Solar Frontier SolarSet 2.0 User manual

Solar Frontier Europe GmbH

Installation and Operating Manual

SolarSet 2.0 / SolarSet 2.4 / SolarSet 3.1 / SolarSet 3.6 / SolarSet 4.1 /

SolarSet 4.8 / SolarSet 5.1 / SolarSet 6.1 / SolarSet 7.1 / SolarSet 8.2

ENGLISH

2

3

Table of contents

1. Preface 5

2. Identication 5

3. General Safety Advice 6

3.1 Safety advice for photovoltaic modules of type Solar Frontier SF170-S 6

3.2 Safety advice for the inverter SF-WR 6

4. Proper Usage 7

5. Scope of Delivery 8

6. About this Manual 9

6.1 Contents 9

6.2 Target group 9

6.3 Markings 9

6.3.1 Symbols 9

6.3.2 Keywords 9

6.3.3 Markings used in the text 9

6.3.4 Abbreviations 10

7. Composition of the Solar Frontier SolarSets 11

8. Installation 12

8.1 Mounting system/ substructure 12

8.2 Mechanical installation of Solar Frontier SF170-S photovoltaic modules 12

8.2.1 Site location 12

8.2.2 Module handling instructions 12

8.2.3 Module mounting instructions 13

8.3 Electrical installation photovoltaic generator 17

8.3.1 Electrical wiring safety precautions 17

8.3.2 Cabling 17

8.3.3 Procedures for electric cabling 20

8.3.4 Grounding 20

8.3.5 Electrical wiring 21

8.4 Installation inverter SF-WR 24

8.4.1 Safety measures during installation 24

8.4.2 Mounting the inverter 25

8.4.3 Preparing the AC-connection 26

8.4.4 Preparing the DC-connections 27

8.4.5 Connecting the inverter and switching on the AC-power 28

8.4.6 Initial commissioning of the inverter 28

8.4.7 Switching on the DC-supply 32

8.4.8 De-installing the inverter 32

4

9. Structure and Function of the Inverter SF-WR 33

9.1 Casing 33

9.2 Operating buttons 33

9.3 Display 34

9.3.1 General information 34

9.3.2 Information 34

9.3.3 Settings 36

9.3.4 Service menu 38

9.4 Cooling 40

9.5 Grid monitoring 40

9.5.1 Data communication 40

9.6 Operation 44

9.6.1 Overview of operating functions 44

9.6.2 General operating functions 45

9.6.3 Main operating functions 45

9.7 Self test (mandatory in Italy) 48

9.8 Troubleshooting 50

10. Registration and warranty 53

11. Maintenance 53

11.1 Maintenance Solar Frontier SF170-S photovoltaic modules 53

11.2 Maintenance DC-System 53

11.3 Maintenance inverter SF-WR 53

12. Accessories 54

13. Transport and Storage 54

14. Disposal 54

14.1 Disposal of Solar Frontier SF170-S photovoltaic modules 54

14.2 Disposal of Solar Frontier inverter SF-WR 54

14.3 Disposal of DC-cabling 54

15. Technical Data, Data Sheets and Certicates 55

15.1 Solar Frontier SF170-S photovoltaic module 55

15.1.1 Technical data 55

15.1.2 Certicates for Solar Frontier SF170-S 58

15.2 Inverter 59

15.2.1 Technical data inverter 59

15.3 Technical data AC-cable and line circuit breakers 61

15.4 Table of countries 61

15.5 EU – Declaration of conformity inverter SF-WR 63

15.6 Plugs and Sockets 65

15.6.1 Product information plugs and sockets 65

15.6.2 TÜV certicate plugs and sockets 66

15.6.3 Product information DC-cable 67

15.6.4 EU declaration of conformity DC-cable 68

15.6.5 TÜV certicate DC-cable 69

16. Exclusion of Liability 70

17. Contact 70

18. Notes 71

19. Appendices 72

19.1 Installation SF-WR 72

19.2 AC-plug SF-WR 73

5

1. Preface

Thank you for choosing a SolarSet with CIS photovoltaic modules from Solar Frontier. Solar Frontier (SF) oers the highest standards in

creating electrical power from solar energy, and in customer service.

This manual contains important information with regards to the installation, operation, maintenance, cabling and use of the SolarSet,

and the safety instructions involved. To ensure a proper and safe use of the SolarSet, all tips and warnings in this document, as well as

the advice of the manufacturers of the system components should be carefully read, understood and applied. Please make sure that

the installer and operator of the plant obtain a copy of this manual. Please save this document for future use. All applicable local and

national laws and norms should be obeyed during installation, cabling, operation and maintenance of the SolarSet. In case of further

questions please get in touch with your dealer or with Solar Frontier directly.

