SolarPower Clarity SPM80V12A User manual

Installation & Operations

Manual

Clarity™ System

Clarity™ Site Server – SPS1

Clarity™ Gateway – SPG1; SPD1

Clarity™ Nodes:

•SPM80V12A

•SPM80V12A-S

•SPM125V8A

•SPM125V8A-S

•SPO350W80V

“Bringing Clarity to Solar Power Generation”

CAUTION

RISK OF ELECTRICAL

SHOCK

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL

Caution

To reduce risk of electrical shock, do not perform any servicing other than that contained in the

Installation and Troubleshooting Instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

Special Symbols That Might Appear on the Equipment and in this Manual

Danger This symbol indicates that dangerous voltage levels are present

within the system. These voltages are not insulated and may be

of sufficient strength to cause fatal, or serious bodily injury when

touched. The symbol may also appear on schematics.

Warning The exclamation point, within an equilateral triangle, is intended

to alert the user to the presence of important installation,

servicing, and operating instructions in the documents

accompanying the equipment.

Caution The exclamation point, within an equilateral triangle, is intended

to alert the user to the presence of important installation,

servicing, and operating instructions in the documents

accompanying the equipment.

Important

Information Accompanies notes that call attention to supplementary

information that you must know and use to ensure optimal

operation of the system.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions for the Clarity™ System, and should be followed during

the installation and maintenance of the system.Please read thoroughly before attempting

installation.

Danger

To reduce risk of electrical shock, do not open a Monitor, Optimizer,

Gateway, Disable Switch, or Site Server. Do not attempt repair. There

are no user-serviceable parts inside.

Danger

When unloaded, Monitors, Optimizers, and their attached PV panels still

present a shock risk. Note that the Monitor or Optimizer output voltage

will be as high as the PV panel’s open circuit voltage (Voc), and any

electrical terminal on a monitor may be as high as 1000V with respect to

ground, depending on site design and wiring connections

Warning

Do not connect or disconnect a Monitor or Optimizer while under

electrical load: DC power and AC power must be disconnected from the

PV system inverter before installing or servicing Monitors.

Warning To ensure safety, all combiner box fuses must be opened prior to

altering any Monitor or Optimizer electrical connections.

Warning

Under extreme environmental conditions, a photovoltaic panel may

produce higher short-circuit currents and/or higher open-circuit voltages

than specified by the panel’s nameplate Standard Test Condition (STC)

rating. Accordingly, these higher values of Isc and Voc should be

utilized when determining compatibility with the Monitor or Optimizer

maximum current and maximum voltage specifications.

Warning

String fuses must be present elsewhere in the system. Clarity™

Monitors and Optimizers do not include string fuses, or any form of over-

current protection

Warning

The Clarity system does not provide any protection from ground faults or

arc faults. Where required, protection from ground faults and arc faults

must be provided elsewhere in the system.

Caution

Monitors, Optimizers, Gateways, Disable Switches, and Site Servers are

designed to be installed outdoors. However, electrical connections to

these products should be made and altered only under dry weather

conditions. Every effort should be made to avoid getting dirt and

moisture into electrical connections before they are mated and properly

sealed. Moisture in electrical connections can present a shock hazard,

and can also accelerate corrosion.

Warning

This equipment operates over the marked Voltage and Frequency range

without requiring manual setting of any selector switches. Different types

of line cord sets may be used for connections to the mains supply circuit

and should comply with the electrical code requirements of the country

of use. The line cord provided with the equipment is acceptable for use

with NEMA Style 5-15R AC receptacles supplying nominal 120 Volts.

iii

FCC Compliance

The SPM80V12A, SPM80V12A-S, SPM125V8A, SPM125V8A-S, SPG1, SPD1 and SPS1 have been

tested and found to comply with the following requirements:

•FCC 47CFR Part 15.247 Operation within the bands 902-928 MHz, 2400-2483.5MHz and 5725-5850

MHz

•FCC 47 CFR 15B Class B verification

•ETSI EN 300 328 ; Issued 2007/01/09 V1.7.1 Electromagnetic compatibility and radio spectrum matters

(ERM); Wideband transmission system; data transmission equipment operating in the 2.4 GHz ISM

band & using wideband modulation techniques; Harmonized EN Article 3.2

•ETSI EN 301 489-1; Issued 2008/04/01 V1.8.1 Electromagnetic compatibility and radio spectrum

matters (ERM); Electromagnetic compatibility (EMC) standard for radio equipment and services; Part 1:

Common technical requirements

•ETSI EN 301 489-17; Issued 2009/05/12 Electromagnetic compatibility and radio spectrum matters

(ERM); Electromagnetic compatibility (EMC) standard for radio equipment; Part 17: Specific conditions

for broadband data transmission systems – V2.1.1

•These devices comply with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

•These devices may not cause harmful interference.

