SOLAREG II Energy HE User manual

Controller unit for solar thermal systems

Energy HE

Installation and operating instructions

English version of original German installation and operating instructions

Version: 1.0

April 201

Terminology

In order to facilitate the use of the assembly and operating instructions, the

following terminology will be used:

•These installation and operating instructions will hereinafter be designated as

"Instructions".

•The Energy HE controller will hereinafter be designated as "Controller".

•The thermal solar power plant will hereinafter be designated as "Solar power

plant".

•Freely definable Prozeda function modules, complete with selectable inputs

and outputs, will hereinafter be designated as "Multi-function controllers"

(MFC).

•Prozeda GmbH will hereinafter be designated as the "Manufacturer".

Declaration of conformity

The product complies with the regulatory requirements and standards on CE

conformity and therefore carries the CE mark.

This manual is designed to help you use the controller properly, safely and economically.

This manual represents only a part of the installation and operating instructions.

Read the document Menus and controller functions before making any settings on

the controller.

Target group

This manual is addressed to all persons who carry out any of the following tasks:

Installing the controller

Connecting the controller

Putting the controller into operation

Setting the controller

aintaining the solar power system

Eliminating faults on the controller and the solar power system

Disposing of the controller

These persons must have the following knowledge and skills:

Knowledge about establishing electrical connections

Knowledge about the hydraulic operation of solar power systems

Knowledge of the applicable regulations at the point of use and the ability to apply them

These persons must have read and understood the contents of this manual.

Availability

This manual is part of the controller. Always keep it in an easily accessible location. Include

this manual with the controller should the controller change hands.

If this manual gets lost or becomes unusable, you can contact the manufacturer for a new

copy.

Style conventions used in the text

Specific style conventions are assigned to different elements in the manual. This makes it

easy to recognise the type of text concerned:

Standard text,

" enu", " enu item", "Button designations",

lists and

actions.

Notes accompanied by this symbol contain information about how to operate the

controller economically.

Style conventions for hazard warnings

This manual makes reference to the following categories of hazard warnings:

DANGER

Information or instructions accompanied by the word DANGER provide a

warning about a hazardous situation that will lead to fatal or serious

injuries.

ARNING

Information or instructions accompanied by the word WARNING provide a

warning about a hazardous situation that may possibly lead to fatal or

serious injuries.

CAUTION

Information or instructions accompanied by the word CAUTION provide a

warning about a situation that can lead to minor or moderate injuries.

Style conventions for warnings of damage to property or

the environment

ATTENTION

Information and instructions of this kind provide a warning about a

situation that can lead to damage to property or the environment.

Table of contents

1

Safety ........................................................................................................................ 7

1.1

Proper use .............................................................................................................................................. 7

1.2

Basic safety information .................................................................................................................... 7

2

Description of the controller ................................................................................... 9

2.1

Overview ................................................................................................................................................. 9

3

Installing the controller ......................................................................................... 10

3.1

Opening the device ........................................................................................................................... 11

3.2

Fastening the controller .................................................................................................................. 11

4

Connecting the controller ..................................................................................... 12

4.1

Connecting cables to the controller ............................................................................................ 12

4.2

Connecting the controller to the power supply....................................................................... 14

4.3

Connecting temperature sensors ................................................................................................. 14

5

Operating the controller........................................................................................ 16

5.1

Description of the display elements ............................................................................................ 16

5.2

Using the operating buttons .......................................................................................................... 18

6

Menus and controller functions ............................................................................ 19

6.1

Displaying values in the "Info" menu ........................................................................................... 19

6.2

Displaying and changing values in the "Program" menu ..................................................... 21

6.3

Controlling switching outputs in the " anual mode" menu ............................................... 22

6.4

Displaying and changing values in the "Basic settings" menu ............................................ 23

7

Setting the general controller functions .............................................................. 25

7.1

inimum collector temperature................................................................................................... 25

7.2

Setting the pump control system ................................................................................................. 25

7.3

Setting the "Tube collector" function .......................................................................................... 27

8

Setting the multi-function controller (MFC) ......................................................... 27

8.1

Setting the "Cooling" function ....................................................................................................... 27

8.2

Setting the "Heating" function ...................................................................................................... 27

9

Setting protective functions ................................................................................. 28

9.1

Setting the "Collector protection" function ............................................................................... 28

9.2

"System protection" function ......................................................................................................... 28

9.3

Setting the "Recooling" function .................................................................................................. 29

10

Measuring the energy yield ................................................................................... 29

10.1

DFG (flow sensor) ............................................................................................................................... 29

11

Faults ...................................................................................................................... 30

11.1

Faults with fault message ................................................................................................................ 30

11.2

Faults without fault message ......................................................................................................... 32

12

Technical data ........................................................................................................ 34

13

Accessories ............................................................................................................. 35

14

Disposing of the controller .................................................................................... 35

Safety

7

1Safety

This chapter contains information on:

•the proper use of the controller and

•the safe use of the controller.

