Sofi SP8 Series User manual

Sofei Technology

SP8serial programmer

manual

Shenzhen Shuofei Technology Co., Ltd.

SOFI TECHNOLOGY CO.,LTD.

TEL: 0755 - 8486 7757

FAX: 0755 - 8486 7941

WEB:http://www.sofi-tech.com/

Publication Release Date: 2018-07

Revision B4

Description: This manual applies toFlyPROsoftwareV4.40or above

Before using the programmer, please read this manual carefully, and operate the programmer correctly as required. Failure to operate the programmer as required will result in damage to the

programmer and no warranty service!

Translated from Chinese (Simplified) to English - www.onlinedoctranslator.com

Sofei Technology manual

SP8 series programmer

target record

Chapter One product description-------------------------------------------------- -------------------------------------------------- ---------------------

Features------------------------------------------------ -------------------------------------------------- ----------------------- SP8Series

function comparison table --------------------------------------------- -------------------------------------------------- --------

programmer hardware-------------------------------------------------- -------------------------------------------------- ------------------5

quick to use-------------------------------------------------- -------------------------------------------------- ---------------------7 Offline

burning-------------------------------------------------- -------------------------------------------------- ---------------------11 Download

offline data -------------------------------------------------------- -------------------------------------------------- ------------------11 Run

Offline - Manual Mode-------------------------------------------- -------------------------------------------------- --------12 Offline

operation - automatic control mode --------------------------------------- -------------------------------------------------- ---12

Offline working mode status indicator --------------------------------------- -------------------------------------------------- -----12

Offline Data View---------------------------------------------- -------------------------------------------------- -------------------13 ISP

Mode burning-------------------------------------------------- -------------------------------------------------- -------------14 ISPs

interface------------------------------------------------- -------------------------------------------------- ---------------------14 ISPs

Connection line ------------------------------------------------ -------------------------------------------------- -------------------14 Target

chip connection--------------------------------------------------------- -------------------------------------------------- ---------------- ISP

Power Mode------------------------------------------------ -------------------------------------------------- --------------- common

problem--------------------------------------------------- -------------------------------------------------- --------------------17 Disclaimer

-------------------------------------------------- -------------------------------------------------- ---------------------19 file revision log

information-------------------------------------------------- -------------------------------------------------- --------20

3

3

4

Chapter two

third chapter

Chapter Four

chapter Five

15

16

Appendix I

Appendix II

Appendix III

Shenzhen Shuofei Technology Co., Ltd.2

Sofei Technology manual

SP8 series programmer

Chapter 1 Product Introduction

Features

⚫USBPower supply and communication without external power supply. Small size, easy to carry.

⚫Specifically designed for serial memory, it is faster and more stable than general-purpose programmers.

⚫support93/24/25Series memory, support software upgrade to add support for new chips.

⚫Supports poor pin contact detection, effectively improving programming reliability.

⚫standard40Foot zero insertion force locking seat, wide and narrow chips and universal adapters can be used.

⚫The overcurrent protection function can effectively prevent the impact of chip placement errors or bad chips on the programmer.

⚫supportISPMode programming, for the onboard SMD chip, it can be directly wired and programmed.

⚫The programmer has a built-in high-speed processor, which provides high-speed programming and precise timing.

⚫Can be run offline(Note1), without connecting to a computer. built-in128Mbitdata storage.

⚫Mass production programming mode, which automatically detects chip placement and starts programming operations.

⚫support25seriesSPI FLASHChip model detection.

⚫Buzzer sound indicates success or failure.

⚫Support low voltage (3.3V)and5Vchip.

⚫Provides device self-check function.

⚫supportWinXP(SP2),VISTA, Win7, Win8, Win10(32bit/64bit).