•These devices must accept any interference received, including interference that may cause undesired

operation.

These devices have been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in any particular installation. If these devices cause harmful interference to radio or

television reception, which can be determined by turning the devices off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and the receiver.

•Connect the devices into an AC outlet different from that to which the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications made to the devices not expressly approved by SPTI may void the users

authority to operate the equipment. These devices do emit Radio Frequency (RF) energy when

powered up. To limit exposure to this RF energy, the user should keep a distance of 20 cm from the

devices.

Contents

1Introduction.................................................................................................................................1-1

1.1 CLARITY™ SYSTEM.................................................................................................................1-1

1.2 Unpacking the Clarity Components ...........................................................................................1-1

1.2.1 Site Server Components to Unpack...................................................................................1-1

1.2.2 Clarity Gateway Components to Unpack...........................................................................1-1

1.2.3 Clarity Nodes: (Monitors & Optimizers)..............................................................................1-1

1.2.4 Other accessories ..............................................................................................................1-1

1.3 FEATURES................................................................................................................................1-2

1.3.1 Clarity™ Site Server (SPS1)..............................................................................................1-2

1.3.2 Clarity Gateway (SPG1 – SPD1) .......................................................................................1-2

1.3.3 Clarity Monitors (SPM80V12A, SPM80V12A-S, SPM80125V8A, SPM80125V8A-S).......1-2

1.3.4 Clarity Optimizers...............................................................................................................1-2

1.4 USING THIS MANUAL...............................................................................................................1-2

1.5 RELATED DOCUMENTATION..................................................................................................1-3

1.6 IF YOU NEED HELP..................................................................................................................1-3

1.7 RETURNS..................................................................................................................................1-3

2Overview ....................................................................................................................................2-4

2.1 CLARITY™ SITE SERVER........................................................................................................2-4

2.2 CLARITY™ GATEWAY .............................................................................................................2-5

2.3 CLARITY™ NODES...................................................................................................................2-5

2.3.1 Input & Output Connections typical for all Nodes ..............................................................2-5

3Installation..................................................................................................................................3-6

3.1 BEFORE YOU BEGIN ...............................................................................................................3-6

3.2 FIRST THINGS FIRST - SITE DOCUMENTATION MAP..........................................................3-6

3.2.1 Building Site Documentation Map......................................................................................3-6

3.3 CLARITY™ SITE SERVER INSTALLATION...........................................................................3-11

3.3.1 Clarity Site Server Mounting: ...........................................................................................3-11

3.3.2 Connecting Environmental Sensors:................................................................................3-12

3.3.3 Connecting Gateway........................................................................................................3-14

3.3.4 Connecting to LAN...........................................................................................................3-15

3.4 ENVIRONMENTAL SENSORS EXTERNAL MOUNTING.......................................................3-16

3.4.1 Irradiance Sensor Mounting.............................................................................................3-16

3.4.2 Ambient Temperature Sensor Mounting..........................................................................3-17

3.4.3 Panel Cell Temperature Sensor Mounting.......................................................................3-17

3.5 GATEWAY MOUNTING (Models SPG1 & SPD1)...................................................................3-18

3.5.1 Weather Proof Connection of CAT5/5e to Gateway or Disable Switch...........................3-18

3.5.2 Mounting Gateway ...........................................................................................................3-18

3.6 POWER TO THE SITE SERVER.............................................................................................3-20

3.6.1 Site Server Penetration Locations....................................................................................3-20

3.6.2 Connecting Power To The Site Server.............................................................................3-20

3.7 INSTALLING CLARITY NODES..............................................................................................3-22

3.7.1 Action 1: Shutdown Inverter / Open Combiner Box Fuses .............................................3-22

3.7.2 Action 2: Connecting a Node to a Panel.........................................................................3-22

3.7.3 Action 3: Attaching a Node to a Panel ............................................................................3-22

