal current drain 100mA

Power supply 8 x AA battery

Output power 10mW

Channel centres 1.5ms

Receiver R7F

Channels 7

Receiving frequency 2.4GHz

Power supply 4.5 – 6.5V

Range 500 yards ground

1000 yards air

Weight 12g

Antenna length 8cm

Mode Switch

Throttle ratchet spring

Elevator centre spring

Table of contents

Other Snelflight Remote Control manuals