Solar Roofs SkyLine 200152C80EX User manual

Wholly owned by ACR Solar International Corp.

5840 Gibbons Dr. Suite G Carmichael, CA 95608 (916) 481-7200

! "#$% ! "# & ! "#

' ( %

INSTALLATION MANUAL

August, 2005

The solar energy system described by this manual, when properly installed and maintained meets the

minimum standards established by the Solar Rating and Certification Corporation (SRCC). This

certification does not imply endorsement or warranty of this product by SRCC.

(Note: SkyLine formerly Fireball)

CONGRATULATIONS!

Thank you!

You have just purchased the most attractive and easiest to install active solar water heater

made! We have worked on every detail to assure you that SolarRoofs water heater will completely satisfy

you in its very high level of performance and dependability.

Table of Contents

SUBJECT SECTION

Tools and Materials………………………………………………………………………1.0.

Systems, Components, Options and Diagram ……………………………………..2.0.

Specifications and Schematics………………………………………………………...2.1.

Antifreeze Safety Data:……………………………………….………………………….2.1.1

Components included with system……………………………………………………2.1.2

Important Notes……………………………………………………………………………2.2.

Collector Location, Orientation and Tilt………………………………………………3.0.

Overview of the Basic Installation Steps………………………………………….….4.0.

Assembling the Collector (Split Kits Only)………………………………….……….5.0.

Collector Installation……………………………………………………………………..6.0.

Determining the Best Pipe Run…………………………………………………….…..7.0.

Making Line Connections……………………………………………………………….8.0.

Control Component Details……………………………………………………….…….9.0.

Tank Connections……………………………………………………………………….10.0.

Charging the Solar Loop……………………………………………………………….11.0

Questions and Answers………………………………………………………………..12.0.

Certifications……………………………………………………………………………..12.1.

PLEASE CALL SolarRoofs.com WITH QUESTIONS

Toll Free USA Technical Install Help Number: (888) 801-9060

NOTE: Installation Color Photo Sheets Accompany this Manual for You to Refer to.

Generally drawings or diagrams are at the end of their respective sections.

WE WELCOME YOUR COMMENTS! We have worked to make SolarRoofs installation instructions easy

and complete. We are always looking to make them better and welcome your comments and suggestions!

PLEASE READ ENTIRE MANUAL

BEFORE STARTING INSTALLATION

The system 5 can be installed in straightforward

situations by two experienced people in less than 6

hours. With no experience, the installation will

probably take 2 people 8 to 12 hours, with added

complications, like a longer pipe run or two stories,

taking longer.

SAFETY FIRST!! See section 2.2

This Installation Manual assumes good

technical experience and ability.

NOTE: The collector has some sharp metal edges and

corners, use caution when handling the collector. 1.0.

Tools and Materials

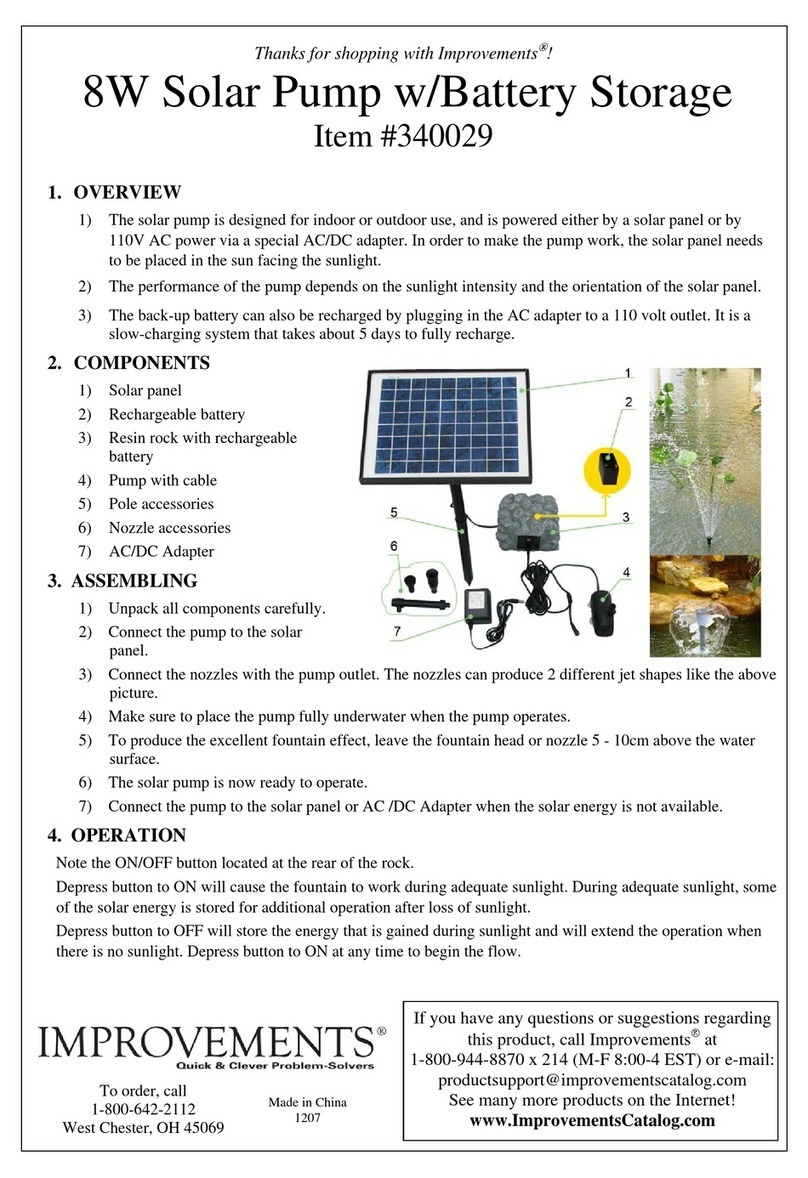

ITEMS SUPPLIED BY SOLARROOFS.COM:

• Collectors, with mounting rails, Ell brackets, U Center brackets and Solar Feed and Return line adapters

• Air Vent, Pressure Relief Valve, copper adaptor

• PV Panel with mounting brackets and hardware

• Storage Tank Heat Exchanger brass connections with Expansion tank, Pressure Gauge, “Floating Ball” Check Valve,

Charging valves, and Temperature Gauge.