3.7.4 Action 4: Connecting a Node to another Node ...............................................................3-22

4Array Commissioning...............................................................................................................4-23

4.1 Verify String Voltages...............................................................................................................4-23

4.2 Inverter Start.............................................................................................................................4-23

5Troubleshooting .......................................................................................................................5-24

6Appendix A...............................................................................................................................6-25

6.1 Site Server Specification..........................................................................................................6-25

6.1.1 Site Server Schematic......................................................................................................6-26

6.2 Gateway Specification..............................................................................................................6-27

6.3 Node Specifications .................................................................................................................6-28

6.3.1 Clarity Monitor ..................................................................................................................6-28

6.3.2 Clarity Optimizer...............................................................................................................6-29

6.4 Daq X-320 Specification...........................................................................................................6-30

6.4.1 Daq X-320 Pinout.............................................................................................................6-30

6.4.2 Daq X-320 Specifications.................................................................................................6-31

6.5 12Volt Power Supply Specification ..........................................................................................6-33

6.6 48Volt Power Supply Specification ..........................................................................................6-34

6.7 Industrial PC Specification (rBox104) ......................................................................................6-35

Installation & Operations Manual 1-1

Section 1

1Introduction

1.1 CLARITY™ SYSTEM

The Clarity System is a complete site performance management solution for commercial and utility

scale PV solar arrays. The Clarity Monitors and Optimizers (Clarity ‘nodes’) provide precise insight

down to the panel level, while the innovative proprietary wireless mesh network allows the system to

scale to the largest utility scale arrays. Data collected from the PV array is sent to the cloud hosted

Clarity Intelligent Array™ Management System, where real time analysis and diagnostics are

performed to provide unprecedented insight and management capability for large scale PV systems..

1.2 Unpacking the Clarity Components

1.2.1 Site Server Components to Unpack

Carefully unpack and check for the following items.

•Irradiance Sensor

•Ambient Temperature Sensor

•Panel Cell Temperature Sensor

•2 Pieces of Metal Tape

•Packet of four (4) RJ45’s & four (4) Cable Glands

1.2.2 Clarity Gateway Components to Unpack

Carefully unpack and check for the following items.

•Gateway

•Conec Connector

1.2.3 Clarity Nodes: (Monitors & Optimizers)

Both Nodes ship in similar cartons. The Optimizer carton is slightly larger than the Monitor carton.

However, both nodes should be handled in the same manner.

•Monitor

•Optimizer

1.2.4 Other accessories

The following accessories may have been shipped with your system:

•2 Meter Lead

•8” Pigtail (For matching panel connector with node connector)

Installation & Operations Manual 1-2

1.3 FEATURES

1.3.1 Clarity™ Site Server (SPS1)

•Industrial PC for consolidating data sent from nodes via the Clarity Gateway

oLAN Connection port

o4 PoE ports – 3 for Gateway’s and 1 for environmental monitoring

•Environmental Monitoring Including:

oIrradiance (Insolation)

oPanel Cell Temperature

oAmbient Cell Temperature

1.3.2 Clarity Gateway (SPG1 – SPD1)

•Data collection from mesh network made up by Clarity Nodes

1.3.3 Clarity Monitors (SPM80V12A, SPM80V12A-S, SPM80125V8A, SPM80125V8A-S)

•Continually measure in real time:

oVoltage

oCurrent

oPower

1.3.4 Clarity Optimizers

•Continually measure in real time:

oVoltage

oCurrent

oPower

•Buck Voltage when needed

•Boost Voltage when Needed

1.4 USING THIS MANUAL

This manual provides instructions to install the Clarity System:

Section 1

Introduction provides a product description, a list of related documentation, the

technical help line telephone number, and the return procedure.

Section 2

Overview describes the Clarity System, an overview of its use. This section also

identifies the Site Server, Gateway and Monitor components.

Section 3

Installation provides instructions on how to install the Clarity Intelligent Array.

Section 4

Commissioning the array and starting the inverter

Section 5

Troubleshooting provides information on common error conditions and their

resolution.

Section 6

Specifications provide the Clarity Array Management System technical

specifications.

Installation & Operations Manual 1-3

1.5 RELATED DOCUMENTATION

The following documentation may be helpful when operating the Site Server, Gateway, Monitors &

Optimizers.

