SOLIDSVAC SV20-SP User manual

201 First Avenue - Bribie Island - QLD 4507 - Australia

SOLIDS PUMPING SYSTEMS

Solidsvac Pumps

SV20-SP Operations Manual

Version 1 - Doc.SV20SP-13122018

CONTENTS

Description Page

Safety First 3

1. Operational Overview 3

2 Design Registration 3

3. Technical Data 4

4. Schematic 4

5. Accessories 5

6. Pump Set-up 5

7. Operation 6

8. Maintenance 6

9. Adjusting the LOAD and DISCHARGE cycles 7

10. Main Components 8

WARNING

Compressed air can be dangerous. Correctly rated hoses and piping should be used in conjunction with the appropriate fittings

and safety devices on all connections.

The unit is not designed to operate above 785kPa (114psi).

telephone +61 456 000 665

email [email protected]

page 3

SAFETY FIRST

CAUTIONS AND GENERAL SAFETY

This manual contains important information concerning the installation, operation and maintenance of the Solidsvac Pump, Model

SV20-SP. To prevent injury to personnel or equipment damage, this manual should be read and understood by those responsible for the

installation, operation and maintenance of the equipment.

• Isolate, tag out and disconnect the air supply to the unit prior to working on any part of the system

• Lift the equipment only at the lifting points provided

• The pump should be installed in a safe level area, which provides adequate access for operating the equipment

• Ensure all hoses are in good condition, correctly rated and certified for the service in which they are to be used

• Inspect the unit regularly for damaged or worn components

• All covers must be fitted prior to operation

• Air Pressure should NEVER exceed the rated pressure

• Tie down points (if fitted) must NOT be used as lifting points

1. Operational Overview

The Solidsvac SV20-SP operates as a shuttle system alternately

discharging, then loading a wide range of flowable materials

Operation is fully automatic and the Solidsvac SV20-SP features

no internal workings, high vacuum and pressure discharge

where suction of up to 50 metres and discharges of up to 350

metres are achievable.

2. Design Registration

The Solidsvac SV20-SP has a Certificate of Plant Design

Registration from Workcover NSW, Australia. A copy of which

may be obtained by contacting Solidsvac Pumps.

DESIGN REGISTRATION # PV-6-198163/16

Technical Standards

• AS2971-2007 Serially Produced Pressure Vessels

• AS4343-2005 Pressure Equipment – Hazard Levels

• AS1210-1210 Pressure Vessels

PRIOR TO OPERATING THE Solidsvac Pump

a. Ensure optimum air supply is 100cfm @ 690 kPa (100 psi)

b. It is recommended that a 25 mm (1”) i.d. air hose is used for compressed air supply to the pump

c. The pump-out discharge line should be a minimum of 50 mm (2”) diameter

WARNING: The pump-out line MUST be secured at the exit point

CAUTION: Be aware of retained material in the tank increasing total weight

www.solidsvac.com

page 4

4. SV20-SP Schematic

TECHNICAL DATA METRIC US IMPERIAL

Height 920 mm 36”

Width 550 mm 22”

Length 1000 mm 40”

Weight 45 kg lb

Air inlet 13 mm 1/2” BSP

Suction inlet 50 mm 2”

Discharge outlet 50 mm or 75 mm 2” or 3”

Suction lift

6.5 m @ 50 cfm

8.0 m @ 100 cfm

21’3” @ 50 cfm

26’2” @ 100 cfm

Air consumption options

1.4 m3Jet Pack

2.8 m3Jet Pack

50 cfm Jet Pack

100 cfm Jet Pack

Delivery 300+ m 1150+ ft

Displacement cycle 17 ltr 4.5 gal

Operating pressure

7 bar (max) @ 690 kPa

4.5 bar (min) @ 448 kPa

105 psi (max)

65 psi (min)

Maximum solids 35 mm 1-1/2”