• 12 Volt Pump and connections.

• 50’ 1/2” outside diameter copper solar loop lines.

• Solar loop installation parts kit including miscellaneous parts, fittings, screws, nuts, bolts, etc.,

• All hardware, two roof boots, 6'high temp. insulation

• Mixing Valve.

• Installation Manual, Operation and Maintenance Manual and Stickers.

TOOLS AND MATERIALS NEEDED:

Overview: Everyday homeowner tools are all that are needed to assemble and install the Skyline solar loop.

Tools and Materials Needed:

• For Assembling a split kit or Skyline split kit model collector: Pop Rivet Gun, 2 large adjustable wrenches and/or

wrench set (to secure collector absorber brass unions and compression fittings and to attach collector sections

together using joiner strip).

• Min 18” “Monkey Wrench (best to have 2)

• Teflon tape (1/2" wide to seal threaded fittings use 6 turns).

• Quality Pipe Sealant (to seal face of brass union ends).

• Ladder(s) (for roof and for access to attic as needed).

• Tape measure, Marking pencil, crayon or chalk (to mark rafters and holes on roof)

• Chalk Snap Line.

• 1 1/2" inch wood bit for roof penetrations (for feed and return lines through roof).

• 7/16" socket with ratchet and 6" extension. (a powerful drill with adapter is desirable for quickly driving lags).

• 1/4” nut driver on high speed drill (to drive 1/4" self taping screws into collector).

• Caulking gun with quality Polyurethane or Silicone roofing caulk (to fill lag holes and seal flashing to prevent

leaks).

• 3/4” or ½” wall, 7/8’ ID (about 12 feet) and 5/8” ID high temperature open cell pipe insulation for inside piping.

• Charging Pump and 2 buckets 3 laundry hoses to charge system with Polypropylene Glycol (usually 2 gallons 100%)

2.0.

The following Systems, Components and Options are

Wholly or Partly Covered in this Manual

Note: This manual covers 20-01 collector installation, we hope the 10-01

collector will soon be OG100 approved for use with this system

System 5. Complete 20 Square Foot (1.86 m

2

), 20” x 12’ (.508 m x 3.66 m), Solar Panels with mounting kit and

Rails, 12 Volt PV Powered Circulator + Complete Rheem Double Wall Heat Exchanger Tank Connections.

These advanced 12V PV powered systems have matched PV Panels and Pumps for best operation. 2 collector

system includes ElSid Circulator with 20 Watt PV Panel, A larger 12V Electronic Circulator and 30 Watt PV Panel

is used for 3 or 4 collectors, with 25'of wire, 50’- 1/2" OD Copper connecting line, all line connections, Collector

Air Vent and Pressure Relief Valve, 2 Temperature Gauges, Mixing Valve, Install Kit, full instructions, Owners

Manual. Includes Expansion Tank and all Connections. 81V080HE1 TANK NOT SUPPLIED.

Two Collectors, Three Collectors, Four Collectors

(double for 10-01 collectors)

:

====================================================================================================

Tilt Kit (option) Tilts collectors approximately 18 degrees from existing roof angle, Other angles available on

request. Tilt kits are used when a better winter angle is desired on a low pitch roof or to “re-orientate” panels to

face south by running the panels up and down an East or West facing roof. See Special Instructions.

Single Panel: Collector kit with 3 Modified 24” rails with 6” legs and hardware:

(Option Code /#TK01) Single panel tilt kit:

Double panels: Collector kit 3 - 4’ 1” x 1” Aluminum Rails with 12” legs and hardware:

(Option Code /#TK02) Double panel tilt kit:

Tripple panels: Collector kit 3 - 6’ 1” x 2” Alum. Rails with 24” legs and hardware:

(Option Code /#TK03) Double panel tilt kit:

Standard Color (Default): Musket Brown (C101)

Free Optional Color: Dove/Old Town (Medium) Gray (C109) - Note: This is a no cost option.

Optional Colors Include:

Colonial (light) Gray (CO102), Tahoe Blue (COl03), Colonial Red (COl04), Forest

Green (COl05), White (COl06), Buckskin Brown (CO107), Beaver (medium) Brown

(CO108), C.B. (medium) Blue (CO110), Spanish Green (CO111), Storm/Slate (dark) Gray (CO112), Royal Brown

(CO113), Ivory (CO114), Sea Blue (CO115), Leaf Green (CO116), Pebblestone Clay (CO117), Woodbeige (CO118),

Peach (great on many light orange tile roofs) (CO119), Almond (CO120), Black (CO121), Adobe Tan (CO121),

Classic Cream (CO122), Bronze (CO123), Heritage Cream (CO124), Marine Green (CO125).

Components ( for individual purchase):

MVWA, Watts Mixing Valve:

QF34, Quad Flow Diverter

TR50, 50 foot roll of 3/8" ID, 1/2" OD soft copper tubing with 2 compression unions

TC01, Taco 006 110V Circulator:

ES10, El Sid 10 Watt 12V Circulator:

HC18, March 809 18 Watt 12V Circulator

PV10, 10 Watt 12V Panel With Mounting Hardware:

PV20, 20 Watt 12V Panel With Mounting Hardware:

PV20, 30 Watt 12V Panel With Mounting Hardware:

PR15, 150 Pound Pressure Relief Valve:

CV01, Floating Ball Check Valve:

TR50, 50 foot roll of 3/8" ID, 1/2" OD soft copper tubing includes 2 compression unions:

