Sofraser 9100 User manual

Original version

REF.: 423-0

9100

Viscosity and temperature

transmitter

Tec nical Manual

Tec nical Manual 9100

REF: 423/0 3

IMPORTANT

THE OFFSET ADJUSTMENT IN THE AIR

MUST BE THE FIRST TASK COMPLETED.

Offset adjustment procedure is detailed in § 3.3.

1. CLEAN AND DRY THE SENSOR ROD.

2. BE SURE THE PROCESS IS EMPTY. THE ROD MUST BE VIBRATING IN THE AIR.

3. INSTALL THE SENSOR ON THE PROCESS AND FIX IT WITH ITS 4 SCREWS.

4. POWER ON THE DEVICE, WAIT AT LEAST 30 MINUTES.

5. PRESS THE “HOME” BUTTON UNTIL REACHING THE OFFSET MENU AND PRESS “OK”.

6. FOLLOW THE INSTRUCTIONS DISPLAYED ON THE ELECTRONICS SCREEN.

7. PRESS “OK” TO ADJUST THE OFFSET. IT MEANS THE RAW SIGNAL IS SHIFTED TO THE

VOLTAGE REFERENCE DEFINED IN THE FACTORY CALIBRATION STAGE.

THE NEW OFFSET VALUE IS THEN DISPLAYED.

Tec nical Manual 9100

REF: 423/0 4

Table of co te ts

1.

TRANSMITTER PRINCIPLE ................................................................................................................. 5

2.

TRANSMITTER TECHNICAL CHARACTERISTICS ............................................................................. 6

2.1

Electronic device size ............................................................................................................................................ 6

2.2

Main features .............................................................................................................................................................. 7

2.2.1

Best performance conditions .................................................................................................. 7

2.2.2

Display ..................................................................................................................................................... 7

2.3

Connections ................................................................................................................................................................ 7

2.3.1

Top connector – current outputs .......................................................................................... 8

2.3.2

Top connector – Power supply and RS485 port .......................................................... 8

2.3.3

Bottom connector – sensor’s coils ........................................................................................ 9

2.3.4

Bottom connector – Pt100 temperature probe & eart ......................................... 9

2.4

Backlig t setting .................................................................................................................................................... 10

3.

THE 9100 OPERATING FUNCTIONS ................................................................................................. 11

3.1

Start and menus ....................................................................................................................................................... 11

3.2

Raw data ....................................................................................................................................................................... 12

3.3

Offset ............................................................................................................................................................................... 12

3.4

Viscosity and temperature units .................................................................................................................. 13

3.5

C eck 4-20 mA ........................................................................................................................................................ 14

3.6

Correlation .................................................................................................................................................................. 14

3.7

Enable or disable temperature ...................................................................................................................... 15

4.

RS485 FRAME PROTOCOL ............................................................................................................... 16

5.

SOFRASER INTERFACE SOFTWARE ................................................................................................ 18

5.1

T e main features ................................................................................................................................................... 18

5.2

T e user-friendly interface ................................................................................................................................ 18

6.

TROUBLESHOOTING ..........................................................................................................................19

Tec nical Manual 9100

REF: 423/0 5

1. Tra smitter pri ciple

T e measuring c ain is composed of t ree inseparable elements: t e sensor, its cable and t e 9100

transducer t at controls it. T e sensor cannot be used wit anot er transducer or anot er

cable type or lengt because t ey are all a part of t e resonant loop so t ey are matc ed

toget er as one vibrating system.

T e active part of t e sensor is composed of a vibrating rod eld in oscillation at resonance frequency

by driving magnets. W en t e rod is immersed into a viscous material, t e amplitude of t e

vibration is dampened. T e vibration amplitude varies according to t e product viscosity

w ere t e rod is immersed.

T e sensor receiving coil detects t e response and t e signal is converted to a viscosity value

t roug t e electronic device. T e factory calibration is performed wit standard oils.

T e transducer acquires t e coils’ amplitudes and frequency and generates various signals. T ese

signals represent t e properties being measured. It is also in c arge of powering t e w ole

system. It gives viscosity and temperature information t roug t e serial communication and

displays it. T e transmitter also allows simple settings as t e very important “zero in t e air”

procedure.