Measured water throughput 200 lpm 53 gpm

• Vessel and valves manufactured in 316 stainless steel

• Individually adjustable load and discharge cycles

VENTURI

VALVE

DISC

TIMERS

LOAD

MICRO SWITCH

SOLENOID

ACTUATOR

LOAD

DISC

AIR SUPPLY

telephone +61 456 000 665

email [email protected]

page 5

5. Accessories

Suction Wand - Attaches to the suction hose allowing the operator to

stand upright

Large Capacity Strainer - attaches to the suction hose to prevent

blockages

Delivery Carousel - Discharge to multiple skips

Hoses - A complete range of high quality suction and discharge hoses

Duck Bill Vacuum Head - Helps focus the vacuum and is ideal for

recovering spilled oil, drill mud or similar from the rig floor or tank bottoms.

Dropbox - Delivery to skip or conveyor

Tool Kit - Contains all you need for basic maintenance on your pump

Service Kit - Contains all you need for basic maintenance on your pump

6. Pump Set-up

Before commencing operation, BULLSEYE PUMPS recommends that a site based Risk Assessment of the pumping operation is

undertaken. Any recommendations arising from the Risk Assessment would be additional to the following.

Before operating the SOLIDSVAC SV20-SP check:

a. The unit and all hoses and fittings are undamaged and in good working order.

b. All covers are fitted and closed.

c. Clean compressed air at a minimum working pressure of 550 kPa (80 psi) at 50 cfm is available.

d. An 18 mm (3/4”) air hose is available.

e. The discharge area has suitable warnings to protect personnel are in place.

f. The correct PPE is available and worn for operating compressed air equipment.

NOTE: The Solidsvac Pump requires NO lubrication

1. Set the Solidsvac Pump up in a safe, level location near the material to be pumped.

2. Attach both suction and discharge hoses along with any accessories (Suction Wand, Drop Box, Delivery Carousel) as required

and ensure safety clips are in place.

*Always position hoses out of walkways where possible

3. Ensure the main air valve is in the off position and attach the 18 mm (3/4”) air hose to the Solidsvac Pump and fit appropriate

safety clips.

4. The pump is now ready for use.

www.solidsvac.com

page 6

8. Maintenance

In use, the Solidsvac SV20-SP requires no maintenance. However

the following procedures are recommended in the event of any

loss of vacuum when operating in either in-line or ETA (Exhaust to

Atmosphere) mode.

Prior to commencing each pumping operation:

1. Check that all fittings and connections are serviceable

2. Regular visual inspection of the units polyurethane check

discs are recommended.

Regular visual inspection of the Polyurethane Check Discs are

recommended.

3. A small in-line filter (right) prevents foreign objects

entering the venturi nozzle via the air supply line, Solidsvac

Pumps recommend periodic inspection and cleaning as

required, replacement filters and seals are available from

your Solidsvac Pumps supplier.

7. Operation

Turn the air supply valve on at the source followed by the valve on the pump. The pump will now commence operation.

Operation is automatic and the pump can be left running unattended indefinitely.

NOTE: The Solidsvac Pump certified lifting point should be used as the units Earthing Point if required.

Solidsvac Pumps recommend checking the pump out-line to ensure it remains correctly anchored at the exit.

NOTE: Dry operation will not damage the pump.

a. When pumping is complete, isolate the air at the pump and then the source.

b. To release pressure from the air supply line turn on the pump air valve. (The pump will cycle till there is insufficient air to

operate.)

c. Select pump air valve to off.

Prior to commencing any work on the unit, the air supply valve MUST be isolated and

the control system tested dead.

SAFETY FIRST

telephone +61 456 000 665

email [email protected]

page 7

9. Adjusting the LOAD and DISCHARGE cycles

Adjusting the Load and Discharge cycles may be required depending on material being transferred and the distances involved etc.

Turning the upper flow restrictor to negative will decrease the loading time, similarly rotating it to positive will increase the load time.

The Pressure Relief Valve can be manually operated via the lever as indicated below.

Caution: It is recommended that only a quarter turn adjustment is made at a time.