Read this chapter through carefully before you install, connect or operate the controller.

1.1 Proper use

The controller is used for monitoring and controlling a solar thermal system.

Appropriate use of the controller includes the following requirements:

•Use the controller exclusively in dry rooms in residential, commercial and/or industrial

environments.

•Use only sensor connection boxes supplied by the manufacturer.

The definition of proper use also encompasses observing and complying with all of the

information contained in this manual - in particular compliance with all safety information

and instructions.

Any other use, or any use exceeding the specifications, will be deemed to be improper use

and may lead to personal injury or damage to property and shall render the warranty void.

Use of the controller in the following situations in particular is considered to be improper

use:

•If you modify the controller independently and without prior authorisation

•If you operate the controller in a humid or wet environment

The manufacturer shall not be liable for damages arising from inappropriate use.

1.2 Basic safety information

This section contains basic safety information relating to working with the controller. You

will find additional safety information relating to specific actions and workflows at the

beginning of the section concerned.

Preventing risks of explosion

•Never use the unit in areas where there is a risk of explosion.

Safety

8

Preventing risks of fatal injury from electric shocks

•ake sure that all regulations applicable at the point of use are complied with.

•Always make sure that the controller is disconnected from the power supply before

carrying out any work on it.

•ake sure that the connections of the protective extra-low voltage areas do not get

mixed up with the power supply connections.

•On completion of installation work, refit the terminal cover and tighten the locking

screw using a screwdriver.

•ake sure that the electrical connection of the controller can be disconnected from

the mains externally if required.

•ake sure that all cables are secured by strain relief devices.

•Use the device only if it is in a fault-free condition.

Preventing risks of fire

•Install the controller on a non-flammable subsurface.

Preventing risks of injury from burns

•Carry out installation work on the solar power system only when it has cooled down.

•The process water can reach very high temperatures. Exercise particular care when

configuring settings on the controller.

•Take water samples after completion of the settings and check them using a suitable

thermometer.

Preventing damage to property

•A damaged controller may cause malfunctions in the system as well as damage to its

components. Use the controller only if it is in a fault-free condition.

•Install the controller with due observance of its protection class. Information about

this can be found in the chapter Technical Data from page 34 onwards.

•ake sure that no moisture gets into the controller.

•If any moisture gets into the controller, disconnect the controller from the power

supply.

•ake sure that the maximum permissible ambient temperature is not exceeded.

Information about this can be found in the chapter Technical Data from page 34

onwards.

•ake sure that all components to be connected to the switching outputs are suitable

for an operating voltage of 230 V/50 Hz.

Description of the controller

9

•When in "manual mode", the system must only ever be operated for a short time and

only for test purposes.

•Install sensor lines separately from 230 V lines.

•Use only sensor connection boxes supplied by the manufacturer.

2Description of the controller

The controller is used for monitoring and controlling a solar thermal system. The

controller allows the system to be configured in accordance with the local situation at the

place of use and with the requirements of the user. In addition, the controller can be used

to carry out system protection functions.

2.1 Overview

Display

Operating buttons

The display (1) shows the menus for monitoring and controlling the solar power system.

The operating buttons (2) allow you to display and change the parameters.

Installing the controller

10

3Installing the controller

DANGER

Risk of fatal injuries due to explosions or fire.

Never use the controller in areas where there is a risk of explosion.

Install the controller on a non-flammable subsurface.

D

ANGER

Risk of fatal electric shock when working on the opened controller.

ake sure that the controller is disconnected from the mains voltage

before removing the terminal cover.

ake sure that the power supply has been secured to prevent it from

being switched on again.

Check that the controller is free from voltage.

Screw the terminal cover securely back in place when work has been

completed.

ATTENTION

Risk of damage and malfunctions due to improper storage before

connection.

Store the controller at room temperature for at least four hours before

connecting it.

Select an installation location which meets the following requirements:

•The installation location must be at eye level.

•The installation location must be close to the storage tank and the solar circuit pump.

•It must have access to the power supply.

•There must be sufficient space in front of the controller to allow it to be operated.

•If you wish to lead cables and lines through the back of the controller, there must be

sufficient space for the cable gland.