Note1: ISPMode does not support offline burning

Shenzhen Shuofei Technology Co., Ltd.3

Sofei Technology manual

SP8 series programmer

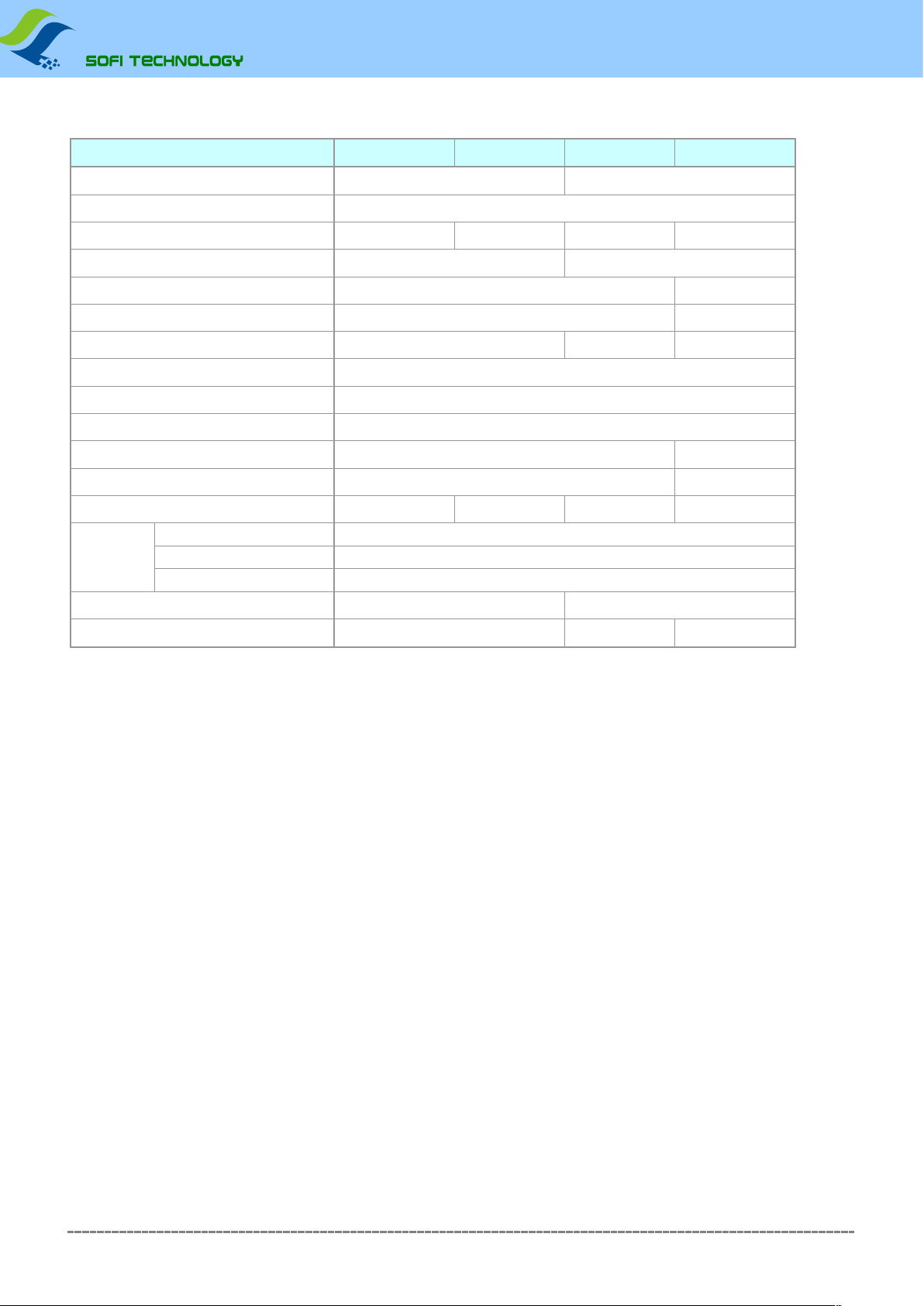

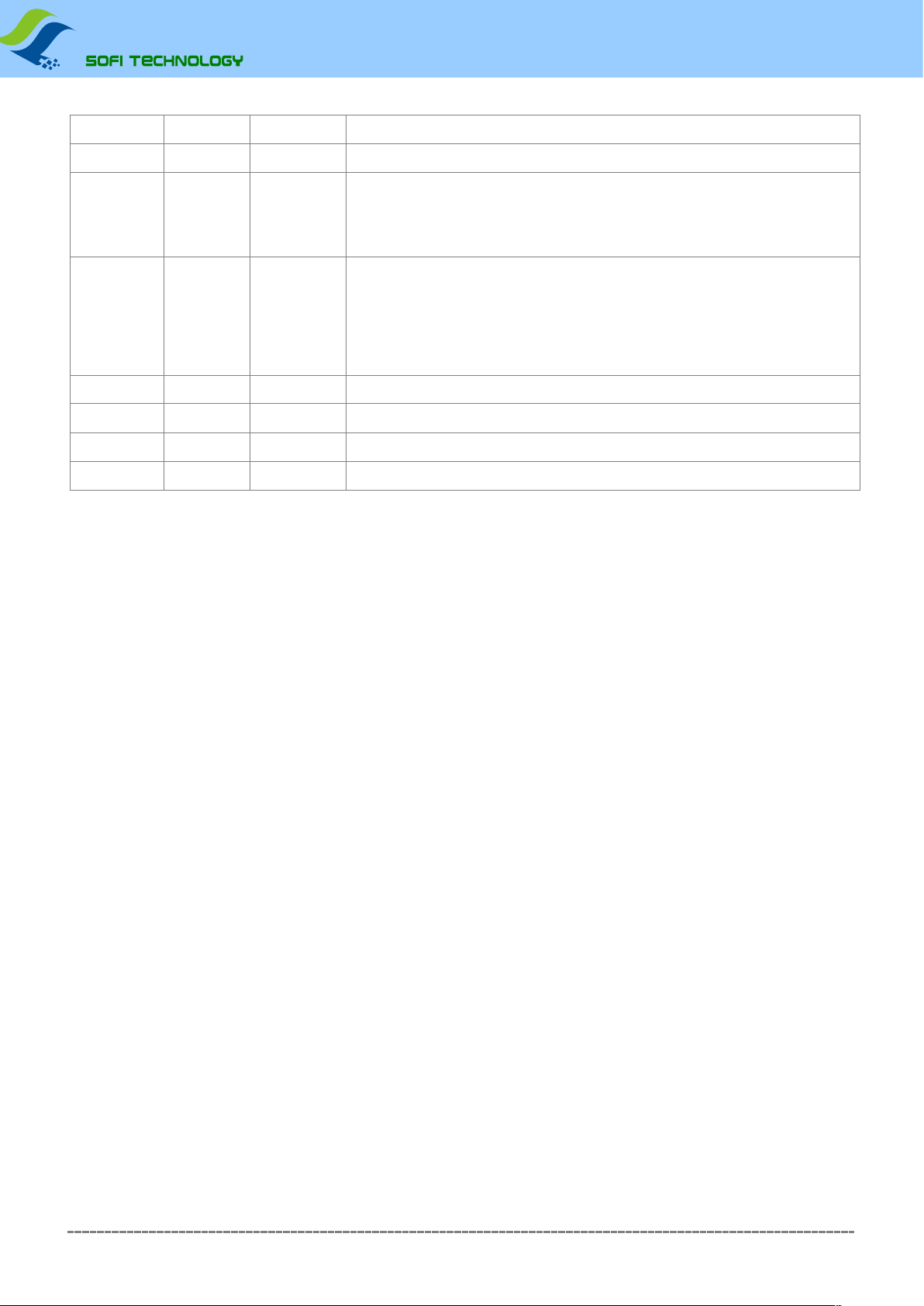

SP8Series function comparison table

Product number:SP8-FX SP8-F SP8-B SP8-A

Support chip maximum capacity(Note1)512Mb(online)/128Mb(offline)512Mb

Support chip voltage 3.3V/5V

Offline burning Y Y N N

Built-in memory (save offline data)128Mb -

Online mass production Y(Automatic detection of chip placement/removal)N

automatic serial number Y(Online burning mode only)N

Buzzer prompt Y(offline mode only)N N

Overcurrent/Short Circuit Protection Y

Lock seat type Domestic gold-plated

ISPburn(Note2)part93/25Series (clock not adjustable)

OTParea read and write(Note2)support not support

Chip configuration(Note2)support not support

Automatic burning machine support (ATE)YN N N

GD25Q16(SOP8) P+V=7.9S

Burning speed

(Note3)

W25Q128FV(SOP8) P+V=60S

MX25L12845E(SOP16) P+V=130S

Offline data download speed 216S@128Mb -

Number of supported chips(Note4)7874 7804 6401

Note 1: SP8Series offline operations support up to128Mbit.

Note 2:Depending on software capabilities, not all chips are supported.

Note 3:The burning speed adopts100%random numbers for testing,Pfor programming,VFor verification; Offline time only applies to products that support the Offline function;

The burning time is for reference only.

Note 4:Number of chips based on software versionV4.06(2016-03-12),Chips will be continuously upgraded, and the numbers in the table are for reference only.

Shenzhen Shuofei Technology Co., Ltd.4

Sofei Technology manual

SP8 series programmer

Chapter 2 Programmer Hardware

Lock seat

Power Indicator (PWR)

Status Indicator (STA)

USB interface

ISP/ATE interface

⚫Lock seat

Used to place chips (including chip adapters/adapters).

Please do not operate the chip that has been soldered on the circuit board through the connection method on the locking seat. The peripheral circuit on the board will cause the operation to fail, and the

programmer will be damaged in severe cases.

Typical Chip Placement Diagram

Pin 1

The placement of other chips (including adapter information) can be found inFlyPROOpen the chip information in the software for viewing.

