3

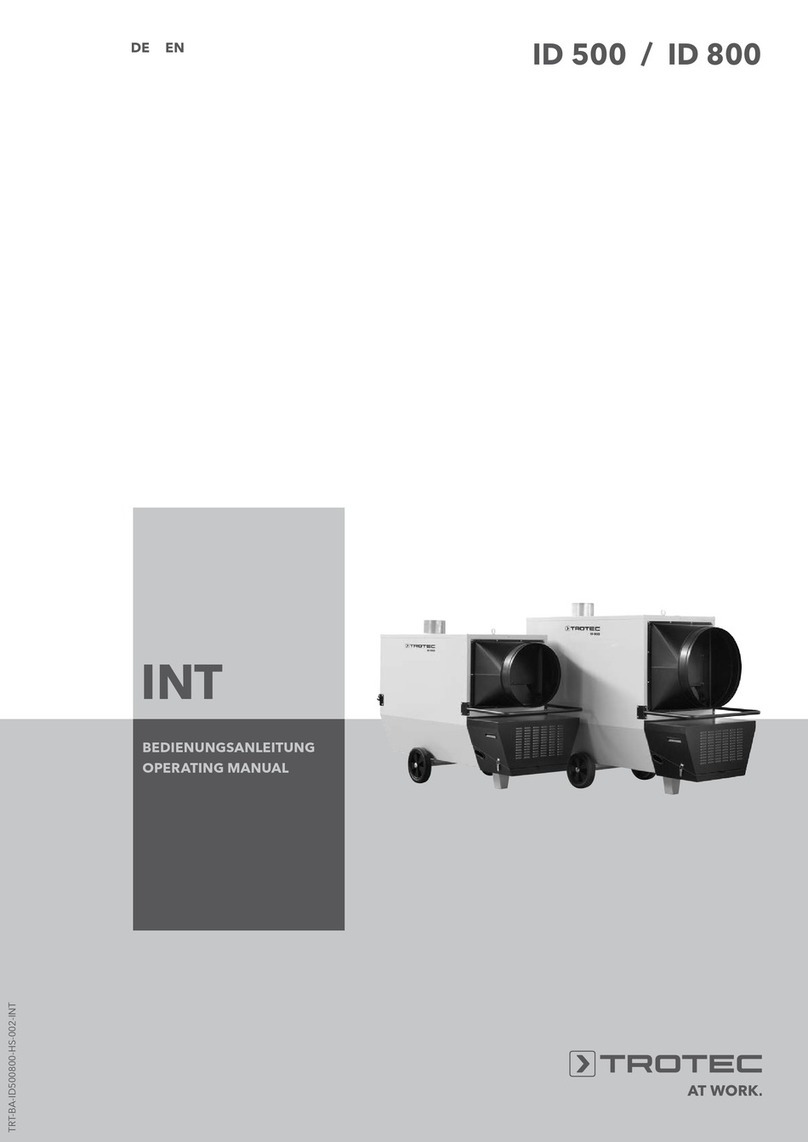

INDEX

1. INTRODUCTION ......................................................................................................................................4

2. SAFETY REGULATIONS AND “CE” MARKING ........................................................................................4

3. GENERAL INSTRUCTIONS .....................................................................................................................4

4. UNIT LABELLING....................................................................................................................................4

