12V Submersible Pump Operating Instructions

High Quality Groundwater and Surface Water Monitoring Instrumentation

(Page 1 of 3)

Model 415

®Solinst is a registered trademark of Solinst Canada Ltd.

SAFETY INSTRUCTIONS

• The 12V Pump Controller can get warm. It is set to turn off

at 65ºC.

• Do not block the fan intake or exhaust vent during operation

of the 12V Pump Controller.

• Do not touch the inside of the 12V Submersible Pump after

it has been running – the motor module gets extremely hot.

• This 12V Submersible Pump is to only be used for

groundwater purging/sampling.

• The 12V Pump Controller is water resistant but not

waterproof. Do not submerge in water.

• Do not use the 12V Pump Controller near flammable liquids

or gases.

• The 12V Submersible Pump is designed to operate when

submerged only.

• The Solinst Model 415 12V Controller is only designed to

work with the Solinst Model 415 12V Submersible Pump.

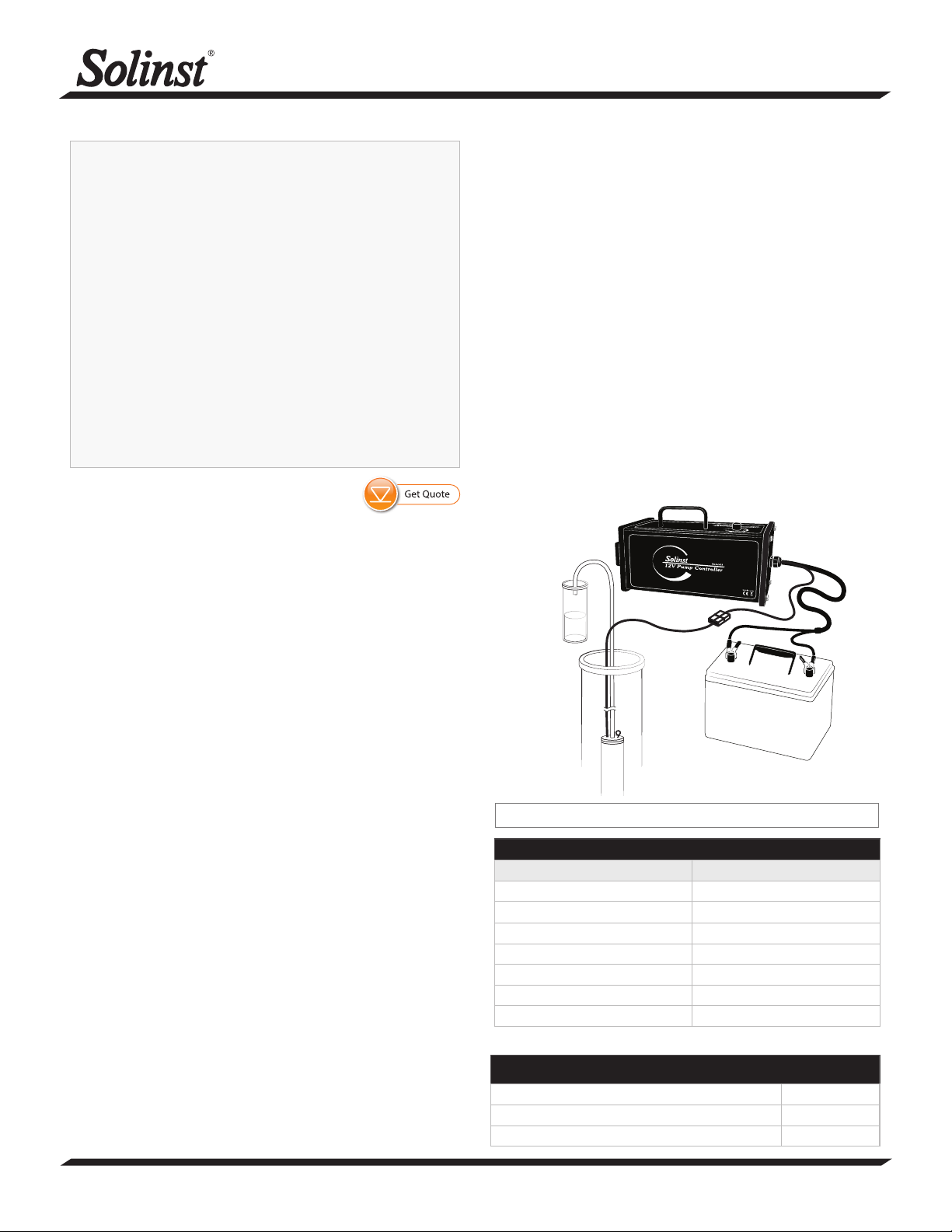

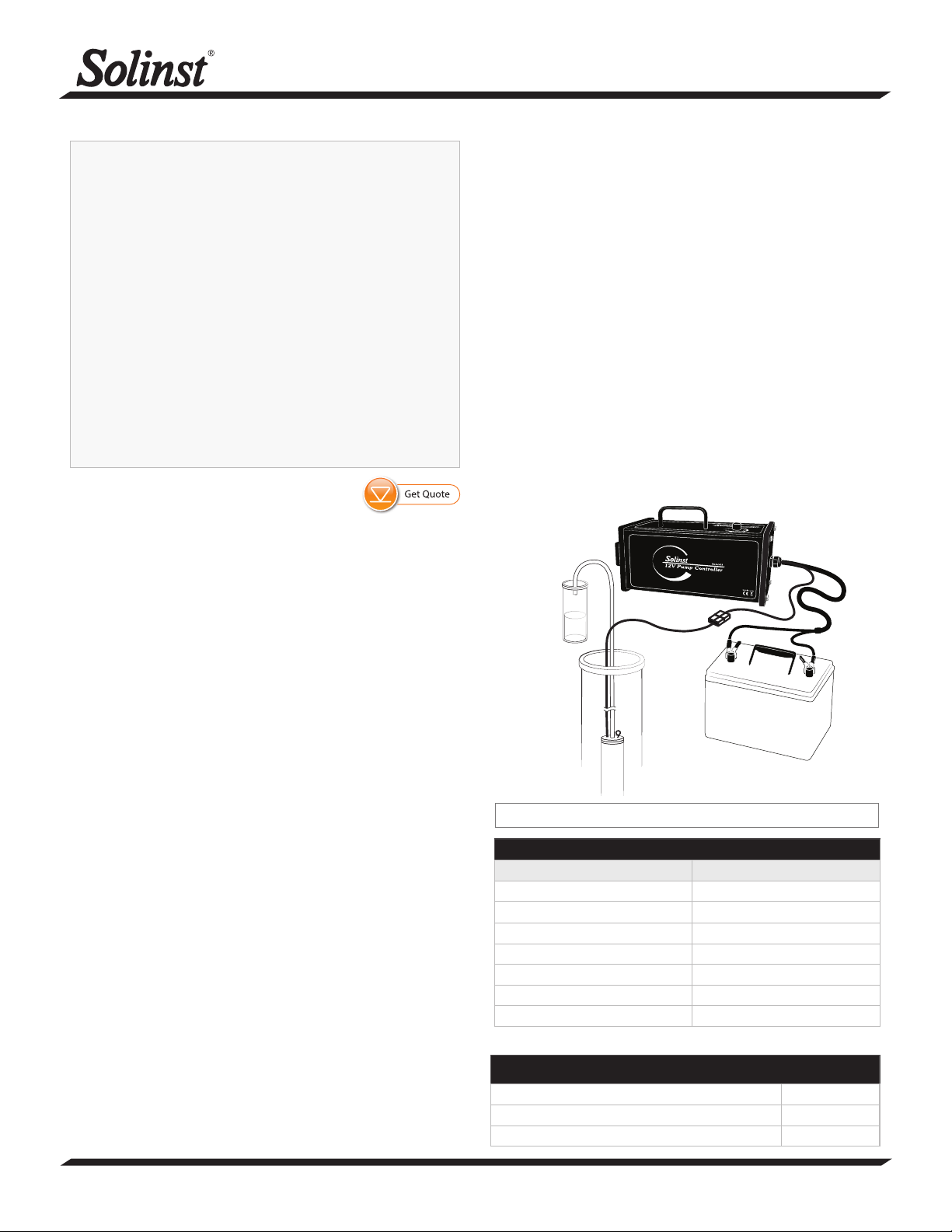

Power Supply

The 12V Pump Controller operates from an external 12 volt

DC power supply such as a car, truck or marine 12 volt battery

that can supply up to 45 amps at maximum draw. The Pump

Controller has a 2.3 m (7.5 ft) power cable with connector clips

for direct battery connection.

The power cable clips are oversized for use with automotive

batteries. The red clip connects to the positive (+) battery

terminal, black to negative (-) battery terminal. If the battery