The locking seat is only used to place the chip to be programmed (including the adapter/programming seat), and it is forbidden to operate the chip that has been soldered on the circuit board through the

connection method. This may cause permanent damage to the programmer.

Shenzhen Shuofei Technology Co., Ltd.5

Sofei Technology manual

SP8 series programmer

⚫Power Indicator(PWR)

Indicates the power supply status, and the red light indicates that the power supply is normal (SP8The programmer directly usesUSBinterface power supply); red flashing indicates that the programmer has

detected a short circuit of the chip or excessive current.

⚫Status Indicator(STA)

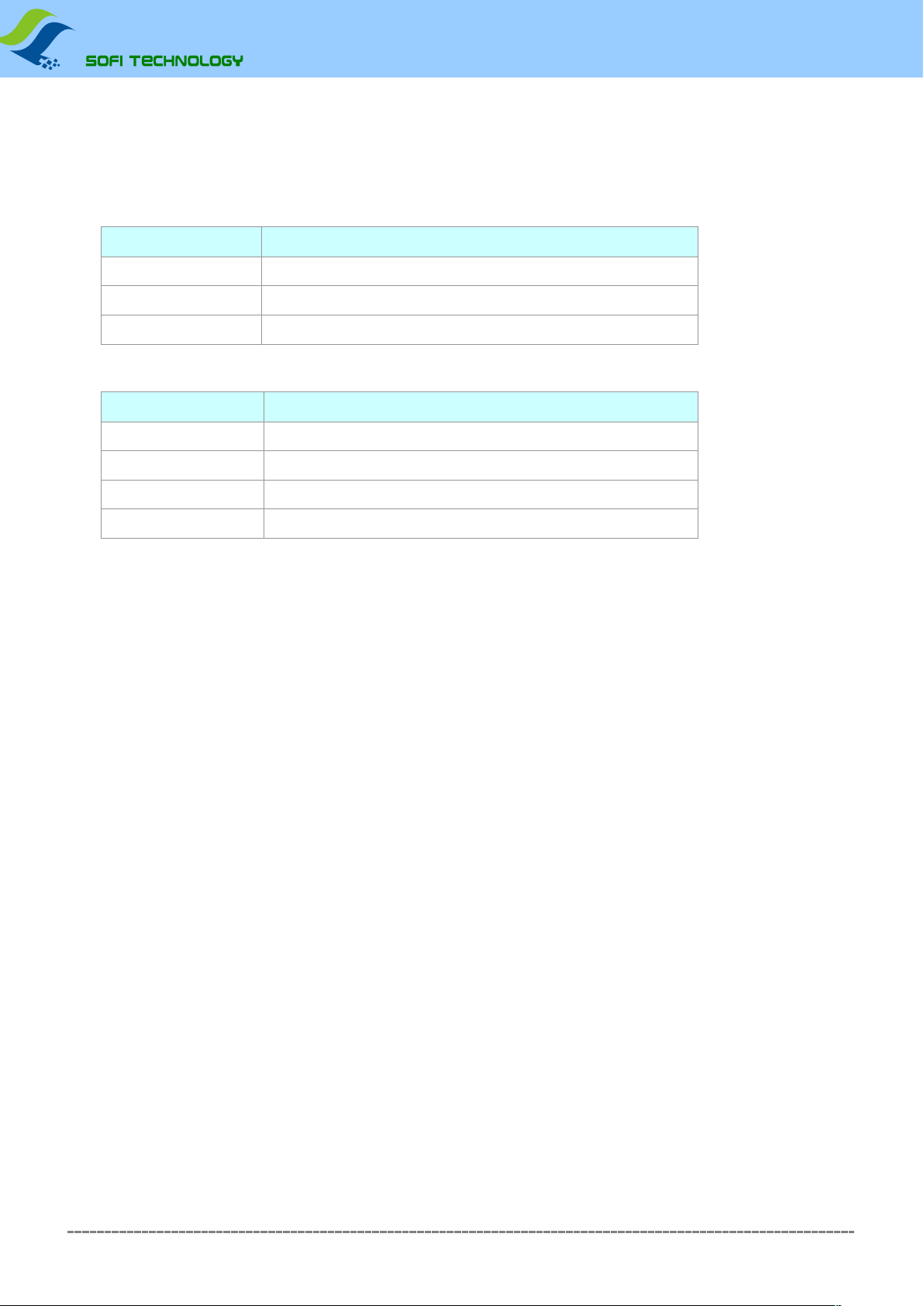

Programmer Status Indicator Description (Online Mode):

STAlight status Status Description

orange chip is being burned

green The chip burning is completed, the burning is successful

red Chip burning failed

Offline programming mode status indicator description (onlySP8-F, SP8-FX):

STAlight status Status Description

flashing green Waiting for chip placement

orange chip is being burned

green The chip programming is completed, the programming is successful, waiting for the chip to be removed

red Chip programming failed, waiting for the chip to be removed

⚫ISP/ATEmulti-function interface

ISPFunction: In the software, select theISP] suffix of the chip model, the programmer will useISPway to burn the chip. This interface is used to connect the target board

(chip). For specific connection diagrams, please refer toChip informationView in

ATEFunction: existSP8-FXIn the product, this interface can be used to connect the automatic control machine (automatic burning machine), the interface

providesSTARTstart signal, andOK / NG / BUSYindication signal.

Note: This interface is a multiplexed function interface and can only work onISPorATEone of the modes.

⚫USBinterface

In online operation mode, theUSBinterface to communicate and supply power to the programmer at the same time. In

offline operation mode, it is used to connect a dedicated power adapter (onlySP8-F,SP8-FX).

Shenzhen Shuofei Technology Co., Ltd.6

Sofei Technology manual

SP8 series programmer

Chapter 3 Quick Use

This chapter explains ShuofeiSP8series programmerFlyPROThe basic operation steps are suitable for users who use this programmer for the first

time. Corresponding product model:SP8-A, SP8-B, SP8-F, SP8-FX.

1.useUSBConnect the programmer to the computer. turn onFlyPROsoftware. After the software is started,

the programmer hardware will be automatically connected.

Information about the programmer will be displayed in the main window of the software. As shown below:

At the same time, the connection status of the programmer will be displayed in the status bar at the bottom of the software. As shown below:

If the programmer is not inserted before when the software starts, the software will pop up the programmer selection dialog. As shown below:

In this case, please use the programmerUSBcable to connect to computerUSBinterface.

Select the correct programmer model, click "Connect (C)"That's it.

2.Select the chip model to be programmed.

Click the toolbar button

chip model.

, or the menu【Chip】-【Choose Chip Model】to open the "Choose Chip" dialog box, select the chip to be programmed

3.Query chip related information

Click the toolbar button

and how/where the chip is placed in the locking seat.