H180,

180 F High Temperature snap switch, open 180 F, close 140 F, place on cold in:

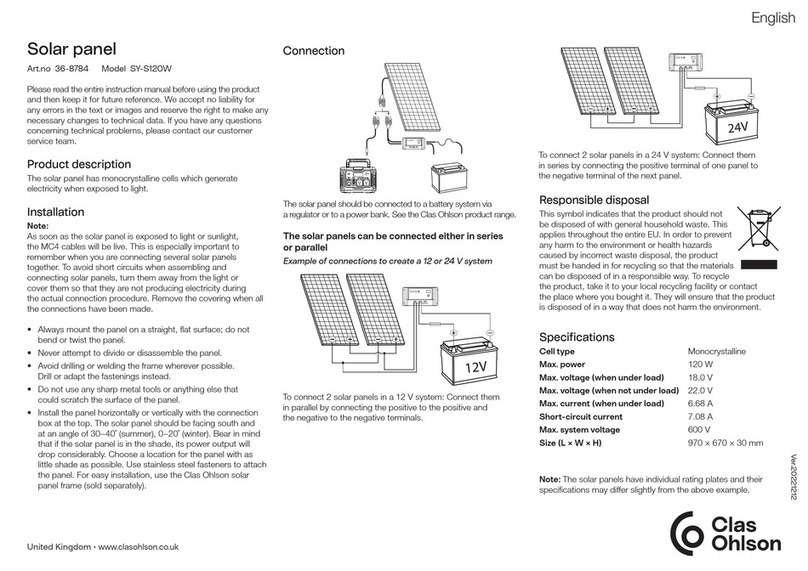

SkyLine System 5

! " $ ! " $ ! " $

Rheem/

Rudd

80 gallon

Solar

Heat

Exchanger

storage

Loop charge valve V1

Loop charging V3

isolation valve

Loop charge drain

valve V2

Air Vent Pressure Relief Valve

PV panel

Solar Loop

Temperature

gauges

Domestic cold in

Mixing

Valve

Tank Drain

Domestic hot out

SkyLine Collectors:

40, 60, or 80 S/F

Floating

Ball

Check

valve

Tank Pressure

Temperature

Relief Valves

Switch

Cold shutoff

12 V PV pump

Expansion

Tank

Solar Loop

Pressure

Gauge

Heat Exchanger

Optional

Hot Out

Temperature

gauges

! " )( $% )( $ ) ! %) !

Rheem/

Rudd

80 gallon

Solar

Heat

Exchanger

storage

Loop charge valve V1

Loop charging V3

isolation valve

Loop charge drain

valve V2

Air Vent Pressure Relief Valve

PV panel

Solar Loop

Temperature

gauges

Existing

30 to 50

gallon gas

or electric

water

heater

Domestic cold in

Mixing

Valve

Tank Drain

Domestic hot out

Fireball 2001 Collectors

Floating

Ball

Check

valve

Tank Pressure Temperature Relief Valves

Switch

Box

Cold shutoff

12 V PV pump

Solar

Bypass

SRCC Required Solar Bypass Valves

Normal Solar Operation: A, and C are Open and B is Closed

Solar Tank bypass: A, and C are Closed and B is Open

A

C

B

Expansion

Tank

Solar Loop

Pressure

Gauge

Heat Exchanger

Hot Out

Temperature

gauges

SkyLine System 5 OG300 2 Tank Installation

2.1.

“20-01” OG300 Solar Water Heater Specifications

COLLECTOR (Panel)

Trim & Frame Materials: Finished 27 mil Aluminum Trim and Frame = Total 54 mil (1.37 mm).

Absorber Material: “Black Crystal” coated - all Copper with unions.

Glazing: .236” (6.0 mm) Twinwall Polycarbonate UV Treated

Dimension / Weight: 200 -144.3”x 20.”x 3” 38 lb (3.67 m x 0.51 m x 0.076 m 17.24 Kg) 18.4 Net s/f (1.71 m

2

)

Fluid Capacity: .3/10 gallon

Recommended Flow Rates: .20 to .35 GPM (0.946 to 1.324 L/min)

Maximum Working Pressure: 150 PSI (10.21 atm).

Maximum Stagnation Temp: 250 °F (121.11 °C).

Heat Transfer Fluid: Potable water or Propylene glycol

Standard Components: Mounting rails, mounting brackets, tech screws and lags

Color: Musket Brown (Cl01 – default color) or Dove/Old Town Gray (C109) + optional colors

PV (Photovoltaic) POWERED CIRCULATOR

PV Panel: 20 or 30 Watt, 12volt DC

Circulator: 12 Volt - “El Sid”, March or equal.

FREEZE PROTECTION

Type: Closed Loop Glycol with Storage Tank Heat Exchanger.

The SolarRoofs.com's closed loop Propylene Glycol Antifreeze heat exchange system's collector as well as feed and return

lines will not be damaged by (ambient) hard freeze temperatures as low as -54 degrees F below zero with a 60/40 mixture of

propylene glycol/water. The solar storage tank must be kept in an area above 32 degrees F.

CONNECTING LINES, INSULATION (standard)

Tubing: 1/2” (12.7 mm) OD copper - 50’ (15.24 m)

Insulation (6’ (1.83 m) supplied): 1/2” (12.7 mm) ID 1/2” (12.7 mm) or 3/4” (19.05 mm) wall

TUBING CONNECTION METHODS (standard)

Type: Brass Union, Compression, (Brass Fittings for Heat Exchanger)

STORAGE TANK - Rheem / Rudd / Richmond Model Number: 81V080HE1 (Not Supplied)

80 Gallon Tank with In Tank Double Wall Heat Exchanger.

Fluid Used: Propylene Glycol (Sierra)

Components Supplied: Expansion Tank, one floating ball check valve, Temperature Gauge,

fill, drain, and pressure relief valves.

CONTROL

Type:

12 Volt Circulator with Switch, which automatically regulates circulator operation.

Although we will make every effort to give notice, Specifications and prices subject to change without notice.

2.1.1.

Antifreeze Safety Data - Sierra Antifreeze-Coolant

FLUID HANDLING, SAFETY AND FIRST AID:

1. Store fluid in tightly closed and properly vented containers, away from heat, sparks or open flame.

Dispose of any aqueous waste at permitted landfill sites only.

2. Chemical splash goggles or full face shield must be worn when possible eye contact exists.

3. Ingestion: Give pint of luke warm water or induce vomiting if large quantity is ingested.

4. EMERGENCY PHONE: 1-800-424-9300 (CHEMTREC)

Freezing point: -28 deg F (50/50 mixture)

Flash Point: 211F

Boiling point: 365 deg F

Appearance: Green

Specific Gravity: 1.04

Vapor Density: 2.6

2.1.2.

Components Included with the SolarRoofs Type 5

PV Panel

PV Panel brackets

Bracket hardware

PV panel wire PV switch

12 Volt Pump

Tempering Valve assembly

Check valve

Dielectric Unions

Tank Nipples

Solar Loop Pressure Gauge

Expansion tank

(pre

-

charge to 38 lb.)