2. Identication

Type plate of the Solar Frontier inverter Type plate of the SF module

SF-WR

1

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Barcode for internal purposes

Technical Data –DC-input

Article number and product designation

Manufacturer

Protection Class II and CE symbols

Country of manufacture

Technical Data – AC-output

Protection classication and grid-monitoring standard

Serial number (and barcoded serial number)

2

3

4

5

6

7

1

2

3

4

5

6

7

Certications and protection classes

Serial number (and barcoded serial number)

Name of product

Technical data at STC

Manufacturer and country of manufacture

General product characteristics

Serial number on frame

Figure 1 Figure 2

Alle Rechte bei Steca Elektronik GmbH, auch für den

Fall von Schutzrechtsanmeldungen. jede Verfügungs-

befugnis, wie Kopier- und Weitergaberecht, bei uns.

C

0

10

20

30

40

50 mm

Ausdruck unterliegt nicht dem Änderungsdienst Blatt 1/1

Zust.

Z01

Änderung

ohne Änderung

Datum Name

Bearb.

Gepr.

Datum Name

Steca

Etikett

Michler

ZET-STSP-NET

10.36.854

749.591

31.07.13 31.07.13

SF-WR-3600

Typenschild

Elektronik

K:\Stsp\WR\Steca_Grid_3600\Schilder\1036854_1-et.ai

Alle Maße ohne Toleranzangabe ±0,2mm

NM

Burger

31.07.13

Manufacturer:

Steca Elektronik GmbH

DC Input: AC Output:

Voltage: 350 - 845V

MPP Voltage: 350 - 700V

Current: max. 10A

Voltage: 230V, 50/60Hz

Power Factor: 0,95 - 1,0

Current: max. 16A

Power: max. 3600W

Model:

SF-WR-3600, StecaGrid 3600

Art. number:

KIT10001, 749.591

IP classification: IP 21

Overvoltage category: III

According to:

VDE 0126-1-1:A1,

VDE AR N 4105

50,8

57

Made in Germany

Schrifttyp: Humanist 777 BT

Selbstklebende Alufolie (silber), mit schwarzem Aufdruck

unbedrucktes Etikett: 744.196

Achtung:

Das CE-Zeichen muss mindestens 5mm hoch sein !

Hinweis:

Feld für Barcode

für Produktion

(letzte 4 Stellen

der Seriennummer)

13/07/22

SD-010-023-05

SD-010-023-05

SD-010-023-05

MADE IN JAPAN

SF170-S

XXXXXXXXXXXXXX

BARCODE

112

2.20

20.0

2400 33.4

170

87.5

1.95

+10 -5

6

3. General Safety Advice

Please ensure all necessary measures are taken to prevent accidents. The use of SolarSets in applications that may endanger human

lives is prohibited, including in air and road transport systems. SolarSets must not be used for anything other than their expressed

purpose.

Solar Frontier strongly advises you to follow the instructions below in order to avoid bodily injury, damage to property and/or death.

SolarSets sold by Solar Frontier GmbH may only be installed by authorized professionals (see 6.2). As soon as it becomes

evident that safe operation is no longer possible (e.g. visible damage), remove the SolarSet immediately from the grid.

3.1 Safety advice for photovoltaic modules of type Solar Frontier SF170-S

•Installation, wiring, and maintenance of SF modules must only be carried out by licensed and trained persons.

•Ensure that all instructions and information related to SF modules and other balance of system components are fully understood

prior to handling and installing a PV solar system.

•The front surface of SF modules should be covered with an opaque material during installation to decrease the potential of electri-

cal shock.

•SF modules only generate direct current (DC) electricity.

•SF modules do not have the ability to store electricity.

•SF modules will experience higher voltage when connected in series and higher electrical current when connected in parallel.

•Only interconnect SF modules with similar electrical characteristics in series or in parallel to prevent system imbalance conditions

and module damage.

•The PV array open-circuit voltage must never exceed the maximum system voltage (including in low temperature conditions).

•Leakage currents could create a shock hazard or re.

•Do not disconnect operational modules or electrical arcing may occur. This may result in serious bodily harm or death.

•Do not use SF modules for purposes other than terrestrial power generation to prevent electrical shock, re or other accidents.

•Do not articially concentrate sunlight on modules using lenses or mirrors.

•Do not use light sources other than natural sunlight and general illumination for power generation.

•Do not use SF modules in water or liquid. There is a serious risk of electric shock, an electric leak or an accident.

•The level of leakage current must be limited in accordance with local regulations for safety reasons.

•Carefully check the polarity of the wiring before installing. Incorrect wiring may damage SF modules or appliances.

•Only use equipment, connectors, wiring and support frames suitable for solar electric systems.