Tec nical Manual 9100

REF: 423/0 6

2. Tra smitter tech ical characteristics

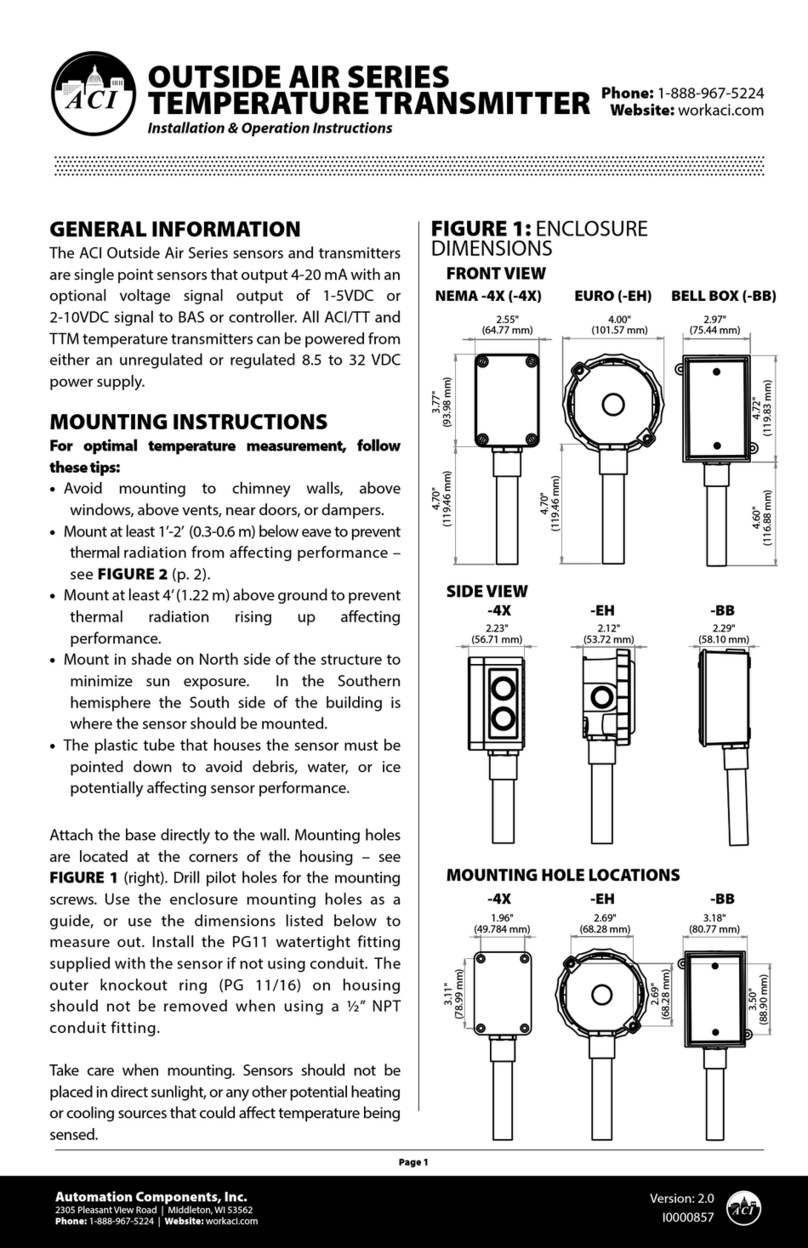

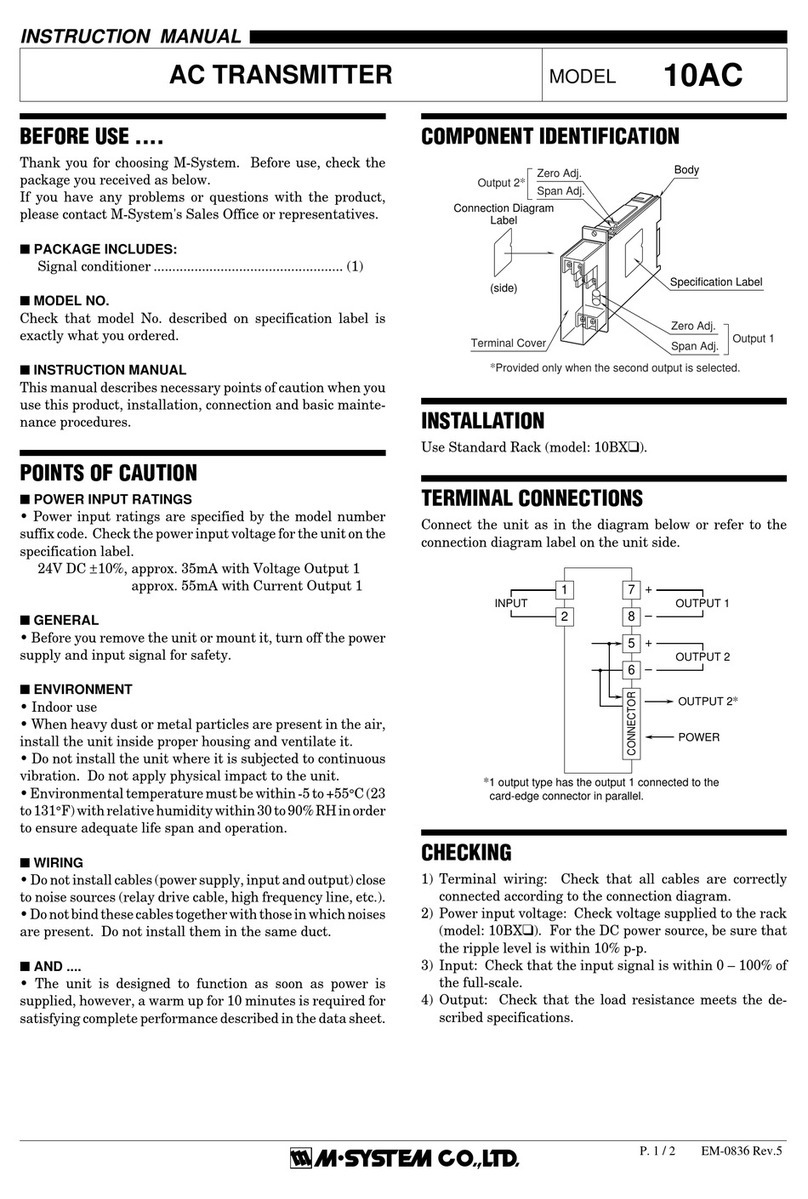

2.1 Electronic device size

T e electronic box as t e purpose to be fixed on a DIN rail, close to t e process line. Its LCD screen

continuously displays t e viscosity value and, w en connected to a Pt100 probe, t e

temperature value.