, or the menu [Chip] - [Chip Information] to open the chip information description to understand the relevant programming instructions of the chip

Shenzhen Shuofei Technology Co., Ltd.7

Sofei Technology manual

SP8 series programmer

4.Load the burn file

Click the toolbar button , or the menu【File】-【Load File】to carry out the data file to be burned.

5.Set Action Options

Click the toolbar button

In most cases, you can use the default settings without additional settings. For details on operation options, please refer to the software manual.

, or the menu【Operation】-【Operation Options】to set the chip programming.

6.Place the chip in the lock seat

Non-in-line chips need to use adapter sockets (adapter sockets).

The placement position and direction of the chip, please click the toolbar button to view.

7.Execute burn

The burning operation can adopt three modes, including manual mode, automatic mode, and automatic mass production mode. Select one of the modes to operate according to different

situations.

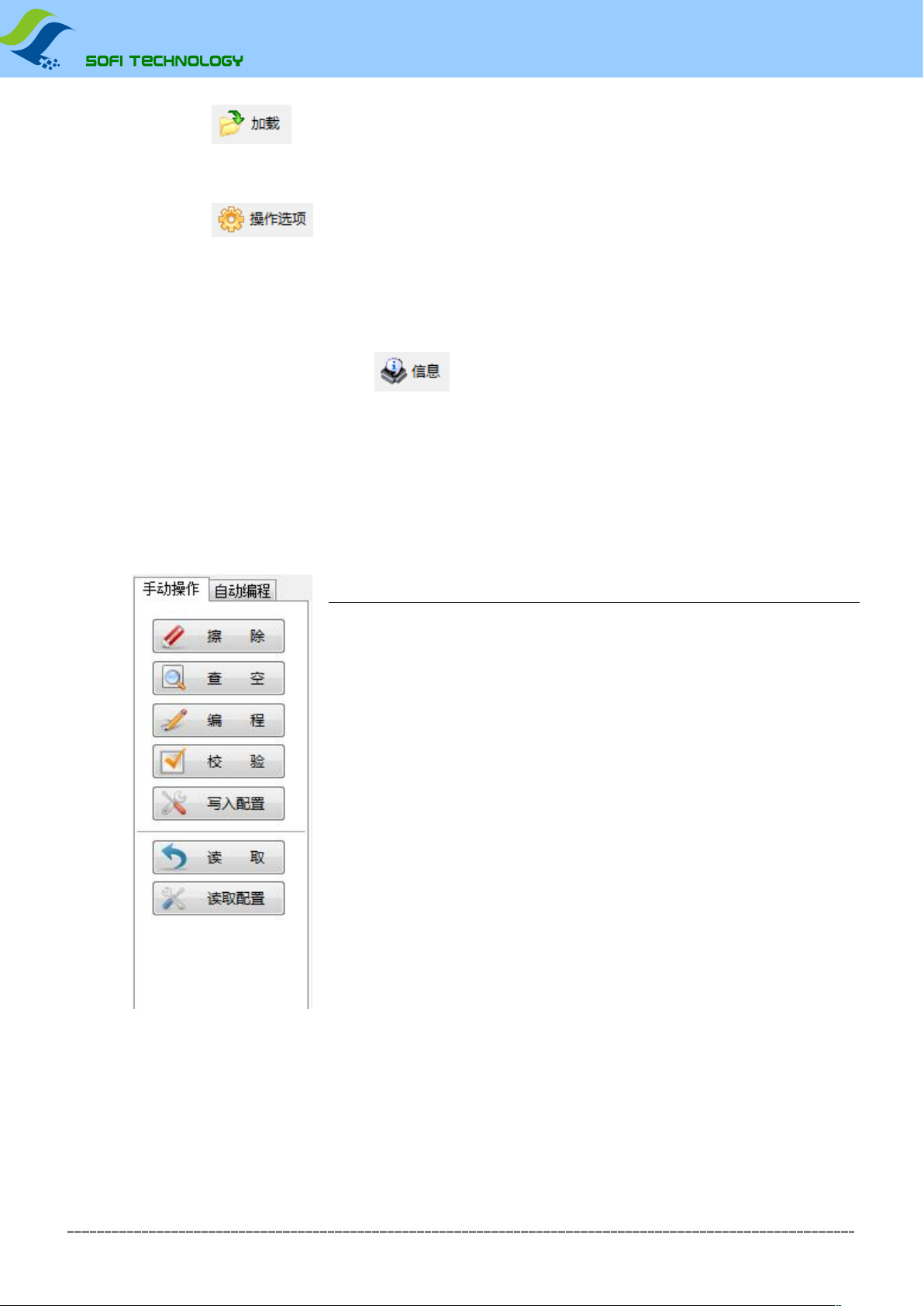

⚫manual mode

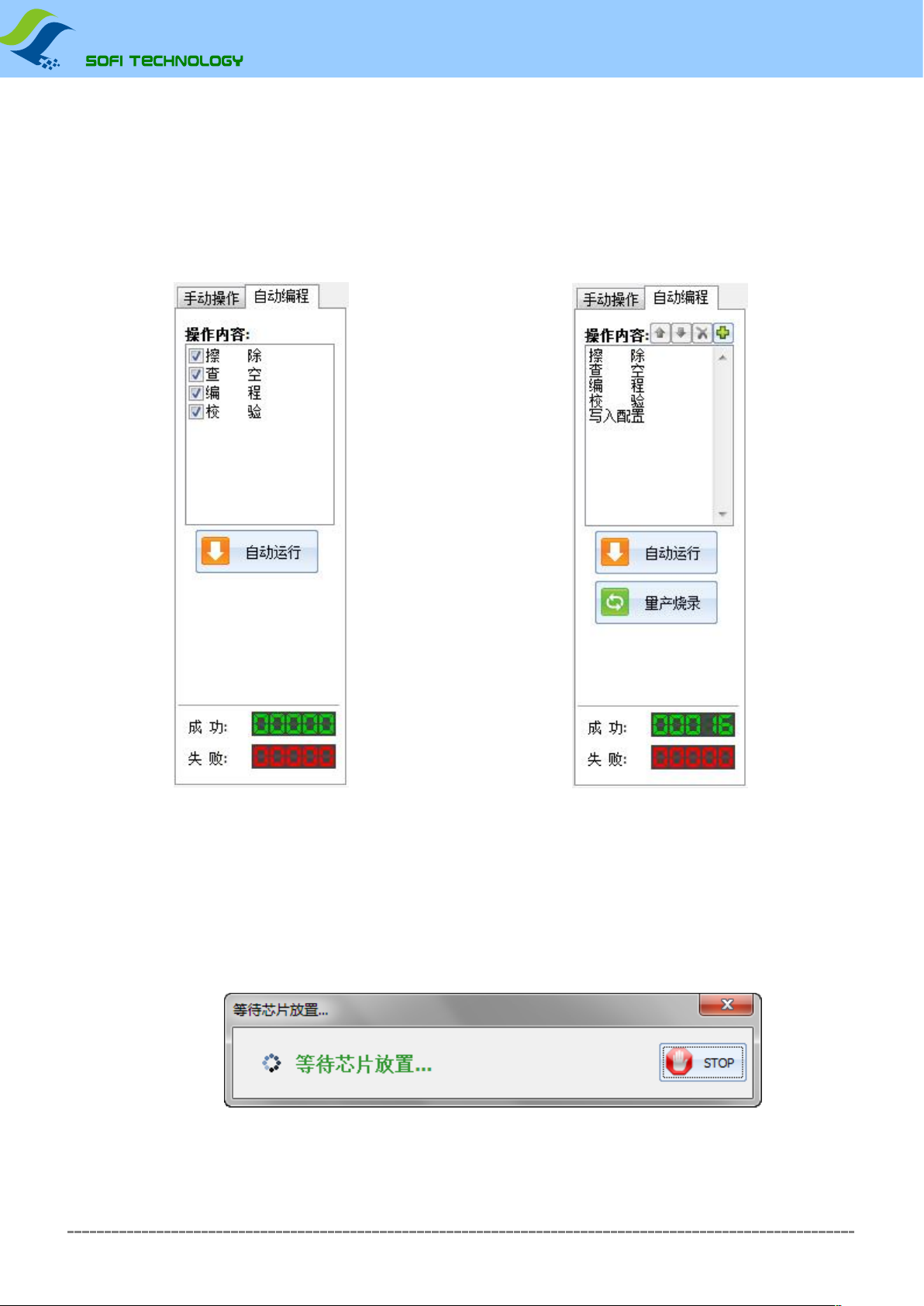

In the command bar on the left side of the main window of the software, select the "Manual Operation" page, as shown in the figure below:

button

Except: clear chip content, only forFlashclass of chips

EEPROMThe chip of this class does not have this function, this button will be disabled

(gray) Check whether the content of the chip is blank (all areFFh)

Write buffer data to the chip.

Need to preload the data file into the buffer

Compare the data in the chip with the data in the buffer (verify whether the data in the chip is

correct)

Function

wipe

check

edit

null:

Procedure:

school Test:

Write configuration:Write configuration information into the chip (egSPI FLASHof

Status Register);

Fetch: read the chip content, the read data will be saved in the software buffer, such asread

Save as a file if necessary (toolbar button: Save).

Read the configuration information of the chip, and the read configuration data will be updated to the configuration

option settings of the software. After doing this, hit the configurable option to view the current chip into the

configuration state.

Read configuration:

Typical operating steps:

➢burnSPI FLASH (25series): erase→check empty→programming→check

➢burnSPI FLASH (25series, brand new blank chip) : programming→check

➢burnI2C EEPROM (24series): programming→check

➢Read chip data and save chip data to file: read→check→save

Shenzhen Shuofei Technology Co., Ltd.8

Sofei Technology manual

SP8 series programmer

⚫automatic mode

In the command bar on the left side of the main window of the software, select the "automatic operation" page, the automatic operation page has2There are two types, namely simple setting and advanced setting,

which are determined according to different product types.

The operation sequence of the simple setting is fixed, and whether the setting operation is valid depends on whether the

