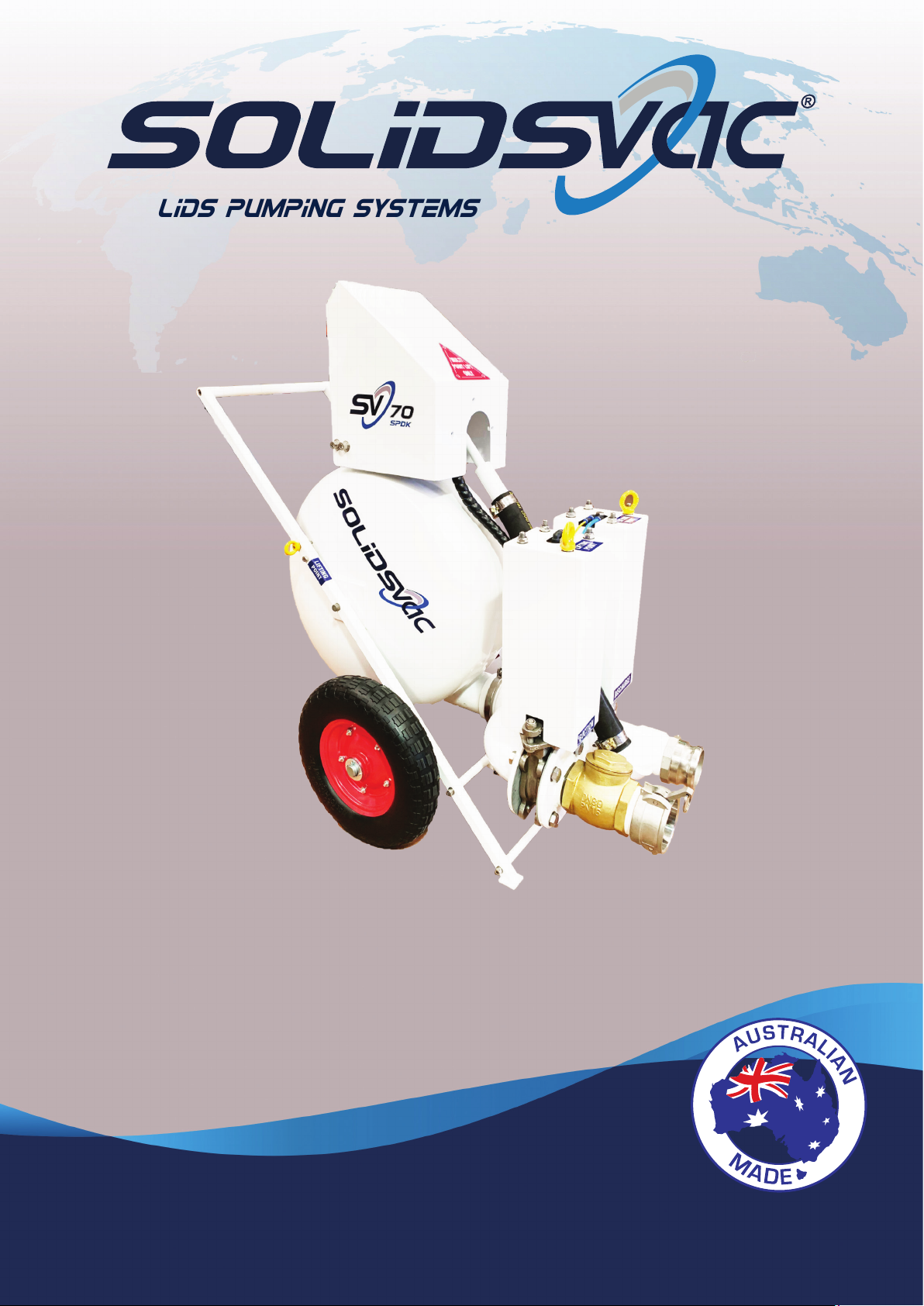

SOLIDSVAC SV70-SPDK User manual

SV70-SPDK Operations Manual

ISSUED DATE - 140421 LAST REVISED - 050821

SOLIDS PUMPING SYSTEMS

V 1.3

U1/ 5-7 Boeing Place - Caboolture - QLD 4510 - Australia

CONTENTS

Description

Safety First

1. Operation Overview

2. Design Registration

3. Technical Data

4. Schematic

5. Pump Set-Up

6. Operation

7. Maintenance

8. Timer Cycling & Adjustments

9. Accessories

10. Operation Risk Assessment

11. Parts Assembly

12. Job Safety Analysis

Page

3

3

3

4

4

5

6

7

11

12

13

21

24

Scan this QR Code for an electronic version of this Operations Manual

www.solidsvac.com

page 3

SAFETY FIRST

CAUTION & GENERAL SAFETY

This manual contains important information concerning the installation, operation and maintenance of the Solidsvac Pump, Model

SV70-SPDK. To prevent injury to personnel or equipment damage, this manual MUST be read and understood by those responsible for

the installation, operation and maintenance of the equipment.

THIS OPERATION MANUAL MUST BE USED IN CONJUNCTION WITH BOTH SITE-SPECIFIC RA AND JSA’s.

- Isolate, tag out and disconnect the air supply to the unit prior to working on any part of the system

- Lift the equipment only at the lifting points provided

- The pump should be installed in a safe level area, which provides adequate access for operating the equipment

- Ensureallhosesareingoodcondition,correctlyratedandcertiedfortheserviceinwhichtheyaretobeused

- Inspect the unit regularly for damaged or worn components

- AllcoversMUSTbettedpriorandduringoperation

- Air pressure should NEVER exceed rated pressure

- Tiedownpoints(iftted)MUSTNOTbeusedasliftingpoint

CAUTION: BE AWARE OF RETAINED MATERIAL IN THE TANK INCREASING WEIGHT

SOLIDSVAC PUMPS EACH HAVE SPECIFIC COMPRESSED AIR REQUIREMENTS DEPENDING ON THE JET PACK FITTED.

The operator MUST ensure that an appropriate and adequate air supply is available depending on the model and Jet Pack in use.

AllSolidsvacPumpsrequireaminimumoperatingpressureof500kPaandhaveamaximumoperatingpressureof720kPa(105psi).

Itisrecommendedthata25mm(1”)i.d.airhoseisusedforcompressedairsupplytothepump.

Note: An 18mm (¾”) i.d. Air hose contains HALF the volume of the recommended 25mm (1”) hose.

TheDischargehoseMUSTbenosmallerindiameterthanthepumpsoutlet75mm(3”)preferablyaself-supportingtypeandsecured

at regular intervals.

WARNING: THE PUMP-OUT LINE MUST BE SECURED AT THE EXIT POINT

1. OPERATIONAL OVERVIEW

The Solidsvac SV70-SPDK operates as a shuttle system

alternately loading via vacuum and discharging via pressure

awiderangeofowableandsemi-owablematerials.

Operation is fully automatic and the Solidsvac SV70-SPDK

features no internal workings, high vacuum and pressure

discharge where suction of up to 50 metres and discharges in

excess of 400 metres are achievable.

WARNING

Compressed air can be dangerous. Correctly rated hoses and

piping should be used in conjunction with the appropriate

ttingsandsafetydevicesonallconnections.

Theunitisnotdesignedtooperateabove758kPa(114psi)and

thePRVwillrelieveat758+/-35kPa(110psi+/-5psi).

2. DESIGN REGISTRATION

TheSolidsvacSV70-SPDKhasaCerticateofPlantDesign

Registration from Workcover NSW, Australia. A copy of which

may be obtained by contacting Solidsvac Pumps.