T e ID label is stuck on a side of t e box. Main information is written down. T ere are also ot er

stickers on eac connector to remind ow to connect t e sensor, t e outputs and t e power

supply (see §2.3).

It as an IP20 rating. Its weig t is about 200 g. Hereunder are t e different views and t e associated

dimensions (in mm) of t e device.

45 mm

105 mm

Top connectors

Bottom connectors

Bottom connectors

Side view

113 mm

Tec nical Manual 9100

REF: 423/0 7

2.2 Main features

2.2.1

Best performance conditions

T e processor must be connected to a 24 VDC (± 2.4 V) stabilized and filtered power supply.

It is very important to respect t e polarity.

T e operating temperature for t is transmitter is up to 50 °C.

It is recommended to install t is transmitter in a safe place wit a stable temperature and non-

condensing atmosp ere.

To ensure t e proper be avior of t e two 4-20 mA current outputs, it is ig ly recommended to

connect t em to a PLC or a regulator t roug a galvanic isolated device (one for eac current

output).

Never connect t e 4/20 mA outputs to a power supply, an active PLC input or tester

2.2.2

Display

T e 9100 transmitter device as a 2-line alp anumeric backlig ting LCD screen. T e effective

dimensions of t is screen are 40 mm * 10 mm. One line can display 8 digits. T is screen is

s owing t e different menus wit t e elp of t e 2-button face plate.

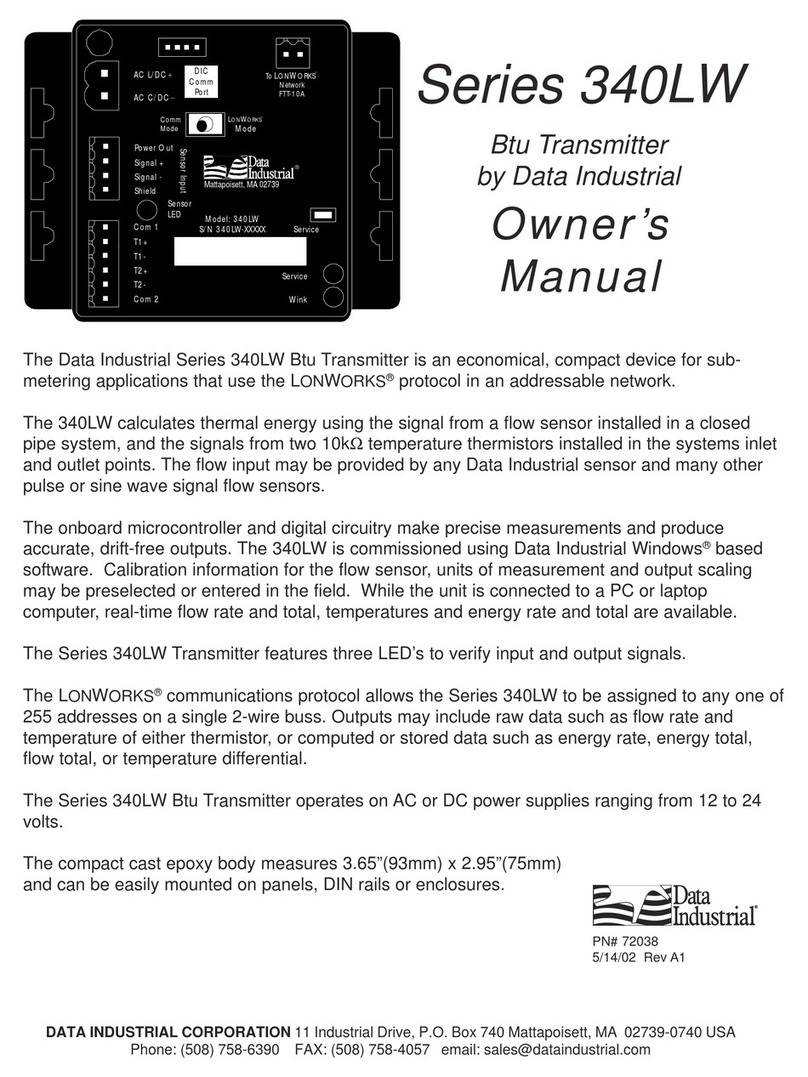

2.3 Connections

All t e connections to t e electronic device are made t roug four connectors.

T ere are two 4-pin connectors on t e top for t e power supply and outputs and two ot er 4-pin

connectors on t e bottom for t e sensor. Refer to t e sensor’s tec nical manual for wires A to

F identification. Connections ave to be made by t e user scrupulously respecting t e

following indications.

Tec nical Manual 9100

REF: 423/0 8

Power supply 24 V 0 V A B RS485 bus

2.3.1

Top connector – current outputs

If t e current outputs are used, t e plugging sc eme of t e connector is as follows:

T e Pins η: 4/20 and T: 4/20 are used to connect t e 4/20 mA outputs for Viscosity and Temperature.

T ey ave been calibrated according to customer's request. T ey must be connected to

installations wit an impedance of not more t an 400Ω. It is recommended to use s ielded

cables for t ese outputs and t e s ield s ould be connected to t e eart . T ey are already

powered internally.