•Wear appropriate protection and take all necessary precautions to prevent electric shock, especially when DC-voltage exceeds

30 VDC.

3.2 Safety advice for the inverter SF-WR

•Install and use the device only after reading and understanding this document.

•Always perform the measures described in this document in the sequence specied.

•Keep this document in a safe place for the entire service life of the device. Pass the document on to subsequent owners and opera-

tors of the device.

•Improper operation can reduce the yields of the photovoltaic system.

•The device must not be connected to the DC- or AC-cables if it has a damaged casing.

7

•If one of the following components is damaged, immediately take the device out of operation and disconnect it from the mains

grid and solar modules.

- Device (not functioning, visible damage, smoke, etc.)

- Cables

- Solar modules

•The system must not be switched on again until:

- The device has been repaired by a dealer or the manufacturer.

- Damaged cables or solar modules have been repaired by a technical specialist.

•Never cover the cooling ns.

•Do not open the casing. This will void the warranty and could result in serious bodily harm or death.

•Factory labels and markings must never be altered, removed or rendered unreadable.

•Observe the respective manufacturer‘s manual when connecting an external device that is not described in this document (e.g.

external data logger). Incorrectly connected devices can damage the inverter.

Safety advice on the inverter

4

5

1

23

10min

Isoler les deux sources

avant toute

intervention

Attention

Présence de deux sources

de tension

- Réseau de distribution

- Panneaux photovoltaïques

S/N: 746867XG001155550005

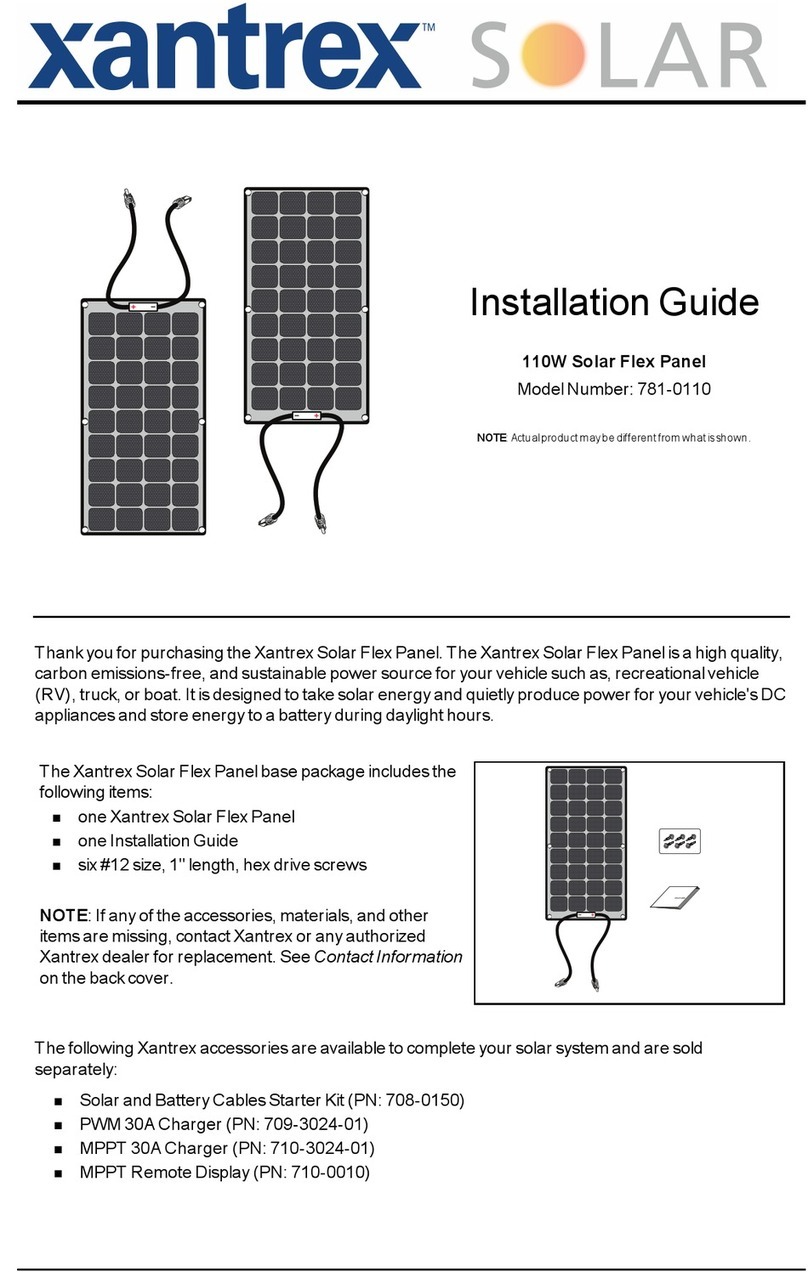

4. Proper Usage

The SolarSet may only be used in grid-connected photovoltaic systems. The modules, inverter, cables, and connectors have been

mutually calibrated for best performance. The connections may not be grounded.