DESIGN REGISTRATION # PV-6-198163/16

Technical Standards

- AS2971-2007 Serially Produced Pressure Vessels

- AS4343-2005 Pressure Equipment - Hazard Levels

- AS1210-1210 Pressure Vessels

telephone +61 456 000 665

email [email protected]

page 4

3. TECHNICAL DATA

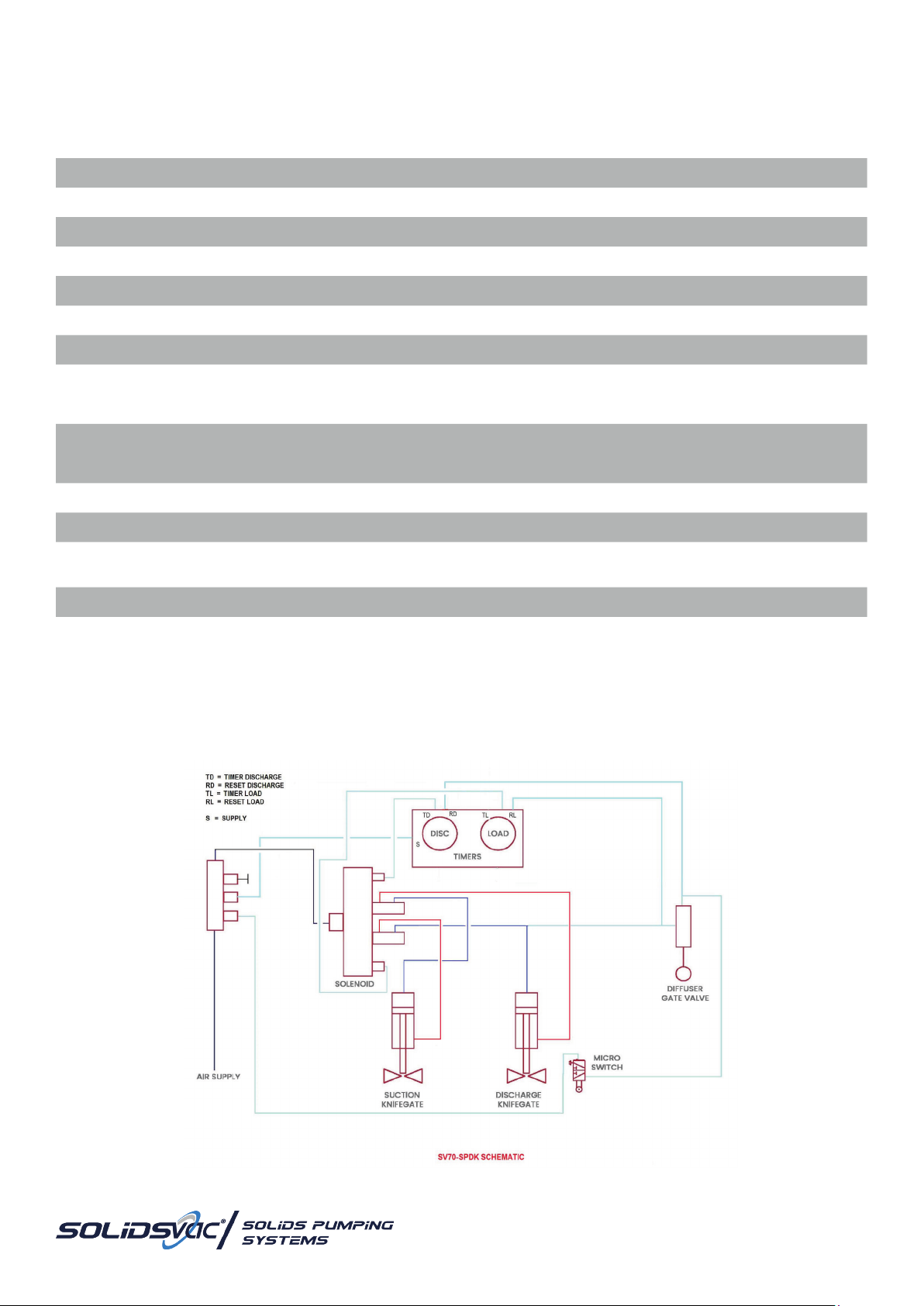

4. SV70-SPDK SCHEMATIC

Height 1150 mm 45”

Width 650 mm 25.5”

Length 1240 mm 48.5”

Weight 130 kg 264 lb

Air inlet 13 mm 1/2” BSP

Suction inlet 75 mm 3”

Discharge outlet 75 mm or 100 mm 3” or 4”

Suction lift 7.9m @ 100 cfm

9.2m @ 180 cfm

11.5m @ 230 cfm

26' 2" @ 100 cfm

30' @ 180 cfm

37' 7" @ 230 cfm

Air consumption options 2.8 m3/Min Jet Pack

5.0 m3/Min Jet Pack

6.5 m3/Min Jet Pack

100 cfm Jet Pack

180 cfm Jet Pack

230 cfm Jet Pack

Delivery 400+ m 1312+ ft

Displacement cycle 65 ltr 17 gal

Operating pressure 7bar(max)@690kPa

4.5bar(min)@448kPa 100psi(max)

65psi(min)

Maximum solids 50 mm 2”

Measured water throughput 400 lpm 106 gpm

TECHNICAL DATA METRIC US IMPERIAL

www.solidsvac.com

page 5

5. PUMP SET-UP

Before commencing operation, Solidsvac strongly recommends each user reads the Operation Manual supplied with each unit and

available online or via the QR code on pump.

Note: No training is necessary to operate the SV70-SPDK however understanding the Operations Manual is essential to safe

practice.

Solidsvacalsorecommendsthatasite-specicRiskAssessment(RA)ofthepumpingoperationisundertaken.Anyrecommendations

arising from the Risk Assessment would be additional to the following:

- Theunitandallhosesandttingsareundamagedandingoodworkingorder.

- Allcoversarettedinplaceandcorrectlysecured.

- Cleancompressedairatminimumworkingpressureof690kPa(100psi)isavailable.

- A25mm(1”)i.d.airhoseisavailable.

- The discharge area has suitable warnings to protect personnel.

- The correct PPE is available and worn for operating compressed air equipment

- Eye Protection

- Hearing Protection

- Gloves

- Safety Boots

- Set the Solidsvac Pump in a safe level location as close to the material to be pumped as possible.

- Attach both suction and discharge hoses along with any accessories as required and ensure safety clips are in place.

- Ensurethemainairvalveisintheoffpositionandattachthe25mm(1”)airhosetotheSolidsvacPump&tsafetyclips.

- The pump is now ready for use.

Note: Always position hoses out of walkways where possible remaining aware of trip and fall hazards.

CONTENTS EXCLUDED FOR PUMPING

Solidsvac recommends that any contents that fall within the scope of the below class liquids should not be pumped with any

Solidsvacunit.Solidsvacalsorecommendsthatasite-specicJSAshouldbeconductedwithreferencetoanyothertypeofmaterial

being pumped.

- ClassIIIAliquidswithaashpointequaltoorgreaterthan140°F(60°C),butlessthan200°F(93°C)haveaNFPA704

ammabilityratingof2.

- ClassIIIBliquidswithaashpointequaltoorgreaterthan200°F(93°C)haveaNFPA704ammabilityratingof1.

OPERATING PARAMETERS

TheSolidsvacSV70-SPDKcanoperatewithinenvironmentsrangingfrom0°Cto50°Candallhumidity.

