Solar Frontier PowerSet Turbo Series User manual

ENGLISHDEUTSCHITALIANONEDERLANDS

Solar Frontier Europe GmbH

Installation and Operating Manual

PowerSet Turbo and PowerSet Mini

Installations- und Bedienungsanleitung

PowerSet Turbo und PowerSet Mini

Manuale di installazione e funzionamento

PowerSet Turbo e PowerSet Mini

Installatie- en bedieningshandleiding

PowerSet Turbo en PowerSet Mini

1

Contents

1. General Safety Advice 2

1.1 Safety advice for Solar Frontier SF165-S/SF170-S photovoltaic modules 2

1.2 Safety advice for Turbo inverters 2

2. Proper usage 2

3. Components included and structure of the PowerSet 2

4. About this Manual 3

4.1 Contents 3

4.2 Target audience 3

4.3 Markings 3

4.3.1 Symbols 3

4.3.2 Keywords 3

4.3.3 Markings used in the text 3

4.3.4 Abbreviations 4

5. Installation 4

5.1 Mounting system / substructure 4

5.2 Mechanical installation of Solar Frontier SF165-S/SF170-S

photovoltaic modules 4

5.2.1 Site location 4

5.2.2 Handling instructions 4

5.2.3 Mounting instructions 4

5.3 Electrical installation photovoltaic generator 6

5.3.1 Electrical wiring safety precautions 6

5.3.2 Cabling 6

5.3.3 Grounding 7

5.3.4 Electrical wiring 7

5.4 Installation of Turbo inverters 8

5.4.1 Safety measures during installation 8

5.4.2 Mounting the inverter 8

5.4.3 Preparing the AC connections 8

5.4.4 Preparing the DC connections 9

5.4.5 Prepare the data connection cable required for

using Power Monitoring 9

5.4.6 Connecting a PowerStorage system 9

5.4.7 Modbus RTU data connection cable for connecting an

energy meter 9

5.4.8 Connecting the inverter and switching on the AC power 9

5.4.9 Initial commissioning of the inverter 9

5.4.10 Switching on the DC supply 11

5.4.11 Feed-in management or PowerStorage 11

5.4.12 Registration and configuring PowerMonitoring 11

5.4.13 De-installing the inverter 11

6. Structure and function of the Turbo inverter 12

6.1 Casing 12

6.2 Operating buttons 12

6.3 Overview of operating functions 13

6.4 Service menu 13

6.5 Troubleshooting 14

7. Maintenance 16

7.1 Maintenance of Solar Frontier SF165-S/SF170-S photovoltaic modules 16

7.2 Maintenance DC system 16

7.3 Maintenance of Turbo inverters 16

8. Transport and Storage 16

9. Disposal 16

9.1 Disposal within the EU 16

9.2 Disposal outside the EU 16

10. Technical data and data sheets 16

10.1 Solar Frontier SF165-S/SF170-S photovoltaic modules

16

10.2 Technical data for Turbo inverter 18

10.3 Technical data AC cable and line circuit breakers 19

10.4 Table of countries 19

10.5 Plugs, sockets, DC cable and Y-cable 22

10.5.1 Product information for plug and socket 22

10.5.2 Product information for DC cable / minimum requirements 22

10.5.3 Product information Y-cable 22

11. Exclusion of Liability 22

12. Contact 22

13. Appendices 23

13.1 AC plug for Turbo inverters 23

13.2 SunClix connectors 26

2

ENGLISH

1. General Safety Advice

Please ensure all necessary measures are taken to prevent accidents. The use of

PowerSets in applications that may endanger human lives is prohibited, including

in air and road transport systems.

PowerSets must not be used for anything other than their expressed purpose.

Solar Frontier strongly advises you to follow the instructions below in order to

avoid bodily injury, damage to property and/or death.

PowerSets sold by Solar Frontier GmbH may only be installed by authorized

professionals (see 4.2). As soon as it becomes evident that safe operation is

no longer possible (e.g., visible damage), remove the PowerSet immediately

from the grid.

1.1 Safety advice for Solar Frontier SF165-S/SF170-S

photovoltaic modules

•Installation, wiring and maintenance of SF modules must only be carried out

by licensed and trained persons.

•Ensure that all instructions and warnings related to SF modules and all instruc-

tions from the manufacturer of the system components are fully understood

prior to installing and operating a PV solar system.

•The front surface of SF modules should be covered with an opaque material

during installation to decrease the potential of electrical shock.

•SF modules only generate direct current (DC) electricity.

•SF modules do not have the ability to store electricity.

•SF modules will experience higher voltage when connected in series and

higher electrical current when connected in parallel.

•Only interconnect SF modules with similar electrical characteristics in series or

in parallel to prevent system imbalance conditions and module damage.

•The PV array open circuit voltage must never exceed the maximum system voltage

(including in low temperature conditions)

.

•Excessive leakage currents are a shock and fire hazard.

•Under no circumstances disconnect the cable from operational modules or

electrical arcing may occur. This may result in serious bodily harm or death.

•Do not use SF modules for purposes other than terrestrial power generation to

prevent electrical shock, fire and other accidents.

•Do not artificially concentrate sunlight on modules using lenses or mirrors.

•Do not use light sources other than natural sunlight and general illumination for

power generation.

•Do not use SF modules in water or liquid. Contact with water or other liquid signifi-

cantly increases the risk of electric shock.

•The level of leakage current must be limited in accordance with local regula-

tions for safety reasons.

•Carefully check the polarity of the connections before installing. Incorrect wir-

ing may damage SF modules or appliances.

•Only use tools, plugs, cables and support structures suitable for solar electric

systems.

•Wear appropriate protective clothing when working on SF modules and take

all necessary precautions to prevent electric shock, especially when DC voltage

exceeds 30 V.

1.2 Safety advice for Turbo inverters

•Install and use the device only after reading and understanding this document.

•Always perform the measures described in this document in the sequence

specified.

•Keep this document in a safe place for the entire service life of the device. Pass the

document on to subsequent owners and operators of the device.

•Improper operation can reduce the yields of the photovoltaic system.

•The device must not be connected to the DC or AC cables if it has a damaged

casing.

•Switch the device off immediately and disconnect it from the grid and the

solar modules if any of the following components is damaged:

- Device (not functioning, visible damage, smoke emission, penetration by

liquid, etc.)

- Cables

- Solar modules

•The system must not be switched back on until

- the device has been repaired by the dealer or manufacturer.

- damaged cables or solar modules have been repaired by a technical

professional.

•Never cover the Device.

•Do not open the casing. Danger! This will void the warranty!

•Factory labels and markings must never be altered, removed or rendered

unreadable.

•Observe the respective manufacturer‘s manual when connecting an external

device that is not described in this document (e.g., external data logger). Incor-

rectly connected components can damage the inverter.

Safety advice for the device:

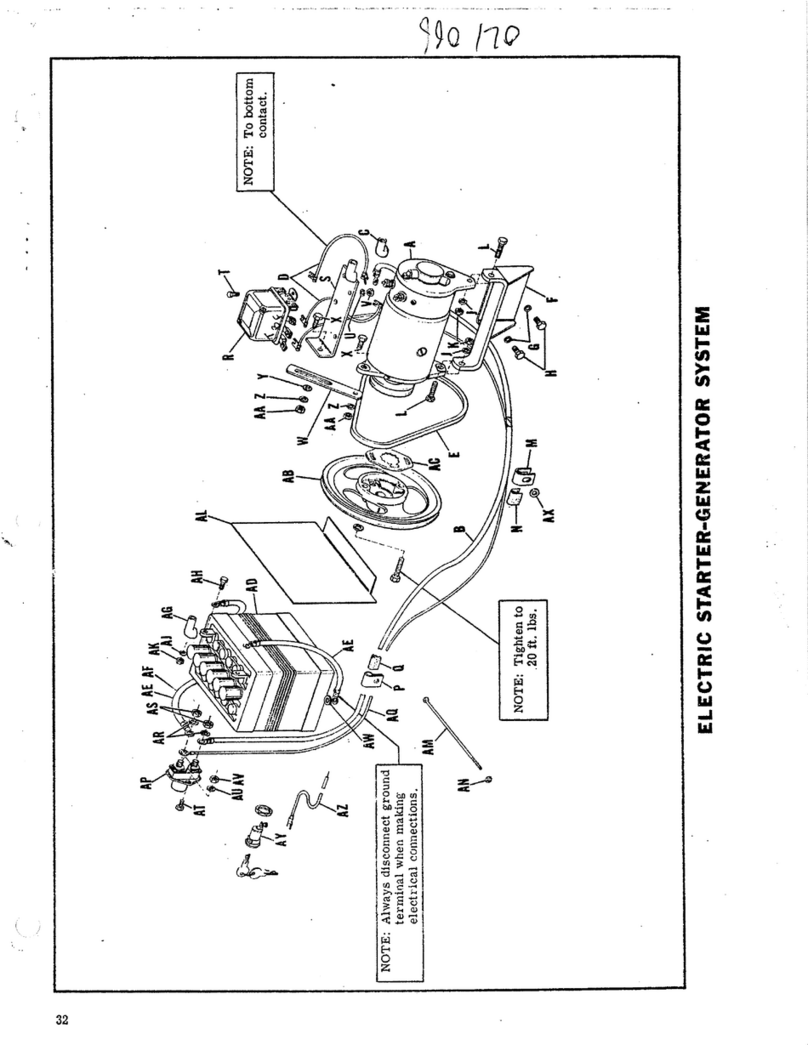

Figure 1

2

3

1

1

1Dangerous voltages can remain present on the components up to 10 minutes

after switching off the DC circuit breaker and the line circuit breaker.

2Read and follow the instructions!

3Serial number as a bar code and in plain text

2. Proper usage

The PowerSet may only be used in grid-connected photovoltaic systems. The

modules, inverter, cables, and connectors have been mutually calibrated for best

performance. The connections may not be grounded.

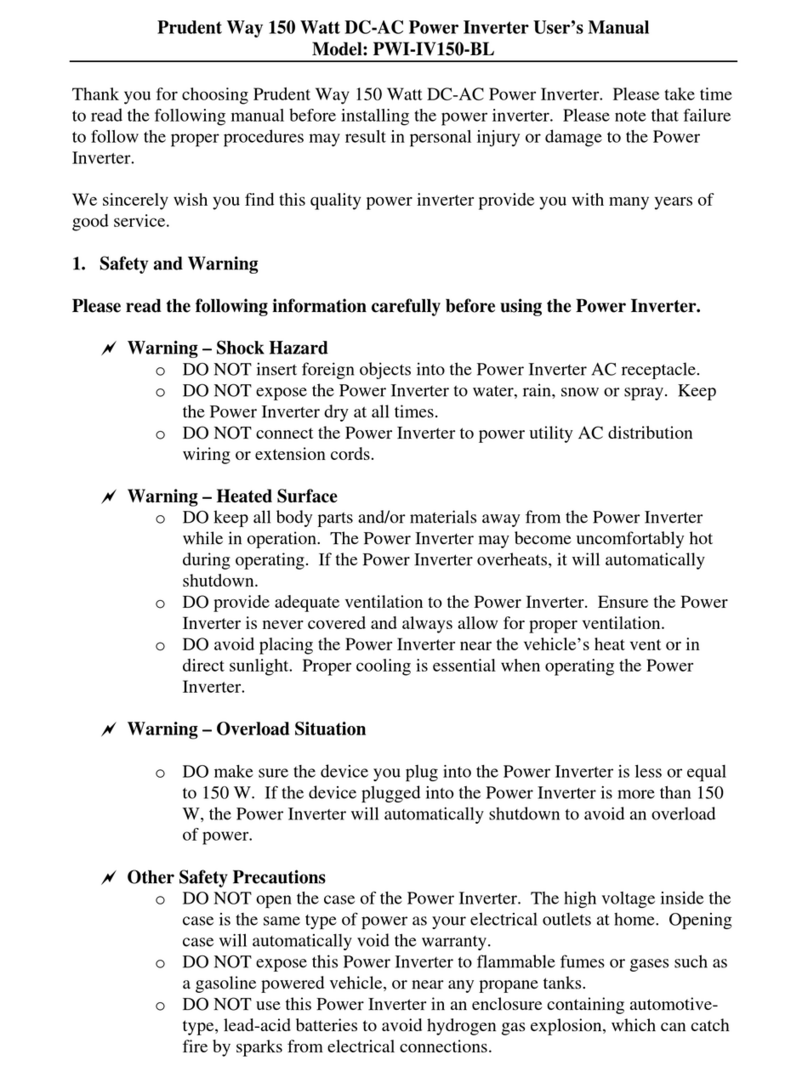

3. Components included and structure of the

PowerSet

The Solar Frontier PowerSet comprises the following components. The number of

components required can be determined using the list below based on the type

of PowerSet you have:

1Solar Frontier SF165-S/SF170-S photovoltaic module

2Solar Frontier Turbo 1P Mini / 1P / 3P1 / 3P2 inverter (incl. inverter, mounting

plate, 1 pair SunClix connectors and AC plug)

3

Y-cables, Version for (+) and (-)

4DC plugs and DC sockets (3 of each in one pack)

5Installation and maintenance manual

3

Area PowerSet Description Capacity Modules Inverters Grid connection Y- cables

Plugs &

sockets

Modules

in series

15.6 m² PowerSet Mini 2.0-170-1p 2.04 kWp 12 x SF170-S 1 x Turbo 1P Mini 1ph 3 (+) & 3 (-) 3 + 3 3