Potential curves of the photovoltaic voltage VPV at 350V and 550V

VPV = Potential between plus and minus poles at the DC-input

1Dangerous voltages can remain present on the compo-nents up

to 10 minutes after switching o the DC circuitbreaker and the

line circuit breaker.

2Warning. There are 2 voltage sources present:

powergrid, solar modules.

3Disconnect both voltage sources from the device beforeworking

on the device: the solar modules via the DC circuit breaker and

the power grid via the line circuitbreaker.

4Disconnect both voltage sources from the device before

working on the device:

The solar modules via the DC-circuit breaker and the power

grid via the line circuit breaker.

5Read and follow the instructions!

Figure 3

Figure 4

175 V

− 175 V

− 275 V

275 V

320 V

U

t

0 V

− 320 V

UPV = 350 V

DC (+)

DC (−)

175 V

−

175 V

−

275 V

275 V

320 V

0 V

−

320 V

U

t

UPV = 550 V

DC (+)

DC (−)

Abb. 2: Potentialverlauf von UPV bei 350 V (links) und 550 V (rechts)

175 V

− 175 V

− 275 V

275 V

320 V

U

t

0 V

− 320 V

UPV = 350 V

DC (+)

DC (−)

175 V

− 175 V

− 275 V

275 V

320 V

0 V

− 320 V

U

t

UPV = 550 V

DC (+)

DC (−)

Abb. 2: Potentialverlauf von UPV bei 350 V (links) und 550 V (rechts)

8

5. Scope of Delivery

The Solar Frontier SolarSet comprises the following components. The number of components required can be determined using the

list below based on the type of SolarSet you have:

1Photovoltaic module Solar Frontier SF170-S

2Solar Frontier inverter SF-WR (incl. Inverter, Mounting plate and AC-plug)

3Connecting cable (Versions for + and -, with either 2, 3 or 4 outputs)

4DC-cable (in 50m or 100m)

5DC-plugs und DC-sockets (5 of each in each package unit)

6Unlocking tool

7Installation Manual

2.0 2.4 3.1 3.6 4.1 4.8 5.1 6.1 7.1 8.2

1SF170-S 12 14 18 21 24 28 30 36 42 48

2SF-WR-XXXX 1111122222

3Connecting cable 2222244444

4DC-cable [m] 50 50 50 50 50 100 100 100 100 100

5Plugs & Sockets 5 5 5 5 5 10 10 10 10 10

6Unlocking tool 1111122222

7Installation Manual 1111111111

Table 1

Not scope of the delivery are:

•Installation scaolding and installation materials

•Tools for installation and confectioning of the cables

9

6. About this Manual

6.1 Contents

This manual contains all the necessary information that an installer or professional requires to install the SolarSet and put it into opera-

tion. Please note the instructions provided by component manufacturers (e.g. AC-cable, substructures).

6.2 Target group

The target group for this manual are professionals and installers, unless otherwise stated.

„Professionals“ means the persons that:

•Have the necessary expertise and knowledge with regards to the terms and skills needed to install and operate photovoltaic systems.

•Have sucient experience, professionally trained, knowledgeable, and aware of the safety work regulations, applicable laws and

norms of the following:

- Installation of electrical appliances

- Assembly and connection of data cables

- Assembly and connection of power supply lines

6.3 Markings

6.3.1 Symbols

Symbol Description Location

General safety advice Manual

Danger from electricity Manual

Device

Read manual before use. Device

6.3.2 Keywords

Keyword Description

Danger Immediate danger of death or serious injury

Warning Possible danger of death or serious injury

Caution Possible danger of light or medium injury

Notice Possible damage to property

Note Tips on operation or usage of the manual

6.3.3 Markings used in the text

Marking Description

√Condition for action

Single step

1., 2., 3., ... Several steps in series

cursive light emphasis

bold strong emphasis

Courier Designation of product elements such as buttons, displays, operating state

10

6.3.4 Abbreviations

Abbreviation Description

ACurrent in Amperes

AC Alternating current

ca. circa

i.e. that is

DC Direct current

Derating Power reduction

MSD Internal grid monitoring of the inverter (Mains monitoring with allocated Switching

Devices).