REPORT ANY DEFECTS

IMMEDIATELY

SAFETY

FIRST

Isolate Air Supply

Valve and have Air

Supply Valve OFF

before commencing

any work

on the unit

Cycle Control Timers

Pressure Relief Valve

www.solidsvac.com

page 8

10. Main Components

EXHAUST

SUCTION

DISCHARGE

AIR SUPPLY

201 First Avenue - Bribie Island - QLD 4507 - Australia

www.solidsvac.com

Model Number

Serial Number

Date of Manufacture

Inspected by

Table of contents

Other SOLIDSVAC Water Pump manuals

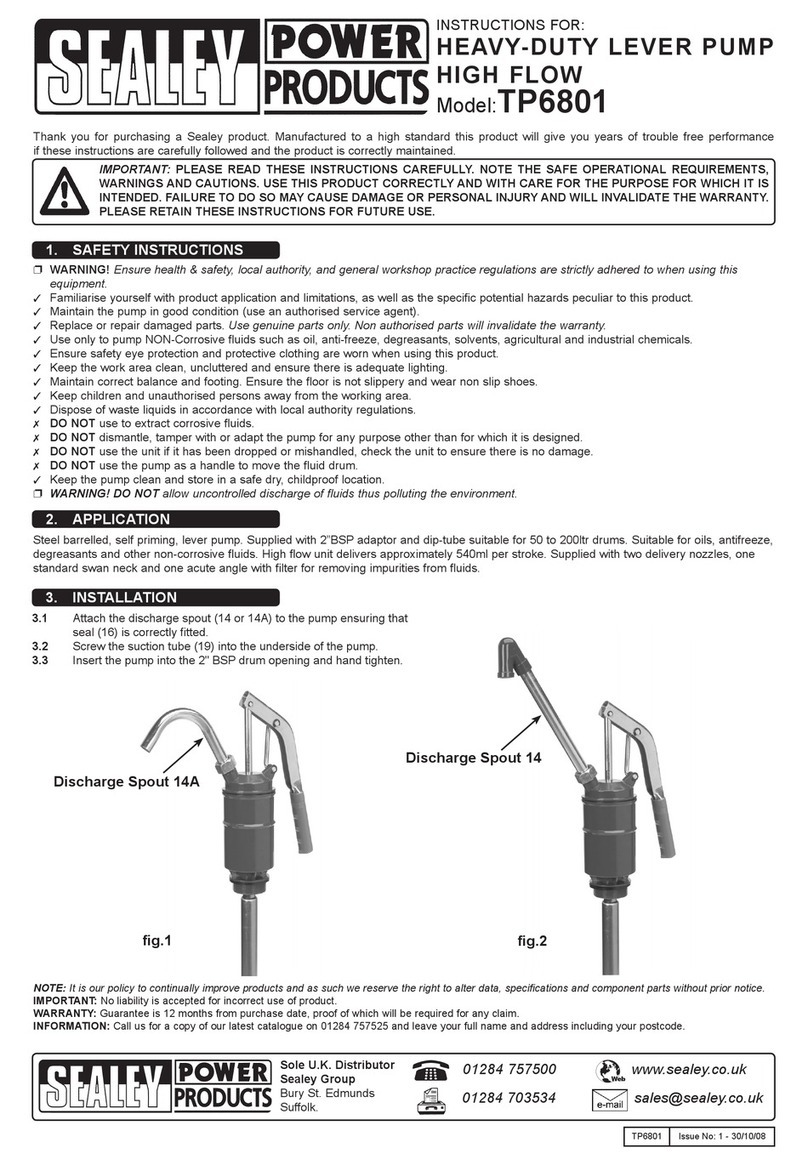

Popular Water Pump manuals by other brands

Boss Hydraulics

Boss Hydraulics PE08TW8 operating instructions

BOC Edwards

BOC Edwards XDS35i instructions

Kärcher

Kärcher SP 5 Dirt operating instructions

Liquiflo

Liquiflo H-Series Installation operation & maintenance

Mesto

Mesto SAUGFIX 3253 Series Instructions for use

BUSCH

BUSCH COBRA DS 0600 E Installation and maintenance instructions