ThemaximummediumtemperatureallowablefortheSV70-SPDKis50°C.

HOSES

Solidsvacrecommendsthehoses(AirSupply,Suction,Discharge)usedinoperationwiththeSV70-SPDKaretobemadeofanti-static

material. If the hoses used in operation with the SV70-SPDK are not made of anti-static material, they MUST be braided to comply with

requirementsforFireResistance&Anti-Static(FRAS)toAS/NZS2660,orotherequivalentstandard.

EARTHING POINT

AllSolidsvacmodelsarettedwithanEarthingPointwhichismandatoryrequirementpriortooperation.Solidsvacstrongly

recommends that the operator takes the necessary measures to earth the unit prior to operation.

WARNING: TO AVOID POSSIBLE ELECTROSTATIC CHARGES PRODUCED BY THE MATERIAL CONVEYED THE

OPERATOR MUST EARTH THE UNIT PRIOR TO OPERATION.

telephone +61 456 000 665

email [email protected]

page 6

6. OPERATION

Turn the air supply valve ON at the source. Turning the pump valve to ON, the pump will now commence its cycle of operation. The

LOAD and DISCHARGE cycles are controlled by adjustable pneumatic timers, these allow for adjusting the pump to varying conditions,

i.e.heavyorlightmaterialorlongorshortdistancesetc.DuringtheLOADcycletheoperatorshouldnoteanaudibledifference(Gargle)

oncethevesselhaslled,adjusttheLOADtimertowherethecyclecompletesjustasorpriortothisoccurring.TheDISCHARGEcycle

depends on both the material being transferred and the distances involved. A discharge setting of 4-6 seconds will accommodate

about 95% of most pumping jobs with the SV70-SPDK.

Once pumping is completed, remove the suction from the material and allow the pump to cycle self-clean, on completion of the

operations isolate the air supply and allow the pump to cycle until the supply in the line is exhausted, then turn the pump off at the

supply line. SOLIDSVAC recommends checking the pump discharge to ensure it remains correctly anchored at the exit. Lubrication is

not required during operation.

Note: Dry operation will not damage the pump.

CYCLE INDICATOR

Thepumpisttedwithanindicatortoinformtheoperatorwhichcyclethepumpisoperatingin,wheninthedischargecyclethe

indicator is yellow and when in the suction cycle the indicator is clear.

Note: If the pump is supplied with a head of pressure it is possible for the pump to siphon when the air supply is turned off. To

prevent siphoning when the pump is not in operation, turn the pump off when it is in the discharge cycle or isolate the material

supply source to the pump.

DISCHARGE CYCLE INDICATED SUCTION CYCLE INDICATED EARTHING POINT

An earthing point is tted to the

SV70-SPDK if required by the site-

specic RA or JSA.

www.solidsvac.com

page 7

7. MAINTENANCE

In use, the Solidsvac SV70-SPDK requires little to no maintenance, however Solidsvac recommends that the following strict measures

are taken to ensure pump remains in good working order.

Maintenance,repairs,andthedisassemblingoftheunitbecarriedoutbyanyqualiedFitterwithabasicknowledgeofpneumatics.

SERVICE TIPS

- Set up a maintenance schedule and follow it diligently.

- Clean the machine areas before removing pneumatic components.

Note: When steam cleaning or using water to clean a machine, be sure that ller openings, breather caps etc are protected

from possible entry of water into the system.

- Use clean plastic plugs to cover the ends of disconnected lines or to plug openings when working on a pneumatic system.

- A clean workbench is an absolute ‘MUST’ when servicing components. An industrial-type vacuum cleaner is a valuable aid in

removing dust, dirt and tiny metal particles from the work area.

- Check the condition of your tools – they should be clean. Always use hammers made of plastic or leather, so there is no danger

of metal chips getting into components.

- When removing parts for service, clean them and then store them in plastic bags or other clean containers until they are

installed again.

- Whencleaningpneumaticparts,useextremecaretoensurethatthecleaninguidisnon-ammableandcompatiblewiththe

system.

- Use common-sense precautions to prevent dirt entering components that have been temporarily removed from the circuit.

SYSTEM PERFORMANCE

Pneumaticproblemsthataffectsystemowandpressurearenotalwayseasytolocate.Thesystemtestingproceduredescribedlater

inthissectionisbasedonausefulstep-by-stepapproachtotroubleshooting.Troubleshootingchartsmakethefault-ndingprocess

easier and faster.

EFFECTS OF A DROP IN SYSTEM FLOW RATE

- A pressure drop will affect the speed and cycle times of a pneumatic machine; actuators will not extend, retract, or rotate at

therequiredspeed.Actuatorcontrolwillbecomejerkywithinconsistenciesinowascylindersandmotorsaresuppliedat

different rates. In many complex pneumatic systems, the sequencing and positioning of component operations will be affected

as cycle times become thrown out of programmed control.

- Thecompressor’sdischargeowrateshouldbecheckedrsttoensurethatthedropinowisnotaproblemofinternal

leakage or incorrect setting of compressor controls.

EFFECTS OF DROPS IN PRESSURE

The major causes of pressure drop include:

- Pipeworkrestrictions(forexample,incorrectsizing)ttingrestrictionsandsharpcorners

- Incorrect pressure settings

- Suddenenlargementinuidconductors

- Longlengthsofuidconductors

- Componentleakage(internalandexternal)

- Broken valve springs

- Blocked or crimped air lines

- Loosettings

- Valves not sealing correctly because of contaminants

- Some combination of the above causes

telephone +61 456 000 665

email [email protected]

page 8

SYSTEM TESTING PROCEDURES

Pneumatic systems, like all machines, require routine maintenance to ensure reliability. However, there are still times when problems

occurandMUSTbelocatedquicklyandefciently,especiallyinproductionapplications.Astep-by-stepmethodhasbeendevisedas

awayofndingandsolvingpneumaticproblemsquickly.

These steps are as follows:

STEP 1: KNOW THE SYSTEM -

Studythemachine’stechnicalspecicationstoobtainanunderstandingofhowthesystemoperatesandthefunctionofthe

machine’s components. Obtain a circuit drawing and check the system through. Check the machine’s maintenance records and

commissioning test results if they are available.

STEP 2: ASK THE OPERATOR -

Determine the symptoms of the problem by asking the operator for a detailed description of the machine’s normal operating

performance.

STEP 3: INSPECT THE MACHINE -

Useyoursenses(touch,smell,sightandhearing)tolocateproblemsordamagesuchasnoisycomponents,airleaks,malfunctioning

components and damaged air lines.

STEP 4: OPERATE THE MACHINE -

Operate the machine and check that the machine’s gauges are reading ‘normal’ and that there are no unusual noises. The operation

of the machine’s controls should not be ‘sticky’ or ‘spongy’. The machine’s performance should not be slow, erratic – nor non-existent.

STEP 5: LIST THE POSSIBLE CAUSES -

Once the fault has been located and recognised, list the possible causes – starting with the simplest.

STEP 6: REACH A CONCLUSION -

Use a troubleshooting chart to check the list of possible causes; then decide which is the most likely.

Note: 99% of all issues are air supply related.

www.solidsvac.com

page 9

SYSTEM MAINTENANCE

A pneumatic system is easy to maintain. However, like any other mechanism, it MUST be operated and maintained correctly.

Pneumaticsystemscanbedamagedbyexcessivepressures,uidcontaminationandbyhighoperatingtemperatures.

