3 Product information

3.9 Innovative technologies

Inverter technology

The scroll compressor not only works in on/off mode,

but is operated with power control (modulating, accor-

ding to the current power requirement).

Advantage:

–Precise power adjustment.

–Increased efficiency through reduced clocking.

–Quieter operation on average due to reduced speed

in the partial load range.

–Reduction of the power of secondary drives (fan,

primary circuit pump)

Intermediate steam injection

In the scroll compressor, wet steam is injected from

the economizer heat exchanger for cooling.

Enhanced Vapourized Injection injection increases

efficiency, while the power requirement is reduced at

the same time. Thus higher flow temperatures and

higher heating output (especially at low outside tempe-

ratures) are possible. The compression temperature

decreases, increasing the life expectancy of the

compressor.

3.10 Smart Grid Ready

The SG-Ready label is a label for heat pumps, the con-

troller of which meet the conditions for inclusion in a

future, intelligent power grid (smart grid = SG).

Purpose of this function: Load balancing in the elec-

tricity networks of the energy supply companies

(ESCs).

The technique: The energy supply company sends

signals to the heat pump control (by means of a so-cal-

led ripple control receiver) and can thus influence the

operating mode of the heat pump within a defined

range.

This means:

–At peak loads, the heat pump can be switched off.

–Surplus electricity can be converted into thermal

energy and stored in the DHW tank or the heating

circuit (e.g. screed of the underfloor heating sys-

tem).

Electricity supplier block

The ESC may switch off the heat pump for a maxi-

mum of 2 hours (depending on the rate up to 3 times a

day) and grants the consumer a reduced rate.

Smart Grid

The ESC cannot switch off the heat pump temporarily

only when needed, but there are four defined operating

modes in the heat pump control, which the ESC may

trigger depending on the power grid load condition.

Operating state 1 - shut down

–The heat pump is switched off by the ESC (for a

maximum of 2 hours, equivalent to the current

ESC block).

Operating state 2 - normal operation

–The control operates in accordance with the

setpoint temperatures set by the system operator

with regard to room heating and DHW storage.

Operating state 3 - start-up recommendation

–The DHW tank is charged to its required tem-

perature (if the required temperature has not yet

been reached).

–The heating circuit is activated [1]. The required

flow temperature is increased by an adjustable

value (can be defined for each heating circuit).

[1] if possible due to the settings, e.g. outside shutdown tem-

perature is not reached, ....

Operating state 4 - Startup command

–In this operating state it is possible to set whether

only the compressor or the compressor and the

electric heating element are activated.

–The DHW tank is charged (within the release

times) by an adjustable value above the setpoint

temperature.

–The set room temperature is increased by an

adjustable value (can be defined for each heating

circuit).

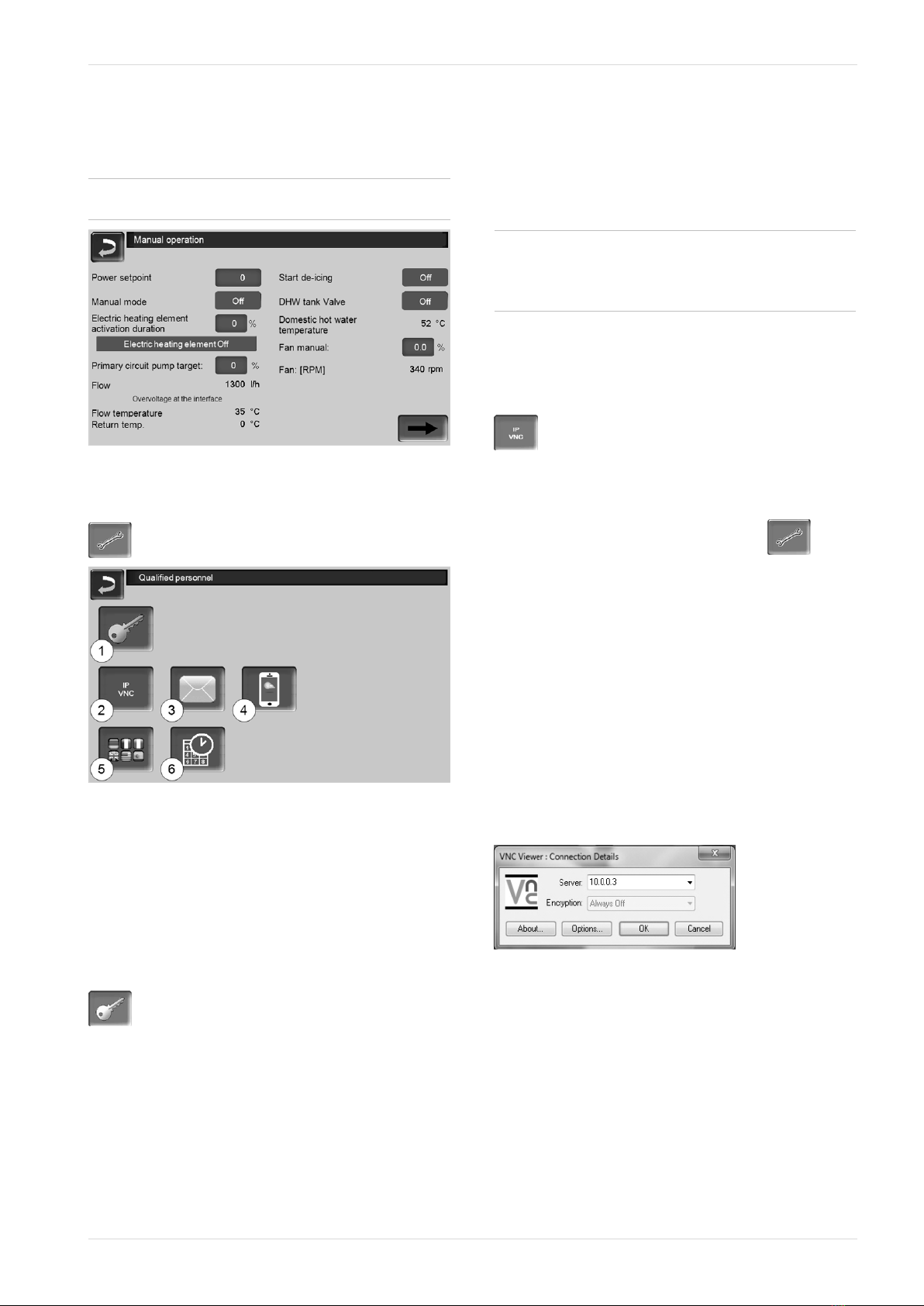

The screens with the corresponding setting

parameters are located in the Service Menu |Smart

Grid button. To enter the service menu of the control, a

qualified personnel code must be entered.

Operation manual vampair 7