18.2 m² PowerSet Turbo 2.4-170-1p 2.38 kWp 14 x SF170-S 1 x Turbo 1P 1ph 1 (+) & 1 (-) 3 + 3 7

23.4 m² PowerSet Turbo 3.0-165-1p 2.97 kWp 18 x SF165-S 1 x Turbo 1P 1ph 2 (+) & 2 (-) 3 + 3 6

23.4 m² PowerSet Turbo 3.1-170-1p 3.06 kWp 18 x SF170-S 1 x Turbo 1P 1ph 2 (+) & 2 (-) 3 + 3 6

23.4 m² PowerSet Turbo 3.1-170-3p 3.06 kWp 18 x SF170-S 1 x Turbo 3P1 3ph 2 (+) & 2 (-) 3 + 3 6

26.0 m² PowerSet Turbo 3.4-170-1p 3.40 kWp 20 x SF170-S 1 x Turbo 1P 1ph 3 (+) & 3 (-) 3 + 3 5

27.3 m² PowerSet Turbo 3.6-170-1p 3.57 kWp 21 x SF170-S 1 x Turbo 1P 1ph 2 (+) & 2 (-) 3 + 3 7

31.2 m² PowerSet Turbo 4.0-165-1p 3.96 kWp 24 x SF165-S 1 x Turbo 1P 1ph 3 (+) & 3 (-) 3 + 3 6

31.2 m² PowerSet Turbo 4.1-170-1p 4.08 kWp 24 x SF170-S 1 x Turbo 1P 1ph 3 (+) & 3 (-) 3 + 3 6

31.2 m² PowerSet Turbo 4.1-170-3p 4.08 kWp 24 x SF170-S 1 x Turbo 3P1 3ph 3 (+) & 3 (-) 3 + 3 6

36.4 m² PowerSet Turbo 4.8-170-1p 4.76 kWp 28 x SF170-S 1 x Turbo 1P 1ph 3 (+) & 3 (-) 3 + 3 7

39.0 m² PowerSet Turbo 5.1-170-3p 5.10 kWp 30 x SF170-S 1 x Turbo 3P2 3ph 4 (+) & 4 (-) 6 + 6 6

45.5 m² PowerSet Turbo 6.0-170-3p 5.95 kWp 35 x SF170-S 1 x Turbo 3P2 3ph 4 (+) & 4 (-) 6 + 6 7

54.6 m² PowerSet Turbo 7.1-170-3p 7.14 kWp 42 x SF170-S 1 x Turbo 3P2 3ph 5 (+) & 5 (-) 6 + 6 7

62.4 m² PowerSet Turbo 8.2-170-1p 8.16 kWp 48 x SF170-S 2 x Turbo 1P 1ph 6 (+) & 6 (-) 6 + 6 6

Accessories congured for the PowerSets are separately available from Solar Frontier: DC cables, mounting and fastening material, tools for assembly of the cables...

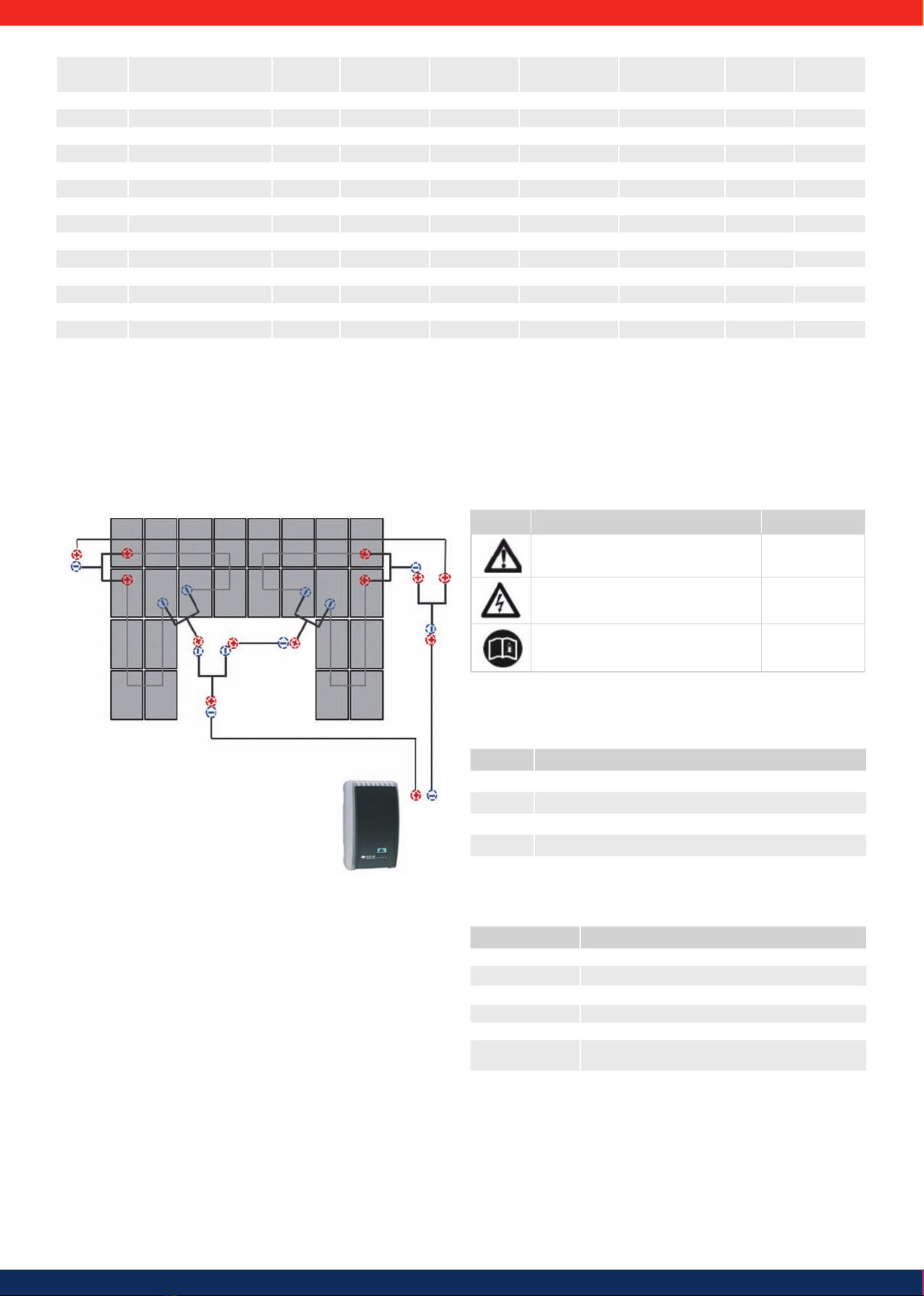

Schematic structure based on

PowerSet Turbo 3.1

example

Inverter

DC-Cable with plug and socket

Y-Cable

PV Generator

Figure 2

4. About this Manual

4.1 Contents

These instructions contain all information required by a technical professional for

setting up and operating the inverters.

When installing other components (e.g., AC cable, mounting system) follow the

manufacturer's instructions.

4.2 Target audience

Unless otherwise indicated, the target audiences of this manual are technical

professionals and system operators.

Technical professionals are persons who, for example:

•have the knowledge of terminology and the skills necessary for setting up and

operating photovoltaic systems;

•because of their professional training, knowledge and experience and knowl-

edge of the relevant regulations can assess the following tasks and recognise

possible dangers:

- mounting electrical devices

- assembling and connecting data cables

- assembling and connecting power supply cables.

4.3 Markings

4.3.1 Symbols

Symbol Description Location

General danger warning Manual

Danger from electricity Manual / device

Read manual before using the product. Device

4.3.2 Keywords

Keywords used in conjunction with the symbols described above:

Keyword Description

Danger Immediate danger of death or serious bodily injury

Warning Possible danger of death or serious bodily injury

Caution

Possible danger of light or medium bodily injury

Attention Possible damage to property

Advice Tips on operation or usage of the manual

4.3.3 Markings used in the text

Markings Description

√ Condition for action

Single step

1., 2., 3., ... Several steps in series

cursive light emphasis

bold strong emphasis

Courier Designation of product elements such as buttons.,

displays, operating state

4

ENGLISH

4.3.4 Abbreviations

Abbreviation

Description

ACurrent in amperes

AC Alternating current voltage

DC Direct current a

Derating Power reduction

DHCP The use of DHCP allows automatic integration of the device into

an existing network (Dynamic Host Configuration Protocol)

MSD Internal mains monitoring for the inverter (mains monitoring

units with allocated all-pole switching devices).

RC Residual current

ICurrent

lkShort circuit current

Impp Current at maximum power point

kVA Kilovoltampere

kW Kilowatt

kWh Kilowatt-hour(s)

mMetre

m2Square metre

MPP Operating point with the highest output (maximum power point)

MPP tra

cker

Controls the power of the connected module strings to match the

MPP

Nm Newton metre

PElectrical power

Pa Pascal

PV Photovoltaic

SELV, TBTS,

MBTS Schutzkleinspannung (EN: safety extra low voltage; FR: Très Basse

Tension de Sécurité; ES: Muy Baja Tensión de Seguridad)

SF Solar Frontier

STC Standard test conditions

UVoltage

ULOpen circuit voltage

Umpp Voltage at maximum power point

UPV

The generator voltage present at the DC connection (photovol-

taic voltage)

VVolt

W/m2Watt per square metre

ηEfficiency

5. Installation

Compliance with all relevant national and local laws, regulations and di-

rectives, especially for accident avoidance, as well as all relevant technical

standards is mandatory for a safe installation.

5.1 Mounting system / substructure

The PowerSets are delivered in standard form without an assembly system. Solar

Frontier offers a suitable assembly system as a separate accessory. For more infor-

mation, see: www.solar-frontier.eu. In general, all commonly available mounting

systems which ensure proper mounting following the guidelines in point 5.2.3 are

suitable. Your installer will be able to suggest an appropriate solution.

5.2 Mechanical installation of Solar Frontier SF165-S/

SF170-S photovoltaic modules

5.2.1 Site location

•Ensure that the maximum wind and snow loads in local conditions do not

exceed the SF module maximum load ratings.

•Avoid installing SF modules in areas where they are exposed to oil vapour and/

or corrosive gas.

•Avoid accumulation of grit or dust on the SF modules as it may reduce the

output yield.

•Do not expose SF modules to sulphurous atmospheres.

•Do not install SF modules in locations where flammable gases accumulate or

flow as there is a risk of sparks from SF PV modules.

•Do not install SF modules near fire.

•Avoid installing SF modules in locations where they may be covered by perma-

nent shadows.This may adversely affect their performance.

•Do not install SF modules in locations where temperatures exceed the tem-

perature range indicated in the module’s technical specifications.

5.2.2 Handling instructions

•Do not disassemble or modify SF modules. This may result in an electric shock,

fire or other accidents. Solar Frontier cannot be held responsible for any loss or

damage caused by unauthorized disassembling, modification or misuse of SF

modules.

•Do not drill additional mounting holes into the aluminium frame. Only pre-

drilled holes should be used.

•Avoid placing any stress onto the SF modules, cables or connectors.

(Minimum bending radius of 39 mm (1.54 in) for module cables is recom-

mended)

•Do not stand or step on SF modules. This may result in damage to the module

and/or bodily harm by falling.

•Do not drop SF modules or drop objects onto them. Both sides of the module

(the glass surface and the back sheet) are fragile.

•Do not strike the terminal box or pull the cables. The terminal box can crack

and break, while the output cable may unplug and cause electricity leakage or

an electric shock.

•Do not scratch the back sheet or cables of the SF modules. Rubbing or scratch-

ing may result in an electric shock, electric leakage or an accident.

•Do not scratch the insulation coating of the frame (except for the grounding

connection). This may weaken the strength of the frame or cause corrosion.

•Do not cover the water drain holes of the frame. Doing so may cause frost

damage.

•Do not use glue when closing the cover of the junction box. Similarly, do not

use a sealant to bond the junction box lid to its base.

5.2.3 Mounting instructions

Mounting structures cautions

• Pay attention to the electrochemical series when selecting support structure

material to avoid galvanic corrosion.

• Fasten and lock bolts completely. Inadequate mounting may result in SF mod-

ules falling or other accidents.

• Make sure that SF modules have been connected securely to the substructure.

The substructure should consist of durable, rustproof. UV resistant material.

Please adhere to national regulations.

• Ensure that your mounting support structure is designed to withstand the

SF module design snow and wind loads applicable for the chosen site. Solar

Frontier will not be responsible if the SF modules are damaged due to the

durability of the mounting support structure. Please consult your mounting

structure manufacturer.

Mounting the solar modules

• PV modules should typically face south in the Northern Hemisphere and north

in the Southern Hemisphere for optimum power production.

• Modules can be installed horizontally (landscape) or vertically (portrait).

• Maintain a space between SF modules and the roof. This will allow air to circu-

late, cooling the module, and allow condensation to dissipate. Solar Frontier

recommends a distance of at least 100 mm (3.94 in).