Regularmaintenancewillreduceyourpneumatictroubles.Byusingaregularmaintenanceprogramme(preventativemaintenance)

to care for a system, you can eliminate common problems and anticipate special ones. Problems can be corrected or averted before

a breakdown occurs.

The following are the key problems that commonly need to be addressed in pneumatic maintenance:

- Water-contaminated air

- Poorairltration

- Incorrect pressure settings

- Incorrect lubricator settings, resulting in sticking valves

- High air temperature

- Loose supply lines

- Faulty seals

IMPORTANCE OF CLEANLINESS

Cleanliness is of supreme importance when it comes to servicing pneumatic systems. Keep dirt and other contaminants out of the

system.Smallparticlescanscorevalves,causeseizingofcomponentsandclogorices,resultinginexpensiverepairjobs.

When servicing a pneumatic system, always do the following to ensure cleanliness:

- Keep the compressor and machine's lubricating oil clean

- Keep the system clean

- Keep your work area clean

- Becarefulwhenyouchangesealorcomponents(takephotos)

- Use caution with compressed air

- Ensure all pneumatic components supply lines are secure

telephone +61 456 000 665

email [email protected]

page 10

AIR INLET FILTER

Prior to commencing each pumping operation:

- Checkthatallttingsandconnectionareserviceable.

- Adequate compressed air is available.

- A general visual inspection of the unit including the suction and discharge valves

is recommended.

Asmallmetalgauzein-linelterpreventsforeignobjectsenteringtheventurinozzleviatheairsupplyline.

SolidsvacPumpsrecommendperiodicinspectionandcleaningasrequired,replacementltersandsealsareavailablefromyour

Solidsvac suppliers.

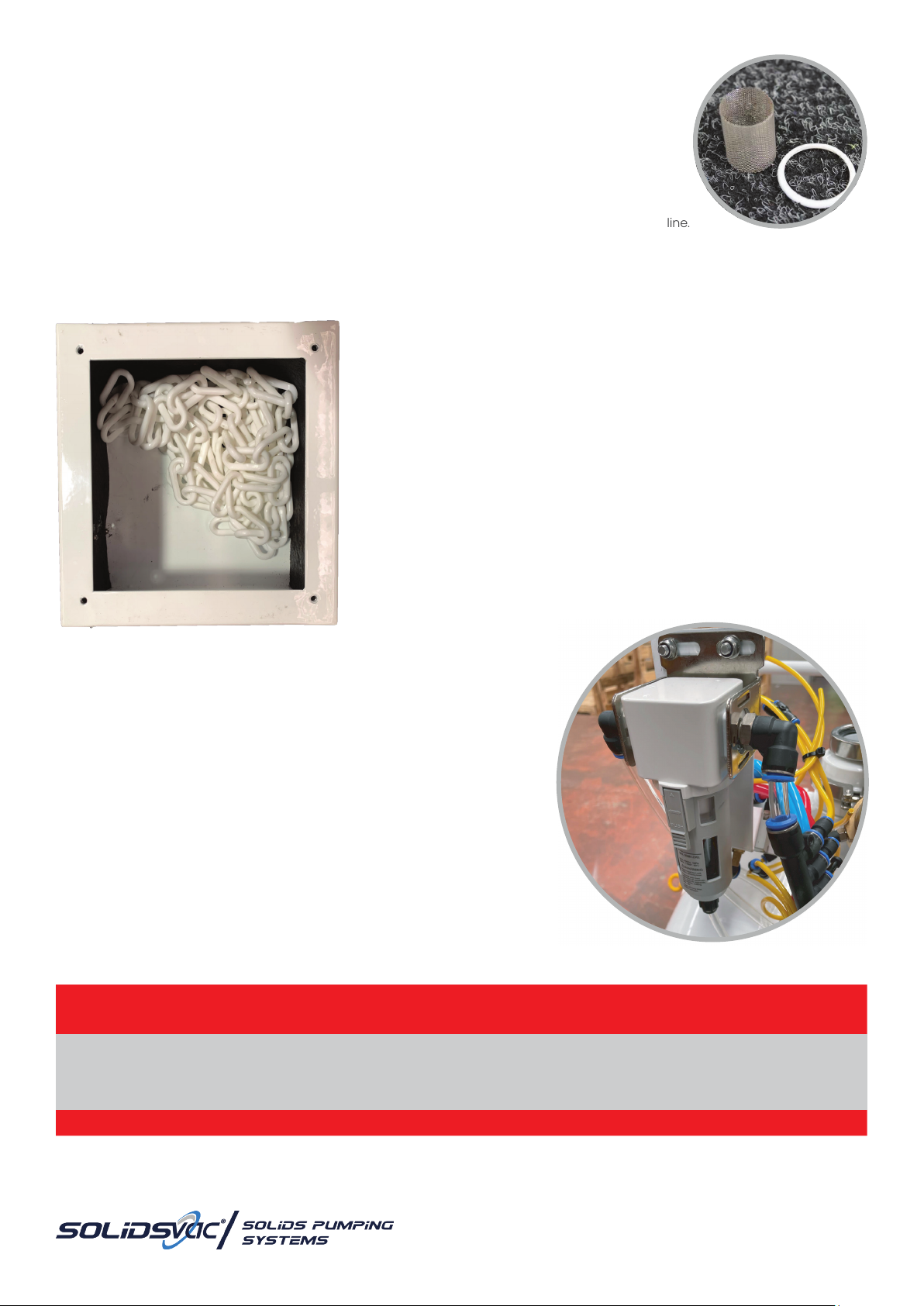

EXHAUST BOX

Iftted,SolidsvacPumpsalsorecommendaperiodicvisualinspectionofthe

exhaust box be carried out.

- With the air supply off and isolated, remove the pump cover.

- Visuallychecktheexhaustopeningandifitappearsblocked,eitherush

the box with a hose, alternatively, remove the 4 cap screws in the side

cover.

- Ensure that there is no foreign material inside the box, remove and clean

the chain and insert back into the box.

- Reinstall the cover and recommence operations.

AIR FILTER

TheSolidsvacSV70-SPDKisttedwithanautodrainltertoreduceforeignmedia

entering via the air supply.

Solidsvacrecommendstheairlterisinspectedregularlyandthelteris

changed as required.

