© Copyright Softing Industrial Automation GmbH 3

Table of Contents

Table of Contents

Chapter 1 ...................................................................................... 7

Introduction

............................................................................................................... 71.1 About FG-200 HSE/FF Modbus

............................................................................................................... 71.2 System requirements

............................................................................................................... 71.3 Scope of delivery

............................................................................................................... 71.4 Safety precautions

............................................................................................................... 71.5 Intended use

............................................................................................................... 81.6 Document history

............................................................................................................... 81.7 Typographic conventions

Chapter 2 ...................................................................................... 9

Hardware installation

............................................................................................................... 92.1 Installation in hazardous locations

.......................................................................................................... 9

General requirements2.1.1

.......................................................................................................... 11

Hazardous Location - European and International Approval (ATEX, IECEx)2.1.2

.......................................................................................................... 11

Hazardous Location - North American Approval (cULus)2.1.3

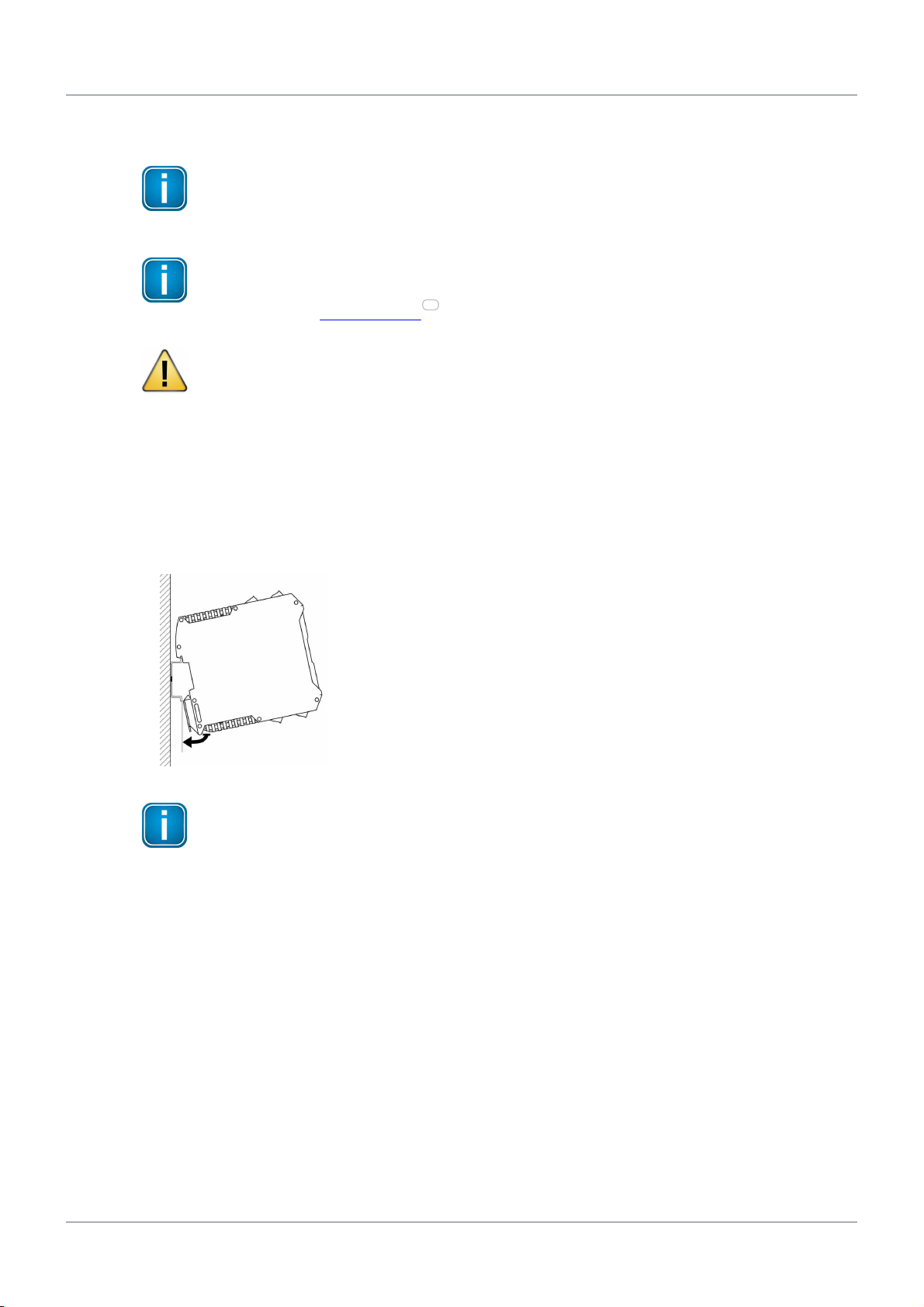

............................................................................................................... 122.2 Mounting and dismounting