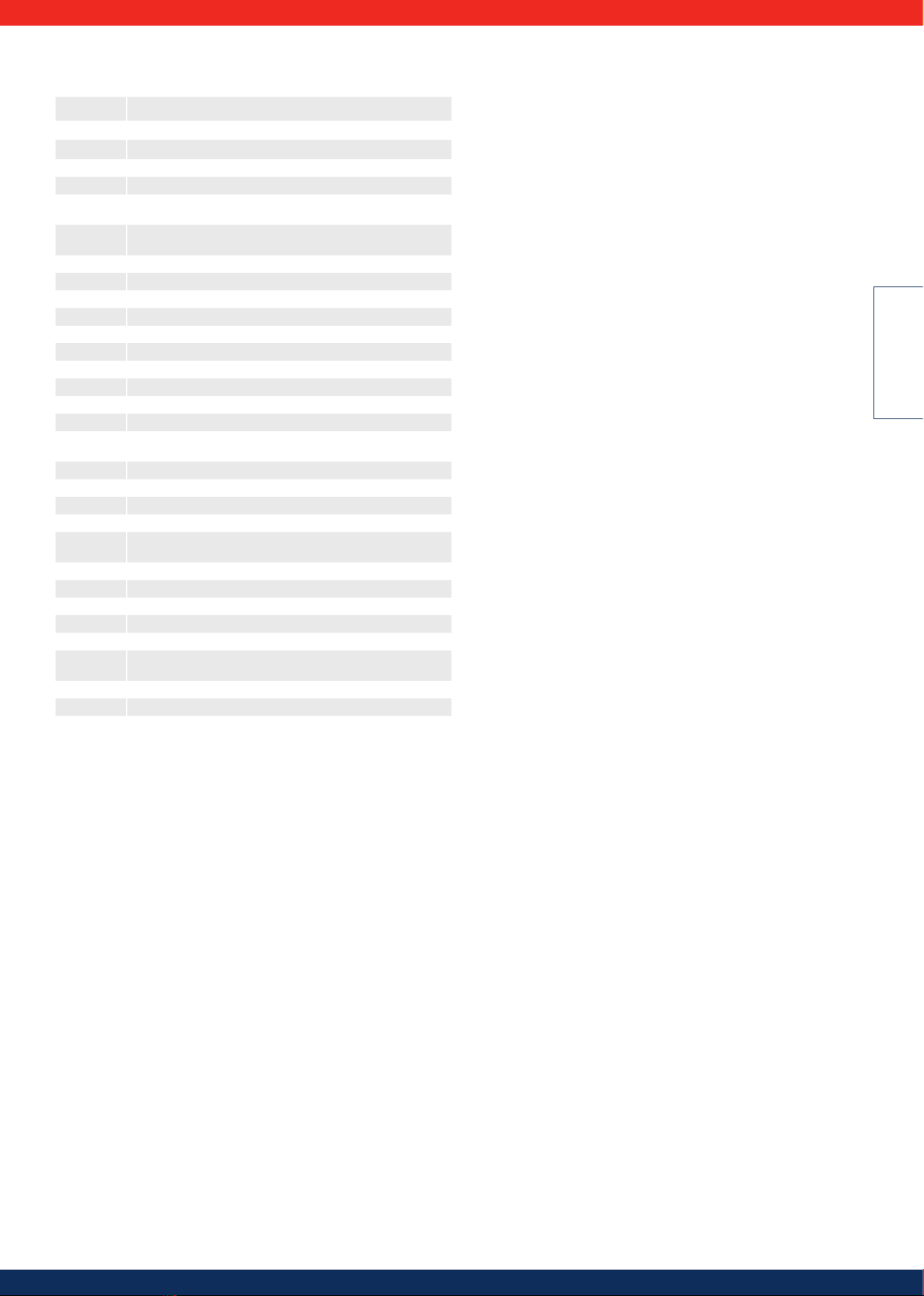

Mounting with clamps

Four or more corrosion-proof clamps should be used to fasten the SF modules to

the support structure securely. The clamps should be secured within the indicated

clamping zones (256 mm +/- 75 mm (10.08 in +/- 2.95 in) from the corners of the

long side of the module) using stainless steel M8 bolts with a minimum length of

20 mm (0.79 in).

All clamps must be at least 30 mm (1.18 in) long and 3 mm (0.12 in) thick and

overlap the module frame by 8 mm (0.31 in) or more.

Clamps must not create shadow nor cover the front glass, and shall not deform

the module frames during installation. For further instructions please contact the

clamp manufacturer.

Maximum load: 2.400 Pa (50 lbs/ft2) to the front and back of the module

5

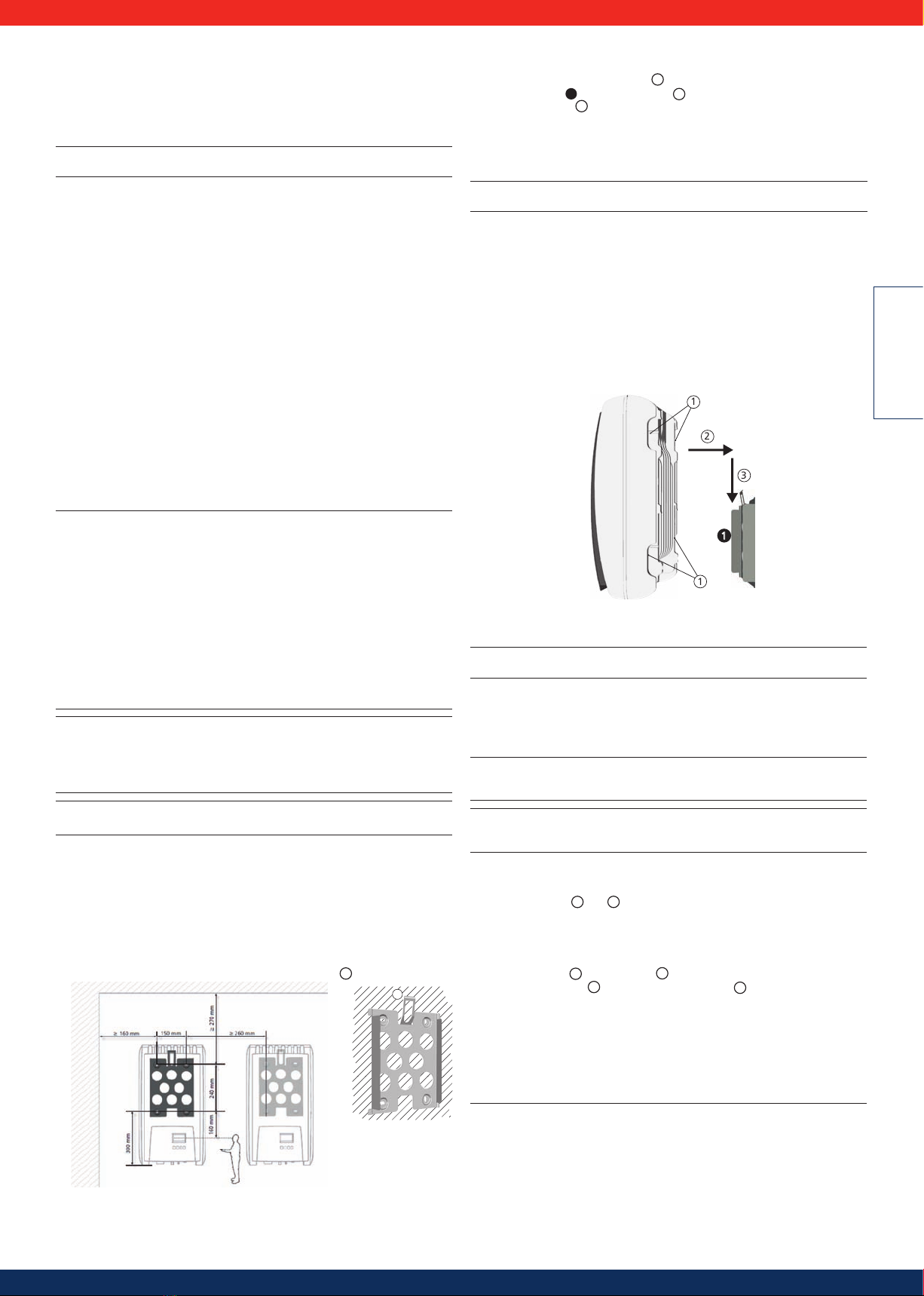

Module perpendicular to support rails

Landscape (horizontal) Portrait (vertical)

256 mm 745 mm

75 mm 75 mm (2.95 in) 75 mm 75 mm (2.95 in)

75 mm 75 mm (2.95 in) 75 mm 75 mm (2.95 in)

75

mm

75

mm

75

mm

75

mm

75

mm

75

mm

7

4

5

mm

25

6

mm

75

mm

75

mm

(2.95 in)(2.95 in)

(2.95 in)

(2.95 in)

(10.08 in)

(10.08 in) (29.33 in)

(29.33 in)

Figure 3

Cross section of an array

Array Installation (section)

ape (

End clamp Middle clamp

Module

support rail

Bolt

Module Module

Nut

Module Module

Module

Clamp to module overlap

min 8 mm (0.31in)

8mm 8 mm 3 mm

3 mm

(10 0

(29.

(0.31 in) (0.31 in)

(0.12 in) (0.12 in)

Figure 4

Module parallel to support rails

256 mm

75 mm

745 mm

75 mm (2.95 in)

75 mm 75 mm (2.95 in) 75 mm (2.95 in)

75 mm

75 mm (2.95 in)75 mm

75 mm (2.95 in)75 mm

745 mm

256 mm

75 mm 75 mm (2.95 in) 75 mm (2.95 in)75 mm

75 mm 75 mm (2.95 in)

(10.08 in)

(10.08 in)

(29.33 in)

(29.33 in) Figure 5

Cross section of an array

Ar

L

Middle clamp

Module

support rail

Bolt

End clamp

Module Module Module

Module Module

Module to rail overlap,

min 10 mm (0.39 in)

10 mm

(0.39 in)

10 mm

(0.39 in)

Nut Nut

8 mm (0.31 in)

Clamp to module overlap,

min 8 mm (0,31 in)

8 mm (0.31 in) 3 mm (0.12 in)

3 mm (0.12 in)

95 in)

75

Figure 6

For alternative mounting methods please consult Solar Frontier.

6

ENGLISH

5.3 Electrical installation photovoltaic generator

5.3.1 Electrical wiring safety precautions

• The sum of Voc of modules in series must not exceed the maximum system volt-

age of the module under any condition. Reverse current applied to the modules

must not exceed 7 A

.

• Do not touch or handle the PV module, terminal box or the end of output

cables with bare hands.

• Do not carry out installation when PV modules, installation tools or installation

area are exposed to water.

• Ensure that the connection parts between SF modules and power receiving

devices are isolated and waterproof. Using SF modules with insufficient isola-

tion and waterproofing could result in an electric shock, an electric leak or an

accident.

• Keep the junction box and connecting cables away from any liquids until the

connectors are mated. Failure to do this may cause faulty wiring.

• The connecting components between the modules must be compatible

with the connecting system. They must enable them to work perfectly and

completely safely.

• Inverters must meet the technical requirements of SF modules.

• Do not connect the PV modules directly to loads such as motors. Variation in

output power may damage the motor.

• Observe and understand the safety instructions of batteries. Their misuse can

result in serious bodily harm due to high electrical current.

• Cables should be adequately protected from damage by wildlife.

5.3.2 Cabling

Solar Frontier places great value on delivering as many components as possible

pre-assembled in order to help avoid sources of error.

As each roof and PV installation has its own peculiarities, certain cables have to be

adapted on site to the system and assembled accordingly. For example, the cables

for extending the connecting cables to reach the inverter have to be assembled

on site. In addition, if there are obstructions on the roof (e.g. dormers) it may be

necessary to bridge the increased distance with extension cables. The DC cable,

sockets and plugs which are included in the PowerSet are for this purpose.

An Hosiden crimping tool (HSC2009-530030) is also required for crimping the

contacts. This is not included in the PowerSet. Pre-assembled connecting cables

must not be altered.

Please ensure a clean and proper assembly of the cables to avoid error

sources and to ensure safe cabling.

The DC cables used must comply with the requirements specified in Section 10.5.2

and be compatible with the plug-in connectors provided by Solar Frontier. Solar

Frontier recommends the use of the DC cables as specified in Section 10.5.2. These

are available from Solar Frontier.