check is enabled. Advanced settings can set any operation content, and the order can also be adjusted at will.

After setting the operation content, click the "Auto Run" button, and the programmer will execute the "operation content" in turn.

Easy Setup

Applicable Model:SP8-A, SP8-B

advanced settings

Applicable Model:SP8-F, SP8-FX

⚫mass production mode

The operation content of mass production mode is the same as "automatic operation", the difference is that the programmer can automatically detect the placement and removal of chips. After clicking the "Burn in mass

production" button, the software pops up a message box to remind the user to place the chip. After the chip is placed, the programming operation will be performed automatically, and the user will be reminded to

remove the chip after the programming is completed. When the user removes the chip, it will continue to wait for the placement of the next chip, and the software keeps repeating this operation until the user clicks "

STOP”button to stop operation.

Wait for the chip placement prompt

Shenzhen Shuofei Technology Co., Ltd.9

Sofei Technology manual

SP8 series programmer

Wait for the chip to be removed

illustrate

⚫Production mode is only available forSP8-B / SP8-F / SP8-FX.SP8-AThe mass production burning function is not supported.

⚫The above operations are just to demonstrate the conventional programming method of general chips, for reference only. The specific operation needs to be determined according to the user's needs.

⚫For more information about the software, please refer toFlyPROSoftware online help.

Shenzhen Shuofei Technology Co., Ltd.10

Sofei Technology manual

SP8 series programmer

Chapter 4 Offline Programming

SP8-F,SP8-FXSupport offline programming, in the offline mode, the programmer does not need to connect to the computer. Programmer built-in128MbitData storage, no additional storage device required. The

offline function has the characteristics of simple use and high burning efficiency. When the programmer works in the offline mode, it will automatically detect the chip placement, start the programming work, and

prompt the programming result through the status indicator and built-in buzzer.

Offline mode includes manual operation and automatic control.

The manual operation mode is the manual operation mode. The programmer automatically detects the placement and removal of the chip, and indicates the working state and programming result through the status indicator light and

built-in buzzer.

through automatic controlISP/ATEThe multi-function interface is connected with the automatic control machine, and the machine controls its functions and outputs corresponding indication signals to the control

machine.

SP8-FOnly supports offline manual mode;SP8-FXWith the above two modes, you can choose any one of the modes to operate through the software settings.