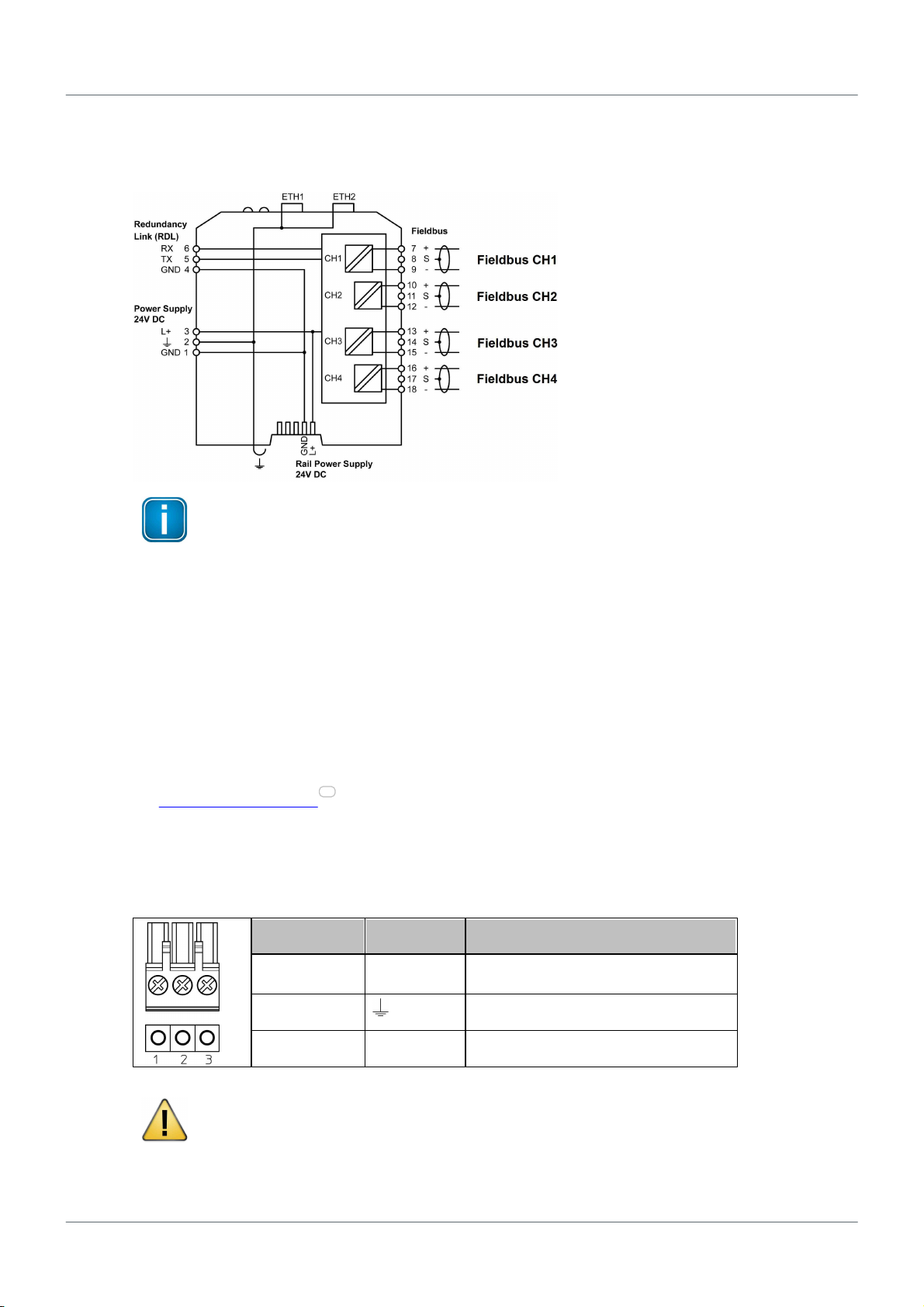

............................................................................................................... 132.3 Connection diagram

............................................................................................................... 132.4 Connecting the power supply

............................................................................................................... 142.5 Connecting to the network