W en t e measured value is out of t e configured range of t e 4/20 output (below minimum value

or over maximum value), t e output passes in default mode and is forced to 2 mA.

Never connect t e 4/20 mA outputs to a power supply, an active PLC input or tester

2.3.2

Top connector – Power supply and RS485 port

T e plugging sc eme of t e connector is as follows:

Pins 24Vdc +V and 0V are for t e 24 VDC (± 2.4 V) stabilized and filtered power supply.

Caution: watc out t e polarity

Pins A and B are used to connect t e RS-485 cable in order to communicate wit an external

console.

Visc 4/20 mA Temp 4/20 mA

Tec nical Manual 9100

REF: 423/0 9

E F G met l

A B C D

2.3.3

Bottom connector – sensor’s coils

T e plugging sc eme of t e connector is as follows:

Pins A, B, C and D make t e connection between t e electronic board and t e coils wires of t e MIVI

sensor cable. T is is ow t e driving signal is generated and ow t e receiving signal is

measured.

2.3.4

Bottom connector – Pt100 temperature probe & eart

T e plugging sc eme of t e connector is as follows:

Pins E, F and G are used to connect t e 3 wires of t e optional Pt100 temperature probe.

Last Pin must be connected to

- t e “metal” wire of t e MIVI sensor cable

- t e ground eart of t e works op

Tec nical Manual 9100

REF: 423/0 10

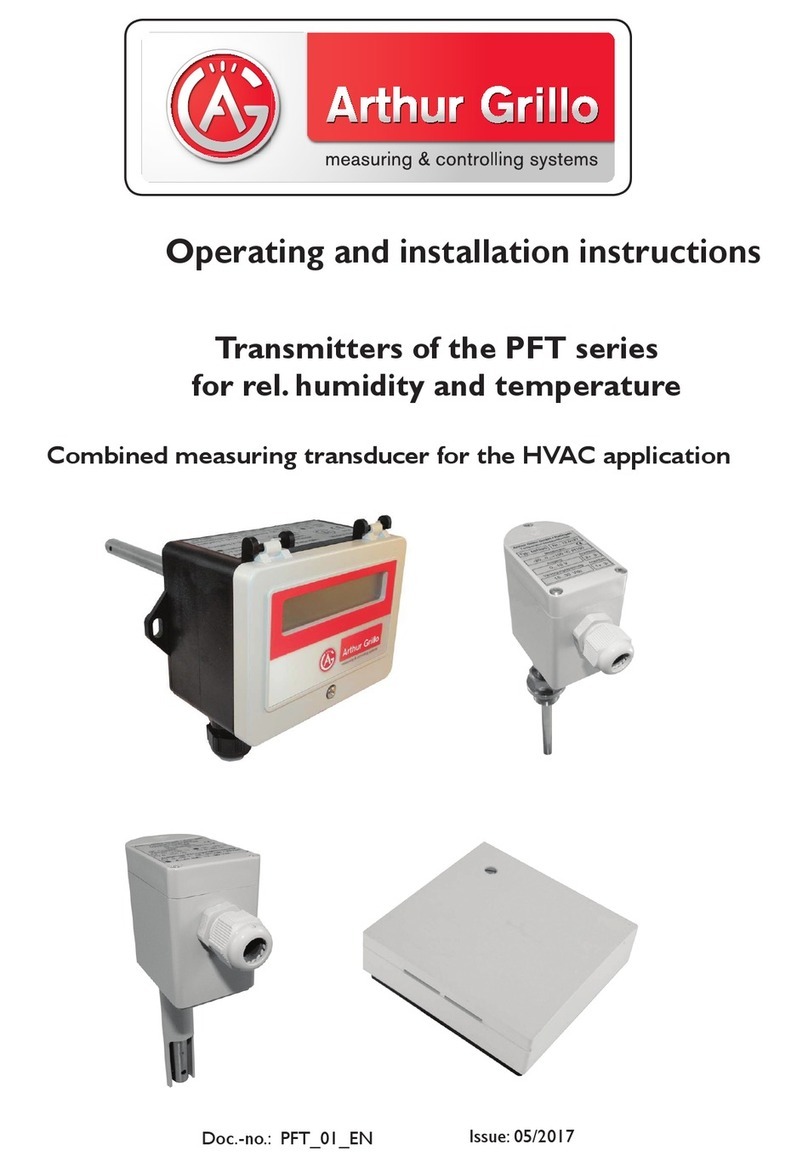

2.4 Backlig t setting

In standard, 9100 is delivered wit disabled display backlig t. T e backlig t can be enabled t anks

to a switc located on t e back side of t e display. Hereunder t e procedure t at describes ow to

access to t e switc and ow to set it.

Power off t e transmitter and remove t e cover

on t e top side of t e transmitter wit a small

flat ead screw driver.

C ange t e position of t e switc to active

and deactivate t e backlig t.

Put t e cover back on.