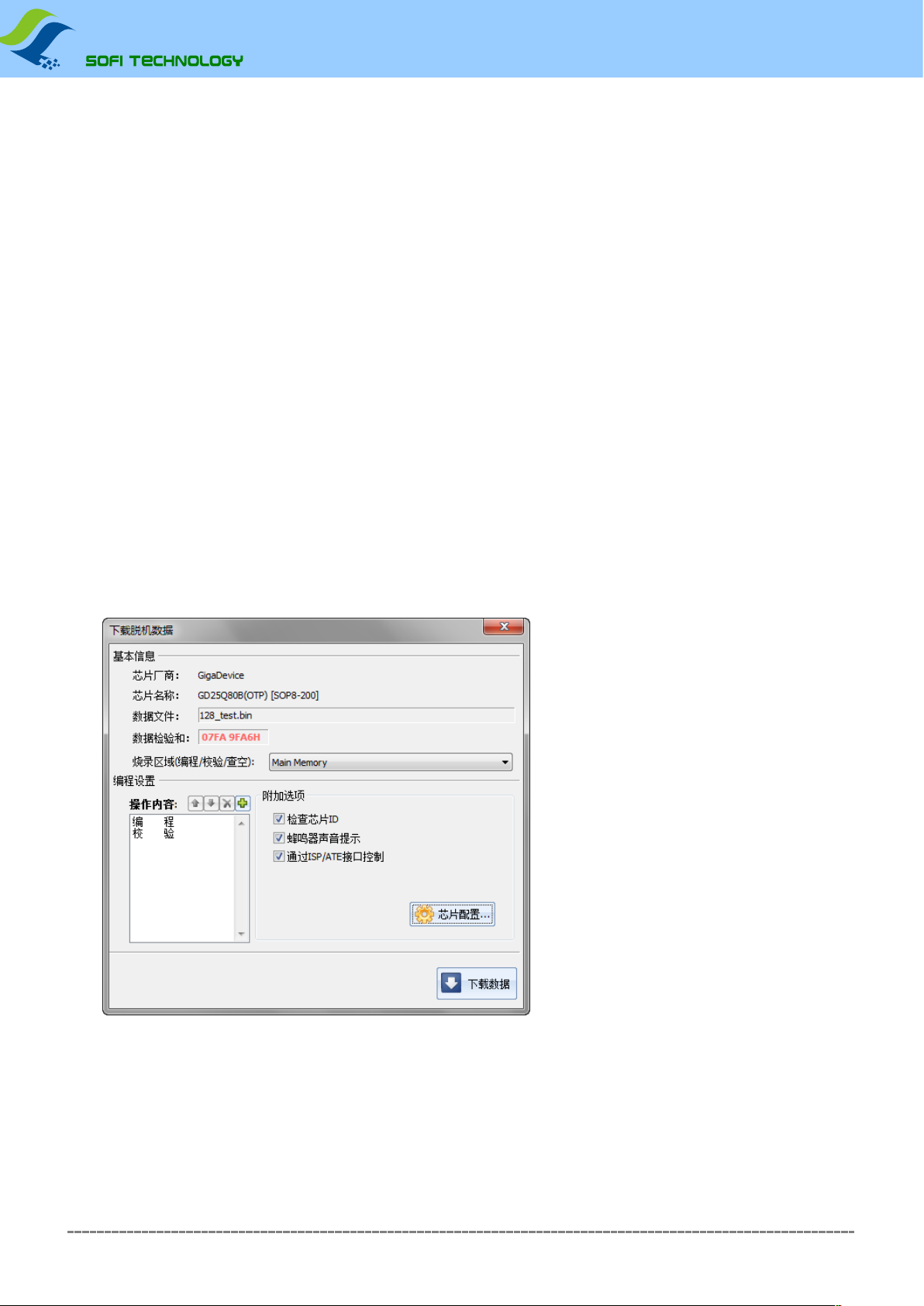

Download offline data

Before offline operation, the offline data must be downloaded to the programmer with a computer in advance. The data download operation steps are as follows:

1.first useUSBCable the programmer to the computer, then turn onFlyPROsoftware.

2.Select the correct chip model.

3.Load the file to be burned.

4.Click the menu [Chip] - [Offline Data Management] - [Download Offline Data] to open the offline data download dialog box and download offline data. As shown below:

passISP/ATEinterface control

This option can only beSP8-FXis available in, after checking this function,SP8-FXIt works in automatic control mode and is used to work with automatic machines. If this

function is not checked, thenSP8-FXWorks in manual operation mode.

* * *For other operation settings, please refer to the software online help or software user manual.

5.After the offline data download is complete, disconnect the connection between the computer and the programmerUSBAfter connecting the cable, the programmer can work independently from the computer.

Shenzhen Shuofei Technology Co., Ltd.11

Sofei Technology manual

SP8 series programmer

run offline‒Manual way

The offline operation steps of the programmer are as follows:

1.Power the programmer with the power adapter that came with the product.

2.After the programmer is powered on, the internal offline data will be checked first to verify the integrity and accuracy of the data.

this needs3~25seconds. If the test passes,STAThe indicator light flashes green, indicating that the programmer has entered the offline programming mode. If the detection fails,STAThe red

flashing state is displayed, indicating that there is no valid offline data in the programmer, and offline programming cannot be started.

3.Programmer'sSTAThe indicator light flashes green, indicating that it is waiting for the chip to be placed.

4.whenSTAStop flashing and display orange, indicating that the programmer has detected the chip and is programming.

5.whenSTADisplays green or red, indicating that the chip programming is complete. Green indicates that the programming is successful, and red indicates that the programming fails. At the same time the programmer starts to wait for the

current chip to be removed from the locking seat. If the buzzer prompt function is turned on, the programmer will make a sound when the programming is completed.

6.After detecting chip removal, the programmer repeats the steps3arrive5Burn the next chip.

run offline‒Automatic control method

The automatic control method is only applicable toSP8-FX, used to cooperate with automatic programming machine, manipulator and other automation equipment to realize automatic chip

operation. When downloading offline data, check the "passISP/ATEinterface control" option to turn on this function. In this way of working, the programmer'sATEinterface providedSTART start

signal, andOK / NG / BUSYindication signal.

Offline work mode status indicator

STAlight status Status Description

flashing green Waiting for chip placement (manual mode only)

orange chip is being burned

green The chip programming is completed, the programming is successful, waiting for the chip to be removed

red The chip programming failed, waiting for the chip to be removed

⚫Offline working mode, not supportedISPway to burn.

⚫When working offline, please use the power adapter provided with the product, and do not use other power sources. Incorrect use of other power sources may cause damage

to the programmer.

Shenzhen Shuofei Technology Co., Ltd.12

Sofei Technology manual

SP8 series programmer

Offline data viewing

Offline data that has been downloaded to the programmer can beFlyPROsoftware to view.

Click the menu [Chip] - [Offline Data Management] - [View Offline Data] to open the offline data viewing dialog box, as shown in the following figure:

Shenzhen Shuofei Technology Co., Ltd.13

Sofei Technology manual

SP8 series programmer

chapter FiveISPMode burning

ISPfull nameIn System Program, that is, online programming.ISPThe programming mode only needs to connect a few signal lines to the relevant pins of the on-board chip to realize the read and write operations of

the chip, which can avoid the trouble of desoldering the chip.

Use ISP programming mode

SP8The series programmer only supports some chipsISPMode burning, in the software select with "[ISP]"suffixed to the chip model number, it is indicated byISPmode to burn. (Choose notISPThe

chip model with the suffix will use the locking socket for programming,ISPThe interface has no function.) Notice:ISPDedicated for burningISPInterface connection, please do not connect the wire

from the locking seat.

ISP interface

SP8Series programmers provide an additionalISPinterface, as shown in the following figure:

9

10

7

8

5

6

3

4

1

2

ISP/ATE interface Interface Pin Diagram

ISPconnecting line

ISPThe connecting line is a ten-color colored cable, and one end of the connecting line is5x2Standard plug, access to programmerISPinterface. the other end is10Root DuPont headers and connect

to the corresponding pins on the target board.