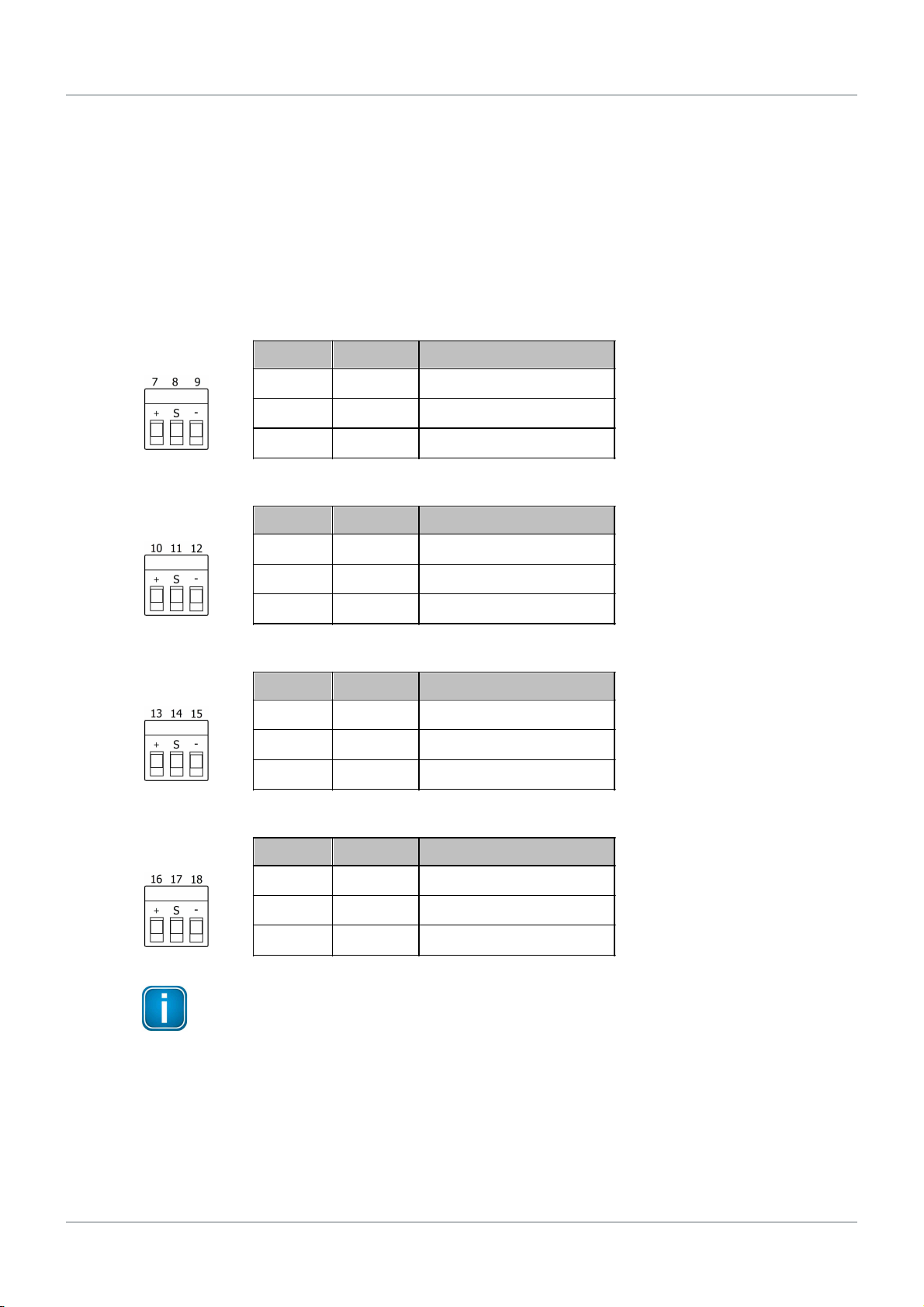

............................................................................................................... 142.6 Modbus serial connection

............................................................................................................... 152.7 Using two FG-200

............................................................................................................... 162.8 Connecting FF-H1 interfaces

............................................................................................................... 172.9 Powering up the device

............................................................................................................... 172.10 Adding a second FG-200 to form a redundant set of FG-200

Chapter 3 ...................................................................................... 18

Commissioning the FG-200 HSE/FF Modbus

............................................................................................................... 183.1 Installing comConf