Expansion tank copper assembly

Pump head

with 1/2” male fitting

s

Cool feed assembly bracket

50’ Roll of 1/2 OD copper

Cool feed line

compression

union

Cool feed lower brass

assembly and temp gauge

Cool feed line

compression union

Hot return assembly with

temperature gauge an

d

check valve

Antifreeze

(not included)

Top charging fill valve V1

(with cap)

Isolation ball valve V3

Bottom charging fill valve V2

(with cap)

Cool feed tank to un

ion adaptor

3

-

1” square tube mounting rails

(2 collector system shown)

6 mounting rail brackets with

6 lags and 6 washers for every

system rail set

Collector component

Assembly:

Air vent

Pressure relief valve

Upper comp. unions 2 90s and 1

straight

Center comp

ression union body

Lower compression 90 union

Color coded bracket

“tec screws”

2 Color codes roof boots

3 Collector U clips

(per extra collector)

System documents and

lab

els

Mixing valve only included with kit, assembly is

included in picture to illustrate complete assembly

or Coin Vent

Pl

ease Note:

SolarRoofs has improved its system and some pictures will not be visually

accurate but show all the components included. Most copper fittings have been replaced

with Brass. More visually accurate pictures will be included in their sections.

2.2.

IMPORTANT NOTES:

CHECK WITH YOUR LOCAL BUILDING DEPARTMENT FOR CODE

COMPLIANCE FOR THE INSTALLATION OF YOUR SOLAR WATER

HEATING SYSTEM.

SAFETY FIRST!!

USE CAUTION!!! Do not attempt to self-install without

help if you have ANY back or physical limitations!!!

GENERAL WARNINGS:

This manual assumes that the installer has good mechanical experience and

can confidently use simple hand tools, building materials and adhere to safe

building practices.

SolarRoofs.com does not assume responsibility for any loss, or injury

directly or indirectly, associated with the installation of this system.

Do not install this system alone wwithout someone knowing where you are

and what you are doing at all times.

In all cases where a firewall (drywall) is penetrated, it is important to seal the

hole. A good general rule is to always fill in and seal around all holes made

for solar lines to prevent heat loss and to maintain fire stops.

Properly support all piping according to local code. As a rule, support

copper pipe every 6’.

SolarRoofs systems are easy to install; however, problems resulting from a

failure to correctly install the system according to the following instructions

and to maintain it according to the operation and maintenance manual are

not covered by the warranty.

3.0.

COLLECTOR LOCATION, ORIENTATION AND TILT

Your solar water system will be providing savings for

your family for decades to come. Because the sun rises

in the east, crosses over the horizon on the south and

sets in the west, you want your collector to face as much

to the south as possible. Your system needs the most

sun it can get!

As long as the collector angle (known as tilt) is at least

14 degrees up from horizontal, (a typical roof angle is

22 to 28 degrees) additional tilt usually has little effect

on total year round performance. The exception is in

areas with very sunny winters (as in most areas of

Colorado) where a higher angle, (facing the collector

more directly into the winter sun) can help year round

performance.

In most areas with heavy winter overcast, a solar

collector's orientation on a low pitched roof can face

anywhere from 45 degrees east to west of south without

losing more than 8% of the energy it would have

produced if it were facing directly south. At 90 degrees

east to west of south the loss is closer to 20%.

Exceptions include easterly facing systems in areas

with a lot of morning fog and clear afternoons where

south facing or west facing would be much better. The

opposite can be true if sunny mornings are very often

followed by rainy afternoons.

Take these facts into consideration when locating

your collector and consult with us if you have any

questions.

ROOF CONDITION:

The condition of your roof should be good although one

of the features of Skyline system is that removing and

replacing the collector is relatively easy for re-roofing.

4.0.

OVERVIEW - THE BASIC

INSTALLATION STEPS:

THE BASIC INSTALLATION STEPS (3 to 8

hours required to install, depending on situation and

experience)

1. Unpack collector, for split kits, assemble the

collector left and right sections into one unit as per

pictures and instructions. Note: not shown, the 24’

collector has a center mullion that needs to be attached

to the collector after joining the unions. Two 6’ sheets

of Polycarbonate glazing go into each side of it.

2. Collector placement on roof located, rafters located

and marked, end mounting rails with brackets lagged

and sealed into rafters, collector placed into mounting

rail brackets, center mounting rail and brackets placed,

lagged and sealed into rafter, mounting rail brackets

screwed into collector.

3. Collector compression unions connecting air vent,

pressure relief valve and components installed, two 1

1/2" holes drilled into roof for hot feed and cool return

lines. Shingles trimmed and "Roof Boots" installed

under shingles and into holes. PV panel installed.

4.Collector cool feed (bottom compression union) and

hot return lines (top compression union) installed

through roof boots to tank area. PV wire connected

and run to water heater area. Insulation partly installed

before tubing connections are made. PV panel

installed.

5. Water Heater Element turned off, water drained,

lower drain removed, Rheem 80 gallon Heat

Exchanger tank installed with Mixing Valve. Water

lines connected including installation of the Mixing

valve. Brass Solar lines with valves connected to heat

exchanger top and bottom. Pump, pressure gauge and

expansion tank installed. Collector cool feed (from

pump) and hot return lines connected by compression

union.

6. Water heater refilled, solar loop purged of air,

pump wired to PV panel. Glycol loop filled, finish

insulating lines, Fill Tank, Element turned back on.

5.0.

ASSEMBLING THE COLLECTOR

(See Supplemental “Split Kit” Addendum)

COLLECTOR INSTALLATION 6.0.

BE SECURE AND USE CARE!!!

Good procedure suggests that you always secure your

ladder to the gutter so it does not slip. Place blocks in the

gutter so the weight of the ladder does not crush the gutter.

Protect the surface of the gutter with a cloth to prevent

marks.

WALKING ON THE ROOF:

Use soft sole shoes. Walk in the center of the shingle to

prevent knocking off the brittle ends of the shingles. This

care will keep the roof in good condition and prevent

dangerous ball bearing like gravel and tar balls from

making the roof treacherous.

Know how to walk on your roof if it is a special type such

as Tile or Metal, ask your roofer or ask us. For example,

stepping in the center of most Tile roof shingles will break

them.