Installing the controller

11

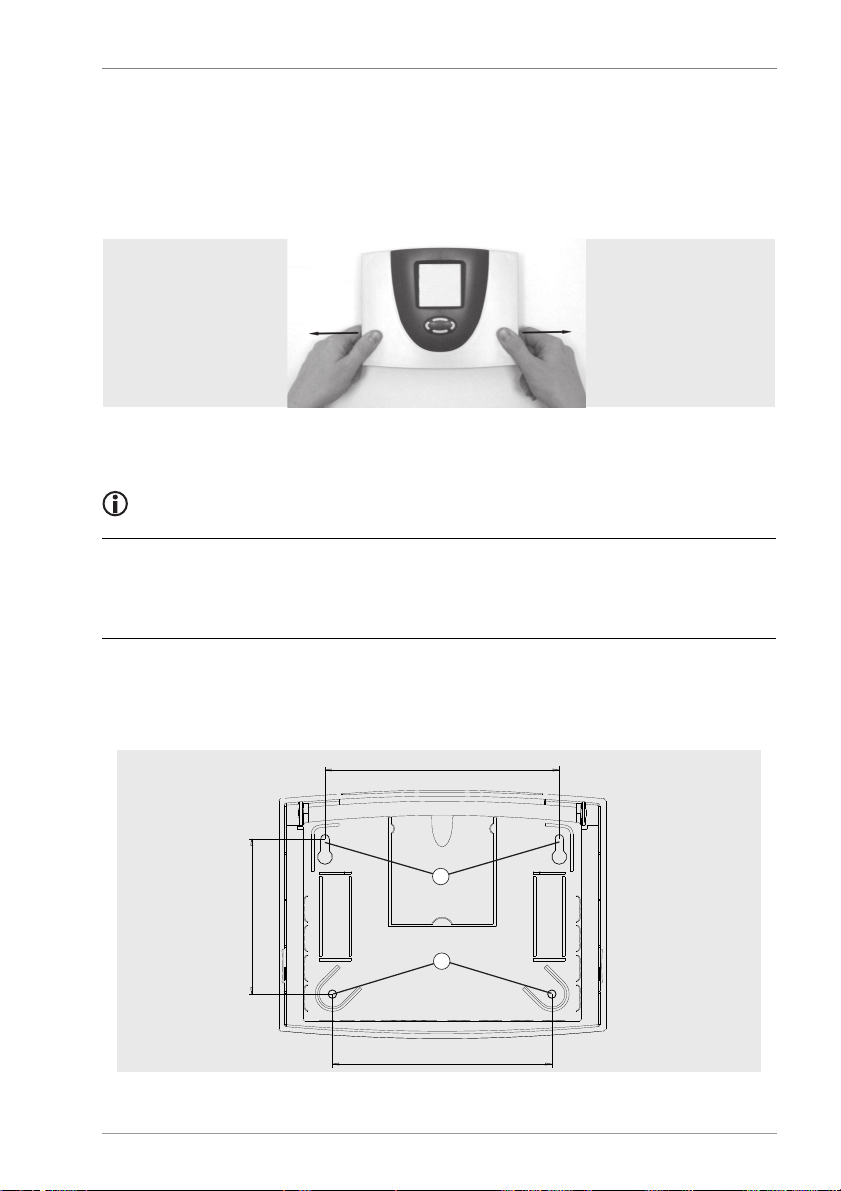

3.1 Opening the device

The upper part of the housing is locked to the lower part using two latches..

Pull the side pieces (cover plates) of the upper part of the housing outwards (see

picture) to unlatch it.

Open upwards until the cover plate snap in place.