is connected with reverse polarity the Controller will not be

harmed, but it will NOT operate until the polarity is connected

correctly (the LED on the Pump Controller will remain off with

reverse polarity).

A circuit breaker reset button is located on the side of the Pump

Controller. In the event the amperage exceeds 50 amps, the

circuit breaker will trip (button pops out) and turn the Controller

off. To reset the breaker, turn the dial to “0” then press the

reset button back in to regain operation.

If the Pump is to be powered by a typical 45Ah vehicle battery,

start the vehicle and run for 15 minutes to recharge the battery,

then restart the vehicle every 15 minutes for 5 minutes to

maintain the battery power during sampling.

Operation

• The Pump Controller should always be kept with the dial

in the OFF position when it is being attached to a power

source or stored.

• The Pump Controller dial is used to adjust the flow of

water being discharged. As you increase the dial, so does

the Controller’s voltage output. This will enable the Pump

motor to spin faster, therefore, increasing the flow of water

being discharged. To slow the flow of water, turn the dial

counter-clockwise.

• When the dial is in the OFF position the Controller will

produce 0 volts, in the highest position “10” the Controller

will output 25 volts.

• The Controller has a low voltage disconnect at 10 volts as

indicated by the slowly flashing yellow light. (However, the

Controller can disconnect at a higher voltage if the Pump’s