The following tools are required to assemble the cables:

- Mounting key (not included in the delivery)

- Crimping tool for twisted contacts (not included in the delivery)

- Insulation stripping pliers (not included in the delivery)

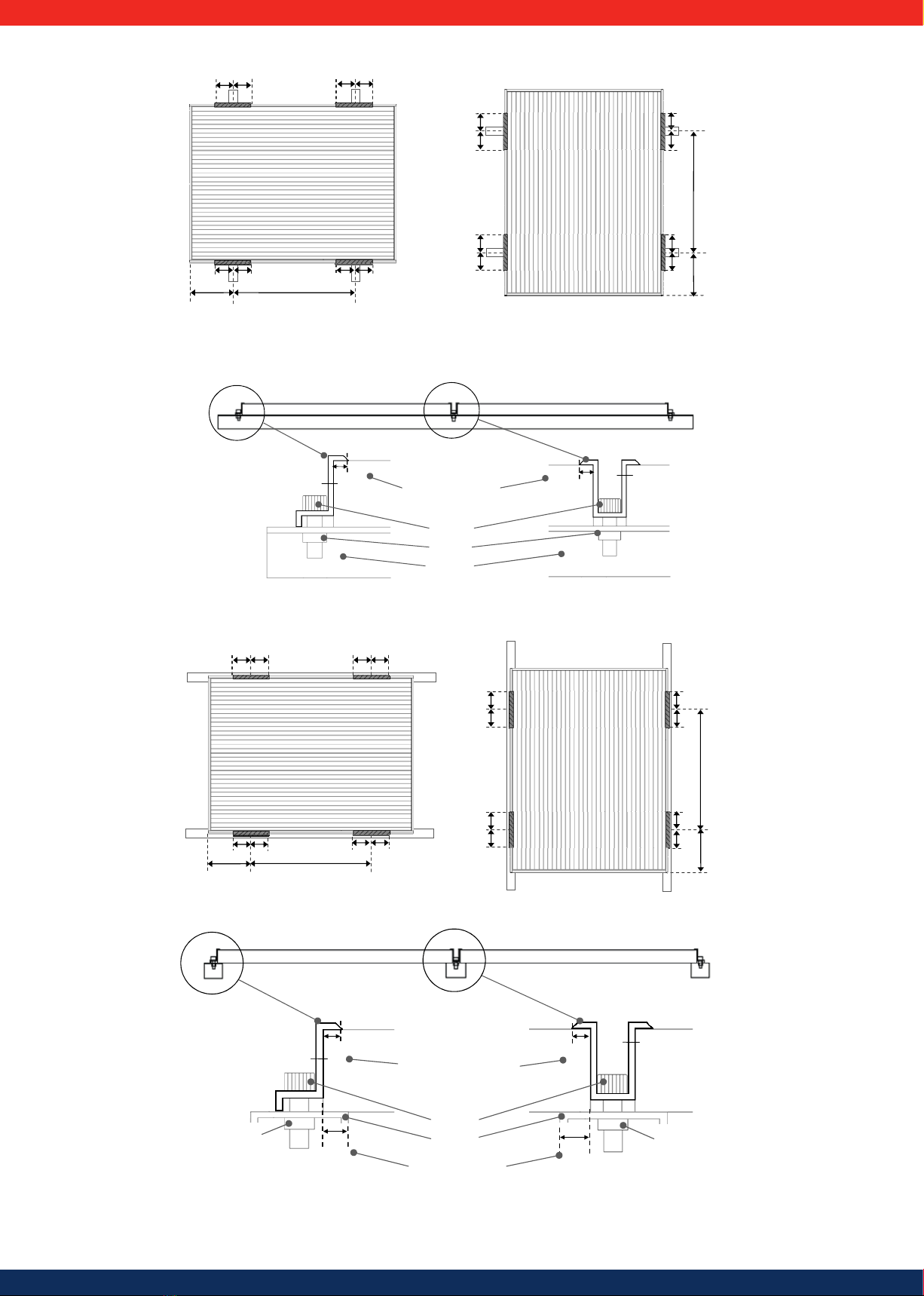

Shortening and stripping the insulation from the DC cable

First, the cable has to be shortened to the proper length. Then the outer insulation

is removed with suitable insulation stripping pliers to a length of 6.5-7.5 mm.

Please take care not to damage the wires in the DC cable. This could reduce

the cross section and cause electrical faults.

Figure 7

Positioning

aid

Adjust the tool:

1. Lift the positioning aid

2. Turn the positioning aid by

±120° in the desired direction

Figure 8

Crimping the twisted contacts

The HSC2010 positioning aid is

used for crimping the pins.

Positioning aid HSC2013 is used for

crimping the contacts.

Figure 9

Crimping

pliers

Place the contact or pin in the posi-

tion for the respective cross-section.

Figure 10

Place the crimping sleeve com-

pletely into the tool as shown in

Figure 11.

Figu re 11

Do not close the crimping pliers

completely at first.

Close the tool gently and check

whether the crimping sleeve is

properly positioned in the crimping

die.

Figure 12

Guide the stripped end of the cable

fully into the crimping sleeve.

Then close the tool completely

while holding the cable until the

locking device has been triggered.

Figure 13

Check the crimping result and the

correct fit of all cable strands.

Figure 14

Connector Contact

Guide the crimped contact into the

connector until it perceptibly clicks

in and locks.

Gently pull at the cable to check

whether the contact holds firmly

and has locked.

Take note that the pin may not

be inserted into the connector.

Socket Pin

Guide the crimped pin into the

socket until it perceptibly clicks in

and locks.

Gently pull at the cable to check

whether the pin holds firmly and

has locked.

Take note that the contact may

not be inserted into the socket.

Figure 15

7

Figure 19

Series connection Parallel connection

Junction box

Carry out installation and wiring work in compliance with all relevant health, safety and environment laws and regulations.

Diagram showing standard module cabling with obstruction

If obstructions make it impossible to connect modules directly side-by-side, the plugs and sockets provided can be used to bridge gaps. A simple example is shown in

Figure 20:

Roof window

Extension Cable

Figure 20

good

not good

Fasten the sealing caps with a

fastening torque of 1.7 Nm.

Check that there is no gap

between the sealing cap and the

connector or socket.

Figure 16

5.3.3 Grounding

Grounding cautions

•Be aware of the necessary grounding requirements prior to installation. Your local

authorities can help you further.

•Install arrestors, surge absorbers or any other appropriate lightning protection tools

as needed.

•Module frames, mountings, connection boxes and metal conduits should be

connected to an earth ground as lightning protection, in accordance with local,

regional and national standards and regulations.

•Holes (d 4 mm, 0.16 in) are provided in the aluminium frame of the SF module to

accommodate grounding. The grounding cable must be attached to the module

frame with a screw and washer. There must be an electrical contact. Use a copper

grounding cable with a cross section of at least 2 mm² (AWG14) and a temperature

range of at least -40 to 85 °C.

•Alternatively, it is possible to use grounding lugs with integrated grounding pin,

lock washers and grounding clips or brackets for PV modules as per NEC Section

250. These components must be used in compliance with the grounding device

manufacturer's guidelines. Consult the grounding device manufacturer to identify

the appropriate grounding and bonding device for your mounting structure or

design.

For alternative grounding methods please consult Solar Frontier.

Connect the grounding cable to the point marked with the electrical earth symbol .

Please refer to further instructions provided by the screw or bolt manufacturer.

Figure 17

Rolling Thread Screw

Lock Washer

Crimping Terminal

Grounding Cable

PV module frame

Grounding (IEC)

Figure 18

5.3.4 Electrical wiring

•The SF modules have a connecting cable with one plug for each pole. Use these to connect the module.

•Do not open the junction box.

•Fasten the module cable to the frame or to the mounting system in order to avoid any stress to the connector.

•Cables drooping from the terminal box are hazardous and must be avoided.

•Cables should be secured so they are not exposed to direct sunlight (such as behind the module).

•The sum of Voc of modules in series must not exceed the maximum system voltage rating of the module under any condition, even at low temperature.

•Reverse current applied to the modules should not exceed 7 A under any condition.

•Minimum cable diameter: 2.5 mm² (0.004 in²).

8

ENGLISH

5.4 Installation of Turbo inverters

5.4.1 Safety measures during installation

Observe the following safety notes when performing the work described in sec-

tion Installation.

Danger

Risk of death by electrocution

• Only technical professionals may perform the work described in section Instal-

lation.

•Always disconnect all DC and AC cables as follows before starting work on the inverter:

1.

Turn the AC circuit breaker to off. Take measures to prevent the system from

being unintentionally switched on again.

2. Set the DC circuit breaker on the inverter to position 0. Take measures to

prevent the system from being unintentionally switched on again.

3.

Disconnect the Hosiden connectors of the DC cables according to

the manufacturer's instructions. A special tool is required for this.

Warning: DC cables are under current if light falls on the modules.

4. Remove the AC plug from the inverter as described in section 5.4.13.

5.

Check that all pins of the AC plug are free of voltage. Use a suitable voltmeter

for this (do not use a simple neon phase checker).

•Do not connect cables to the inverter until explicitly asked to do so in the

instructions.

•Do not open the casing of the inverter.

•Connect only SELV circuits to the RJ45 sockets.

•Lay the cables such that the connection cannot come loose accidentally.

•When laying cables, ensure that no damage occurs to any of the constructional

fire safety measures in the building.

•Make sure that no flammable gases are present.

•Observe all applicable installation regulations and standards, national laws and

connection values specified by the regional power supply company.

Attention

Danger of damage to the inverter or derating!

•The mounting location must satisfy the following conditions:

- The mounting surface and the immediate environment are stationary,

vertical, level, flame retardant and not constantly vibrating.

- They meet the requirements for environmental conditions; see 10.2. Technical

data for Turbo inverter.

- The inverter has the following clearances around it:

above/below: at least 200 mm

to the sides/in front: at least 60 mm

•Do not install the inverter in areas where animals are kept.

•Observe the connection ratings specified on the type plate.

• The DC cables must not be connected to an earth potential (DC inputs and AC

output are not galvanically isolated).

Attention

When transmitting data over a public network:

•Transmitting data over a public network can incur additional costs.

• Data transmitted over a public network is not protected from access by third

parties.

Advice

•Avoid exposing the inverter to direct sunlight.

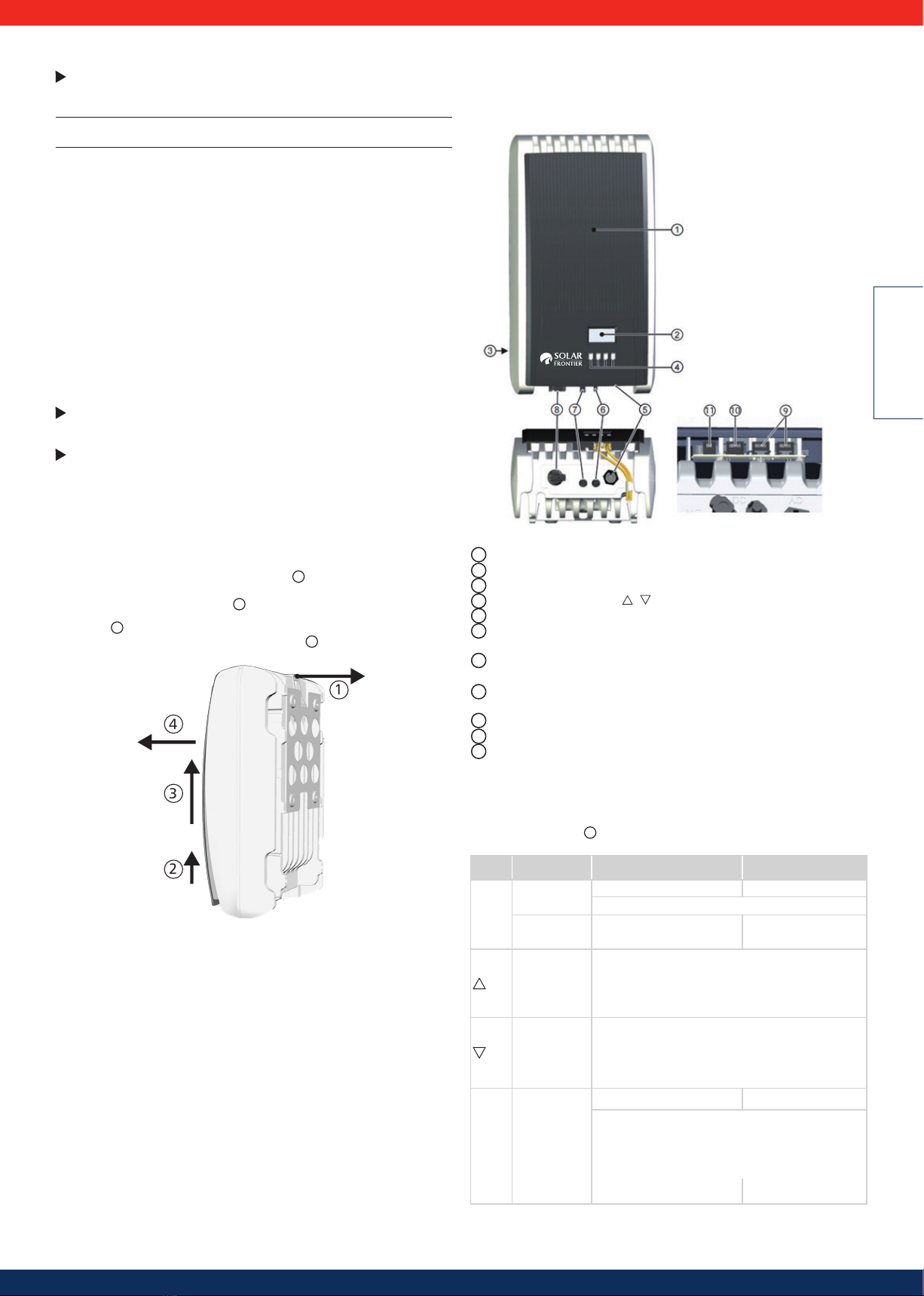

5.4.2 Mounting the inverter

Fastening the mounting plate

Screw the mounting plate to the mounting surface using 4 screws:

•Use screws (and dowels etc.) appropriate for the weight of the inverter.

•The mounting plate must lie flat on the mounting surface and the metal strips

at the sides must point forwards (Figure 22 ).

•Install the mounting plate vertically with the retaining plate

1

at the top (Figure 22).

Figure 22

Figure 21

1

Mounting the inverter on the mounting plate

1. Pick up the inverter by its handles 1or edges, place it in the middle of the

mounting plate 1and press in gently 2(Figure 23).

2. Lower the inverter

3

until the retaining plate on the mounting plate clicks

audibly into place.

The hooks on the back of the inverter must pass over the lugs on the mount-

ing plate.

3. The inverter must be firmly seated on the mounting plate and it must not be

possible to push it upwards.