tot. total

lCurrent

lkShort circuit current

Impp MPP circuit current

incl. inclusive

kVA Kilovoltampere

kW Kilowatt

kWh Kilowatthour

mMeter

m2Square meter

MPP maximum power point

Nm Newtonmeter

PElectrical power

Pa Pascal

PV Photovoltaic

SELV Safety Extra Low Voltage

SF Solar Frontier

STC Standard Test Conditions

UVoltage

et al and others

ULOpen circuit voltage

Umpp Voltage im Maximum Power Point

UPV Voltage of the generator at the DC-connection (photovoltaic voltage)

etc. and so on

VVolt

W/m2Watt per square meter

e.g. for example

ηEciency

11

7. Composition of the Solar Frontier SolarSets

Solar Frontier currently oers ten dierent Solarsets with nominal power outputs from 2.0 kW to 8.2 kW. The SolarSets consist of Solar

Frontier modules, Solar Frontier inverter(s), the necessary connecting cables, DC-cable and plugs and sockets.

Table shows the exact composition of each SolarSet, including the electrical structure:

Position Description 2.0 2.4 3.1 3.6 4.1 4.8 5.1 6.1 7.1 8.2

Module SF170-S 12 14 18 21 24 28 30 36 42 48

Inverter SF-WR-3000 1 1 1 1 2 2 1

Inverter SF-WR-3600 1 1 2

Inverter SF-WR-4200 1

Roof Area Area in m215,6 18,2 23,4 27,3 31,2 36,4 39 46,8 54,6 62,4

Module Number in Series 6 7 6 7 6 7 6 6 7 6

Strings Number parallel 2 2 3 3 4 4 5 6 6 8

Connecting cable 2+ 1 1 2 1

Connecting cable 2- 1 1 2 1

Connecting cable 3+ 1 1 1 2 2

Connecting cable 3- 1 1 1 2 2

Connecting cable 4+ 1 2

Connecting cable 4- 1 2

DC-cable 50 Meter 1 1 1 1 1

DC-cable 100 Meter 1 1 1 1 1

Plugs 5 pces. 1 1 1 1 1 2 2 2 2 2

Sockets 5 pces 1 1 1 1 1 2 2 2 2 2

Unlocking tool Number 1111122222

Table 2

Schematic structure based on SolarSet 3.1

Figure 5 shows the schematic structure of the SolarSet. The modules are connected serially to strings. The outputs of each single string

are drawn together using the appropriate connecting cable. The connecting cables have to be assembled on the spot, and serve to

extend the connection to the inverter.

The connecting cables have two, three or four

outputs depending on the plant size. Cables are

provided for each polarity (plus and minus).

Figure 5

12

8. Installation

For a safe installation, all relevant national and local laws, regulations and directives, especially for accident avoidance,

as well as all relevant technical standards are to be adhered to.

8.1 Mounting system/ substructure

The SolarSets are delivered without mounting systems. In general, all mounting systems commercially available, are suitable (e.g. No-

votegra (MHH), HatiCon, K2 Mounting Systems, Easy Roof (IRFTS), Schletter, Tritec) provided that the installation is in accordance with

the requirements indicated in 8.2.3. Your installer will be able to suggest a suitable solution.

8.2 Mechanical installation of Solar Frontier SF170-S photovoltaic modules

8.2.1 Site location

•Ensure that the maximum wind and snow loads in local conditions do not exceed the SF module maximum load ratings.

•Avoid installing SF modules in areas where they are exposed to oil vapour and /or corrosive gas.

•Avoid accumulation of grit or dust on the SF modules as it may inuence the output yield.

•Do not expose SF modules to sulphurous atmospheres.

•Do not install SF modules in locations where ammable gases accumulate or ow as there is a risk of sparks from SF PV modules.

•Do not install SF modules near re.

•Avoid installing SF modules in locations where they may be covered by permanent shadows. This may adversely aect their perfor-

mance.

•Do not install SF modules in locations where temperatures exceed the temperature range indicated in the module’s technical

specications

8.2.2 Module handling instructions

•Do not disassemble or modify SF modules. This may result in an electric shock, re or other accidents. Solar Frontier cannot be held

responsible for any loss or damage caused by unauthorized disassembling, modication or misuse of SF modules.

•Do not drill additional mounting holes into the aluminum frame. Only pre-drilled holes should be used.

•Avoid placing any stress onto the SF modules, cables or connectors.

(Minimum bending radius of 39 mm for module cables is recommended)

•Do not stand or step on SF modules. This may result in damage to the module and/ or bodily harm by falling.

•Do not drop SF modules or drop objects onto them. Both sides of the module (the glass surface and the back sheet) are fragile.

•Do not strike the terminal box or pull the cables. The terminal box can crack and break, while the output cable may unplug and

cause electricity leakage or an electric shock.

•Do not scratch the back sheet or cables of the SF modules. Rubbing or scratching may result in an electric shock, electric leakage or

an accident.