Top connectors

Current outputs

24VDC power supply & RS485 output

Bottom connectors

Viscosity sensor

Eart & Pt100 temperature probe

Tec nical Manual 9100

REF: 423/0 11

3. The 9100 operati g fu ctio s

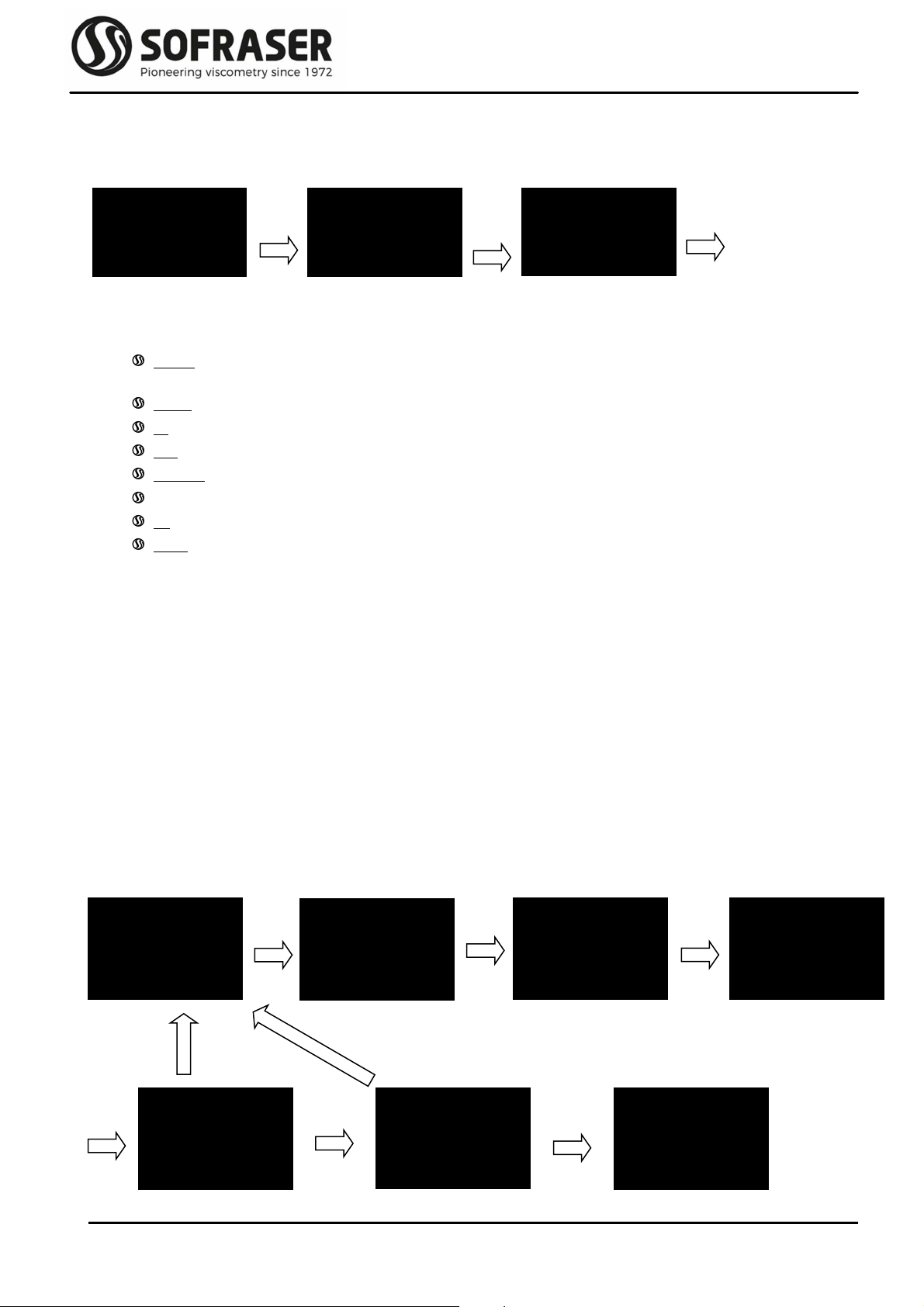

3.1 Start and menus

After turning on t e device, t e LCD screen switc es on and it will take a few seconds to display t e

measured viscosity and temperature values.

T is is t e main screen, t e one displayed in working mode.

By pressing t e “Home” button (small ouse icon), we get access to t e seven different menus

proposed by t e transmitter. We can browse from one to t e ot er wit t e elp of Home. To

enter into a menu, press OK.

If bot Home and OK buttons are pressed simultaneously, t e 9100 display will move back to t e

main screen s owing t e viscosity and t e temperature.

V 24.38

T 22.4

UNIT

T DegC

UNIT

V mPa.s

CORREL

NONE

CHECK

4-20mA

OFFSET

OFF 17

PT 100

ENABLED

RAW DATA

Tec nical Manual 9100

REF: 423/0 12

OK

OK

OK

3.2 Raw data

T is menu as eig t screens. It allows t e user to read t e raw data of t e main measured signals

and ot er information specific of t e unit.

Mainly, t ese data are used to diagnose w en somet ing wrong appens wit t e sensor.

Passing from one screen to t e next is done t anks to OK button and t e order is as follow:

AMP: T e amplitude value, image of t e amplitude of t e oscillating rod wit no correction

and no calculation.

FRQ: T e frequency of t e vibration.

C: T e coil value, image of t e inner temperature.

TC: T e inner temperature.

PROG: T e program version is displayed for after-sale purposes.

T e serial number of t e sensor (4 digits) and t e electronics (3 letters).

D: T e date of manufacturing.