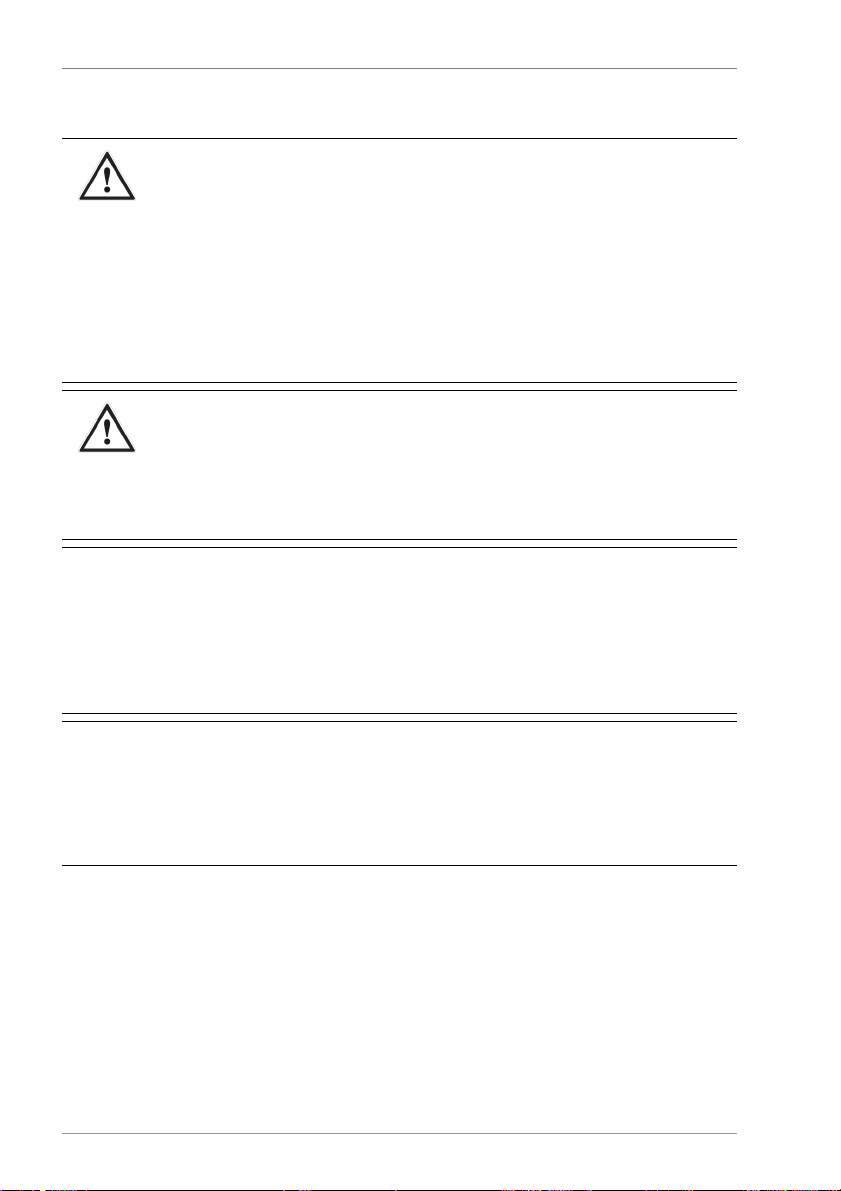

3.2 Fastening the controller

If you wish to lead cables and lines through the back of the controller, you need to

do this before you fasten it.

ATTENTION

Risk of damage to the controller housing due to screws tightened too firmly.

Tighten the screws only as firmly as necessary.

Use only suitable screws and dowels for fastening the controller.

Hang the controller on the top screws by the keyhole (1).

Fasten it with the screws from the inside through the bottom screw holes (2).

126

118

83,75

1

2

Connecting the controller

12

4Connecting the controller

DANGER

Risk of fatal electric shock when working on the opened controller.

ake sure that the controller is disconnected from the mains voltage

before removing the terminal cover.

ake sure that the power supply has been secured to prevent it from

being switched on again.

Check that the controller is free from voltage.

Screw the terminal cover securely back in place when work has been

completed.

DANGER

Risk of fatal electric shock due to ripped out cables.

ake sure that all cables are adequately secured in position by screw

clamps.

ake sure that there is no pull on the cables.

ATTENTION

Risk of damage to the controller and the solar power system due to the

connection of unsuitable system components.

ake sure that the operating voltage of the system components

matches that of the controller. Information about this can be found in

the chapter Technical Data from page 34 onwards.

ATTENTION

Risk of damage and malfunctions due to improper storage before

connection.

Store the controller at room temperature for at least four hours before

connecting it.

4.1 Connecting cables to the controller

ake sure that the cables and the controller are disconnected from the voltage.

Remove the terminal cover.