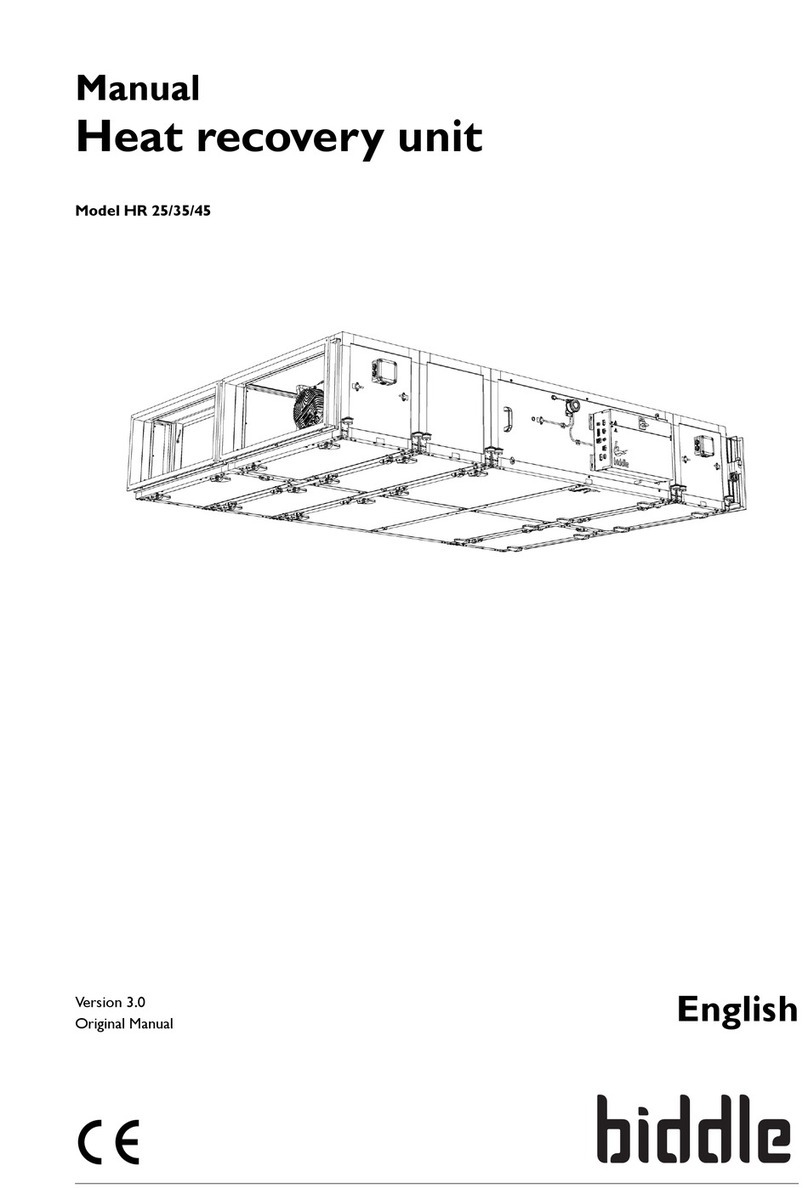

5. HANDLING..............................................................................................................................................5

6. INSTALLATION .......................................................................................................................................5

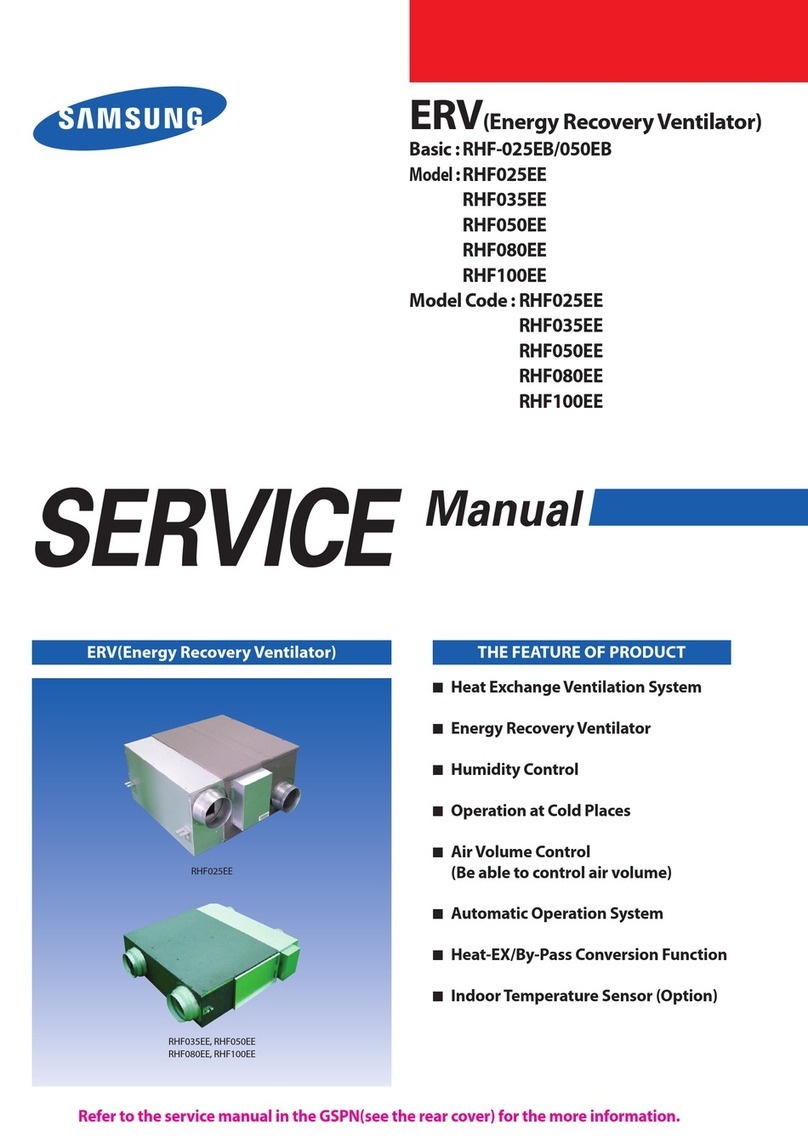

6.1. Introduction......................................................................................................................................5

6.1.1. Outdoor installation................................................................................................................6

6.2. Dimensions and free space for maintenance..................................................................................8

6.3. Mounting process of an additional supply filter..............................................................................9

6.4. Range specifications......................................................................................................................10

6.5. Connections .................................................................................................................................10

6.5.1. Connection with air duct ......................................................................................................10

6.5.2. Condensate drainage ...........................................................................................................10

6.6. Electrical connection .....................................................................................................................11

6.6.1. Wiring diagram.....................................................................................................................11

6.6.2. Fan operation without speed regulation. Operation at maximum speed............................12

6.6.3. Connecting electrical accessories.......................................................................................13

6.6.3.1. VAV control (Variable airflow), manual adjustment................................................13

6.6.3.1.1. Manual adjustment by REB-ECOWATT (accessory)................................13

6.6.3.2. VAV Control (variable airflow), with CO2sensor or similar ....................................14

6.6.3.3. CAV control (constant airflow) ................................................................................14

6.6.3.4.COP Control (constant pressure).............................................................................15

6.6.3.5. Pressure switch connection....................................................................................16

6.7. Reverse outdoor air / indoor air side ............................................................................................18

7. INSPECTION, MAINTENANCE AND CLEANING...................................................................................19

7.1. Filters replacement .......................................................................................................................19

7.2. Additional filter installation...........................................................................................................19

7.3. Heat exchanger..............................................................................................................................20

7.4. Fans................................................................................................................................................20

7.5. Condensation drainpipe.................................................................................................................20

8. OPERATION ANOMALIES......................................................................................................................21

8.1. General anomalies.........................................................................................................................21