Advice

The procedure for removing the inverter from the mounting plate is described in 6.4.9

5.4.3 Preparing the AC connections

Line circuit breaker

Information on the required line circuit breaker and the cables to be used between

the inverter and the line circuit breaker is provided in chapter 10.3.

Residual current circuit breaker

If the local installation regulations require the installation of an external residual

current circuit breaker, then a Type A residual current circuit breaker as per

IEC 62109-1, Section 7.3.8. is sufficient.

2

3

1

1

Figure 23

Wiring the AC plug

Danger

Risk of death by electrocution! Observe the warning notes in 5.4.1!

Grid voltage 220 V ... 240 V

Wire the AC plug supplied as described in 13.1.

Grid voltage 100 V ... 127 V

Danger

Risk of death by electrocution! Never connect one of the phases L1, L2 or L3 to PE

or N on the mains grid side.

Advice

If the grid voltage is between 100 V and 127 V, the inverter can be connected

between the external conductors L1, L2 and L3 as follows:

2-phase mains grids

•N and L are connected between the L1 – L2 external conductors on the

inverter side. See 2and 3in Figure 24.

•One of the two connected external conductors is connected to PE at the

inverter side. This connection can be made within the AC plug or in an external

junction box.

•Figure 24 shows an example of an inverter-side connection between L1 and PE:

Top: Connection 1in the AC plug 5

Bottom: Connection 4in an external junction box 6

3-phase mains grids

•N and L are connected between the L1 – L2 or L1 – L3 or L2 – L3 external

conductors on the inverter side.

•Connect the external conductor on the inverter side to PE: as above.

•Figure 24: as above.

The external conductor voltages are shown in Figure 25.

1. Wire the AC plug supplied to match the selected external conductors, as

described in chapter 13.1. Do not yet close the AC plug.

2. Connect one of the two connected phases to PE at the inverter side. Make this

connection inside the AC plug or use an external junction box; see Figure 24.

9

5.4.7 Modbus RTU data connection cable for connecting

an energy meter

A 4-pin telephone cable with RJ10 connector on the inverter side can be used as a

data connection cable to connect an energy meter for feed-in management.

Device

Connection

Inverter

RJ10

Signal

41

Contact 1 Data A

2 Data B

3 Ground

4 — Figure 27

Contact allocation (= wire num-

ber) of the RJ45 connector

Advice

•Material damage due to electrical voltage! The alternative data connection

cable may only be produced by a specialist.

•Risk of destroying the Modbus RTU input of the inverter. Contact 4 of the RJ10

socket carries voltages < 20V. Do not use this contact.

5.4.8 Connecting the inverter and switching on the AC power

Danger

Risk of death by electrocution! Observe the warning notes in 5.4.1.

Attention

Maintain a minimum clearance of 200 mm (7.87 in) between the data connec-

tion cables (RS485/Ethernet) and the DC /AC cables to prevent data transmission

interference.

•Before connecting the PV system to the grid, ensure that the complete system

has been checked, tested and approved in accordance with the relevant

regulations.

• Depending on local regulations, only accredited personnel may connect the

PV system to the grid and commission it.

1. If necessary, establish a data connection.

2. Push the Amphenol Helios H4 opposing connector of the DC cable firmly

into the DC connection of the inverter until it audibly clicks into place.

3. Insert the AC plug into the socket on the inverter until it audibly clicks into

place.

4. Switch on the AC line circuit breaker. The start page for initial commissioning

is shown on the display.

5. Perform initial commissioning and switch on the DC supply, as described in

5.4.9 and 5.4.10.

5.4.9 Initial commissioning of the inverter

Conditions for starting initial commissioning

Initial commissioning starts automatically when at least the AC connector has

been installed and switched on as described previously, If initial commissioning is

not fully completed, then it starts anew the next time the device is switched on.

Guided initial commissioning

Initial commissioning is a guided procedure that sets the following information:

•PowerSet

•Display language

•Date / Time

•Country

•Reactive power characteristic curve (if prescribed for the selected country)

Setting the country

The following applies when setting the country:

•The set country must always be the same as the country where the inverter is

installed. This causes the inverter to load the prescribed grid parameters for the

selected country. More information on this is provided in the table of countries

in section 10.4.

•The country can only be set once!

•If you have selected the wrong country, contact your installer or Solar Frontier.

•If you cannot select your country on the inverter, contact your installer or Solar

Frontier.

•The country setting does not affect the language used on the display. The

display language is set separately.

Only for the Turbo 1P Mini and Turbo 1P inverter:

Figure 24

Connecting N and PE

in the AC plug (top)

or distribution box (bottom)

1Connecting cable between N and PE with the connection point inside the AC plug

2External conductor L1

3External conductor L2

4Connecting cable between N and PE with the connection point in the junction box

5Casing of the AC plug

6Junction box

Figure 25

External conductor voltages

in 2 and 3 phase grids with

100 V ...127 V

L2

L3

L1

N

100 - 127 V

100 - 127 V

100 - 127 V

L

1

L

2

N

100 - 127 V

100 - 127 V

Only for the Turbo 3P1 / 3P2 inverter:

Wire the AC plug provided as described in the following Figure.

1Phase 1

2Phase 2

3Phase 3

4

As the inverter is protection class II.

the PE protective conductor has no

function and need not be connected.

5Neutral conductor

Figure 26

5.4.4 Preparing the DC connections

Danger

Risk of death by electrocution!

Use the SunClix connectors provided to maintain the specific protection class.

Attention

Danger of damage to the inverter and modules.

Connect the mating parts matching the DC connectors to the DC cable with the

correct polarity.

The Hosiden mating parts to the DC cable as per the instructions in section 5.3.2.

5.4.5 Prepare the data connection cable required for

using Power Monitoring

Provide an RJ45 standard cable (patch cable Cat5) to use the on-line Power Moni-

toring service or provide an alternative data connection cable as required.

5.4.6 Connecting a PowerStorage system

The initial operation and configuration of the PowerSet can be completed accord-

ing to these instructions when a PowerStorage system is used.

Thereafter, commission the PowerStorage system as described in the instructions

provided for this purpose. They describe all the necessary adjustments for the

PowerSet in detail.

10

ENGLISH

Operation

Starting initial commissioning

√ The check list for initial commissioning is

displayed.

• The PowerSet entry is selected.

• The checkboxes are not selected.

Advices

•When a check list item is called up the corre-

sponding checkbox is automatically selected.

• The following items are only displayed if the

use of a reactive power characteristic curve

is prescribed for the country selected in the

Country item:

•– Reactive power characteristic curve

(reactive power characteristic curve type)

– Number of nodes1)

– Node 11)

– Node 21)

– Node n1) 2)

– Display characteristic curve

1): Only displayed for reactive power character-

istic curve type Enter characteristic curve.

2): Only displayed if Number of nodes has

been set to a value > 2.

•Initial commissioning is completed by calling

up the Finish item.

•Finish can only be performed when all other

checkboxes are selected.

1. Press to select a check list item.

2. Press SET to call up the item.

The items are described separately below.

1. Press SET. The first digit of the PowerSet

code flashes.

2. Press to change the first digit of the

PowerSet code.

3. Press SET

.

The change is adopted.

4. Press . The second digit of the PowerSet

code is highlighted.

5. Repeat steps 1 to 3 for the second digit of

the PowerSet code.

6. Press ESC

.

The check list is shown.

Language

1. Press to select a display language.

2. Press SET

.

The language is adopted.

3. Press ESC. The check list is shown.

Date format

1. Press to select a date format.

2. Press SET. The date format is adopted.

3. Press ESC. The check list is shown.

Date

1. Press SET. The date flashes.

2. Press to change the day.

3. Press SET

.

The change is adopted.

4. Press . The month is selected.

5. Repeat steps 1 to 3 for the month.

6. Press . The year is selected.

7. Repeat steps 1 to 3 for the year.

8. Press ESC. The check list is shown.

Time format

1.

Press to select a time format.

2.

Press SET

.

The time format is adopted.

3. Press ESC. The check list is shown.

Time

1. Press SET. The hour display flashes.

2. Press to change the hour.

3. Press SET

.

The change is adopted.

4. Press . The minutes are selected.

5. Repeat steps 1 to 3 for the minutes.

6. Press ESC. The check list is shown.

Country selection

Advice

The country can only be set once!

1. Press to select a country.

2. Press SET.

3. Press ESC. The dialogue shown on the left is

displayed.

4. Press ESC to select a different country by

performing steps 1 and 2 or press

SET for a longer period of time (> 1 s) to

confirm the currently selected country. The

check list is shown.

Reactive power characteristic curve

1. Press ESC to call up this point.

2. to mark one type of reactive power

characteristic.

3. Press SET. The reactive power type is ac-

cepted.

4. Press ESC. The check list is shown..

Advice

: An additional Load Templates menu point

is shown when "cosPhi = 1" was not selected.

1. Press , to mark Load Templates.

2. Press SET.

3. Press , to select a standard characteristic.

4. Press SET.

Standard characteristic is accepted.

5. Press ESC. The check list is shown.

Number of nodes

1. Press SET. The value flashes.

2. Press to change the number of nodes.

3. Press SET. The value is adopted.

4. Press ESC. The check list is shown.

Node n

1. Press to select a parameter for the node.

Advice: P% cannot be changed at the first and last

nodes (000%.100%).

2. Press SET. The parameter value flashes.

3. Press to change the value.

4. Press SET

.

The change is adopted

.

5. If necessary repeat steps 1 to 4 for the other

parameters.

6. Press ESC. The check list is shown.

Display characteristic curve

1. The previously set reactive power characteristic

curve is displayed graphically (example in Fig.

left).

2. Press ESC. The check list is shown.

11

Advice:

The settings regarding the feed-in manage-

ment must be provided in the energy man-

agement sub-menu.

Modus

1. Press SET to call up this point.

2. Press to mark the energy meter or to

activate PowerStorage.

3. Press ESC.

4. Press ESC to move up one level to energy

management.

Dynamic feed regulation

Advice:

The power fed into the mains network is set

in 10 W steps.

It can be limited to a minimum of 0 W.

Conguration energy meters

Advice:

The inverter can only work with energy me-

ters that have already been pre-programmed

in the inverter. The pre-programmed energy

meters are listed under Meter Type.

1. Press SET to call up this point.

2. Press to mark the meter type.

3. Press ESC

.

4. Press ESC to leave the sub-menu.

Advice

:

The connection to the energy meter can be veri-

ed with a connection test.

5.4.12 Registration and conguring PowerMonitoring

The registration and the monitoring set-up can be performed once commission-

ing has been completed.

Please follow the link to be found on the sticker attached to the front of the device

housing. Follow the guided registration process to its end. Additional information

regarding registration can also be found at this link.

5.4.13 De-installing the inverter

Danger

Risk of death by electrocution!

Only technical professionals may perform the work described in section

De-installing the inverter.

Observe the warning notes in 5.4.1.

Switching o AC and DC supplies

1. Turn the AC circuit breaker to off.

2. Set the DC circuit breaker on the inverter to position 0

(Figure 29).

Figure 29

Finish

√ Finish has been selected in the check list

and SET has been pressed.

One of 2 possible dialogues is displayed.

1. Proceed as follows, depending on the dialogue

.

• Dialogue Settings are incomplete: Press SET and

work through the open items in the check list.

• Dialogue

Are all settings correct?

Press ESC to correct settings or press

SET for a longer period of time (> 1 s) to finish

initial commissioning.

2. If SET is pressed for a longer time then the

inverter restarts and synchronises itself with

the grid (Fig. left).

5.4.10 Switching on the DC supply

Set the DC circuit breaker on the inverter to position I

(Figure 31). After testing via the internal MSD (approx.

2 minutes), the power fed into the grid can be shown on

the display (assuming that sunlight is present).

Figure 28

5.4.11 Feed-in management or PowerStorage

Feed-in management or PowerStorage

It is also possible to use an energy meter for feed-in management. It must be con-

nected to the Modbus RTU interface and comply with the following requirements:

The inverter communicates with energy meters through the Modbus RTU. The

following applies:

• Only energy meters that were pre-programmed in the inverter can be used.

• The pre-programmed energy meters are:

• Herholdt ECS3, item number: ECSEM72

• Janitza ECS3, item number: ECSEM68MID

• B+G SDM630, item number: 1141103

• Carlo Gavazzi EM24, item number: EM24-DIN.AV9.3.X.IS.X

• The energy meter must measure in positive direction relative to the mains

network. Take note of the manufacturer's instructions

This menu point can alternatively be used to activate the PowerStorage function

when a Solar Frontier battery system is used. Details are provided in the Power-

Storage manual.

12

ENGLISH

Disconnecting DC connections from the inverter

Disconnect DC cables according to the manufacturer's instructions. A special

tool is required for this.

Warning

DC cables are under current if light falls on the modules.

Disconnecting the AC plug from the inverter

For the Turbo 1P Mini / 1P inverter:

1. Remove the AC plug from the socket on the inverter as described in chapter 13.1.

2. Check that all pins of the AC plug are free of voltage. Use a suitable voltmeter for

this (do not use a simple neon phase checker).

For the Turbo 3P1 / 3P2 inverter:

1. Disconnect the AC plug from the inverter: gently press in the ratchet near the

front of the AC plug with a suitable object to unlock it, and remove the plug.

2. Check that all pins of the AC plug are free of voltage. Use a suitable voltmeter for

this (do not use a simple neon phase checker).

Opening the AC plug (only if required)

For the Turbo 1P Mini / 1P inverter:

Open the AC plug as described in the Appendix under Mounting > AC plugs.