•Do not scratch the insulation coating of the frame (except for the grounding connection). This may weaken the strength of the

frame or cause corrosion.

•Do not cover the water drain holes of the frame. Doing so may cause frost damage.

•Do not use glue when closing the cover of the junction box. Similarly, do not use a sealant to bond the junction box lid to its base.

13

8.2.3 Module mounting instructions

Mounting structures cautions

•Pay attention to the electrochemical series when selecting support structure material to avoid galvanic corrosion.

•Fasten and lock bolts completely. Inadequate mounting may result in SF modules falling or other accidents.

•Ensure that the SF modules are securely fastened to the mounting support structure that is durable, made of UV and corrosion

resistant material, and follow the applicable local and civil codes.

•Ensure that your mounting support structure is designed to withstand the SF module design snow and wind loads applicable for

the chosen site. Solar Frontier will not be responsible if the SF modules are damaged due to the durability of the mounting support

structure. Please consult your mounting structure manufacturer.

Mounting the solar modules

•PV modules should typically face South in the Northern Hemisphere and North in the Southern Hemisphere for optimal power

production.

•Modules can be installed horizontally (landscape) or vertically (portrait).

•Maintain a space between SF modules and the roof. This will allow air to circulate, cooling the module, and allowing condensation

to dissipate. Solar Frontier recommends a distance of at least 100 mm (3.94 in).

Mounting with Screws

SF modules should be fastened to the support structure using the mounting holes on the frame. The support structure should be

securely fastened to a non-corrosive roof. Tighten the screws with an adequate torque value. Please refer to further instructions and

adequate torque value provided by the screw manufacturer.

Mounting with Inner Holes

Each module will require four M6 (or 1/4 in) bolts with washers, lock washers and nuts. Tighten the screws with an adequate torque value.

UL: Recommended tightening torque is 8 Nm (70.8 lb in) minimum.

TUV: 2,400 Pa (50 lbs/ft2) to the front and back of the module

UL: 1,600 Pa (33.4 lbs/ft2) to the front and back of the module

1.5 times the design load is applied to the module during UL testing. 2,400 Pa (50 lbs/ft2) is applied to test 1,600 Pa

(33.4 lbs/ft2) UL design load.

Landscape (horizontal)

256 mm ±1 mm 745 mm

Portrait (vertical)

Portrait (vertical)

256 mm ±1 mm 745 mm

174 mm ±1 mm 909 mm

909 mm

174 mm ±1 mm

Landscape (horizontal)

14

Mounting with Outer Holes

Each module will require four M8 (or 5/16 in) bolts with washers, lock washers and nuts. Tighten the screws with an adequate torque value.

UL: Recommended tightening torque is 15 Nm (132.8 lb in) minimum.

TUV: 2,400 Pa (50 lbs/ft2) to the front and back of the module

UL: 1,600 Pa (33.4 lbs/ft2) to the front and back of the module

1.5 times the design load is applied to the module during UL testing. 2,400 Pa (50 lbs/ft2) is applied to test 1,600 Pa

(33.4 lbs/ft2) UL design load.

Please refer to further instructions and adequate torque value provided by the screw manufacturer.

Landscape (horizontal)

256 mm ±1 mm 745 mm

Portrait (vertical)

Portrait (vertical)

256 mm ±1 mm 745 mm

174 mm ±1 mm 909 mm

909 mm

174 mm ±1 mm

Landscape (horizontal)

15

Mounting with clamps

Four or more corrosion-proof aluminum clamps should be used to fasten SF modules to the support structure. Center-line of the

clamps shall be secured within the indicated clamping zone (256 mm +/- 75 mm) from the corners of the longer side of the module

frame using stainless-steel M8 bolts with a minimum length of 20 mm. Tighten the clamps with an adequate torque value.*1

All selected module clamps must be at least 50 mm long, 3 mm thick, and overlap the module frame by 8 mm or more.

Clamps must not create shadow nor cover the front glass, and shall not deform the module frames during installation. Please refer to

the instructions provided by the clamp manufacturer for further instructions.

*1UL: Recommended tightening torque is 15 Nm (132.8 lb in) minimum.

TUV: 2,400 Pa (50 lbs/ft2) to the front and back of the module

UL: 1,600 Pa (33.4 lbs/ft2) to the front and back of the module

1.5 times the design load is applied to the module during UL testing. 2,400 Pa (50 lbs/ft2) is applied to test 1,600 Pa

(33.4 lbs/ft2) UL design load.