Always put your weight on the last two (overlapping)

inches of the tile and away from the side that overlaps the

next tile (to avoid chipping off the delicate vertical overlap

strip).

On some shingles, such as “Fire-Free”, or shake, more

damage is done stepping on the end than in stepping on the

center. Shake roofs are usually easy to walk on but use

care on shake roofs to not crack or break off brittle shakes.

Shake roofs, as well as most roofs, can be treacherous

when wet.

As the 20-01 collector is 12’ long, it is important to place

the line connection end so it is the shortest distance from

the storage tank.

The collector can be flipped either way to be closest to

your storage area. Remember that the feed line from the

pump goes to the bottom collector connection and the hot

return goes to the top collector connection as shown in the

diagrams.

On an average, low pitch single story roof, one able person

can safely install the Skyline collector. Do not install this

system alone, be sure someone knows where you are

and what you are doing at all times.

The 20-01 collector is 12 feet long, only 20 inches wide

and under 38 pounds, making it an ideal size and weight

for one person to lean against the roof or gutter, go up the

ladder and simply pick up the collector and pull up onto

the roof.

Collector installation Components:

Note 10-01 collectors will have 2 sets of collector brackets instead of 3

It is important to not over-

tighten these fittings.

Spraying a little silicone on

the threads is helpful.

A couple of turns of Teflon

tape around the ring helps

make sealing easier.

½’ OD Compression

Union and Ell

Compression Ell

Nut with Ring Inside

Tube

must extend beyond ring

about

¼” and bottom out inside the

compression

body

before tightening

nut

Nut, Ring, Union Body

PV Parts Bag contains PV

switch Brackets and

hardware. See 9.0,

Control Component

Detail.

Roof Kit contains:

Mounting Ells and washers,

3.5 or 4” Lags,

Center U Brackets for 2 or

more collectors,

Color coded Tec Screws for

securing Ell brackets and U

brackets to collector,

Low profile Roof Boots.

Plumbing Kit:

50’ of ½” OD Copper,

Pressure Relief,

Coin (air) vent,

Soldered adaptor,

Compression fittings,

1 Compression union

body per extra

collector,

2 compression unions

to connect tubing to

tank.

Important Instructions Regarding Installing Compression Unions

Collectors mount horizontally and Collector Mounting Rails go as shown below.

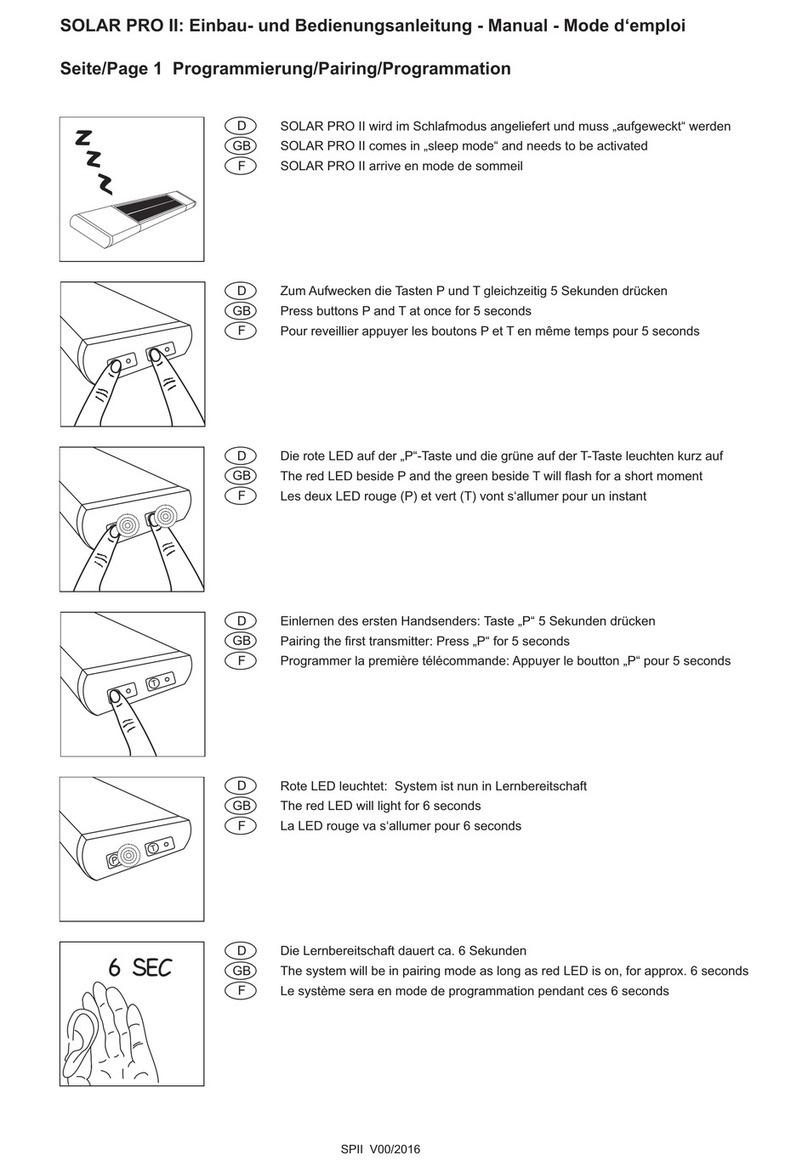

Two Collector 20-01 Top View

(10-01 collectors use 2 rails about 1’ in from the ends)

The Diagram above is a top view of two collectors installed together showing:

1. Two 20" x 12'Collectors mounted with connections to the right.

2. The Mounting Rails with Mounting Brackets (3 rails and 6 Mounting Brackets plus 3 Quick Connect Clips (QCC)

per additional collector set (6.), 3 two panel rails, 6 Mounting Brackets and 3 QCCs shown in this diagram).

2A. Mounting Rail Lag holes top and bottom.