current increases, e.g. if the Pump is running at maximum

current (20 amps), the battery can disconnect at 11.7 volts.)

The Controller will shut off and then turn on every few

seconds (pulsate) or the water flow from the Pump will slow

if the output voltage on the battery drops to 10.75 volts

when in use. Stop operation, disconnect the power, and

recharge the battery.

1. Connect the negative (black) battery clip to the negative

terminal post on a 12 volt DC battery and the positive (red)

battery clip to the positive terminal.

2. Connect the Pump’s cable to the connector cable from the

Pump Controller.

3. Connect the 3/8" ID tubing to the Pump. Ensure the

tubing is pushed all the way onto the tubing barb.

4. Lower the Pump to the required sampling depth. Use

a safety line connected to the eyebolt on the top of the

Pump, if desired (such as a Model 103 Tag Line).

5. Turn the dial to adjust the flow as desired.

Maximum Flow Rate Estimates

Depth to Water Flow Rate

30 ft (10 m) 12.5 L/min

40 ft (12 m) 11.0 L/min

50 ft (15 m) 9.5 L/min

70 ft (21 m) 7.5 L/min

80 ft (24 m) 6.0 L/min

100 ft (30 m) 4.25 L/min

110 ft (33.5 m) 1.5 L/min

Tubing Specications

1/2" OD x 3/8" ID LDPE (100 ft coil) 109490

1/2" OD x 3/8" ID LDPE (250 ft coil) 109489

1/2" OD x 3/8" ID LDPE (500 ft coil) 109488

Battery

Pump

Sample

12V Pump

Controller

Note: See Model 415 12V Submersible Pump data sheet for full pump curve.

Note: See Page 3 for dedicated set up using a 2” Well Cap Assembly.

More Info | Instructions | Get Quote