FSR: T e viscosity range of t e sensor.

Exit t is menu by pressing Home.

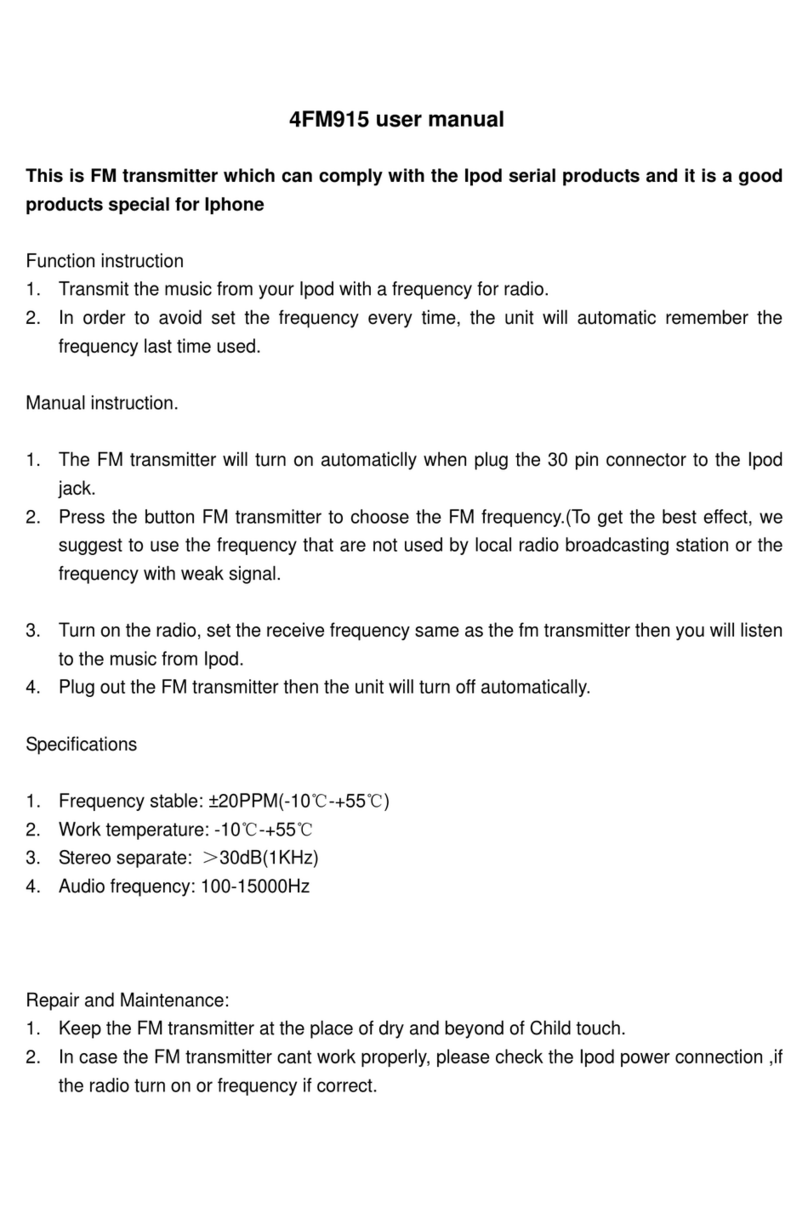

3.3 Offset

In t is menu, we set t e zero in t e air. T is is a very important step in t e installation procedure of

t e equipment and it must be done eac time t e sensor is installed again after being

removed for cleaning, calibration or maintenance.

Before proceeding to t e zero setting, t e rod must be clean and dry. Be sure t e process is empty

and t at t e rod is vibrating in t e air at a stabilized temperature. T e sensor must be fixed on

its final position and will ave to remain so. If not, t e offset calibration will ave to be done

again.

Press OK to enter t e Offset menu. Two warning messages will appear w en pressing OK

confirming t at t e rod must be clean and dry. If OK is pressed, t e transmitter calculates and

t en displays after a couple of seconds t e new adjusted value ( ere -26). T e user can validate

t e new offset pressing OK or e can get out of t e menu by pressing Home.

OK

RAW DATA

AMP11810

RAW DATA

FRQ 279

OK

OFFSET

OFF 17

OFFSET

RODCLEAN

OK

OFFSET

ROD DRY

OFFSET

WAIT….

OFFSET

OFF -26 OK

OFFSET

VALIDATE

OK

OFFSET

OFF -26

OK

…

RAW DATA

C 1935

Tec nical Manual 9100

REF: 423/0 13

T e viscosity signal delivered to t e outputs of t e electronic device is calculated by using t e

adjusted amplitude of t e rod. If t e offset is done in a wrong way or as been forgotten, t e

viscosity value will be wrong.

It is THE essential setting during installation and as to be performed wit t e most extended

attention in order to set t e MIVI in its best conditions for optimal measurements.

Note:

T e user s ould wait at least one minute between two zero adjustments, in order to get

accurate signals and calculations.

If t e offset is not done correctly, a warning message will appear:

T is message appears automatically w en t e offset value is too ig (or too low in t e negative). If

so, c eck t at t e sensor is correctly installed on t e process, wit t e vibrating rod clean and

dry and let t e unit stabilize. T en redo t e zero in t e air procedure.