For the Turbo 3P1 / 3P2 inverter:

Open the AC plug: First open the cable gland at the back and then push in the

ratchets on the left and right of the plug casing (simultaneously) and unlock

with a suitable tool. Then remove the upper part of the casing from the con-

tact part.

Removing the inverter from the mounting plate

1. Use one hand to press the retaining plate on the mounting plate approx.

5 mm (0.20 in) towards the mounting surface 1(Figure 30).

2. Use the other hand to push the inverter upwards, far enough so that the

retaining plate no longer latches. 2Release the retaining plate.

3. Lift the inverter with both hands until the hooks on the rear side of the inverter

are free 3

4. Remove the inverter from the mounting surface 4

3

1

2

4

Figure 30

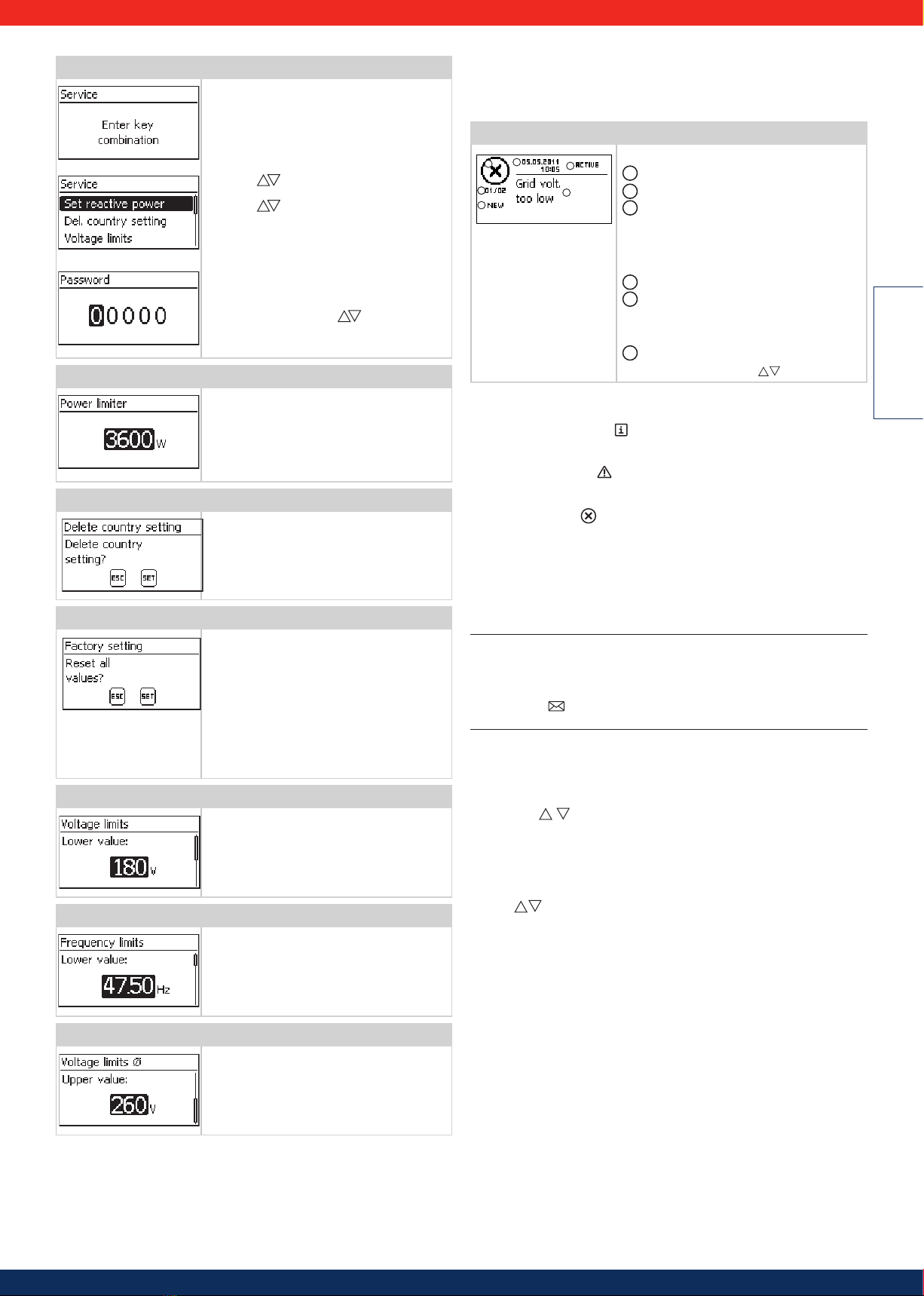

6. Structure and function of the Turbo inverter

6.1 Casing

Figure 31

1Hood

2Display (monochrome, 128 x 64 pixels)

3Type plate, Serial number, warning notices

4Operating buttons: ESC, , , SET (from left to right)

51x AC connector

61x DC connector plus (+) for solar modules

(Phoenix Contact SunClix, insulated)

71x DC connector minus (−) for solar modules

(Phoenix Contact SunClix, insulated)

8DC circuit breaker

(interrupts plus and minus inputs simultaneously)

92x RJ45 sockets (RS485 bus)

10 1x RJ45 socket (Ethernet)

11 1x RJ10-socket (Modbus RTU)

The casing components are described in detail below.

6.2 Operating buttons

The operating buttons ( 4in Figure 31) have the following functions:

Button Action Function general Guided conguration

ESC

Press

briefly

jumps up by 1 menu level navigates 1 step

discards any changes

Press longer

(≥ 1 second) jumps to status display

jumps to the start of the

guided configuration process

Press

briefly

• moves the highlighted bar or the content of the

display up

• moves the highlighted position in a numerical setting

one digit to the left

• increases a setting by one step

Press

briefly

• moves the highlighted bar or the content of the

display down

• moves the highlighted position in a numerical setting

one digit to the right

• decreases a setting by one step

SET

Press

briefly

jumps down 1 menu level

–

• a selected numerical value begins to flash and can be

altered

• adopts any changes

• alters the state of a control (checkbox/radio button)

Press longer

(≥ 1 second)

answers a query dialogue with yes

navigates 1 step forward

Table 1

13

6.3 Overview of operating functions

For the sake of clarity, only the operating buttons and SET are illustrated.

SET SET SET

SET

SET SET

SET SET

SET

SET

SET

SET

Del. country

settting

Configuration

*)

Contrast

RS485

address *)

Network

Alarm

Self test *)

Backlight

Service

Self

consumption *)

Time/date

Remuneration

*)

Energy

management *)

Daily

Monthly

Annual

Yield

Remuneration

*)

Event log

Total

Contact info

System info

Country

setting

React. pwr.

char. curve *)

Autarky level *)

Settings

Self test *)

Operating

hours *)

Internal

temp. *)

Derating *)

Abs. max.

power *)

Day max.

yield *)

Max. daily

power *)

Status

display Main menu

Grid voltage

Gener. ch.

curve

Output power

Current day

yield *)

Grid current *)

Grid

frequency *)

PV voltage *)

PV current *) Meas. values

Reset max.

vals.

DHCP

IP addressLanguage

Clear

event log

Submenus

Information

DNS

Web portal

Subnet

mask

Gateway Voltage limits

off *)

PowerStorage

*)

Energy

meter *)

RS485

address *)

Dyn. feedin

control *)

Mode *)

Meter type *)

Reactive

power *)

*) Dieser Menüpunkt wird nicht immer angezeigt. Ob er vorhanden ist, hängt von den

Einstellungen am Wechselrichter und der Fimware-Version ab.

CO2 saving *)

Total yield *)

Frequency

limits

Voltage

limits Ø

Power limiter

Fixed voltage

Factory

setting

All parameters

Network

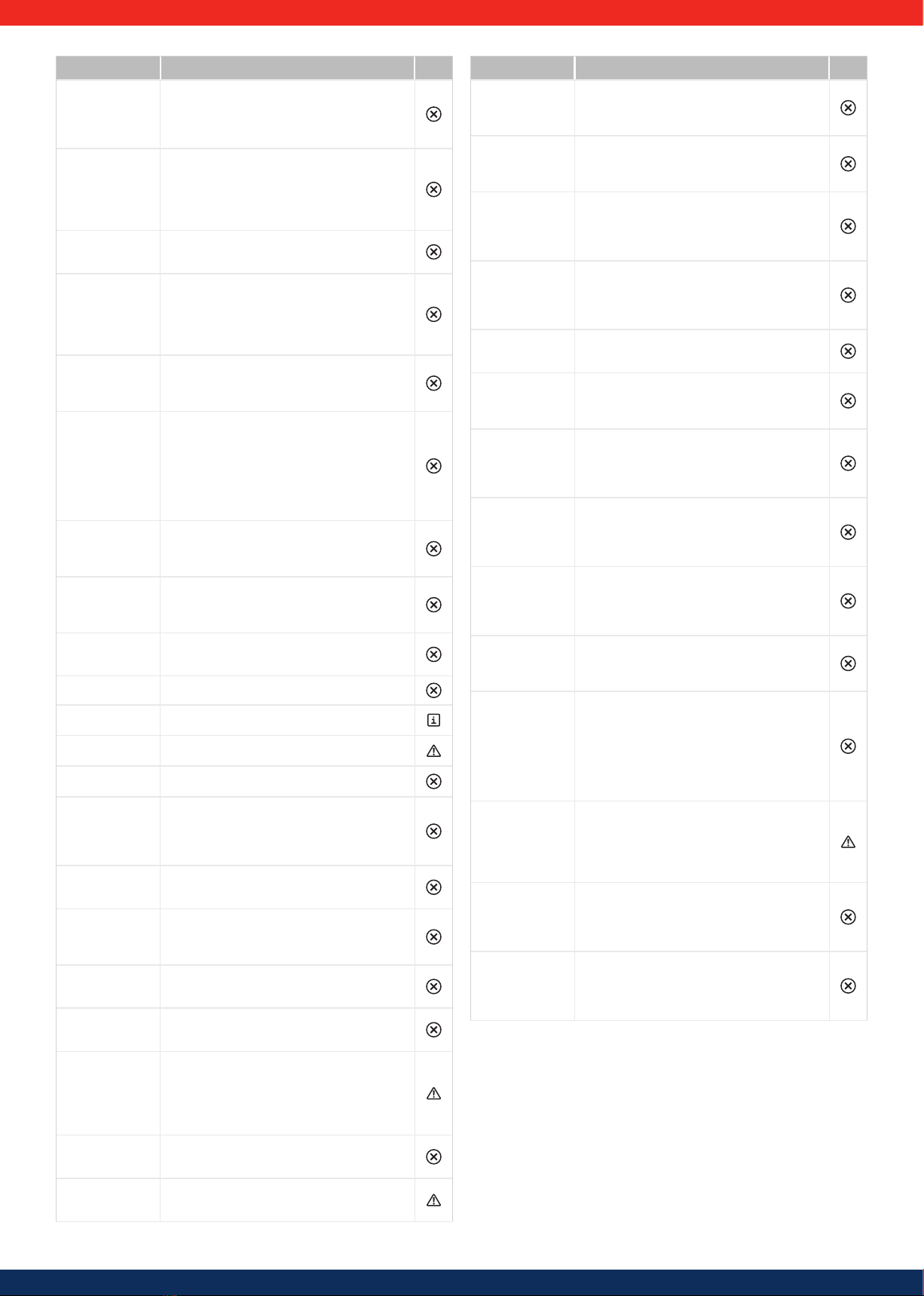

6.4 Service menu

The following section describes service menu items. Some items have password protection.

Obtain the password from technical support.

Attention

Risk of reduced yields. Inverter and grid parameters can be changed in the service menu. The service menu may only be used by technical professionals who can ensure

that the changes do not contravene the applicable regulations and standards.

14

ENGLISH

6.5 Troubleshooting

Faults are indicated by event messages as described below. The display flashes red.

Table 2 "List of event messages" contains information on troubleshooting and fault

correction.

Structure

23

54

6

1Event messages have the following information:

1Symbol for the type of event message

2Date/time when the event occurred

3ACTIVE = The cause of the event message is

still present or

date/time when the cause of the event

message was corrected.

4Cause of the event message:

5Counter: No, of the displayed event message/

Total number of event messages;

max. total number of event messages = 30

6NEW is displayed until the event message is

confirmed using ESC or .

Function

Event message types

•Type Information (Symbol )

The inverter has detected an error that does not affect the feed-in process.

The user does not need to intervene.

•Type Warning (symbol )

The inverter has detected an error that may result in reduced yields. It is highly

recommended that you correct the cause of the error.

•Type Error (Symbol )

The inverter has detected a serious error. The inverter will not feed into the grid

while this error is present.

Please contact your installer. More information is provided in table 6“List of

event messages.”

Display behaviour

New event messages are displayed immediately. The messages disappear after they have

been confirmed or their cause(s) have been corrected.

Advice

When an event message is confirmed, the user thereby simply confirms that he/

she has seen the message. This does not correct the error that caused the event

message to be shown!

If messages exist whose cause has been corrected but which have not been

confirmed then is shown in the status display. If an already confirmed error

recurs then it is displayed again.

Operation

Conrming event messages

√An event message with the comment NEW is displayed.

Press ESC/ / . The event message is confirmed.

Displaying event messages

1. Select Event log in the main menu.

2. Press SET. The event messages are displayed in chronological order (latest

message first).

