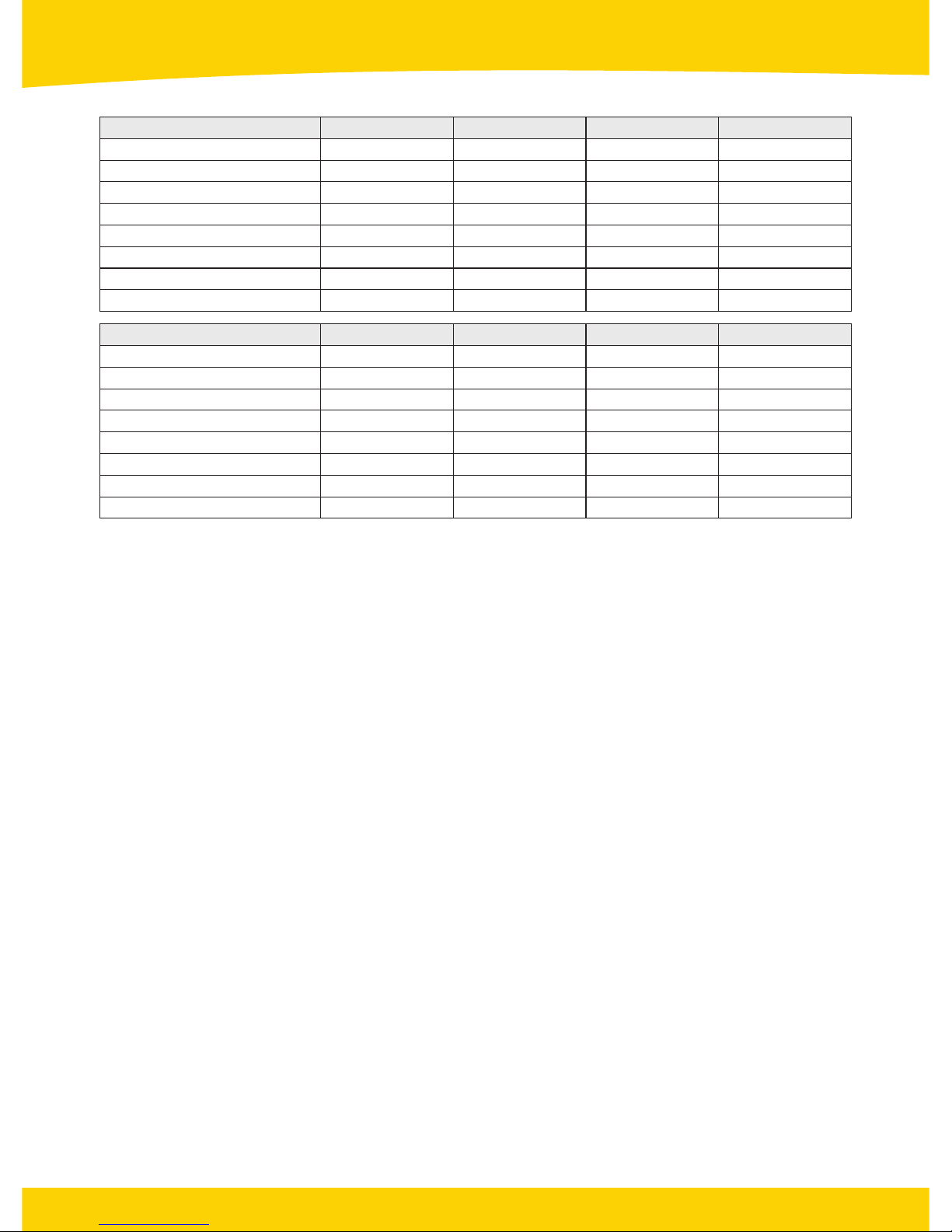

1. Electrical Performance Parameters

01

www.solarland.com.au

SLPXXX-24V (where XXX is directly related to module’s rated power) series solar modules are made of 72pcs

156×78mm mono crystalline solar cell in series with high efficiency, high transmission rate, low iron tempered

glass, anti-aging EVA, high flame resistant TPT laminate, and anodized aluminium alloy frames. Wuxi Tianran

Photovoltaic Co., Ltd. (SOLARLAND) modules have long life, easy installation, high wind and hail impact

resistance and many other advantages.

SOLARLAND modules are made according to international standards and have passed several third party test

centre’s examination for certification.

SLPXXX-24V series solar modules mainly include 120Watt, 125Watt, 130Watt, 135Watt, 140Watt.

Value Parameters

Max Power (Pmax)

Operating Voltage (Vmp)

Operating Current (Imp)

Open-Circuit Voltage (Voc)

Short-Circuit Current (Isc)

Maximum System Voltage

Output Tolerance

Maximum Series Fuse Rating

SLP010-12V

10W

17.0V

0.58A

21.6V

0.68A

±3%

1000V

1 A

SLP015-12V

15W

17.2V

0.87A

21.6V

0.96A

±3%

1000V

2 A

SLP020-12V

20W

17.2V

1.16A

21.6V

1.31A

±3%

1000V

2 A

SLP025-12V

25W

17.2V

1.45A

21.6V

1.60A

±3%

1000V

2 A

SLP030-12V

30 W

17.2 V

1.75 A

21.2 V

1.90A

±3%

1000V

3A

Value Parameters

Max Power (Pmax)

Operating Voltage (Vmp)

Operating Current (Imp)

Open-Circuit Voltage (Voc)

Short-Circuit Current (Isc)

Maximum System Voltage

Output Tolerance

Maximum Series Fuse Rating

SLP035-12V

35 W

18.1 V

1.94 A

21.9 V

2.09 A

±3%

1000V

3A

SLP040-12V

40 W

17.2 V

2.33 A

21.6 V

2.55 A

±3%

1000V

4 A

SLP045-12V

45 W

18.0 V

2.50 A

21.8 V

2.73 A

±3%

1000V

4 A

SLP050-12V

50 W

17.4 V

2.88 A

21.2 V

3.15 A

±3%

1000V

5A

Value Parameters

Max Power (Pmax)

Operating Voltage (Vmp)

Operating Current (Imp)

Open-Circuit Voltage (Voc)

Short-Circuit Current (Isc)

Maximum System Voltage

Output Tolerance

Maximum Series Fuse Rating

SLP055-12V

55 W

17.9 V

3.08 A

21.7V

3.38 A

±3%

1000V

5A

SLP060-12V

60 W

17.2 V

3.49 A

21.2 V

3.81 A

±3%

1000V

6 A

SLP065-12V

65 W

17.7 V

3.68 A

21.6 V

4.01 A

±3%

1000V

6 A

SLP070-12V

70 W

18.1 V

3.87A

21.9 V

4.18 A

±3%

1000V

6 A

NOTE: All technical data at standard test condition (E=1000W/m² TC=25°C Am=1.5)