Module perpendicular to support rails

Array Installation (section)

Landscape (horizontal) Portrait (vertical)

End clamp Middle clamp

Module

support rail

Bolt

Module Module

Nut

Module Module

Module

Clamp to module overlap

min 8 mm

8mm 8 mm 3 mm

3 mm

256 mm 745 mm

75 mm 75 mm 75 mm 75 mm

75 mm 75 mm 75 mm 75 mm

75

mm

75

mm

75

mm

75

mm

75

mm

75

mm

7

4

5

mm

25

6

mm

75

mm

75

mm

Array Installation (section)

Landscape (horizontal) Portrait (vertical)

End clamp

Middle clamp

Module

support rail

Bolt

Module Module

Nut

Module Module

Module

Clamp to module overlap

min 8 mm

8mm 8 mm 3 mm

3 mm

256 mm 745 mm

75 mm 75 mm 75 mm 75 mm

75 mm 75 mm 75 mm 75 mm

75

mm

75

mm

75

mm

75

mm

75

mm

75

mm

7

4

5

mm

25

6

mm

75

mm

75

mm

16

For alternative mounting methods, please consult Solar Frontier.

Module parallel to support rails

Array Installation (section)

Landscape (horizontal) Portrait (vertical)

Middle clamp

Module

support rail

Bolt

End clamp

Module Module Module

Module Module

Module to rail overlap,

min 10 mm

10 mm

10 mm

Nut Nut

8 mm

Clamp to module overlap,

min 8 mm

8 mm

3 mm

3 mm

256 mm

75 mm

745 mm

75 mm 75 mm 75 mm

75 mm 75 mm 75 mm

75 mm

75 mm75 mm

75 mm75 mm

745 mm

256 mm

75 mm 75 mm 75 mm75 mm

Array Installation (section)

Landscape (horizontal) Portrait (vertical)

Middle clamp

Module

support rail

Bolt

End clamp

Module Module Module

Module Module

Module to rail overlap,

min 10 mm

10 mm

10 mm

Nut Nut

8 mm

Clamp to module overlap,

min 8 mm

8 mm

3 mm

3 mm

256 mm

75 mm

745 mm

75 mm 75 mm 75 mm

75 mm 75 mm 75 mm

75 mm

75 mm75 mm75 mm75 mm

745 mm

256 mm

75 mm 75 mm 75 mm75 mm

17

8.3 Electrical Installation photovoltaic generator

8.3.1 Electrical wiring safety precautions

•The sum of Voc of modules in series must not exceed the maximum system voltage of the module under any condition.

Reverse current applied to the modules must not exceed 7 A.

•Do not touch or handle the PV module, terminal box or the end of output cables with bare hands.

•Do not carry out installation when PV modules, installation tools or installation area are exposed to water.

•Ensure that the connection parts between SF modules and power receiving devices are isolated and waterproof.

Using SF modules with insucient isolation and waterproong could result in an electric shock, an electric leak or an accident.

•Keep the wiring box (junction box) and the module connector away from any liquids until connectors are mated. Failure to do this

may cause faulty wiring.

•Components interconnecting the modules must be compatible with the connectors, and must provide system operation and fault

protection.

•Inverters must meet the technical requirements of SF modules.

•Do not connect the PV modules directly to loads such as motors. Variation in output power may damage the motor.

•Observe and understand the safety instructions of batteries. Their misuse can result in serious bodily harm due to high electrical

current.

•Cables should be adequately protected from damage by wildlife

8.3.2 Cabling

Solar Frontier places great value on delivering as many components as possible pre-assembled in order to help avoid sources of error.

Since roof and PV installation has its own specialities, it may be necessary to adapt certain cables on site to t them best (e.g.: connec-

tions cables to the inverter shall be cut and assembles on site, and/or extension cable will be necessary to wire around interrupted

strings on the roof of obstacles exist such as chimneys). The DC-cable, sockets and plugs which are included in the SolarSet are for this

purpos. A suitable crimping tool is necessary but excluded of the SolarSet).

Please ensure a clean and proper assembly of the cables to avoid error sources and to ensure safe cabling.

To assemble the cables the following tools are necessary:

- Mounting key (not scope of the delivery)

- Crimping tool for twisted contacts (not scope of the delivery)

- Insulation stripping pliers (not scope of the delivery)

Shortening and stripping the insulation from cables

First, the cable has to be shortened to the proper length. Then the outer insulation is removed with a suitable insulation stripping

pliers to a length of 7 mm.

Ensure that the wires are not damaged – a reduction of the cross-sectional area can result in electrical errors.

18

See Figures 12 and 13:

Crimping the twisted contacts

Push the stripped end of the cable into the crimp sleeve as shown in Figure 14 Make sure that all wires are inside the crimp sleeve. The

wires must be visible in the small opening.

To crimp the sleeves use the„hex“ or„4-ident“ crimp die. Put the crimp sleeve with the cable in the respective slot on the crimp pliers.