3. The "Hot Out" Collector connection going to the storage tank.

4. The between Collector connection.

5. The "Cold In" Collector connection from the storage tank.

6. The Quick Connect Clip bolts to the mounting rail here with the tabs overlapping the top of the collector.

7. Collector Glazing (Lexan)

8. Collector trim sections.

2

7

8

3

4

5

6

1

1

2A

Above: Allowing from 14” to 2’ for collector overhang, find and mark Rafters for the Three Collector Rails,

(shown in this picture are 3 rails for 3 collectors) Use a chalk line to get the 3 rails even at the bottom. Get the

center rail as close to center between the end rails as possible. Using a hammer to “Sound Out” the rafters

usually finds the rafters. If not, use a feeler bit (long small drill) to drill through the roof from the inside, just

beside the rafter. Be sure to squeeze calk into all holes to seal them!

Pre-Drill the bottom holes for the 2 end rails (which will be about 8’ apart – you can use the lag itself to “pre

drill”), squeeze Caulk into Lag Hole, Place end mounting rail with mounting bracket and washer over hole

(above left). Drive Lags into holes but do not tighten. Carefully place the center rail along the chalk line, repeat

the proceedure for the end rails. Install the upper lags using the same proceedure. Note: )ne and two collector

systems have lags at the top and bottom of the rails. Three and four collectors use a center lag at the center of

the end rails only. Other Quick connect clips use a carrage bolt.

2001 Side View

The above Diagram shows a side view of the Collector installed on the roof and shows:

(Refer to Color Pictures for Details of Ell Brackets)

1. Side view of a Collector.

2. Mounting Rails (3 per 20-01 collector).

2A. Mounting Rail Lag.

2B. Roof sheathing.

2C. Roof Rafter.

3. Collector feed or return connection.

8. Collector Trim.

LAGS AND RAFTERS:

For maximum strength, you want your mounting rail (2) lags (2A) to go into rafters. After locating the best area for

the collector, “sound out” the roof for the rafters with a hammer and mark the rafter centers with chalk. On thick roofs,

such as shake, you may need to drill a small hole from the underside of the roof next to the rafter to locate it from the

roof and use measurements from thereon. On thin composition roofs, a good stud finder can be very helpful in finding

the center of the studs.

It is best to “run the lag into the roof once, remove it, then fill the hole with caulk and run the lag with washer

back in and tighten.

Some installers like to pre-drill the hole with a smaller bit than the lag to prevent cracking shake shingles.

The Easy Way, (avoids having to locate rafters):

In areas with average wind conditions, (Highest winds

up to 75 MPH) the light weight of the collector allows

you to use “Hollow Wall Expanding Anchors.”

If using this method, be sure to use the ¼” size bolt.

Drill a ½’ hole through the sheathing to allow for the

thickness of the anchor. Place the anchor in the hole,

pull the nut end up, using the supplied ¼” bolt, until it

is tight, but do not over tighten!

Expanding Anchor Tile Roof Installations: (be

prepared to get longer ¼ / 20 bolts)

NOTE: Correct placement of the collectors on tile is

very important. Look for the best locations for the rails

so the collector will not bottom out or “Rock.” Do not

drill through 2 tiles and do not drill to close to the edge

to prevent cracking.

Holes drilled about 3” – 4” in from the end of the tile

are usually the best locations. This allows the hole to

be only through one tile and closer to the stronger

overlap. Relocate holes in the rail as needed. The

collector can go over lag heads in the rail.

The expanding anchor can make tile roof installations

much easier. On flat tile, a spanner tube usually is not

needed, just be sure to not over tighten the anchor bolt.

On barrel tile, make a spanner tube out of ½” conduit,

copper tube or other sturdy material, drill a hole just

large enough to fit the tube through the tile, with it

sticking up about ¼” when seated on the Anchor base.

Drill a ½” hole through the sheathing (if you happen to

hit a rafter, use a lag). Lift up the end of the tile and

place the anchor in the hole and tighten to seat it

securely in place.

1

8

3

2B2A 2C

2

Hollow Wall

Expanding Anchor

GETTING THE COLLECTOR ONTO THE

ROOF:

Use wisdom, when pulling collectors up onto the roof,

have the collector at a good angle to the roof (out at the

bottom). Protecting the gutter with a heavy cloth may be

a good idea. Do not lean over the edge of the roof at all,

simply pull and leverage the collector up onto the roof.

The assembled collector is very sturdy but avoid

“twisting” it.

If the edge of the roof is over 10 feet from the ground, the

bottom of the collector may be placed on a sturdy object

or someone may be needed to boost the collector up to

you.

On two story houses we strongly recommend two

people for safety.

A sling can be made with sturdy rope going all the way

around the bottom of the collector with shorter pieces

going around the collector to secure the rope in place. Be

sure to secure it very well and always have a secure safety

rope you can grab onto. Have the second person push

the collector up the ladder while it is pulled at the top.

Protect Edge of Roof with a Tarp

and Lean Collector Against Roof

Keeping your body weight over

the Roof, pull the Collector Up

Move Up the Roof as you Pull

the Collector Up a Foot or so at a

Time.

Balance the Collector in

the Center and Carry to

Installation Area.

Mounting

Rail

Ell Bracket

A NOTE ON MAKING TUBE

CONNECTIONS:

The tube connections top and bottom shown in top

view as 3 & 5, are made at the top and bottom of ONE

end of the collector. The connections can be at either

end of the collector simply by placing the collector

end left or right. When two or more collectors are

used they also connect at the same end (4).

Make sure you do not have a rafter

directly under the collector feed as the

feed hole is 1 and ½ inches below and in

from the end of the collector.

MOUNTING RAIL AND MOUNTING

BRACKET INSTALLATION STARTING

WITH SINGLE COLLECTOR:

A single 20-01 collector is attached to the roof by

three "mounting rails and 6 mounting Ell brackets"

(2).

Position the Ell bracket

between the

trim and frame so it is CENTERED

over the Lag hole.

Install the collector

onto the rails with the mounting bracket tab

UNDER the trim and BETWEEN the frame.

The small bend at the bottom of the trim makes

inserting the mounting bracket easy. Be sure to

press the collector all the way down on the

mounting rail and secure with two 1/4” color

coded self tap screws evenly just above the

small bend in the trim.

Be sure to catch the tab

with both screws!

Above: Complete Collector mounting kit

for 2 collectors. 3 Ell brackets bottom,

three U bracket sets per additional

collector and 3 Ell brackets top.

Note: 10

-01 collector has 2 sets of each.

Above: Top Ell Bracket in place and

ready for top collector to be installed.

