HR MANUAL INTRODUCTION

Manual version 3.0 (10-10-2017) en-9

en

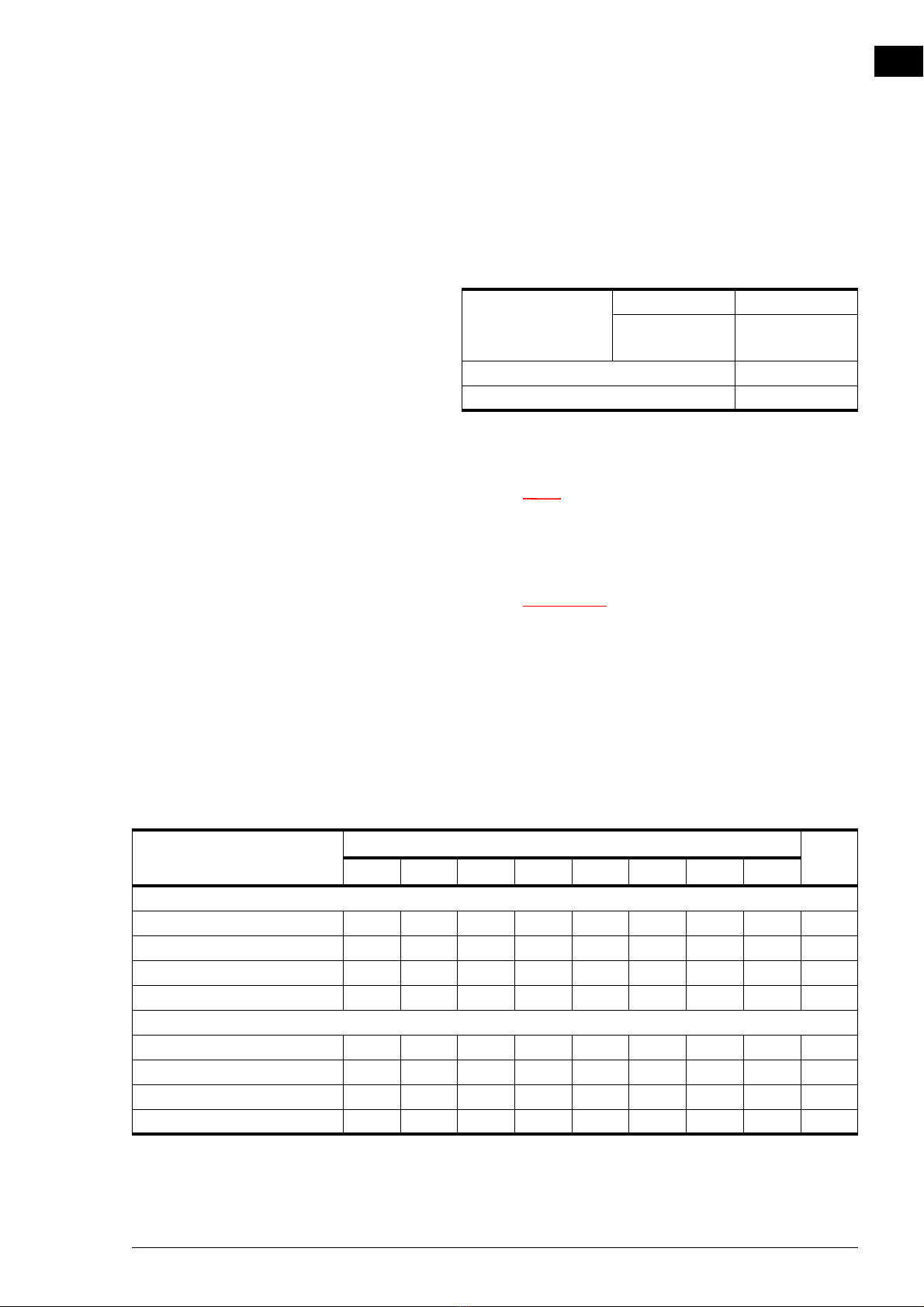

1.3.6 Field of application

Observe the following limits for the unit:

Operating limits for all models

Parameters of use for water-heated models

nConsult Biddle if you want to connect a unit to a

water flow-path with higher temperatures and higher

pressure.

wThe unit may not be used in potentially

explosive environments, outdoors or in very

dusty or aggressive air conditions.

Biddle shall not be held liable for damage caused by

use under these conditions.

Sound levels

Maximum sound power level in ducts

Ambient conditions Temperature 5 °C to 40°C

Relative air

humidity

20% - 95%, not

condensing

Power supply voltage see type plate

Power see type plate

SOUND POWER LEVEL

(LWRE. 10-12 W)

OCTAVE BAND CENTRE FREQUENCY (HZ)LWA

DB(A)

63 125 250 500 1000 2000 4000 8000

HR 25

supply air 69.8 65.6 76.4 75.1 78.8 80.4 78.5 74.1 85.5

extract air 65.7 60.5 70.6 69.9 67.4 70.8 70.9 66.7 76.6

exhaust air 69.8 65.6 76.4 75.1 78.8 80.4 78.5 74.1 85.5

fresh air 65.7 60.5 70.6 69.9 67.4 70.8 70.9 66.7 76.6

HR 35

supply air 75.8 70.7 78.6 78.4 81.3 81.2 78.3 75.4 86.6

extract air 68.6 65.8 75.5 72.3 69.2 70.2 68.2 67.2 76.7

exhaust air 75.8 70.7 78.6 78.4 81.3 81.2 78.3 75.4 86.6

fresh air 68.6 65.8 75.5 72.3 69.2 70.2 68.2 67.2 76.7