SAFETY FIRST

PRIOR TO COMMENCING ANY WORK ON THE UNIT, THE AIR SUPPLY VALVE MUST BE

ISOLATED AND THE CONTROL SYSTEM TESTED DEAD

www.solidsvac.com

page 11

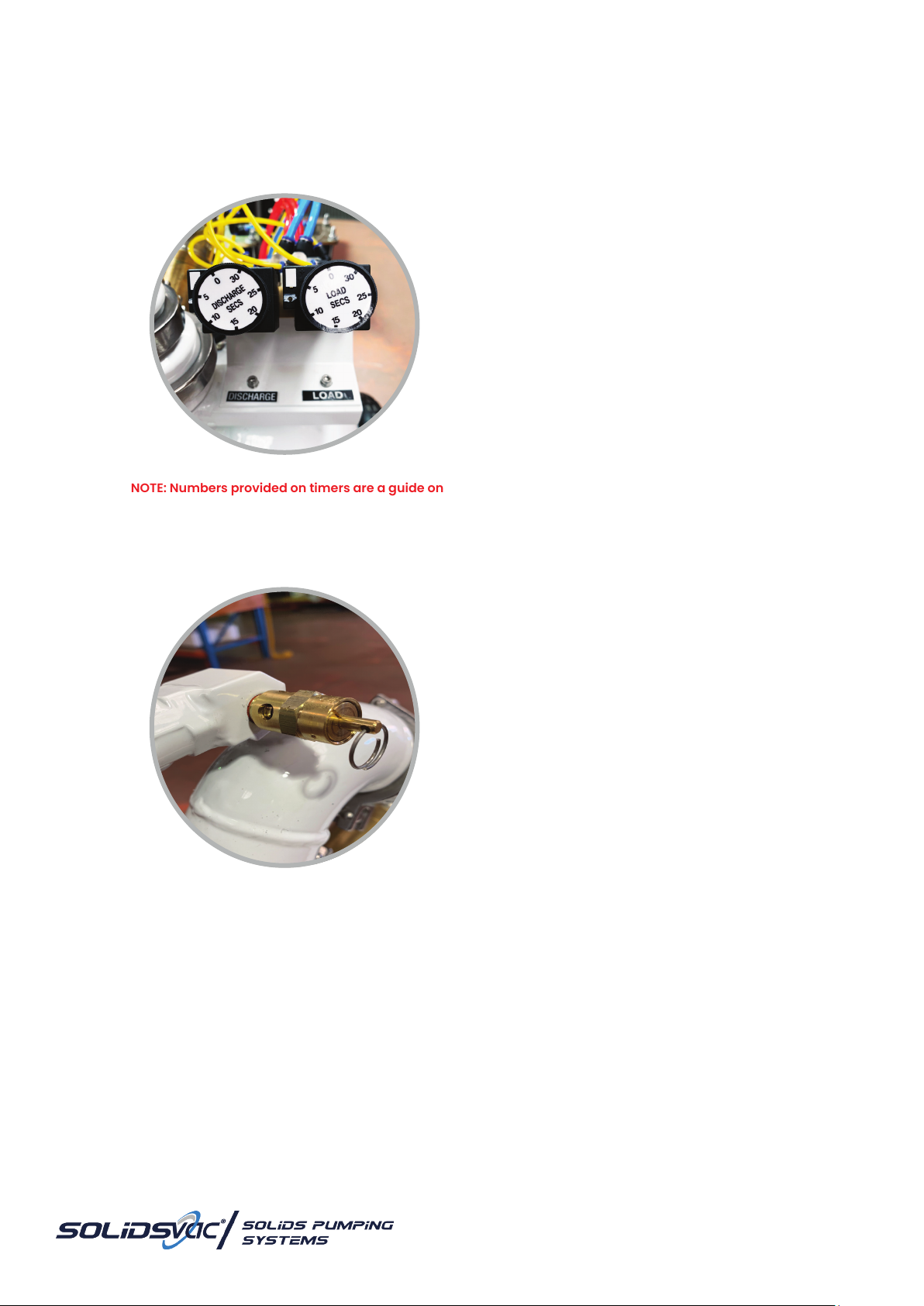

8. ADJUSTING THE LOAD & DISCHARGE CYCLES

Adjusting the LOAD and DISCHARGE cycles may be required depending on the viscosity of the material being transferred and the

distances involved etc. Turning either respective Timer Dial clockwise increases the load or discharge time and turning it anti-clockwise

decreases the load or discharge time.

NOTE: Do NOT turn the knob more than one turn (360’) when adjusting the cycle time.

IMPORTANT NOTE: Numbers provided on timers are a guide only and may not be approximate to actual timer gure indicated.

PRESSURE RELIEF VALVE

The Pressure Relief Valve can be operated by pulling the ring as indicated below:

Adjust timers to dial marking beside each timer.

Only adjust timers when required.

Before starting the pump, adjust timers to

between 4-6 seconds.

telephone +61 456 000 665

email [email protected]

page 12

9. ACCESSORIES

Suction Wand - Attaches to the suction hose allowing the operator to

stand upright and ambient air to be introduced at the material inlet.

Strainer - Available in two sizes and attaches to the suction hose to

prevent the ingestion of oversize particles.

VacHead - An industrial vacuum head with squeegee brush allows the

operator to stand upright, recovering material from hard surfaces i.e. an oil

spill from a road surface.

Note: It is recommended that the suction timing cycle is set to 15 seconds

when using this accessory.

Delivery Carousel - Controlled discharge to either a conveyor or

multiple points/skips etc.

Hoses - A complete range of high quality suction and discharge hoses are

available.

Hoover Head - Helps focus the vacuum and is ideal for recovering

heavier material such as barite, oil sludge, mud or similar from tank bottoms

and various hard surfaces.

Dropbox - Deliveryofmaterialtoaskip,conveyororspecicpoint.

Tool Kit - Contains all you need for basic maintenance on your pump.

Service Kit - Contains all you need for basic maintenance on your pump.

www.solidsvac.com

page 13

OPERATIONAL RISK

ASSESSMENT

telephone +61 456 000 665

email [email protected]

page 14

OBJECTIVE:

Theobjectiveofthehazardidenticationandriskreviewprocessistoensureallhazardsareidentiedandaccuratelyassessedforrisk.

Suitable and effective controls MUST be nominated and implemented to keep workplace safe.

CONTEXT:

The Solidsvac Mobile Solids Pump is designed to be used for the purpose of pumping and transferring heavy slurry/media. The

SolidsvacMobileSolidsPumpwillbeinastationarypositionontheoor.Theoorconditionsneedtobesafeandlevel.

SCOPE:

The Scope of the risk assessment as follows:

1) IdentifyoperationalhazardsassociatedwiththeuseoftheSolidsvacMobileSolidsPump

2) RiskAssesseachoftheidentiedhazards

3) Implementcontrolstominimiseanyhazardstoanacceptablelevel

INVOLVED PERSONS/STAKEHOLDERS:

Risk Facilitator

Solidsvac Management/Tradespeople

ASSUMPTION:

Supplier

Competent, comply with standards and drawings.

End User (Owner/Hirer/User)

The end user has:

- Competent(operatorsaretrained,competent,authorised,etc.)

- Procedures(changemanagement,trafcrules,riskassessed,developed,effectivelyimplemented,etc.)

- Equipmenttforpurpose(rated,designedcompatible,maintained,inspected,monitored,etc.)

- Leadership(communication,directions,monitoring,etc.)

- Environmentalconditionsarecompatibletotheoperationalcapabilitiesoftheequipment(naturalvs.man-made,etc.)

INCLUSIONS:

Only the aspects directly related to Solidsvac Mobile Solids Pump.

EXCLUSIONS:

TransportingandstoringtheSolidsvacMobileSolidsPump(Usersoperationalriskassessment,training,competence);

Assessmentoftheenvironmentalconditionsintheoperationalarea(Usersplanningandlocalriskcontrol)

REFERENCE MATERIAL:

QLD Coal Mining Safety & Health Act 1999

QLD Coal Mining Safety & Health Reg 2001

Recognised Standard 02 Control of Risk Management Practices

www.solidsvac.com

page 15

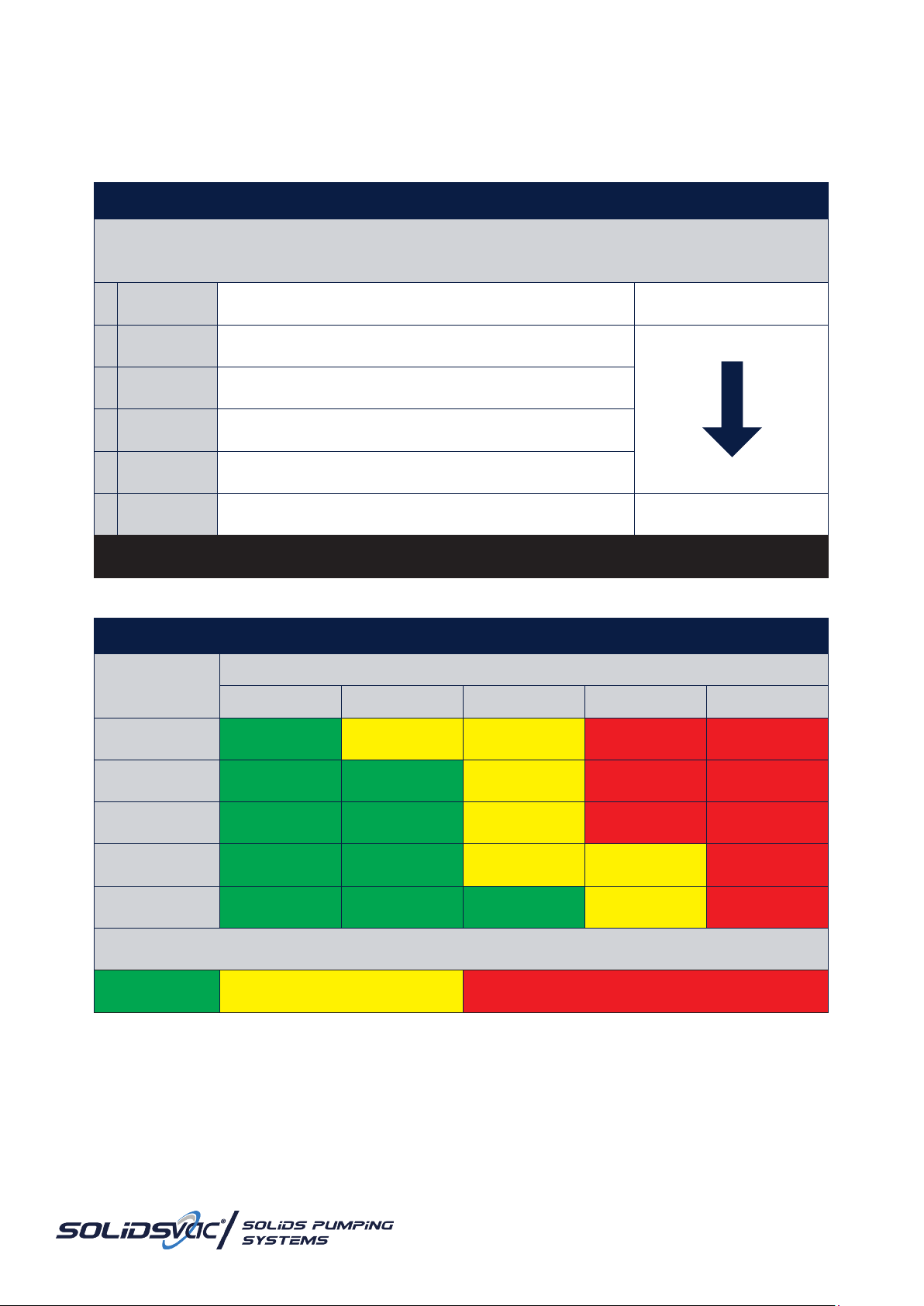

RISK MATRIX

Step 1: Establish the Consequence (1-5)

Consequences

Injury / Occupational Illness

or Disease

(How to manage Work Health and Safety

Risk – Code of Practice. Safety Work

Australia 10 August 2011). The company

must ensure levels of consequence and

likelihood are relevant to the company’s

Business risk.

Business

Loss/Asset

Damage

Reputation/

Social/

Community

Legal and

Regulatory/

Contract

Environmental

Impact

(e.g. Hydrocarbon spills)

1Insignicant Report only <$5k Complaint/

Single project or

stakeholder

Minor non-

compliance

- internal report

only

Negligible pollution

2 Minor

First Aid Treatment Injury/Illness

Non-prescription medication/

treatment that can be

administered by rst aider.

<$20k Local public

concern

Minor legal non-

compliance -

Contractual issue

Minor pollution/

Nuisance

3 Moderate

Medical Treatment Injury/Illness

Prescription medication/treatment

that can only be administered by a

registered doctor/nurse.

Minor LTI <5 full days work lost

<$50k Regional public

concern/Multiple

stakeholders

Serious breach of

law/Investigation

by authority/

On the spot ne.

Major breach of

contract.

Noticeable pollution

4 Serious

Serious Lost Time Injury/Illness

Loss of 5 or more days work/

admission to hospital/serious

injury under WHSA denition

<$100k National public

concern

Signicant

penalties/

Termination of

contract

Signicant

environmental event

5 Major Fatality

Single or multiple fatalities <$100k International

public concern

Law suits/

Prosecution/

Removal from

suppliers list

Major environmental

event/Material

environmental harm

Step 2: Establish the Likelihood (A-E)

Description Frequency Examples

(How to manage Work Health and Safety Risk – Code of Practice. Safety Work Australia 10 August 2011).

A Certain to occur Expect to occur in most circumstances (>1 event/month)

B Very likely Will probably occur in most circumstances (2 to 1 events/year)

C Possible Might occur occasionally (1 event/1 to 2 years)

D Unlikely Could happen at some time (1 event/2 to 3 years)

E Rare May happen only in exceptional circumstances (>3 to 5 years)

telephone +61 456 000 665

email [email protected]