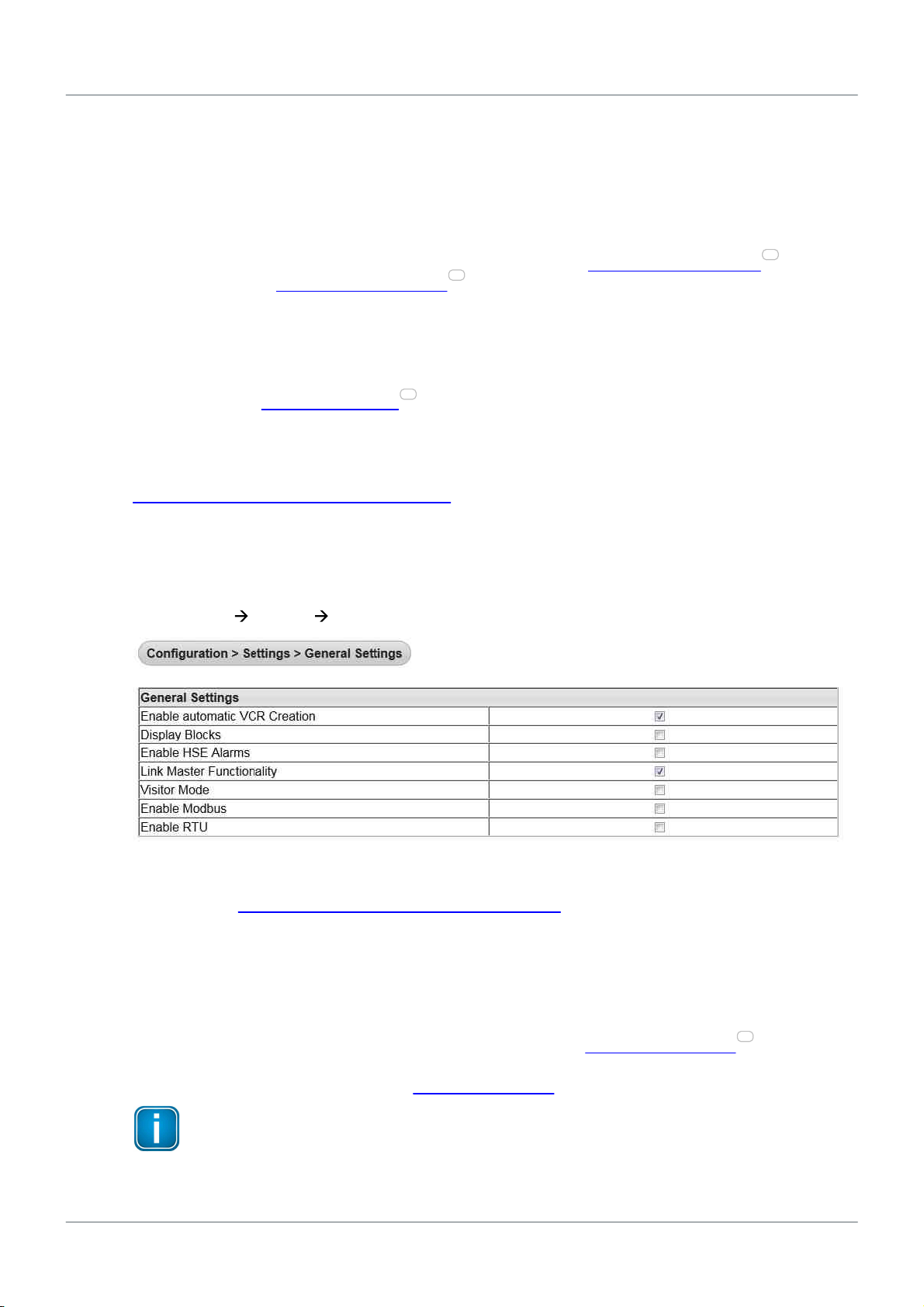

............................................................................................................... 183.2 Configuring IP address and Modbus parameters

Chapter 4 ...................................................................................... 19

Working with the FG-200 HSE/FF Modbus

............................................................................................................... 194.1 FG-200 acts as a Modbus / FF-H1 Gateway

.......................................................................................................... 19

FG-200 acts as link active scheduler4.1.1

.......................................................................................................... 19

FG-200 acts as visitor host4.1.2

.......................................................................................................... 20

Configuring the Modbus mapping table4.1.3

.......................................................................................................... 21

Modbus statistics counter4.1.4

............................................................................................................... 224.2 FG-200 acts as a FF-HSE/ FF-H1 gateway

.......................................................................................................... 22

FG-200 acts as an H1 interface used by Emerson AMS System4.2.1