•Clarity™ Intelligent Array™ Software Users Guide

•User documentation for broadband connection, rBOX104, and other components

1.6 IF YOU NEED HELP

If you need assistance while working with the Clarity System, contact the SPTI Technical Support:

•Inside or Outside the U.S.: 512-782-8957

•Solar Power Technologies, Inc. website: www.spowertech.com

•SPTI Support email: support@spowertech.com

The SPTI Technical Support is open from 8:00 AM to 5:00 PM US Central Time, Monday through

Friday.

1.7 RETURNS

Material may be returned to Solar Power Technologies, Inc. (SPTI) only with prior written

authorization from Customer Service. Contact Customer Service at (512) 782-8957, or email:

support@spowertech.com to obtain an RGA. Upon authorization, an RGA form will be issued based

on the following terms and conditions:

•Product must be either (i) defective in materials or workmanship from Supplier, or (ii) new and

unopened and in original carton. Any product received contrary to this provision is subject to

return or no credit issued.

•All defective returns must be properly packaged. Any returned units that have been

damaged in shipping due to insufficient packaging will be subject to no credit issued.

•Products must be returned within the warranty period. Out-of-date products are subject to

return or no credit issued.

•Goods returned are only for those products previously authorized and written on the RGA

from. Any unauthorized returned products are subject to return or no credit issued.

•A minimum of 30% restocking charge will apply to any approved new material returns.

•All freight and duties on returned goods are the responsibility of the Customer. RGA # must

be referenced on all outside cartons and packing list. All returned goods are shipped to:

Solar Power Technologies, Inc.

3006 Bee Caves Road, Suite A-330

Austin, Texas 78746

Installation & Operations Manual 2-4

Section 2

2Overview

This section describes the hardware components of the Clarity System.There are three main

components:

•Site Server

•Gateway

•Clarity Nodes:

oMonitor

oOptimizer

Important

Information All Clarity Nodes are installed in the same manner.

2.1 CLARITY™ SITE SERVER

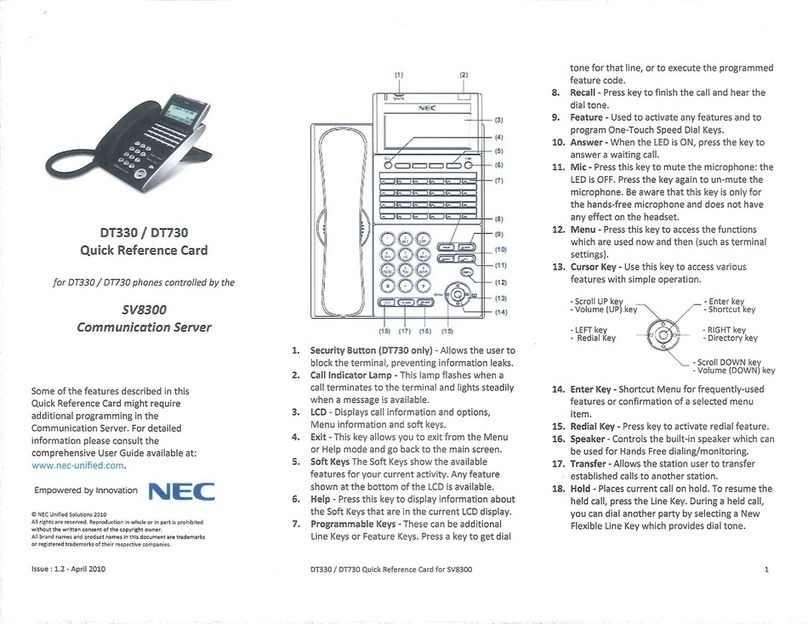

Figure 2-1

Table 2-1

Key Function

1

12VDC Power Supply for Environmental

Components

2 48VDC Power Supply for Industrial PC

3 Industrial PC (rBOX104)

4 Ground Lug

5 Terminal Blocks feeding Power Supplies

6 5Amp Breaker

8 Environment collection component

9

Cable Management

Danger

To reduce risk of electrical shock, do not perform any servicing other than

that contained in the Installation and Troubleshooting Instructions unless

you are qualified to do so. Refer all servicing to qualified service personnel.

Important

Information See Section 6 for Site Server Internal Wiring Schematic

Installation & Operations Manual 2-5

2.2 CLARITY™ GATEWAY

Figure 2-2

Table 2-2

Key

Function

1 Seal Tight Location for CAT5/5eTermination

Warning To reduce risk of electrical shock, do not open a Gateway. There are no

user-serviceable parts inside.