Connecting the controller

13

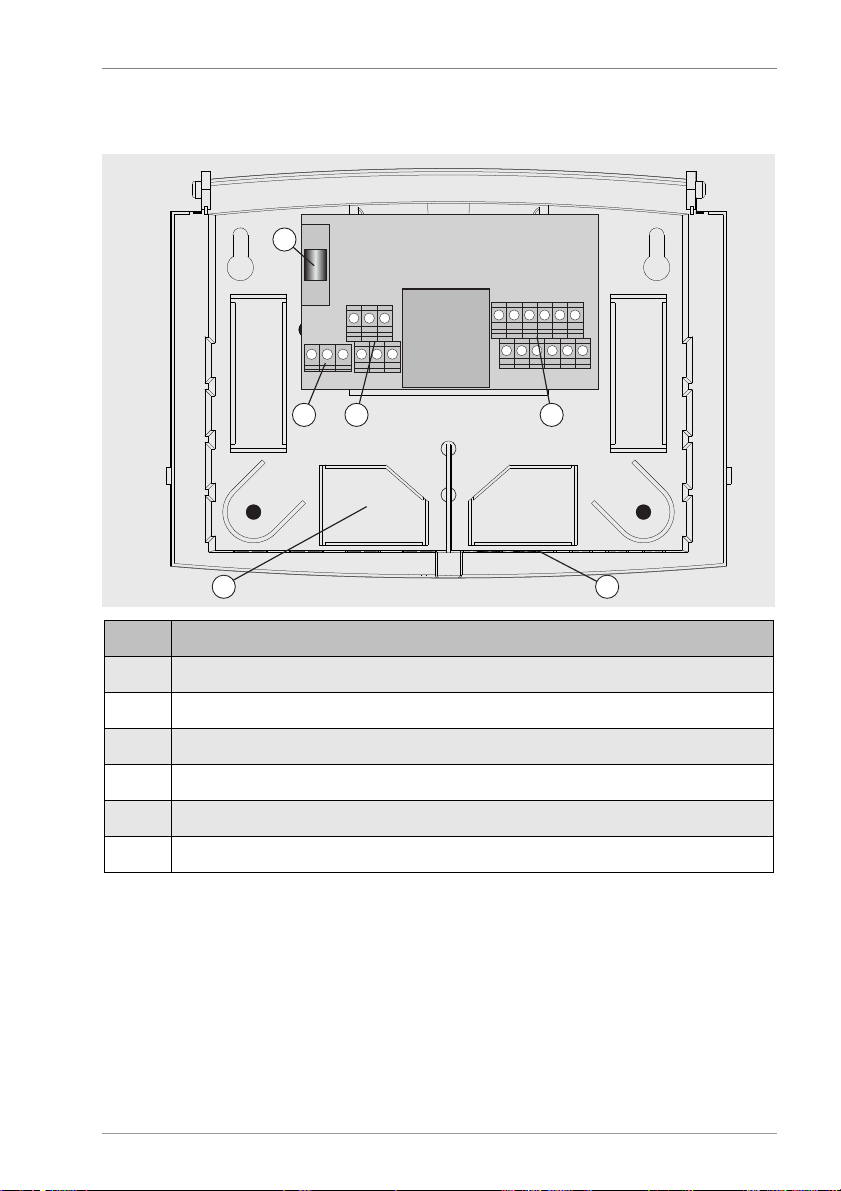

The following illustration shows the elements of the controller that are important for

connection:

1

2 3 4

5 6

Pos.

Description

1

Fuse

2

Terminals for protective conductor

3

Terminals for 230 V area

4

Terminals for extra

-

low voltage area

5

Cut

-

out apertures for cable feedthrough at the back

6

Cut

-

out apertures for cable feedthrough on the underside

Connect the cables to the corresponding terminals.

Information about connecting the system components to the corresponding terminals

can be found in the section Assignment of the terminals to the system components from

page 15 onwards.

Close the cover securely back in place.

Connecting the controller

14

4.2 Connecting the controller to the power supply

When making the mains connection, you must ensure that the mains supply can be

disconnected at any time. If you make a permanent mains connection, proceed as follows:

Install a switch on the supply lead of the controller.

If you make the mains connection complete with cable and earthing pin plug, proceed as

follows:

ake sure that the earthing pin plug is easily accessible.

Plug the earthing pin plug in the plug socket.

4.3 Connecting temperature sensors

ATTENTION

Risk of damage and malfunctions on the controller due to improper

connection of the temperature sensors.

Use only sensor connection boxes supplied by the manufacturer.

Use only shielded cables for line extensions.

Connect the shield of the extension cable to a PE terminal.

Install sensor lines separately from 230 V lines.

Use cables with the following cross-sections for line extensions:

Up to 15 m: 2 × 0.5 mm

2

15 to 50 m: 2 × 0.75 mm

2

When connecting the temperature sensors, you do not need to observe polarity

for the two wires.

Connecting the controller

15

Terminal assignment for the hydraulic layout

Terminal

Use

L

-

N

-

PE

ains

, 230 V

~

R1

-

N

-

PE

Solar circuit pump 1, 230 V connection

HE

–

Power control for

high

-

efficiency pump (HE pump)

230 V power supply for the pump via switching output

R1

S1

-

S1

Te

mperature sensor for collector

S2

-

S2

Tempe

rature sensor for storage tank

bottom

Assignment of the terminals to the system components

The connections in the following table are options that may be used in the hydraulic

layout:

Terminal

Use

S3

–

S3

Connection for PT1000 temperature sensor

S4

–

S4

Temperature sensor of the collector return line for the "Energy yield

measurement" function

S

5

–

Flow sensor

for the "Energy output measurement" function

Operating the controller

16

5Operating the controller

This chapter provides you with an overview of the controller's display elements and

operating elements. This is followed by explanations of all the basic actions.

5.1 Description of the display elements

The following menu symbols are displayed in the top part of the display in the main

menu:

Main menu

Symbol

Description

"Info" menu

This is for displaying measurement and output values and status messages.