The corresponding relationship between the color of the connecting line and the pin number is as follows

color pin number color pin number

brown 1blue 6

red 2Purple 7

orange (or pink)3grey 8

yellow 4White 9

green 5black 10

Shenzhen Shuofei Technology Co., Ltd.14

Sofei Technology manual

SP8 series programmer

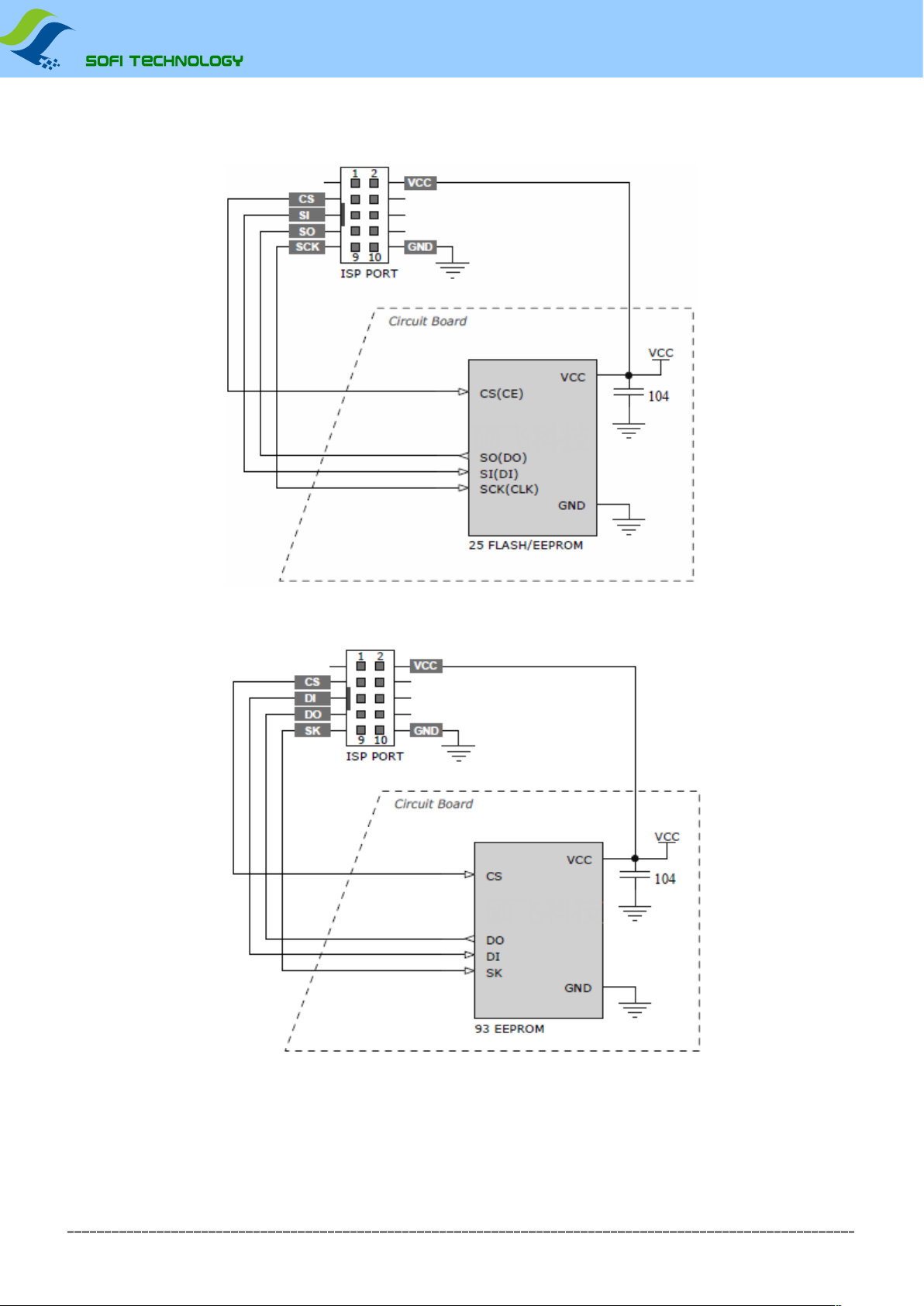

target chip connection

Common25series and93seriesFLASH/EEPROMThe connection diagram is as follows

typical25seriesFLASHConnection Diagram

typical93seriesEEPROMConnection Diagram

The connection method will be different for different chips. For the detailed connection information of the chip, please refer toFlyPROOpen the chip information in the software for viewing.

Shenzhen Shuofei Technology Co., Ltd.15

Sofei Technology manual

SP8 series programmer

ISPPower Mode

ISPDuring programming, the target chip has two power supply modes to choose from. power supply mode can beFlyPROset in the operating options of the software.

⚫powered by programmer

That is, the programmer provides voltage to the target board, and the power supply voltage is3.3Vor5V(existFlyPROset in the operating options of the software). In this mode, if the programmer detects that

the target board power supply already exists, it will give a power supply conflict error message. The programmer comes with an overcurrent detection function, when power is supplied to the target board,

the current is limited to250mA, when the current exceeds this range, overcurrent protection will occur. If the operating current of the target board is greater than250mA, please use the target board self-

powered mode.

⚫Target board self-powered

The programmer in this mode does not supply power to the target board.

SP8The programmer can support an operating voltage range of2.7V~5.5Vtarget board.ISPThe signal drive voltage of the target board will follow theVCCVoltage is automatically adjusted.

ISPimportant

ISPThe implementation of programming is relatively complicated, and it is suitable for people with certain professional knowledge. If only a small number of chips are to be programmed, it is recommended to remove the chips from the

board, and after programming with a conventional programming socket, solder them back to the motherboard. it might be better thanISPway more efficient. When usingISPWhen programming in this way, you must pay attention to the

following matters:

⚫Know the target board circuit diagram (if you haveISPFor consultation on programming related issues, you must provide us with the schematic diagram);

⚫useISPMode burning the chip on the board, all signal pins of the chip must be isolated from other circuits on the board, it must be ensured that the main control chip on the board does

not access the target chip, and all the connections of the main control chip must beIOIt needs to be set to a high-impedance state (the main control chip can be set toRESETstate);

⚫Regardless of the power supply mode used by the target board, the target board'sVCCmust be combined withISPthe first part of the interface2pin connection;

⚫rightISPUnused pins in the interface, please keep them floating, and do not connect with any signal in the target board;

⚫chip not connectedIOThe normal working conditions of the chip must be met (for example:25 SPI FLASHofHOLDandWPpin must be pulled high);

⚫Programmer'sISPin the interface4,6,8,10feet areGND, in practical application, usually only need to connect any one of them to the target board;

⚫Keep the line connections as short as possible (some chips even use the includedISPline, it may also be too long to cause programming failure).

pay attention:ISPBurning is from the programmerISPinterface (bottom10pindedicated interface) to connect, and select the[ISP]Model with suffix (like

The chip strip is not available in the software[ISP]Models with suffixes are available for selection, it means that the chip is not supportedISPburn),Please do not remove the40pin

socket).