Two, Three and Four Panel Mounting Rails and

Tilt Kit (two collector maximum per tilt kit):

For installing two to four collectors or when two

collectors are installed on the optional tilt rack, a

special Quick Mount clip (6) is used between the

collectors to firmly hold them onto the mounting rail.

All holes are predrilled. With a tilt kit sets of 1/4"

nuts, bolts and washers are supplied as needed in

addition to lags to bolt the tilt kit together and secure

the angle brackets.

The Quick Mount clip allows mounting of two

collectors on the two panel-mounting rail or the

heavy-duty tilt rail without needing to screw a

mounting bracket tab into the side of the collector.

The U shaped clip with outward tabs that go over the

edge of the two collectors is secured with a bolt in the

center. In high wind areas, it is recommended that the

clips be Tec screwed into the frame through the

glazing with 2 screws.

Notes on Two, Three and Four Collector Flush

Mount Installations:

Place the first collector in place with mounting

bracket tabs inserted for final assembly. Tighten

down the lags. Place three Quick Mount clips in place

over their rail lag hole locations. Partially install the

lags to hold the clips loosely in place. (you will need

an extension to your lag driver to get between the

collectors). Slip the next collector under the clips,

connect the compression unions (4) so alignment is

assured and then tighten down the lags. Repeat until

all collectors are installed.

Quick Connect Clips

(QCC’s) are supplied

in One or Two pieces

with the single piece

shown. Shown, in the

top right above, laid

out as to how they will

go and individually to

the left next to the rail

with carriage bolt.

It is

easiest to remove the

nu

t before placing the

collectors on the rails.

Being sure the trim is pushed in, secure the U

bracket at the top on both sides with 2 tec screws

going through the bracket, trim and glazing. This

makes a very strong connection.

Line up the collectors so the center union body

can be installed. Secure the nut to the outside

while it is still on the ground so it is not “lost”

inside the collector.

FLASHING IN UNDER SHINGLES

For Tile and other roofs, consult with the Factory.

For Composition and Cedar Shake Installation:

ACRSI supplies two special roof “Flashings” which

are used to make a waterproof seal for the solar

collector feed and return lines. These flashings easily

slip under a composition or shake shingle with

minimum cutting.

The tubing hole is large enough for the 1/2” od copper

pipe to easily slip through and the small space left can

be easily sealed with caulk and further covered with

insulation. The base of the flashing can flex and be

moved in different directions.

The 6” aluminum base is usually large enough to

make a watertight seal and can easily be flashed over

by a larger aluminum sheet when needed. It is

recommended that a 1 ½” hole be drilled for the

tubing hole.

“Roof Boot” Flashing and Waterproofing Details

The 2 aluminum flashings supplied with the system

are easily installed but require careful alignment to

assure a good fit. It is recommended that up to a 1½ “

hole be drilled to give “working room” when

installing the roof boot. Spacers are included with

flush kits to make boot installation easier. Pre-fit

roof connections prior to drilling (see Section 8, top

and bottom connections).

NOTE: sound out your roof to be sure no rafters

are under where holes will need to be drilled!

Preposition the roof boot where it will go when the

pipes are connected to the compression 90 in its final

“out” position. Mark the center of the hole, remove

the fitting and place out of the way. Using a 1 ½”

hole saw or paddle bit, drill the hole. Carefully pry up

the shingle and slip the Roof Boot under the shingle

so water will freely flow over the roof boot.

If needed, add aluminum flashing to assure a

watertight installation (especially needed with Cedar

Shake). Caulk the sides as needed and it is good to

put two roofing nails in the bottom of the boot to

secure it AFTER the pipes are installed and fully

secured.

Roofing nails

(last)

Roof Boot Hole Cut in shingle Roof Boot Flashing under shingle

Note that Roof Boot is UNDER the shingles at the top and most of the sides so water flows over the top.

The shingle is cut down from where the hole is drilled.

Drill a 1 ½” hole 1 ½” in and centered

2” below the edge of the collector.

Slip flashing under shingles.

Use a “lifting Tool” with smooth edges to go

under and lift the shingle without cutting it.

Lift shingles before installing collectors.

Properly placed, the feed line is right

above the flashing tube hole.

The edge of the collector is 1 ½” above

the lower edge of the rails.