"Program" menu

This is for displaying and changing parameters.

"Manual mode" menu

This is for switching outputs on and off for test purposes.

Only specialist personnel are permitted to make changes to the values in this menu.

"Basic settings" menu

This is for displaying and changing basic settings.

Only specialist personnel are permitted to make changes to the values in this menu.

Operating the controller

17

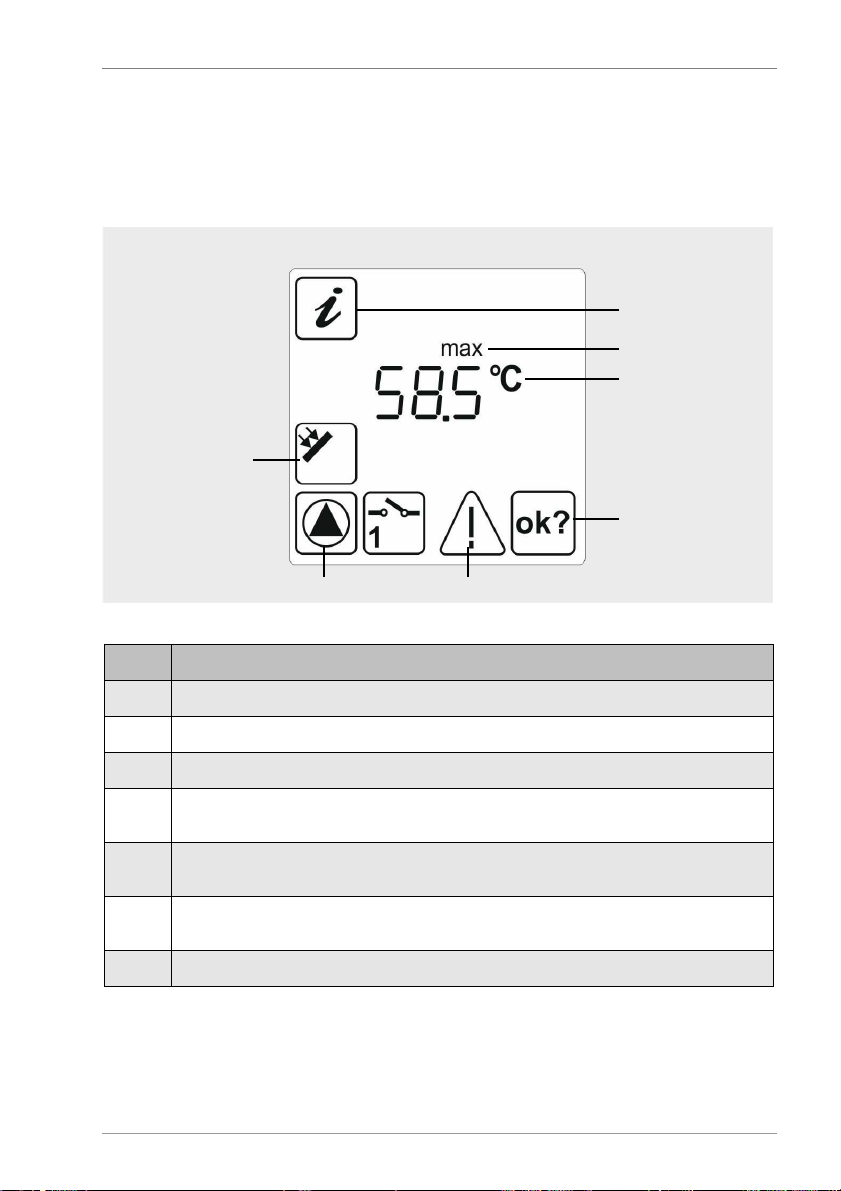

When you have selected a menu, the applicable menu symbol (1) will be displayed. The

bottom section of the screen displays the value (3) complete with a corresponding

addition (2) and a measurement value symbol (7). Below these, status information and

messages may be displayed (4–6), depending on the specific menu item. The following

illustration shows a display screen by way of illustration:

Pos.

Descrip

tion

1

Active menu (In this case: "Info" menu)

2

Addition to the value displayed

3

Value

4

OK symbol

If you make any changes to a value, this symbol flashes.

5

Fault symbol:

This symbol is displayed flashing in the event of a fault.

6

Pump symbol

T

his symbol rotates whenever the pump is switched on.