Shenzhen Shuofei Technology Co., Ltd.16

Sofei Technology manual

SP8 series programmer

Appendix I Frequently Asked Questions

☺whytwenty fourSerial chip does not have erase function

◼The chip is based onEEPROMtechnology, chip data can be directly rewritten without pre-erasing, so no erase operation is available.

◼To clear the chip data, please write directly to the chipFFHdata can

☺What is the reason for the software prompting chip initialization error?

When programming some chips (such astwenty fourseries chips), the programmer will perform initialization detection on the chip, if the detection fails, it will give the error prompt. Chip

initialization errors usually have the following reasons:

◼The chip is not placed on the locking seat, or the chip pins are not in good contact

◼The chip is placed in the wrong direction or position

◼There is a problem with the chip itself

◼The chip model does not match, that is, the model selected in the software is different from the one actually placed on the locking seat

◼ISPConnection line problem (onlyISPmode, i.e. with [ISP]suffix chip)

☺What is the reason for the programmed chip not working properly?

The programmed chip does not work normally for the following reasons:

◼The data file is not loaded correctly before flashing the chip

◼There is a problem with the data file itself

◼Programming operation step error

◼Chip working circuit/voltage problem

☺Is it possible to program the chips on other circuit boards with the leads on the locking seat?

Can't. It is forbidden to use this method to program the chip, as this method may cause permanent damage to the programmer. The resulting damage to the programmer will not be

covered by the free warranty.

☺Can the burner burn?imgdocument?

The file encoding formats supported by the burner software are binary (binary) and hexadecimal (Inter HEX) formats, the regular suffix of binary files is *.bin,

and the regular suffix of hexadecimal files is *.hex

img is just a file suffix and does not represent the file encoding format. Usually (more than 90%) such files are binary encoding, and can be loaded directly in the software.

The software will automatically identify whether the file is binary encoding and use the recognized format. to load.

In order to ensure the accuracy of file loading, we recommend that users check the buffer checksum and file checksum (in the programmer software) with engineering technicians (or file

code providers/customers, etc.) after loading such files. This information will be displayed at the bottom of the main window).

☺How should the chip configuration bits be set?

All configuration options of the chip are listed according to the specifications of the chip manufacturer, and the user needs to make the correct configuration according to their own project

needs and chip specifications.The programmer is only responsible for writing the data set by the user into the chip, the programmer manufacturer cannot tell the user how to set it, please

contact the project engineer/code provider.

The configuration option is realized by "Write Configuration". In automatic programming (including offline operation/machine operation), the write configuration needs to be added to the last step of the

operation, for example: "Program"→”check"→”write configuration"

Shenzhen Shuofei Technology Co., Ltd.17

Sofei Technology manual

SP8 series programmer

☺The programmed chip is soldered to the upper part of the product and cannot run, but it can be re-programmed after soldering it down. Is it because the programmer did not program the chip correctly?

During the final test of the product, it is found that the data in some chips is wrong/or lost/or empty chips. There are many reasons for this. The following

common situations are:

1. When the product is powered on and tested, due to interference, unstable power supply, abnormal access, software malfunction, etc., the chip data will be rewritten or erased.

2. When sorting chips, mix up <put the chip that failed to be programmed, or the chip that has not been programmed to the OK side>

3. The temperature stability of the chip is poor, and data is lost or changed due to high temperature during soldering. According to our statistics, most of the problems are in cases 1 and 2,

and no cases caused by the programmer have been found for the time being. Ensure that the chip data after programming is correct. For the data errors found after high temperature

soldering, the product is powered on and running <chip has been read/written> and other processes, it is not within the scope of the programmer's guarantee.

If you want to rule out or verify if there is a problem with the programmer, it is recommended to do a 100% inspection of the chip before SMD soldering.

For case 1: If the chip is SPI FLASH, there is a way to avoid it, that is, when programming the chip, add a protection function to the chip to

prevent accidental overwriting, see:http://www.sofi-tech.com/html/6184791048.html

☺ISPWhat are the precautions for burning?

The implementation of ISP programming is relatively complicated, and it is suitable for people with certain professional knowledge. If only a small number of chips are to be programmed, it is recommended to remove the chips

from the board, and after programming with a conventional programming socket, solder them back to the motherboard. . This may be more efficient than the ISP method. When using the ISP method to program, you must pay

attention to the following matters:

1. Know the circuit diagram of the target board. <If you have questions about ISP programming, you must provide us with the schematic diagram>

2. When the programmer is programming the target chip, it must be ensured that the main control chip on the board does not access the target chip, and all the connected IOs of the main

control chip must be set to a high-impedance state. <You can try to set the main control chip to for RESET status>

3. Keep the line connection as short as possible. <Some chips may be too long even with the included ISP line>

4. The IOs that are not connected to the chip must meet the normal working conditions of the chip.

For example: HOLD and WP pins of 25 SPI FLASH must be pulled up to high level.

Special attention: ISP programming is to connect from the ISP interface of the programmer (the dedicated interface of the bottom 10pin), and select the model with the [ISP] suffix in the

software (if there is no [ISP] suffix after the chip model, it means no This chip supports ISP programming), please do not connect the cable from the locking socket (40pin socket).

Shenzhen Shuofei Technology Co., Ltd.18

Sofei Technology manual

SP8 series programmer

Appendix II Disclaimer

Shenzhen Shuofei Technology Co., Ltd. will do its best to ensure the correctness of the product and its related software and data. For possible product (including software and

related data) defects and errors, the company will try its best to solve the problem with commercial and technical capabilities. The company is not responsible for all kinds of

incidental, consequential, direct, indirect, special, extended or punitive damages arising from the use or sale of this product, including but not limited to profits, goodwill, loss of

availability, Business interruption, data loss, etc., do not bear any direct, indirect, incidental, special, derivative, punitive damages and third-party claims.

Shenzhen Shuofei Technology Co., Ltd.19

Sofei Technology manual

SP8 series programmer

Appendix IV Document Revision Record

release date Version Revised by illustrate

2011-08 A2 Freeman the first1Version

2011-12 A3 Freeman Modify file load/save content

Increase25seriesSPI FLASHModel detection function update

software /USBDriver installation content

2013-04 A4 Freeman corresponds toV2.61and aboveFlyPROThe software increases the data buffer search

function, modifies the logic operation, and adds the byte exchange content to the chip

IDError handling

add disclaimer

2014-11 B1 Freeman Cancel the software description part, please refer to the independent software user manual for the software part.

2016-08 B2 Freeman Update product selection table

2018-05 B3 Sauwa IncreaseFAQ

2018-07 B4 Freeman Update some software pictures

Shenzhen Shuofei Technology Co., Ltd.20

Other manuals for SP8 Series

1

This manual suits for next models

4

Table of contents

Other Sofi Motherboard manuals