page 16

RISK MATRIX

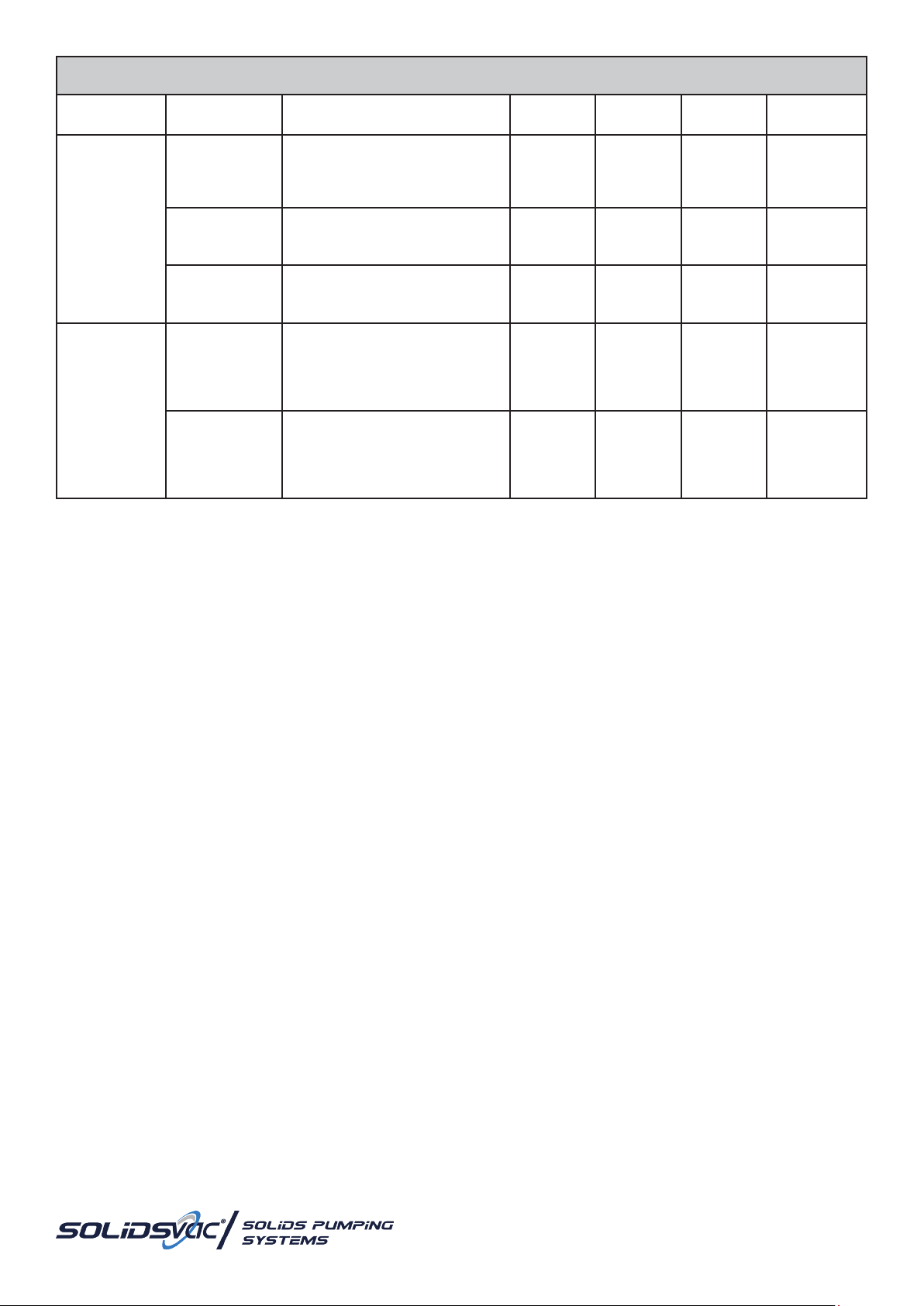

Step 3 : The Hierarchy of Risk Control Model

Start at the top and only if you can’t select controls from one section, move to the next one down.

You need to use a combination of control measures to achieve the second level of risk control.

If a particular hazard can’t be removed the risk associated with the hazard can never be eliminated.

1 Elimination Complete removal of the hazard Most effective

2 Substitution Replacing the material of process with a less hazardous one

3 Isolation Separate the hazard from people

4 Engineering Guarding, ventilation, design, re-design etc

5 Administration Providing controls such as training and procedures

6 PPE Use of PPE when other controls are not practical Least effective

7 Post Mitigation after an event (ell Fire extinguisher)

Using the Matrix to Determine Risk Score

Likelihood

Consequences

1 2 3 4 5

A

Certain to occur Low

11 Moderate

16 Moderate

20 High

23 High

25

B

Very likely Low

7Low

12 Moderate

17 High

21 High

24

C

Possible Low

4Low

8Moderate

13 High

18 High

22

D

Unlikely Low

2Low

5Moderate

9Moderate

14 High

19

E

Rare Low

1Low

3Low

6Moderate

10 High

15

ALARP - As low as reasonably practical

Tolerable Take action to manage ALARP Intolerable (without specic senior management approval)

www.solidsvac.com

page 17

Risk Assessment assumes that current

controls are adequate and working.

The Risk Scores have been achieved

using the qualitative risk analysis

matrix from the Solidsvac Risk

Management procedure and is

attached at the end of this document.

OPERATIONAL RISK ASSESSMENT

THIS IS A BASIC R.A

SOLIDSVAC STRONGLY RECOMMEND THAT

A SITE-SPECIFIC R.A IS CONDUCTED.

Reviewed

by Date

REFERENCE ACTIVITY SUB ACTIVITY HAZARD RISK EVENT EXISTING CONTROLS

CURRENT RISK WITH EXISTING CONTROLS RISK TREATMENT

(Accept, Transfer,

Avoid, or Further

RiskReview)

ADDITIONAL RECOMMENDATIONS

STATUS

(Complete,

Incomplete,

Inprogress)

TARGET

RESIDUAL

RISK AFTER

TREATMENT

CONSEQUENCE LIKELIHOOD RISK RATING

1.0 Transport to

work site Travel position Inadequate transport

method

Resulting in personal

injury and damage

to the Solidsvac SV70

Mobile Solids Pump

during transport

Wheels and handle on the Solidsvac SV70

Mobile Solids Pump

Designed well balanced

Mine transport rules

L 8

Placement and loading of the

Solidsvac SV70 Mobile Fluids Pump

to be included in the training and

assessment document in the

Solidsvac SV70 Mobile Solids Pump

Open

1.1 Set up Environment

Solidsvac SV70 Mobile

Solids Pump set up on

uneven ground or pump

is inadequately secured

to rib when on uneven

ground resulting in

unplanned movement

of pump

Resulting in personal

injury and damage

to the Solidsvac SV70

Mobile Solids Pump

during operation

Operation manual and training documents

set up procedure on level ground or

securing pump to the rib using rated

restraining devices when operating on

uneven ground

2 C L8 ALARA Training and assessment in the

Solidsvac SV70 Mobile Solids pump

package

Manual handling Failure of the correct

manual handling

technique

Manual handling training at Induction team

lifts where required

Most set up and removal tasks conducted

fromoorlevelandreasonableheight

2 C L 8 ALARA Training and assessment in the

Solidsvac SV70 Mobile Solids pump

package

1.2 Operation

Nip/crush points and

“Line of Fire” issues from

mobile equipment, low

roof height issues during

set up and removal

resulting in crush injuries

Resulting in personal

injury

Operation manual and training documents

setup, removal procedures

Operation manual and training documents

identify the need to drain pump before

disconnecting. Mine transport rules Line of

sight before any movements

No machine movements without positive

communications

Hi-viz clothing

3 C M 13 ALARA Training and assessment in the

Solidsvac SV70 Mobile Solids pump

package

High pressure

compressed air

Failure of the

compressed air

system resulting in:

Personal injury from

being exposed to

compressed air due

to hose failure and/or

damage

Rated pressure hoses

Mine Site Induction and Training

Competencies 3 C M 13 ALARA

Work on or around a

moving belt

Interaction with

conveyor resulting in

personal injury

Mine Site Induction and Training

Competencies 2 C L 8 ALARA

Discharged material

(at100psi)contacts

operators

Resulting in personal

injury

Operation manual and training documents

the set up procedure incorporates

barricading discharge area with caution

tape

2 C L 8 ALARA

Pinch points on Solidsvac

SV70 Mobile Solids pump

during operation

Resulting in personal

injury Fitforpurposecoversttedtopumpduring

operation, MUST be in place 2 C L 8 ALARA

Blocked discharge hose

resulting in exposure

to stored energy while

unblocking hose

Resulting in personal

injury

Operation manual and training documents

unblocking procedure

Pressure relief valve at the pump relieves

discharge pump pressure

2 C L 8 ALARA

Blocked suction hose

resulting in process delay

Resulting in personal

injury and/or process

delay

Operation manual and training documents

unblocking procedure

Isolation training and procedures

Low pressure i.e. 10psi

Strainerornozzlettedtosuctionhose

2 C L 8 ALARA

1.3 Maintenance Incorrect maintenance

resulting in equipment

failure

Resulting in personal

injury and/or process

delay

Tested to Australian Standards

OEM Maintenance scheme 2 C L 8 ALARA Maintenance to be carried out as

per OEM Suppliers SV70

Operation/Maintenance Manual

telephone +61 456 000 665

email [email protected]

page 18

RISK REGISTER ACTION PLAN

No ITEM/ISSUE AGREED ACTION WHO WHEN COMP DATE REVIEW/AUDIT

DATE

Operation Storage Communicate to end user to

develop work procedures for

storage of Solidsvac SV70 Mobile

Fluids Pump

Solidsvac Delivery

Travel position Communicate to end user to

develop work procedures for

travelling

Solidsvac Delivery

Use of Solidsvac

SV70 Mobile

Fluids Pump

Supplier to develop work

procedures for operating the

Solidsvac SV70 Mobile Solids Pump

Solidsvac Delivery

Maintenance Daily Supplier to develop daily

and/or pre-use visual inspections

procedures for using and

operating the Solidsvac SV70

Mobile Solids Pump

Solidsvac Delivery

Weekly Supplier to develop weekly

visual, operational, maintenance

inspections for using and

operating the Solidsvac SV70

Mobile Solids Pump

Solidsvac Delivery

www.solidsvac.com

page 19

PUMP PREVENTATIVE

MAINTENANCE PROGRAM

The following is the work to be performed to a SV70-SPDK Pump during Preventative Maintenance Check.