7

easurement point symbol (In this case: Collector)

1

2

3

4

6 5

7

Operating the controller

18

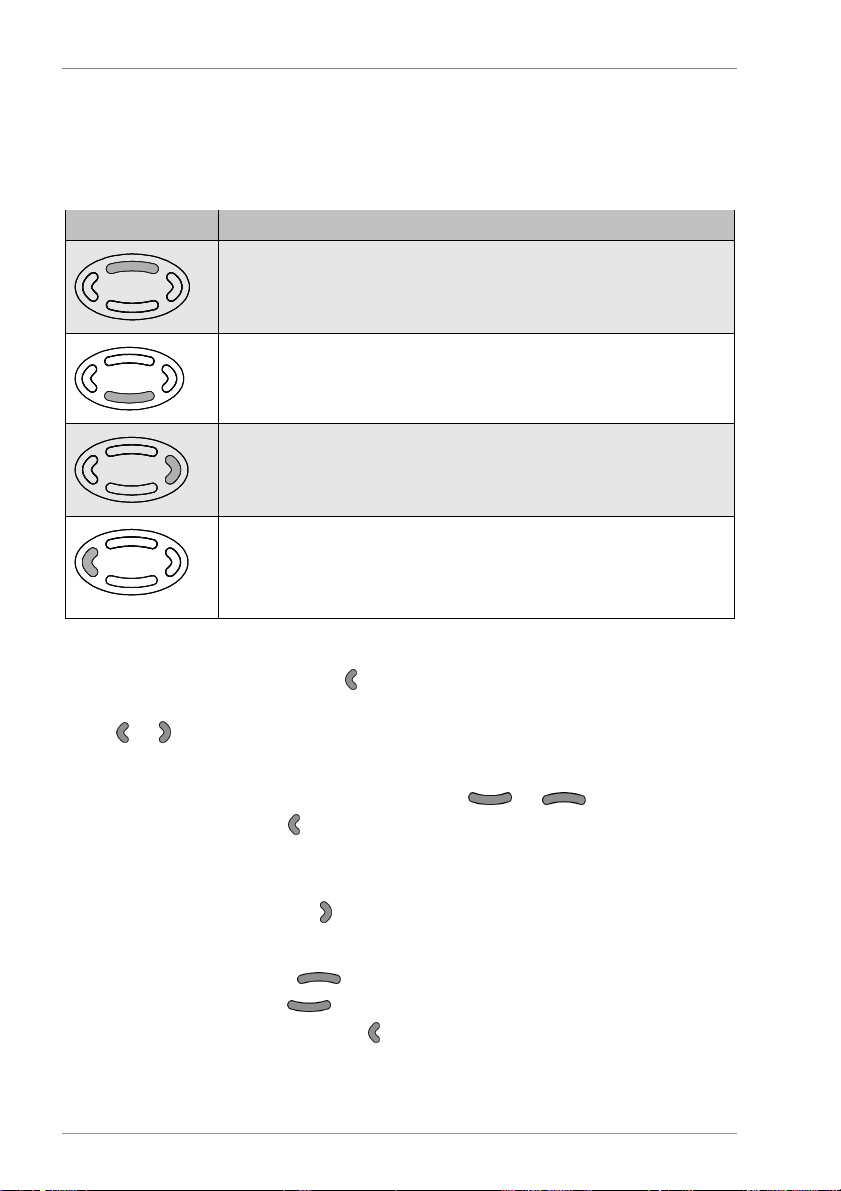

5.2 Using the operating buttons

The operating buttons allow you to navigate in the menus and make changes to values.

The following table explains the functions of the operating buttons:

Operating buttons

Function

ove up in the list.

Increase the displayed value.

ove down in the list.

Call up the selected menu.

Reduce the displayed value.

ove to the right in the main menu.

Select or activate a menu item.

Confirm a change to a value.

ove to the left in the main menu.

Cancel the activation of a menu item. Any value changes that have not

been confirmed will be discarded. The value that is currently set will be

displayed.

Return to the main menu.

Navigating in the menus

To switch to the main menu, press as often as required until the main menu is

displayed.

Use or to select the required menu.

The selected menu symbol flashes.

To display the various different menu items, select or .

To exit a menu item, select .

Changing values

To activate a menu item, select .

The value flashes.

To increase the value, select .

To reduce the value, select .

To abort the change to a value, select .

enus and controller functions

19

The value stops flashing. The value that is currently set will be displayed.

To confirm the entry, select .

To re-confirm the entry, select .

The OK symbol will no longer be displayed. Your entry has been adopted.

If you press the or buttons once, the value will be increased or

reduced in steps. If you keep these buttons pressed, the value will be increased or

reduced on a continuous basis.

6Menus and controller functions

This chapter provides an overview of the menus and menu items.

6.1 Displaying values in the "Info" menu

The "Info" menu allows you to display measurement and output values and status

messages. Values that are marked by "×" in the "Reset" column can be reset.

Depending on which additional functions have been activated, not all values will

necessarily be displayed.