2.3 CLARITY™ NODES

There are two types of Clarity Nodes: Monitors and Optimizers. Regardless of type, all nodes install in the

same manner.

•Clarity Monitors

oSPM80V12A

oSPM80V12A-S

oSPM125V8A

oSPM125V8A-S

•Clarity Optimizer

oSPO350W80V

2.3.1 Input & Output Connections typical for all Nodes

Figure 2-3

Table 2-3

Key

Function

1

Positive Output to next node or

homerun to combiner/inverter.

2

Negative Output to next node or

homerun to combiner/inverter.

3

Positive Input from PV Module.

4

Negative Input from PV Module.

Danger To reduce risk of electrical shock, do not open a Monitor or Optimizer.

There are no user-serviceable parts inside.

Installation & Operations Manual 3-6

Section 3

3Installation

This section provides instructions to install and cable the Clarity System. Covered in this section:

•Before You Begin

•Site Documentation

•Site Server Installation

oMounting Site Server

oProper Site Server Penetration Locations

oSite Server Component Connections

Gateway

Environmental Sensors

•Gateway Installation

•Sensor Installations

oIrradiance

oAmbient Temperature

oPanel Cell Temperature

3.1 BEFORE YOU BEGIN

PLANNING IS THE KEY!

•READ ALL INSTRUCTIONS COMPLETELY BEFORE BEGINNING INSTALLATION.

•INSTALLAION TO BE PERFORMED BY QUALIFIED PERSONNEL ONLY.

•INSTALL IN ACCORDANCE WITH ALL LOCAL CODES.

3.2 FIRST THINGS FIRST - SITE DOCUMENTATION MAP

The Clarity™ Intelligent Array™ Management System utilizes a broader dataset than existing PV

system optimization, monitoring and management solutions. This dataset is captured in a Site

Documentation Map (SDM).

The SDM describes the array’s DC electrical hierarchy plus the physical location of individual panels,

strings, combiners and inverters.

3.2.1 Building Site Documentation Map

3.2.1.1 Panel to String Hierarchy - Negative to Positive (Bottom up Approach)

•Rule 1: (See Figure 3-1)Regardless of the number (N) of panels per string, to ensure

consistent documentation, position 1-of N is ALWAYS defined as the most negative voltage

string position. It is the negative lead from panel 1-of-N that is the homerun wired to the

combiner or inverter. 2-of-N is the next panel wired in series and so on until total N is

achieved. It is the positive lead from panel N (Total number of panels in string.) that is the

positive homerun wired to the combiner or inverter.

Installation & Operations Manual 3-7

Figure 3-1

3.2.1.2 String to Combiner to Inverter Hierarchy

String to combiner hierarchy is site specific.In isolated cases the Inverter may also act as combiner.

If this is the case proceed to section 3.2.1.3.

Emphasis here to be consistent using the following rule:

•Rule 2: (See Figure 3-2) When building String to Combiner Hierarchy always begin with the

Inverter and move outward.

oStep 1 - Label Inverter

oStep 2 – Label Combiner

oStep 3 – Label Strings

oStep 4 – Label Panels in strings starting with bottom of string (Most Negative / 1 of N)

Installation & Operations Manual 3-8

Figure 3-2

3.2.1.3 Expressing Your Array in an X Y Grid format

The panels are designated. Strings to combiners to inverters are labeled. Next is the X Y Grid

documentation. The only way to associate a node with a panel is to express both in an X Y Grid

•Rule 3: Building the xy axis.

oStep 1 – Build an X Y Chart (See Figure 3-3)

oStep 2 – Associate a panel with an X Y position (See Figure 3-4 & 3-5)

Installation & Operations Manual 3-9

Figure 3-3

Note: Layout below illustrates panel gaps that may be due to roof top obstructions. In all cases of this

nature, if the panel does not exist, than the xy location will not be recorded.

Figure 3-4

Figure 3-5

Best

Practice When associating an xy axis to an array, think about how the array will

be displayed on a computer screen.

Installation & Operations Manual 3-10

•Rule 4: Record node MAC address and Panel Information, then create site hierarchy..

oStep 1: Document the MAC address of the Node.

oStep 2: Document the Brand, Model, & serial number of the Panel.

Use the following table as a guide:

Table 3-1

Rule 1: Bottom up Approach

Most Neg Panel in String 5

Rule 2: Inverter moving out.