The crimping tool must be suitable for drilled crimp contacts of the type Amphenol Helios H4. For more detailed information on using

the crimp pliers please consult the operations manual of the pliers manufacturer.

See Figures 15 and 16:

Checking the crimping results

A visual check of the crimping results, and a pull test are needed to ensure a correct crimping.

Figure 17 and Figure 19 show a good result for a„hex“ crimping; Figure 18 and Figure 20 show a good result for a„4-ident“ crimping:

The pull test should be for at least 310 Newton.

Inspection hole

Figure 12

Figure 13

19

Assembling the plugs and sockets

To assemble the plugs and socket the respective cover should be pushed over the contact until a clear click is heard or felt. The click

shows that the contact is in the right position in the plug/socket. Contacts cannot be released when they have been positioned.

See Figures 21 to 24:

The covering cap is to be tightened with 2.6 to 2.9 Nm. A suitable installation spanner can be used for this purpose.

Connecting and disconnecting the plug/socket combination

Connect the plug and socket to each other. A click shows that the connection has been successful. To open and disconnect the plug/

socket combination a suitable tool is necessary. This could be a disconnecting tool as delivered or another suitable tool.

See Figure 27.

Never disconnect plug/socket combinations when the plant is in operation in order to avoid light arcing, which can lead to

serious injury or death.

20

8.3.3 Procedures for electric cabling

The electrical cabling of Solar Frontier SolarSets has to be done as described in Chapter 7, Table 2. Take care that the exact number of

modules in series are connected in accordance with Table 2, and that the respective number of parallel strings is adhered to.

String connection

The serial connection of modules should be done in accordance with 8.3.5, Figure 31 and 32.

Procedure by interrupted strings:

If it isn’t possible to connect modules directly, the plugs, sockets and DC-cable provided can be used to bridge gaps.

An exemplary approach is shown in 8.3.5, Figure 33 and 34. The basics on assembling an extension cable can be found in Chapter 8.3.2

Assembly. Please note that only a limited number of plugs/sockets are provided in the set, and that the cable provided is primarily for

the extension from the generator to the inverter.

If you should need extra material, please ensure that the compatibility to the SolarSet products is conrmed. If in doubt

please contact Solar Frontier.

Connecting the strings

The string connecting cable in the set is used to connect the strings and lead them to a mutual collection point. The number of strings

can be determined in Chapter 7, Table 2.

DC-cable

The DC-cable is used to extend the connecting cables in the PV generator with the inverter. Basics on assembling the cable can be

found in chapter 8.3.2

Connecting to the inverter

The connection of the PV generator to the inverter is described in detail in chapter 8.4. Please ensure that the instructions and proce-

dures described there are strictly adhered to to avoid possible danger sources and to ensure a safe installation.

8.3.4 Grounding

Grounding cautions

•Be aware of the necessary grounding requirements prior to installation. Your local authorities can help you further.

•Install arrestors, surge absorbers or any other appropriate lightning protection tools as needed.

•Module frames, mountings, connection boxes and metal conduits should be connected to an earth ground as lightning protection,

in accordance with local, regional and national standards and regulations.

•Grounding holes (ф 4 mm) on the aluminum frame of the SF modules are provided to accommodate grounding. Use a grounding

wire made of copper, not smaller than 2 mm² (14AWG). Temperature rating of the conductors must be between -40 °C to 85 °C. En-

sure that the crimping terminal is tightly tied to the module frame with a rolling thread screw and a lock washer to ensure electrical

contact.

•Grounding devices such as module clamps with an integrated grounding pin, serrated washers, grounding clips or lugs, designed

for bonding photovoltaic modules to the mounting structures may also be used for grounding as described in NEC section 250.

These grounding devices shall be made in conformance with the grounding device manufacturer instructions. Consult the ground-

ing device manufacturer to identify the appropriate grounding and bonding device for your mounting structure or design.

For alternative grounding methods please consult Solar Frontier.

UL: The module with exposed conductive parts is considered to be in compliance with UL 1703 only when it is electrically grounded

in accordance with the instruction presented below and the requirements of the NEC.

Other manuals for SolarSet 2.0

1

This manual suits for next models

9

Table of contents

Other Solar Frontier Solar Panel manuals

Popular Solar Panel manuals by other brands

JIANGYIN TITANERGY

JIANGYIN TITANERGY TT-ADJUSTABLE TILT LEGS installation manual

Dwyer Instruments

Dwyer Instruments SPK quick start guide

SUNPRO

SUNPRO SP410-108M10 installation manual

FAFCO

FAFCO CoolPV owner's manual

IBC SOLAR

IBC SOLAR AeroFix Series installation instructions

Viessmann

Viessmann Vitosol 100-FM SV1F Installation, operating and service instructions