3. Press to page through the Event Messages.

Calling up the service menu and editing the values

1. Select the Service menu item.

2. Press SET. The fig. shown at the left appears.

3. Press simultaneously for 3 seconds.

The service menu is displayed (fig. left).

4. Press to select a menu item.

5. Press SET to go into the menu item.

The following applies:

• Enter the password if required (fig. left).

• Within a menu item press if required to dis-

play and alter further settings (e.g., voltage limits).

• - The menu items are described in section 9.3.4.

Power limiting

The inverter's output power can be restricted

manually to a minimum of 500 W. If the power is

manually restricted, the symbol Derating and the

reading Derating/reason: User default

are displayed in the status display.

Delete country setting

After the country setting has been deleted, the

device restarts and displays the guided initial

commissioning menu.

Factory setting

Resetting the device to the factory setting de-

letes the following data:

• Yield data

• Event messages

• Date and time

• Country setting

• Display language

• Network settings

After the factory setting has been deleted, the

device restarts and displays the guided initial com-

missioning menu.

Voltage limits (peak values)

The following voltage limits can be changed:

• Upper disconnection value 1)

• Lower disconnection value 1) (figure left)

1)

The disconnection value refers to the peak value

of the voltage.

Frequency limits

The following frequency limits can be changed:

• Upper disconnection value.

• Lower disconnection value (figure left)

• Derating switch-on threshold (because fre-

quency is too high)

• Frequency threshold when switching on again.

Voltage limits Ø (average value)

The following voltage limits can be changed:

• Upper disconnection value 1) (Figure left)

• Lower disconnection value 1)

• 1)

The disconnection value refers to the average

value of the voltage.

15

Event message Description Type

Data acceptance

failed

One setting, e.g. during commissioning, has failed,

as it was not correctly transmitted.

Repeat the setting.

Inform your installation company if the fault

persists.

Grid

islanding

detected

There is no grid voltage present (inverter running

independently). For safety reasons, the inverter

must not feed into the grid and switches off while

the error is present (dark display).

Contact your installer if this error occurs fre-

quently.

PE not

connected

The protective earth is not connected. For safety

reasons, the inverter must not feed into the grid.

Contact your installer.

Residual cur-

rent too high

The residual current flowing from the plus or minus

inputs to the earth via the photovoltaic modules ex-

ceeds the maximum permissible value. Due to legal

requirements, the inverter switches off automati-

cally for as long as the error state exists.

Contact your installer.

Faulty function of

boost converter

An internal component of your inverter is faulty. The

inverter does not feed or feeds with reduced power

into the mains network.

Contact your installer.

Device over-

heated

Despite derating, the maximum permissible tem-

perature has been exceeded. The inverter feeds no

power into the grid until the maximum permissible

temperature is no longer exceeded.

1. Check that the installation conditions are satis-

fied.

2. Contact your installer if the message occurs

frequently.

Boost converter

has wrong HW

version.

The inverter cannot recognise an internal component

or is not compatible with the other components. The

inverter cannot feed into the mains network.

Contact your installer.

Boost converter

not connected

The connection to the internal components is inter-

rupted. The inverter does not feed into the mains

network.

Contact your installer

Boost converter

defective

The boost converter is defective; the inverter is not

feeding into the grid or is feeding at reduced power.

Contact your installer.

Boost converter

not detected

Contact your installer.

Internal Info

Contact your installer if the message occurs

frequently.

Internal

warning

Contact your installer if the message occurs

frequently.

Internal Error

Contact your installer if the message occurs

frequently..

Insulation

error

The insulation resistance between the plus or minus

inputs and earth is less than the permissible value.

For safety reasons, the inverter must not feed into

the grid.

Contact your installer.

No branding The inverter has wrong or faulty device data. It can

therefore not feed into the mains network.

Contact your installer.

L and N swapped

The live and neutral conductors are wrongly con-

nected. For safety reasons, the inverter must not

feed into the grid.

Contact your installer.

Faulty country

setting

An inconsistency exists between the selected country

settings and those stored in memory.

Contact your installer.

Country param-

eter invalid

The inverter cannot feed into the mains network

because it does not have valid parameters.

Contact your installer.

Reduced perfor-

mance due to

temperature

The power inverter is reducing its output, as the maxi-

mum permitted temperature has been reached.

1. Check that the installation conditions are satis-

fied.

2. Contact your installer if the message occurs

frequently.

Reading of the

country setting

faulty

The inverter could not correctly read the country

selected from memory.

Contact your installer

Fan faulty

The internal fan of the inverter is faulty. In certain situ-

ations the inverter will feed less power into the grid.

Contact your installer.

Event message Description Type

Grid frequency

too high for

reactivation

After switching off, the inverter cannot resume

feeding because the grid frequency exceeds the

legally prescribed switch-on value.

Contact your installer if this error occurs frequently.

Grid frequency

too low for re-

activation

After switching off, the inverter cannot resume

feeding because the grid frequency exceeds the

legally prescribed switch-on value.

Contact your installer if this error occurs frequently.

Grid frequency

too high

The grid frequency at the inverter is greater than

the maximum permissible value. Due to legal re-

quirements, the inverter switches off automatically

for as long as the error state exists.

Contact your installer if this error occurs frequently.

Grid frequency

too low

The grid frequency at the inverter is less than the

minimum permissible value. Due to legal require-

ments, the inverter switches off automatically for as

long as the error state exists.

Contact your installer if this error occurs frequently.

Network relay

defective

The inverter has detected that a network relay is faulty

and therefore does not feed into the mains network.

Contact your installer.

Grid voltage

too low for re-

activation

After switching off, the inverter cannot resume

feeding because the grid voltage exceeds the

legally prescribed switch-on value.

Contact your installer if this error occurs frequently.

Grid voltage Ø

too high

The output voltage averaged over the legally

prescribed period of time exceeds the permissible

tolerance range. The inverter switches off automati-

cally for as long as the error state exists.

Contact your installer if this error occurs frequently.

Grid voltage Ø

too low

The output voltage averaged over the legally pre-

scribed period of time exceeds the permissible toler-

ance range. The inverter switches off automatically for

as long as the error state exists.

Contact your installer if this error occurs frequently.

Grid voltage

too high

The grid voltage at the inverter is greater than the

maximum permissible value. Due to legal require-

ments, the inverter switches off automatically for as

long as the error state exists.

Contact your installer if this error occurs frequently.

Grid voltage

too high for

reactivation

After switching off, the inverter cannot resume

feeding because the grid voltage exceeds the

legally prescribed switch-on value.

Contact your installer if this error occurs frequently.

BCONV over-tem-

perature

The maximum permissible boost converter tem-

perature has been exceeded. The inverter feeds no

power into the grid until the maximum permissible

temperature is no longer exceeded.

1. Check that the installation conditions are satis-

fied.

2. Contact your installer if the message occurs

frequently.

Time/date lost

The inverter has lost the time settings because it

was disconnected from the grid for too long. Yields

cannot be stored and event messages will have the

wrong date.

Correct the time under Settings/Time/

Date.

No connection to

the energy meter

There is no or no correct communication link between

the inverter and the energy meter (or the PowerStor-

age system).

Inform your installation company to have the

connection checked.

No connection to

PowerStorage

There is no or no correct communication link between

the inverter and the energy meter (or the PowerStor-

age system).

Inform your installation company to have the

connection checked.

Table 2

16

ENGLISH

7. Maintenance

7.1 Maintenance of Solar Frontier SF165-S/SF170-S

photovoltaic modules

A monthly visual check is highly recommended in order to maintain the efficiency

of SF modules and the security of the mounting.

•Remove any dirt, fallen leaves or bird droppings from the surface, and check

that there is no damage to the surface. Do not use detergent or chemicals

for cleaning dirt off SF modules as it may damage the modules and result in

degradation of insulation.

•Do not use hard brushes for cleaning. Use only soft cloths to remove dirt from

the modules.

•When replacement parts are required, be sure the installer/servicer uses parts

specified by the manufacturer with the same characteristics as the original

parts. Unauthorized substitutions may result in fire, electric shock or other

hazard.

•Stop using SF modules when any damage or unusual phenomena are ob-

served. Have them immediately replaced or removed by a qualified technician.

7.2 Maintenance DC system

The DC system is maintenance-free. It is still recommended that cables and con-

nectors are regularly checked for signs of damage.

7.3 Maintenance of Turbo inverters

The inverter is basically maintenance-free. Despite this, it is a good idea to regu-

larly check that the cooling fins on the front and rear sides of the device are free of

dust. Clean the inverter when necessary as described below.

Attention

Danger of destruction of components in devices.

•Do not allow cleaning agents and devices to penetrate between the cooling

fins at the front of the inverter (under the grey hood).

In particular, do not use the following cleaning agents:

- Solvent-based cleaning agents

- Disinfectants

- Coarse or sharp-edged cleaning materials

Removing dust

Dust should be removed using compressed air (max. 2 bar).

Danger

Risk of death by electrocution! Risk of death by electrocution.

Use cleaning agents only with a slightly damp cloth.

Remove heavy soiling with a slightly damp cloth (use plain water). If neces-

sary, use a 2% curd soap solution instead of water. After cleaning, remove any soap

residue using a slightly damp cloth.

8. Transport and Storage

Pay attention to all advice on the packaging when storing or transporting SF Power-

Sets. A dry room should be chosen for storage. The packaging is not waterproof.

All electronic components should be kept away from liquids during transport and stor-

age. The SF PowerSets must remain in the original packaging until the installation.

Small amounts of white powder from packaging material may adhere to the mod-

ules. This may safely be ignored and has no affect on performance.

9. Disposal

9.1 Disposal within the EU

This sign on the modules and inverters indicates that these

products must not be disposed of in household waste

when they reach the end of their life cycle.

For disposal and recycling, please take the products to

authorised collection points where you can hand them over

free of charge. Alternatively, in some countries you may

hand them in at the dealer's where you obtain your replace-

ment goods.

Please contact your local authority for further details on

your nearest authorised collection point.

The DC cables can be disposed of at municipal collection points as electric waste.

Penalties may be imposed for violation of the rules depending on the applicable law.

9.2 Disposal outside the EU

The symbol of a dustbin with a line through it is only valid in the European Union

(EU). If you want to dispose of your product please contact your local authority or

dealer to find out the correct disposal method.

10. Technical data and data sheets

10.1 Solar Frontier SF165-S/SF170-S photovoltaic modules

Electrical characteristics

Standard test conditions (STC)*1

Module SF165-S Module SF170-S

Rated output Pmax 165 W 170 W

Open circuit

voltage

Voc 110 V 112 V

Short circuit cur-

rent

Isc 2.20 A 2.20 A

Rated voltage Vmpp 85.5 V 87.5 V

Rated current Impp 1.93 A 1.95 A

Nominal operating

cell temperature (NOCT)*2

Module SF165-S Module SF170-S

Rated output Pmax 123 W 126 W

Open circuit

voltage

Voc 100 V 102 V

Short circuit

current

Isc 1.76 A 1.76 A

Rated voltage Vmpp 80.2 V 82.1 V

Rated current Impp 1.53 A 1.55 A

*1 Data measured under standard test conditions (STC) defined by the IEC standard

(1000 W/m² irradiance, 25 °C module temperature, AM 1.5 with tolerances of ±10% for

Isc and Voc and +10% / -5% for Pmax). The module efficiency with 200 W/m² irradiance is

typically 98% (±1.9%) of the STC efficiency.

*2 Nominal operating cell temperature (NOCT): Module operating temperature with 800 W/m2

irradiance, 20 °C air temperature, 1 m/s wind speed and in the open circuit condition.