Inverter INV1

DC Disconnect DCD1

Combiner C1

Sub-Combiner SC2

String S2

Rule 3: xy axis position of panel Location 2,5

Rule 4: MAC address & Brand

MAC F4-e6-d7-00-01-00-xx-xx

Brand Brand X – P240W

SN of Panel xxxxxxx-xxxxxxxx

Following is an example of the data above in spreadsheet form.

Note: The spreadsheet below starts with Locations. However, consistency is the most important

thing to remember.

Important

Information

Larger installations may require more layers of definition in the SDM, such

as sub-combiners, sub-arrays or multiple inverters. The Intelligent Array

data model supports this additional hierarchy. For specific requirements not

covered within the SDM examples provided, please contact

support@spowertech.com.

Important

Information

An accurate SDM ensures that the Intelligent Array Software Suite will

deliver the best and most precise fault identification and analytics at initial

commissioning.

Important

Information

An incomplete or inaccurate SDM does not prevent Monitor or Optimizer

operation; however, the SDM should be updated as necessary to

accurately reflect the actual status and configuration of the array.

Installation & Operations Manual 3-11

3.3 CLARITY™ SITE SERVER INSTALLATION

The Site Server utilizes a 16” x 14” x 8” NEMA-4R composite (non-metallic) enclosure with a lockable

front door, and is shipped with the following contents packed inside:

•Mounting brackets for the Site Server (wall or uni-strut installation)

•Irradiance sensor with a 20-meter, shielded, low-voltage, UV-resistant interconnect cable

and mounting hardware.

•“One Wire” ambient-temperature sensor with a 50-foot shielded, low-voltage, UV-resistant

interconnect cable and mounting hardware

•“One Wire” panel cell-temperature sensor with a 50-foot shielded low-voltage, UV-resistant

interconnect cable and mounting hardware

Upon receipt, carefully unpack and verify that the Site Server arrived undamaged with all components

noted above. Contact your supplier or support@spowertech.com immediately regarding any shipping

damage or missing components.

3.3.1 Clarity Site Server Mounting:

The site server is design for surface mount

and uni-strut mount only. Flush mount is not

supported at this time.

Surface Mount

Prior to installation:

•Wall finishes should be complete.

•The wall cavity must have sufficient

backing or support to ensure a firm

mounting of the enclosure to the wall

surface (see specifications for

weight).

To install:

•Secure the surface mount flanges to

the back of the enclosure with the

screws provided.

•Use appropriate screws to attach the

enclosure by the flanges to the wall

surface.

•Level the enclosure then tighten all

screws.

Figure 3-6

Installation & Operations Manual 3-12

Strut Channel Mount

Prior to installation:

•Strut channel bracketing should be

complete.

•Bracket should have sufficient

support to ensure a firm mounting of

the enclosure (see specifications for

weight).

To install:

•Secure the surface mount flanges to

the back of the enclosure with the

screws provided.

•Use appropriate screws to attach the

enclosure by the flanges to Strut

channel.

•Level the enclosure then tighten all

screws.

Figure 3-7

3.3.2 Connecting Environmental Sensors:

Important

Information Take care when drilling through or mounting the enclosure to avoid

damaging internal electronic components.

Caution Make sure there is NO POWER feeding the site server before wiring

environmental sensors.

SPTI utilizes a daq X-320 to gather environmental data. The Irradiance, Ambient Temperature, and

Panel Cell Temperature sensors are all wired to the X-320.

Figure 3-8

Installation & Operations Manual 3-13

A removable terminal connector is provided for simple wiring.

•Step 1: Make sure there is no power to the site server.

•Step 2: Remove the terminal connector from the X-320™ and make wiring connections to

the terminals as shown in Figures 3-4 and 3-5.

•Step 3: Reconnect the terminal connector.

Connect Sensors as Shown:

Figure 3-9

Important

Information MAKE SURE WIRES ARE PROPERLY ATTACHED TO THE

TERMINALS. SEE FIGURE 3-5 FOR EXAMPLES.

Installation & Operations Manual 3-14

Figure 3-10

3.3.3 Connecting Gateway

Gateway connections are made to one of the four (4) PoE ports on the Site Server PC.

•Step 1: Locate the Site Server PC (See Figure 2-1)

Figure 3-11

This manual suits for next models

4

Table of contents