If t is message remains even after carrying all t e precaution recommended by Sofraser, t e end-

user can anyway validate t e Offset value by pressing OK and t en OK again after a last

validation screen.

3.4 Viscosity and temperature units

It is possible to select t e viscosity and t e temperature units for t e main display on t e LCD screen.

Press OK to enter t e menu, c oose between t e different units by pressing OK and validate t e

c oice wit Home.

T e c oices are mPa.s and Pa.s for t e viscosity and degree Celsius (°C) or degree Fa ren eit (°F) for

t e temperature.

OK

OFFSET

( ! ) 2327

OFFSET

( ! ) 2327

OFFSET

VALIDATE

OFFSET

OFF 2327

OFFSET

OFF 17

OK

OK

UNIT

T DegC

UNIT

V mPa.s

Tec nical Manual 9100

REF: 423/0 14

3.5 C eck 4-20 mA

In t e same c ecking approac , t is menu lets t e user c eck t e good calibration of t e 4-20 mA

outputs. In t is function, we ask t e processor to send t ree different known current values to

t e outputs and t e user as to c eck wit t e elp of an ammeter t e value w ic is delivered

on t e dedicated top connector (see c apter 2.3.1).

Do not use an active tester (write mode), only use a passive tester like an ammeter (read mode).

By pressing OK, it sends t e first current value (04 mA). T en by browsing wit OK, it goes to t e

next two values (12 mA and 20 mA).

Exit t e menu by pressing Home.

3.6 Correlation

T is menu allows t e user to enable or disable t e correlation function. After positioning on t e

Correlation menu c ange t e status by pressing OK and exit by pressing Home w en t e

desired status is reac ed.

OK OK

OK

OK

OK

OK

OK

CHECK

4-20mA

CHECK

04mA

CHECK

20mA

CHECK

12mA

CORREL

NONE

CORREL

EQUATION

CORREL

TABLE

Tec nical Manual 9100

REF: 423/0 15

It is necessary to use t e Sofraser Interface Software (SIS, see c apter 5) to c oose t e type of

correlation (Linear wit ax + b formula or Table) and to c ange t e values of correlation.

W en t e correlation is activated, an asterisk * appears on t e bottom rig t corner of t e main

screen (see c apter 2.2.2).

3.7 Enable or disable temperature

T is menu allows t e user to enable or disable t e display of temperature on t e main screen. After

positioning on t e Temperature menu, c ange t e status by pressing OK and exit by pressing

Home w en t e desired status is reac ed.

Pressing Home one more time leaves t e Menu and goes back to t e main screen (see c apter

2.1).

OK

OK

PT 100

ENABLED

PT 100

DISABLED

Tec nical Manual 9100

REF: 423/0 16

4. RS485 frame protocol

Goal: read viscosity and Pt100 values using RS-485 communication

S: send from t e console to t e board

R: response from t e board to t e console

Viscosity: viscosity in t e unit displayed on t e 9100 screen (mPa.s or Pa.s)

Pt100: value in t e unit displayed on t e 9100 screen (°C or °F) of t e temperature read by t e probe

w en t ere is one

COM port c aracteristics:

Speed: 9600 bits/s Number of bits: 8 Parity: none Stop bit: 1

Generic frame format (all t e data in t e frames are in Hexadecimal)

S = SN 04 XX XX YY YY <CRC-16>

R = SN 04 AA {DATA} <CRC-16>

SN: slave number 04: reading function

XX XX: starting point for t e addresses to be read YY YY: number of words to be read

AA: read bytes number DATA: content of all t e asked addresses

<CRC-16>: c ecksum Modbus RTU on 16 bits (can be automatic if PLC or software is compatible)

NB: 1 word = 2 bytes

List of addresses:

T e viscosity value read t roug t e RS-485 is t e viscosity displayed on t e 9100 main screen

multiplied by a factor w ic depends of t e viscosity range of t e unit.

T erefore, t e viscosity read t roug t e RS-485 as to be divided by a factor in function of its full-

scale range and w ic is indicated in t e table below:

Full scale range

Multiplied factor

0 to

4,000

mPa.s

1,000,000

4,00

1

to

40

,

000

mPa.s

10,000

Above 40,00

1

mPa.s

1,000

Data to read

Address in

Hexadecimal

Number of

words

Multiplied factor of

t e data received

Frame to send wit a

unit at slave

address 01

Viscosity

(in cP, P

mPa.s or

Pa.s)

0x 00 14

2 words

4 bytes

(UINT_32)

1,000

or 10,000

or 1,000,000

(see table below)

01 04 00 14 00 02 31 CF

Temperature

(in °C or °F)

0x 00 12

2 words

4 bytes

(INT_32)

100,000 01 04 00 12 00 02 D1 CE

Tec nical Manual 9100

REF: 423/0 17

Example 1: to read t e viscosity of a unit w ic as a slave address 01 (01 in Hexadecimal), wit a full-

scale range of 100 mPa.s and w ic measures a viscosity of 67.65 mPa.s

S = 01 04 00 14 00 02 31 CF

R = 01 04 04 04 08 4F 18 4F 4C

01: slave number of t e viscometer in Hexadecimal 04: reading function

00 14: viscosity address 00 02: number of words 31 CF: c ecksum of sending frame

04: number of bytes read 04 08 4F 18: viscosity value in Hexadecimal w ic is converted to