17

Thermal characteristics

NOCT 47 °C

Temperature-coecient Isc α +0.01%/K

Temperature-coecient Voc β -0.30%/K

Temperature-coecient Pmax δ %-0.31%/K

Characteristics for system design

Maximum system voltage Vsys 1.000 V DC

Limiting reverse current Ir 7 A

Mechanical Data

Dimensions (L x W x H) 1.257 x 977 x 35 mm

(49.5 x 38.5 x 1.4 in)

Weight 20.0 kg (44.1 lbs) / 16.3 kg/m2

(3.3 lbs/ft2)

Module operating temperature -40 °C to 85 °C

Application class

as per IEC 61730

Class A

Fire safety class

as per IEC 61730

Class C

Cable

2.5 mm2/ AWG14 (halogen free)

Snow load (to the front of the module) 2.400 Pa (IEC61646) / 1.600 Pa design

load (UL1703)

Wind load (to the back of the module) 2.400 Pa (IEC61646) / 1.600 Pa design

load (UL1703)

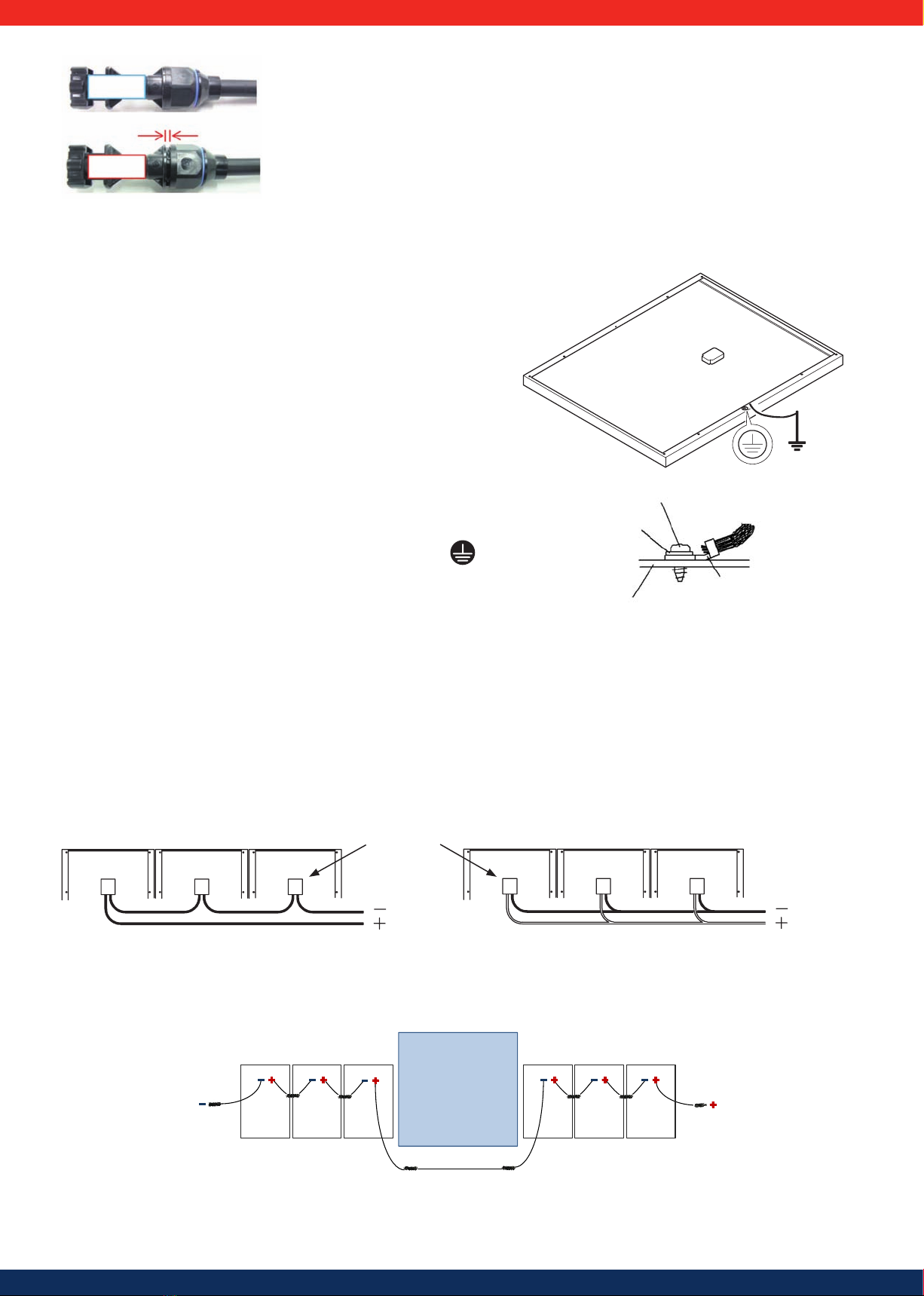

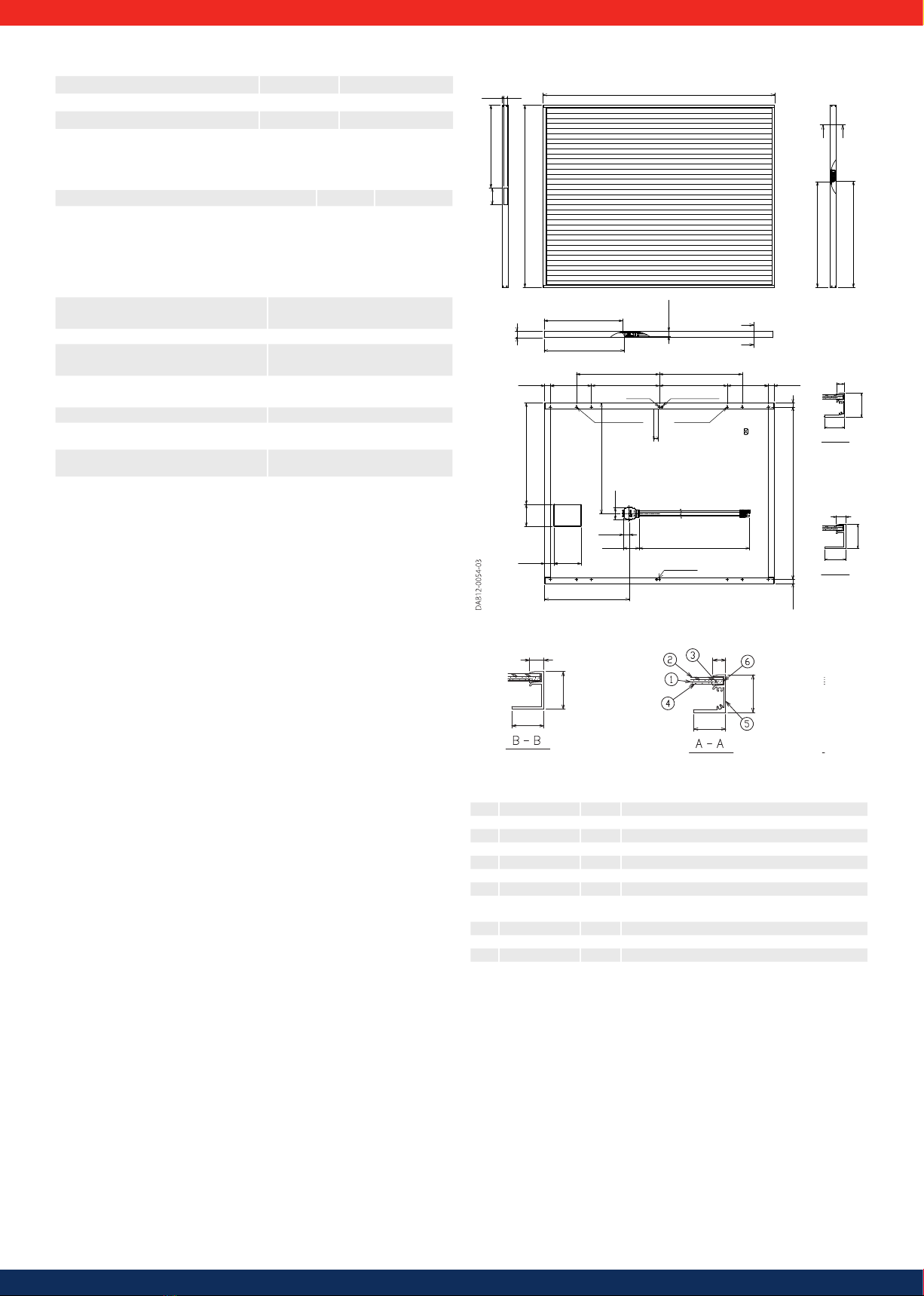

Module drawing

30

12

35

)

13,5

35

30

35

±0.5

A

A

φ

φ

φ

φ

427.1

±5

449.9

±5

(23.8)

1257

±2

977

±2

B B

90

(444)

20

565.5

±5

574.9

±5

(7)

±0 5

934

±2

598.5

±5

1200±100

2×Grounding

474.9

±5

88.1

66

47.8

21.5 21.5

120 (538.5)

150

(50)

31

±1

225 372.5 31

±1

225372.5

454.5 454.5

Mounting holes

Mountingholes

Label

8)

(-)

(+)

±2

4)

5 5

±5

9

±5

3

13.7

φ

φ

φ

φ

A-A

30

35

12

±5

φ

φ

φ

φ

L

B-B

30

35

13 5

4 × Ø 8.5

2 × Ø 4

2 × Ø 4.5

4 × Ø 6.6

No. Item Qty Description

1 Cell 1 CIS on substrate glass

2 Cover glass 1 Clear tempered glass

3 Encapsulant EVA

4 Back sheet Weatherproof plastic film

5 Frame 1 Set Anodized aluminium alloy / Colour:black

6 Edge sealant Butyl rubber

7 Junction box 1 With bypass diode

8 Cable 2.5 mm2(0.004 in²) / AWG14 (with waterproof

plug, Hosiden HSC - MC4 plug-in)

9 Adhesive Silicon

10 Label 1 Product label

11 Screw 8 Stainless tapping (SUS304J3)

12 Bar code label 1 Serial number

18

ENGLISH

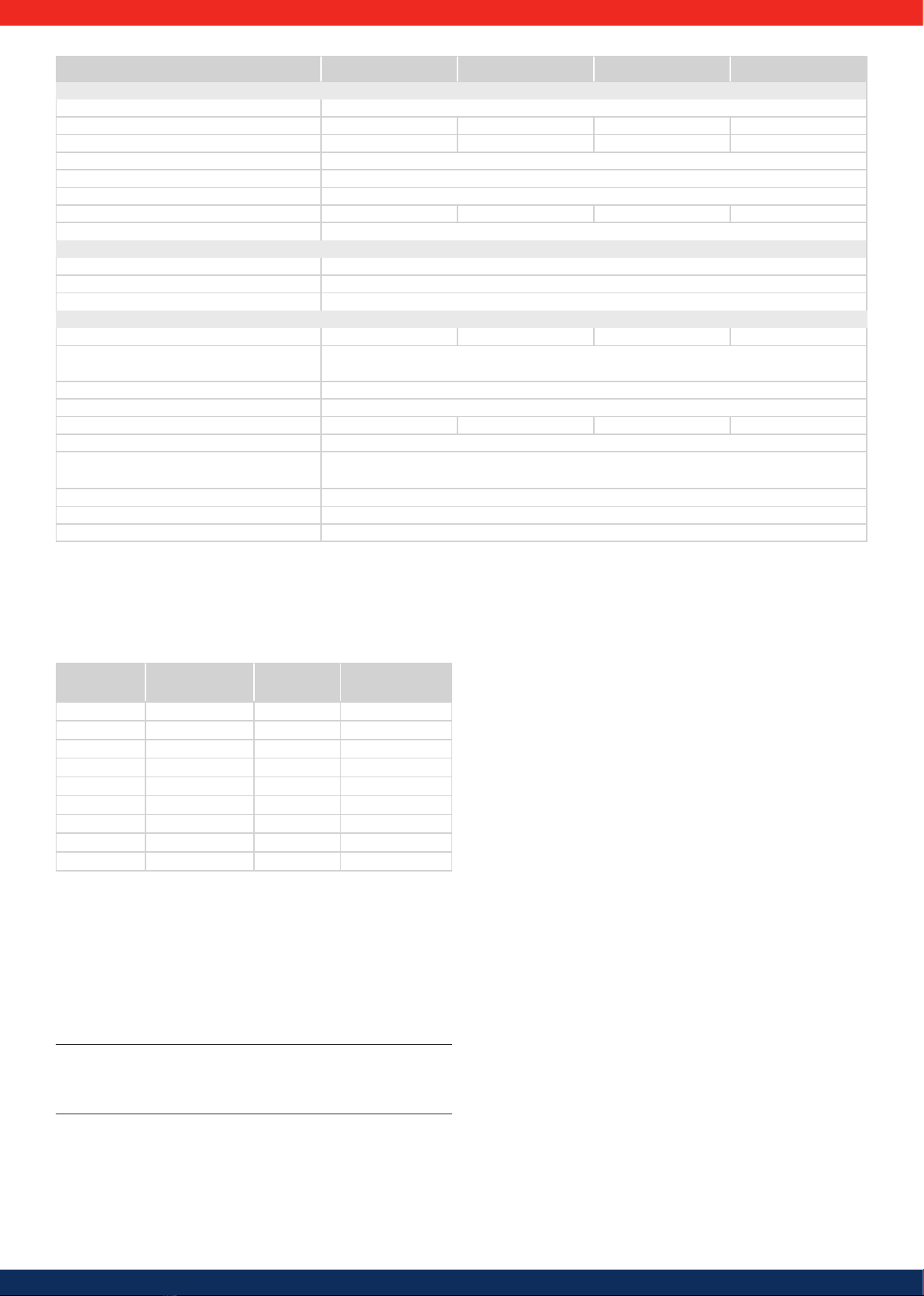

10.2 Technical data for Turbo inverter

Turbo 1P Mini Turbo 1P Turbo 3P1 Turbo 3P2

DC input side (PV generator connection)

Number of DC inputs 1 1 1 1

Maximum start voltage 420 V 845V 1000 V 1000 V

Maximum input voltage 420 V 845 V 1000 V 1000 V

Minimum input voltage for grid-feeding 75 V 350 V 250 V 250 V

Startup input voltage 90 V 350 V 250 V 250 V

Rated input voltage 255 V 540 V 510 V 790 V

Minimum input voltage for rated output 180 V 360 V 375V 575 V

MPP voltage 75 V … 350 V 360 V … 700 V 375 V … 700 V 575 V … 700 V

Maximum input current 11.5 A 12 A 11 A 11 A

Rated input current 8 A 8 A 8 A 8 A

Maximum input power at maximum output active

power 2050 W 4310 W 4100 W 6330 W

Rated input power (cos φ= 1) 2050 W 4310 W 4100 W 6330 W

Derating/power limiting Occurs automatically when:

• input power > max. recommended PV power

• cooling is inadequate

• input current too high

• grid current too high

• internal or external derating

• grid frequency too high (according to country settings)

• limiting signal received via an external interface

• output power is limited (set at the inverter)

AC output side (mains grid connection)

Output voltage

(depending on the country setting) 185 V ... 276 V 185 V ... 276 V 320 V ... 480 V 320 V ... 480 V

Rated output voltage 230 V 230 V 400 V 400 V

Maximum output current 12 A 18.5 A 7 A 10 A