All items, except annual checks (Tradesman), are to be carried out by a Competent Operator.

- Lock and tag out equipment

- Record equipment data

- Checkallmountingandangeboltsaresecureandtight

- Check vessel support frame and wheels for soundness

- Visual inspection of pump for any damage

- Check for knife gate seal leaks

- Checkconditionofangegaskets

- Check knife gate packing for excessive leakage and adjust and/or replace

- Make sure all timers are operational

- Check operation of Pressure Relief Valve

- Checkin-linegauzelter

- Inspectconditionofairlinesandttings

- Checkoperationofswingcheckvalve(iftted)

- Check condition of venturi nozzle

- Test the operation of the SV70-SPDK pump prior to returning to service

- Makenoteontheeldreportofanyndingsthatmayrequireadditionalwork

telephone +61 456 000 665

email [email protected]

page 20

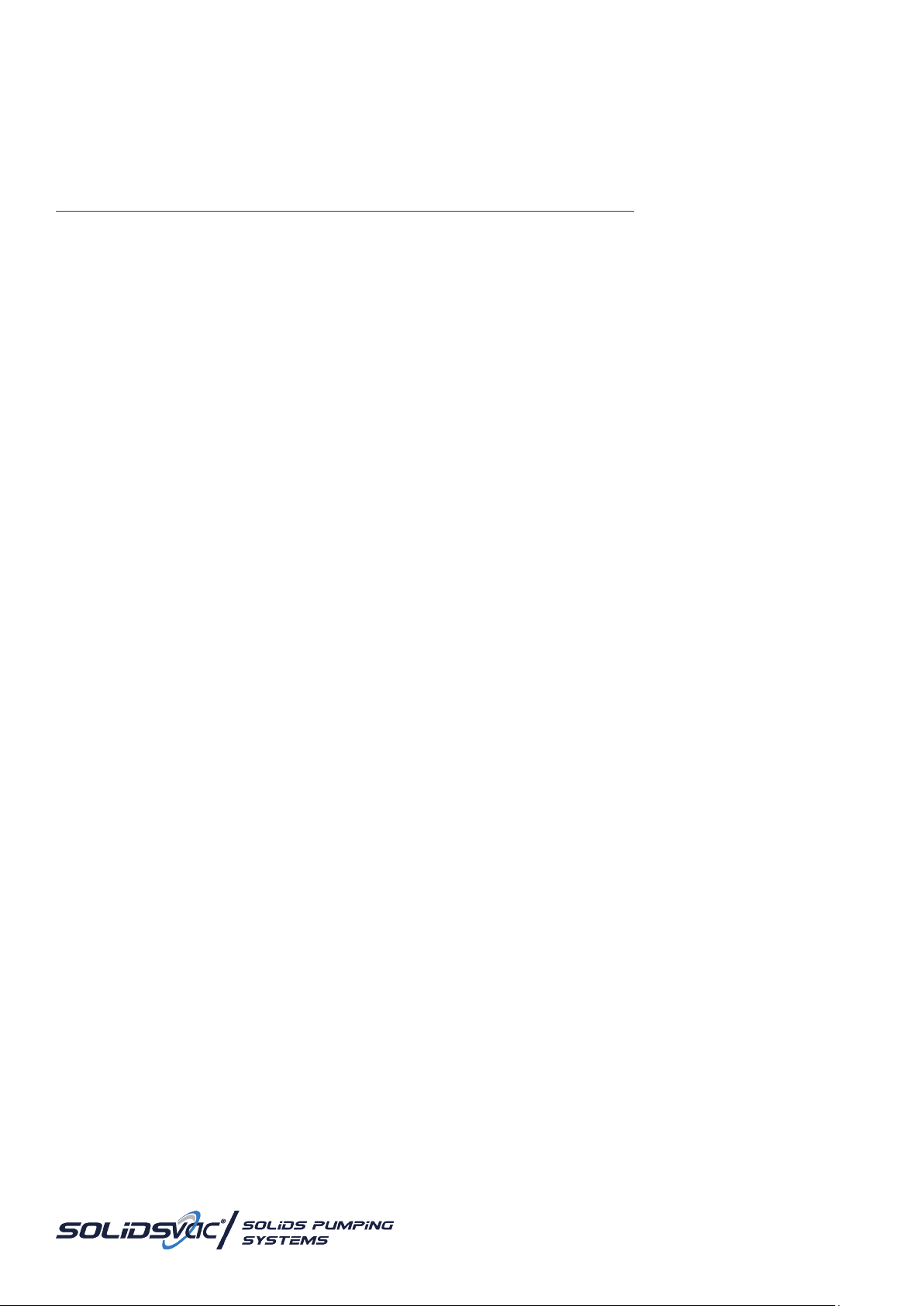

PUMP MAINTENANCE CHECKLIST

DESCRIPTION COMMENT

MAINTENANCE FREQUENCY

DAILY WEEKLY MONTHLY ANNUALLY

Pump use and

timing Check operation of pump prior to use. X

Overall visual

inspection

Complete overall visual inspection to be sure all

equipment is operating and safety systems are in

place. X

Check knife gate

seals Assure that all seals are in good condition and not

worn, split or damaged. X

Check knife gate

packing Check packing for wear and leakage and repack as

necessary. X

Check airlines and

ttings Inspectairlinesforanydeterioration,checkttingsfor

cracks and leaking. X

Check bolts Checkandsecureallangebolts. X

Check in-line gauze

lter Checkin-linelterforcleanlinessandobstructions.

Clean as necessary. X

Check venturi

nozzle and PRV Check the condition of the venturi nozzle. Check

operation of the PRV. X

Pressure Vessel

Inspection Inspect the vessel for wear, cracks and/or damage. X

Full Service and PRV Conduct a full service on the pump and replace the

PRV. X

Table of contents

Other SOLIDSVAC Water Pump manuals

Popular Water Pump manuals by other brands

SAMES KREMLIN

SAMES KREMLIN REXSON 4B6000 user manual

Pentair

Pentair JUNG PUMPEN SKS 800 Series instruction manual

ewuaqua

ewuaqua iMizar OPP 9-8 Installation and operation manual

Pentair

Pentair MYERS MSP50A owner's manual

Whale

Whale Gulper 220 user manual

Ruby

Ruby 025 FDA Installation, operation and maintenance

Grundfos

Grundfos CR Service instructions

BSC

BSC GVD8-Single phase instruction manual

Textron

Textron Greenline H4665A instruction manual

Renkforce

Renkforce 1526585 operating instructions

Pentair

Pentair MYERS SP33 Series Installation, Operation & Parts Manual

TorcUP

TorcUP EP500 Owner's operation and maintenance manual