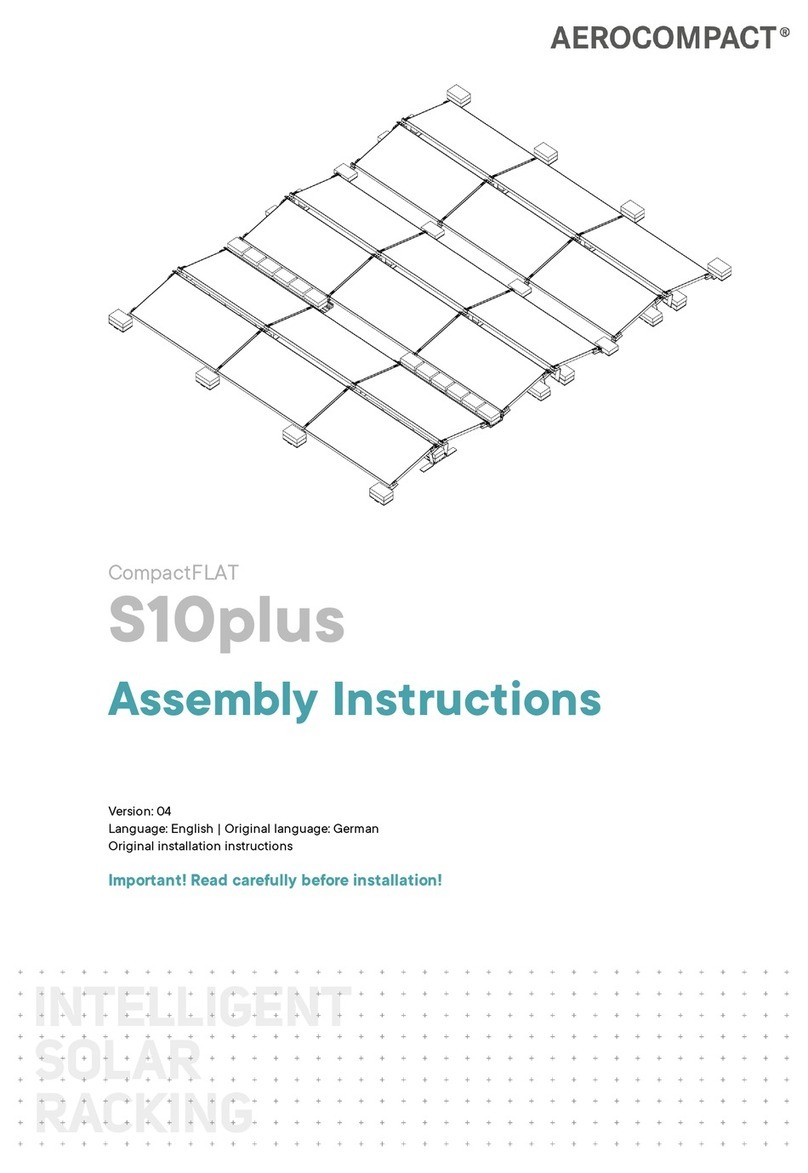

SN10plus longside

About This Document

www.aerocompact.com 7

Guarantee

The warranty period for the system is 25 years. The warranty period for galvanized steel parts is 10 years. The

guarantee is only valid if the installation is carried out professionally and all system components are pur-

chased from Aerocompact. If the assembly instructions or the planning documents are disregarded, the war-

ranty will be invalidated.

Photovoltaic racking systems are not maintenance-free. Carry out maintenance annually and immediately

after unusual weather events, e.g., after heavy storms or heavy snowfall, etc. If the maintenance is not carried

out at the specified interval, the warranty will become void.

General information on liability

We would like to point out that the flat roof system is being sold as part of a sales contract. Assembly/-

processing by the purchaser or third parties is not carried out on behalf of or for Aerocompact and must be

carried out by qualified personnel strictly in accordance with the assembly instructions. The Aerocompact

system must be designed and planned with the AEROTOOL software. Aerocompact is not responsible for the

project-related statics of the roof structure, for obtaining and documenting the roof manufacturer's

approval for the installation of the corresponding fasteners on the respective roof (in terms of warranties),

nor for the professional execution.

Errors and damage as well as limited or insufficient functionality of the system due to incorrect installation

and/or installation that deviates from the installation instructions and/or the project report (AEROTOOL)

exclude any material defect for which Aerocompact is responsible. In the event of improper handling, the

rights of the buyer due to a material defect shall expire. The system warranty is only valid if all system com-

ponents are purchased from Aerocompact.

Systems with clamping on the short side of the module

For a system with a clamp on the short side of the module, it is assumed that the module may also be used

with this installation method (clamp on the short sides of the module). This approval can either be generally

available as part of the module certification or, under certain circumstances, can also be given by the mod-

ule manufacturer on a project-specific basis.

Systems with roof protection pads

The roof protection pad included in the scope of delivery is matched to the roof surface defined in the pro-

ject. Due to the many available roof surfaces on the market, the responsible designer should ensure the com-

patibility of and the coefficient of static friction between the protection pad and the roof surface of the

building used in the design. The friction value is determined during the planning process with a coefficient

of friction test.

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+