To reset a value, proceed as follows:

Select .

The OK symbol will be displayed.

Press to confirm.

The value will be reset.

enus and controller functions

20

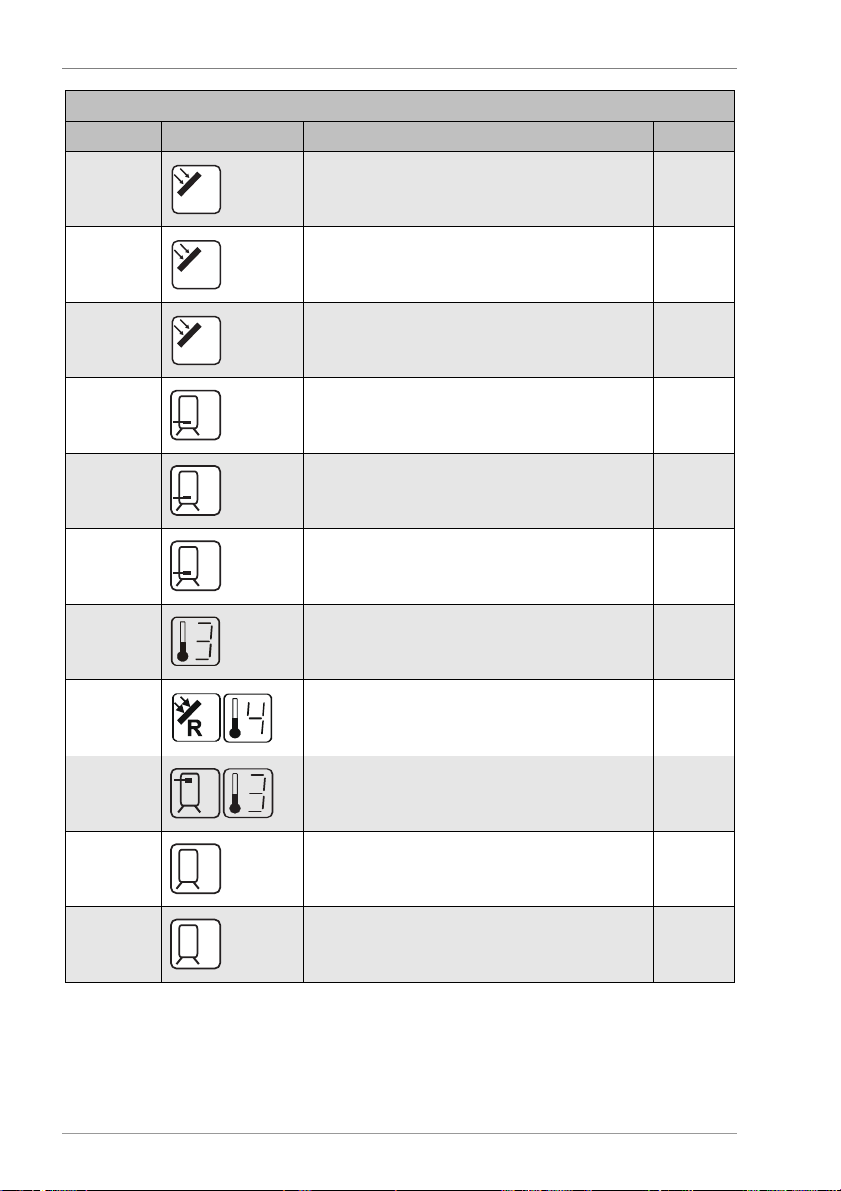

„Info“

Menu

Example

Symbol

D

esc

ription

Reset

75

°C

Current temperature of collector

–

min. 12

°C

inimum temperature of collector

×

max. 105

°C

aximum temperature of collector

×

52

°C

Current temperature of storage tank

–

min. 40

°C

inimum temperature of storage tank

×

max. 67

°C

aximum tempera

ture of storage tank

×

25

°C

Display for the general temperature

measurement point (hidden if not connected)

–

60

°C

Current temperature of collector re

turn

–

60

°C

"Heating", "Cooling" functions of a multi

-

function

controller (R2)

Sensor for the source (S3)

–

1234

h

Operating hours for charging

To

0

h

927

kWh

Energy output for the storage tank

To

0

kWh

Table of contents

Popular Controllers manuals by other brands

Alpha Group

Alpha Group OutBack Power MATE3 owner's manual

Mitsubishi Electric

Mitsubishi Electric Central Controller G-50A installation manual

ABB

ABB ACS 800 Series Hardware manual

HomeMatic

HomeMatic HM-LC-Sw1-DR Installation and operating manual

EUROSTER

EUROSTER 10M Installation and operation manual

SKF

SKF IMx-M user manual