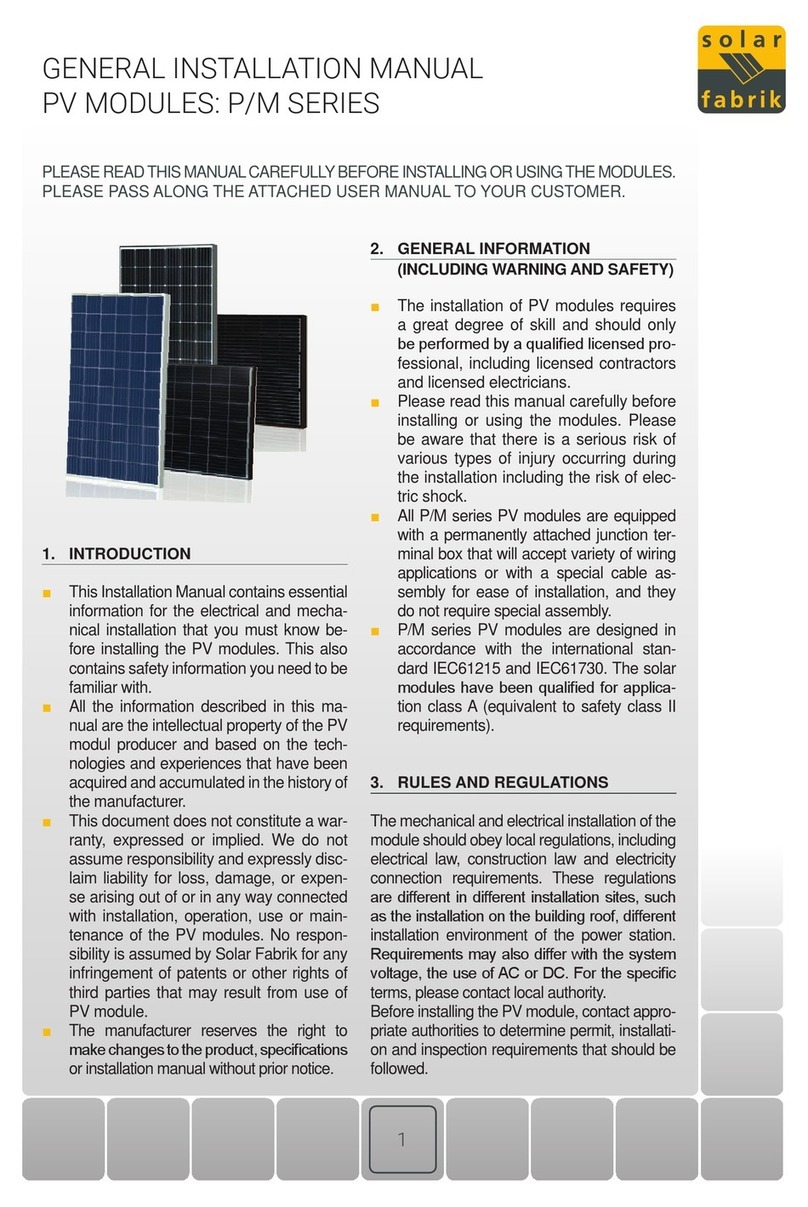

SC01 Stacked Array Installation Kit

Loosely assemble your kit, per the following pictures, to locate the exact location of your

roof penetrations and then follow the flashing and roof boot installation instructions.

Feed Ell from Pump

SC01 - Stacked Collector

Array Installation Kit

Pre-soldered adaptor for

Pressure Relief Valve

and Coin Vent

Coin Vent

2” stick of ½” OD copper

Assembled SC01

Stacked Collector

Array

1 compression Ell for the feed. Bottom Roof “Boot”

Top roof “Boot”

150 Lb

pressure relief

valve

(PRV)

1 compression

TEE, to collector

1 compression

Ell for the

Collector Hot

Return

One union body

is supplied per

additional

system

collector.

IMPORTANT:

Be sure the

union body is

fully in place

before

tightening any

Lags, Bolts or

Tec screws.

Solar Hot

Return to

Tank

The SSC1 is the same as SC01 with addition of a

Tee and 2” stick of copper for 2

nd

collector.

IMPORTANT SSC1 TIP:

Before installing the last Left collector, lift shingle for

the flashing to go under See: “Roof Boot” Flashing and Waterproofing Details.

SSC1 Side by Side Collector Installation Kit

The SSC1 Feed has an

additional Ell,

2 copper sticks

and a

Tee for the second collector.

7.0.

DETERMINE THE BEST PIPE RUN

COORDINATE THE PIPE RUN WITH THE BEST SOUTH FACING COLLECTOR LOCATION

FOR THE SHORTEST RUN.

IMPORTANT: SLOPE all lines to DRAIN! It is important that all pipes between the collectors maintain a 1/4"

per foot drop to prevent traps and assure that all fluid drains when the drain valves are opened.

COMMON RUNS

In many one-story homes, the run is a simple matter of

going up into the garage rafter area and to the roof or

going through a wall or ceiling into the attic.

Common pipe runs to the basement include runs adjacent

to air return chases, plumbing and vent lines and through

closets. In a two story house runs can be challenging;

however, it is amazing how often a good solution is at

hand.

CHASES: Look for pipe, fireplace and duct chases with

room around them. The pipes can often be dropped

down next to a duct, especially in a one-story house, in

just a few minutes.

CLOSETS: Sometimes the easiest way to run the pipes

is through closets (look for "stacked" closets in a two-

story house). Since 1/2” copper pipes are fairly flexible,

drilling through even many shelves with an angle drill is

easy as alignment does not have to be precise.

NOTE: Copper pipes get harder, even brittle with

multiple bending, bend your pipe as little as possible

for the easiest installation! Unroll the soft copper in

smooth even strokes and be sure the connections for

the collector are above the roofline so no water could

get into the house if the connection leaks.

DRYWALL: It is sometimes necessary to cut drywall

at the floor or ceiling level in order to cut the holes in a

fire stop. Usually this hole can be made out of sight in a

closet. After sealing the fire-stop, it may be desirable to

make the remaining drywall removable by putting a

simple frame around it and placing it back in place with

a few finish nails.

INFILTRATION AND FIRE STOPS: In all

situations, remember that infiltration is one of the main

sources of energy loss in a house. In no way should the

installation of a solar system contribute to this loss!

ALWAYS seal up any holes made in the house envelope

especially in the attic and fire stops. Fire stops must be

properly put back in place so their important function is

preserved. Converting to copper pipe for two feet on

either side of the firestop may be required in some areas.

STORAGE: You will need to purchase a ‘Rheem

Storage Tank, 80 Gallon with heat exchanger, Model #

RH-81V080HE1.

You will need room to work around it and space for the

solar hardware, usually a foot on the drain side of the

heater is adequate. Install the tank connection

components.

The Rheem Storage Tank is equipped with a top element

only. To enhance your DHW efficiency, during the

winter, first try using low flow showerheads and aerators

and/or add a 220v switch to the top element. Another

good plan is to use a 220v timer set to heat the water for

two hours before you get up in the morning and for two

hours before you get home from work.

Try turning the power off during sunny summer days.

You should have ample Hot water with 2 panel for a

family of 3 and with 3 panels for a family of 4 or 5 on

clear summer days.

INSULATION: INSULATION OF EXPOSED

COPPER PIPES IS NEEDED. A MINIMUM 1/2"

R-2.6 (closed-cell insulation)* IS NEEDED AND 3/4”

R-4.5 OR BETTER IS RECOMMENDED. Check your

state and local codes to see if any greater thickness is

required ESPECIALLY IF REBATES OR

INCENTIVES ARE INVOLVED.

This manual suits for next models

2

Table of contents

Popular Solar Panel manuals by other brands

PREFORMED LINE PRODUCTS

PREFORMED LINE PRODUCTS POWER RAIL 60 Cell Assembly instructions

REC

REC REC265 Series installation manual

AEROCOMPACT

AEROCOMPACT CompactFLAT SN10plus Assembly instructions

Kyocera

Kyocera KK Series Assembly and maintenance instructions

Motech

Motech XS60GB-315 installation manual

Sharp

Sharp ND-255QCS Installation and user manual