67,653,400 in Decimal and t is value as to be divided by 1,000,000

(because range is below 4,001 mPa.s) so t e viscosity is 67.65 mPa.s

4F 4C: c ecksum of receiving frame

Example 2: to read t e viscosity of a unit w ic as a slave address 01 (01 in Hexadecimal), wit a full-

scale range of 10,000 mPa.s and w ic measures a viscosity of 3,495.2 mPa.s

S = 01 04 00 14 00 02 31 CF

R = 01 04 04 02 15 54 DC D4 A1

01: slave number of t e viscometer in Hexadecimal 04: reading function

00 14: viscosity address 00 02: number of words 31 CF: c ecksum of sending frame

04: number of bytes read 02 15 54 DC: viscosity value in Hexadecimal w ic is converted to

34,952,412 in Decimal and t is value as to be divided by 10,000

(because range is between 4,001 and 40,000 mPa.s) so t e viscosity is

3,495.2 mPa.s

D4 A1: c ecksum of receiving frame

Example 3: to read t e temperature of a unit w ic as a slave address 01 (01 in Hexadecimal), w ic

measures a temperature of 25.92 °C

S = 01 04 00 12 00 02 D1 CE

R = 01 04 04 00 27 8C FE AE CF

01: slave number of t e viscometer in Hexadecimal 04: reading function

00 12: temperature address 00 02: number of words D1 CE: c ecksum of sending frame

04: number of bytes read 00 27 8C FE: temperature value in Hexadecimal w ic is converted to

2,591,998 in Decimal and t is value as to be divided by 100,000 (always

t e same factor) so t e temperature is 25.92 °C

AE CF: c ecksum of receiving frame

Tec nical Manual 9100

REF: 423/0 18

5. Sofraser I terface Software

T e Sofraser Interface Software (SIS) as been designed for working wit t e 9100 transmitter. It

allows t e communication between t e electronic board of t e 9100 and a computer in order

to make some data logging or to set some parameters.

T is software as been designed to work on Windows XP, Windows Vista, Windows 7 and Windows

10 systems. T e communication is establis ed t roug t e RS485 port, MODBUS (code RTU)

protocol.

T is is optional and is not included in standard wit 9100 device.

5.1 T e main features

T e main features of t e SIS are as following:

display and refres t e dynamic values from t e sensor: viscosity, temperature (w en t ere

is a Pt100 probe), amplitude, coil and frequency signals

make t e zero adjustment in t e air

data log of t e dynamic values in an Excel file

adjust some correlations for t e viscosity

5.2 T e user-friendly interface

W en connecting t e 9100 to a computer, c oose t e COM port on w ic is connected t e

viscometer. T en click on t e double arrow button; t e SIS will automatically detect t e board,

display t e serial number of t e device and open a new window. T e user is ready to start

working wit t e equipment.

Eac equipment is protected wit a registration. At first use, you will ave to activate t e software

by entering t e registration key given by Sofraser (go to menu “File\Add Sensor” or “F6”). From

t en on, t e SIS installed on t is computer will always be able to communicate wit t e 9100.

Different levels of security ave been set up in t e SIS, so t at different users can ave different

possibilities on t e equipment t roug menu “Options\Connect As” or “F9”.

User

Password

Tec nician

1111

Manager

1111

Tec nical Manual 9100

REF: 423/0 19

6. Troubleshooti g

T e ereunder table lists all t e reasonable malfunctioning and some advices in order to analyze

t em and to fix t em:

Observed malfunctioning

C ecking advice

T e screen does not lig t on w en we turn

on t e power supply.

C eck t e wiring connections and t e

power supply of t e equipment (see § 2.2.1

and 2.3.2).

Take care to t e polarity of t e 24 VDC

power supply. Inversion may damage t e

electronics board.

If it does not solve t e problem, please

contact Sofraser or your distributor.

T e sensor is not vibrating but t e screen

lig ts on.

C eck t e resistor value between wires A

and B and between wires C and D on t e

sensor cable.

T e screen displays Out Of Range instead of

t e viscosity.

T e viscosity measured is over t e calibrated

range of t e unit.

Contact Sofraser or your distributor for a

new calibration.

T e screen displays Sensor BREAK.

C eck t e connections of t e wires A to D of

t e MIVI sensor on PIN 11 to 14 on t e bottom

connector (see § 2.3.4).

T e screen displays Pt100 BREAK.

C eck t e connections of t e wires E to G of

t e MIVI sensor on PIN 15 to 17 on t e

bottom connector (see § 2.3.3).

If t e MIVI sensor is not equipped wit a

Pt100, just disable temperature

measurement (see § 3.7)

T e screen displays an asterisk * on t e

bottom rig t corner.

It indicates t at a correlation is activated

(see § 3.6).

T e temperature is not displayed on t e

main screen.

T e temperature feature is deactivated (see

§ 3.7 to activate it).

T e value of t e current 4-20 mA output is

not consistent wit t e measured value

displayed on t e main screen.

C eck t e range of t e current output in t e

specific notes.

Contact Sofraser or your distributor if t e 4-

20 mA output range must be modified.

T ere is no signal on t e current output. Contact Sofraser or your distributor.

Current output delivers 2 mA

T e p ysical value is out of t e t res olds

set for t e current output. See specific

notes. Contact Sofraser or your distributor

for c anging t e setting.

Table of contents

Other Sofraser Transmitter manuals