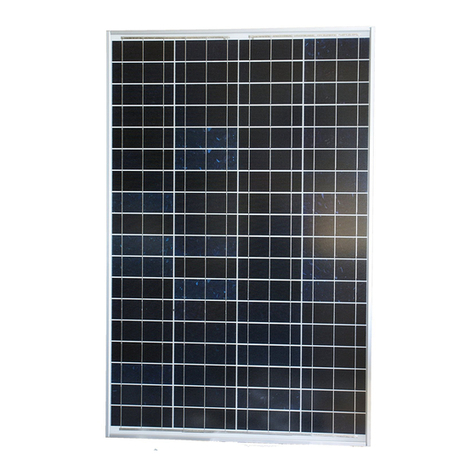

1) Series: MC4

Made by Multi Contact (www.multi-contact.com)

Pole Positive Negative

Model PV-KBT4/6Ⅱ-UR PV-KST4/6Ⅱ-UR

Symbol +-

Figure

2) Series: MC4-EVO3

Made by Multi Contact (www.multi-contact.com)

Pole Positive Negative

Model PVMC4PLS-XX PVMC4PLS-XX

Symbol + -

Figure

3) Series:H4 UTX

Made by Amphenol (www.amphenol.com)

Pole Positive Negative

Model H4 UTX H4 UTX

Symbol + -

Figure

NOTE: When making connections with the connectors,

make sure the array is disabled. DO NOT MAKE

CONNECTIONS WHILE UNDER LOAD.Module output

connections are marked “Do not disconnect under load”.

NOTE: MAXIMUM SYSTEM VOLTAGE IS 1000 VDC.

The PV module and most PV system components have a

maximum system voltage rating of 1000 volts DC. Some

grid-tie systems operate at or near this voltage rating. Like

other polycrystalline PV modules, the open-circuit voltage

of the PV modules increases as the ambient temperature

decreases. Maximum system voltage is computed as the

sum of the open-circuit voltage of the series-connected PV

modules for the lowest expected ambient temperature.

Refer to the National Electrical Code Article 690-7(A) for

determining the maximum number of the PV module that

can be placed

in series. Temperature coefficients, specific

to the module of use, can be used to provide the most

accurate prediction of module voltage under temperature

extremes.

NOTE: Limit the maximum number of series connection of

the PV module so that the system voltage is 1000V or less.

NOTE: Do not connect the modules in parallel without

maximum over current protection.

NOTE: The minimum radius that the cable can be bent for

the PV module is 1.14” (29mm).

NOTE: Under normal conditions, PV module is likely to

experience conditions that produce more current and/or

voltage than reported at standard test conditions. The

requirements of the National Electrical Code (NEC) in

Article 690 shall be followed to address these increased

outputs. In installations not under the requirements of the

NEC, the values of ISC and VOC marked on this module

should be multiplied by a factor of 1.25 when determining

component voltage ratings, conductor ampacities,

overcurrent device ratings, and size of controls connected

to the PV output.

8. GROUNDING

Before installation, consult the local codes and the

authorities having jurisdiction to determine the necessary

grounding requirements. When installing in the US market,

attach all PV module frames to an earth ground in

accordance with the National Electrical Code (NEC) Article

250. Proper grounding is achieved by connecting PV

module frames and all metallic structural members

contiguously to one another using a suitable grounding

conductor. The grounding conductor shall be of copper,

copper alloy or another material suitable for use as an

electrical conductor per NEC. The grounding conductor

must then make a connection to earth using a suitable earth

grounding electrode. Ensure positive electrical contact

through the anodizing on the module frame extrusion by

utilizing one of the following methods.

Attach the grounding conductor:

(1) to one of the .28” (7mm) diameter holes marked

“ground” using 1/4”(6mm) stainless steel bolt. Wrap

conductor around bolt. Tighten the screws with

adequate torque (62 in-lb: UL evaluation torque).

(2) to a ground lug (manufacturer:ILSCO, model:GBL-

4DBT). The lug is attached to one of the .28”(7mm)

diameter holes marked “ground”, using #10-32

stainless steel bolt with 40 in-lb torque.

(3) to a ground lug (manufacturer:ILSCO, model:GBL-

4DBT). The lug is attached to one of the .16”(4mm)

diameter holes marked “ground”, using #10-32

stainless steel tapping machine screw with 30 in-lb

torque. Screw length should be 1/2"(12.7mm) or less.

(4) to a wire bolt (manufacturer:Tyco, model:2058729-1)

using 3/8”(10mm) wire biding nut with 45 in-lb torque.

The bolt is attached to one of the .19”(4.7mm) diameter

holes marked “ground”, using #8-32 (4mm) mounting

washer nut with 25 in-lb torque.

NOTE: A stainless steel star washer or mounting washer

nut, having contact with anodized surface of the frame,

must be employed to break through the anodized layer of

the frame extrusion and electrically connect the grounding

conductor to the conducting aluminum frame material.

NOTE: As a general rule, avoid direct contact of copper or

copper alloy ground conductors with the aluminum frame to

prevent galvanic corrosion. All ground bond securing

hardware in contact with either the aluminum module frame

and/or copper or copper alloy ground conductors must be

stainless steel.

NOTE: Where common grounding hardware (nuts, bolts,

star washers, spring-ring lock washers, flat washers and

like that) is used to attach a listed grounding/bonding device,

the attachment must be made in conformance with the

grounding device manufacturer's instructions.

NOTE: Common hardware items such as nuts, bolts,

star-washers, lock washers and the like have not been

evaluated for electrical conductivity or for use as grounding

devices and should be used only for maintaining

mechanical connections and holding electrical grounding

devices in the proper position for electrical conductivity.

Such devices, where supplied with the module and

evaluated through the requirement in UL 1703, may be

used for grounding connections in accordance with the

instructions provided with the module.