- ENGLISH - Base tool MultiSystem 109LG

ENGLISH 1

Instruction manual

Original instructions

Caution! Before initial use, read these

operating instructions and the operating

instructions of the changeover tool to be used

(accessory) carefully and observe all safety

instructions.

Observe the maintenance guidelines closely to

ensure the long service life of your equipment.

Your dealer will be glad to assist you with any

questions.

For USA only:

Emissions Control Warranty Statement

The Environmental Protection Agency and Solo

are pleased to explain the emission control system

on your small non-road power equipment engine.

In the US new small non- road engines must be

designed, built, and equipped to meet the

Environmental Protection Agency's standards.

Solo must warrant the emission control system on

your small non- road engine for the period of time

listed below provided there has been no abuse,

neglect, or improper maintenance of your small

non-road engine.

Your emission control system includes parts such

as the carburetor, the ignition system, and the

exhaust system.

Where a warrantable condition exists, Solo will

repair your small non-road power equipment

engine at no cost to you including diagnosis, parts,

and labor.

Manufacturer’s Warranty Coverage

Solo's small non-road power equipment engines

are warranted for a period of two years. If any

emission control related part on your engine is

defective, the part will be repaired or replaced by

Solo.

Contact Information for Authorized Service Center

Locations, Replacement Parts,

Warranty and Technical Information

Warranty repairs must be completed by a SOLO

Authorized Service Center.

SOLO USA, Inc. 1-800-765-6462

Newport News, VA 23605

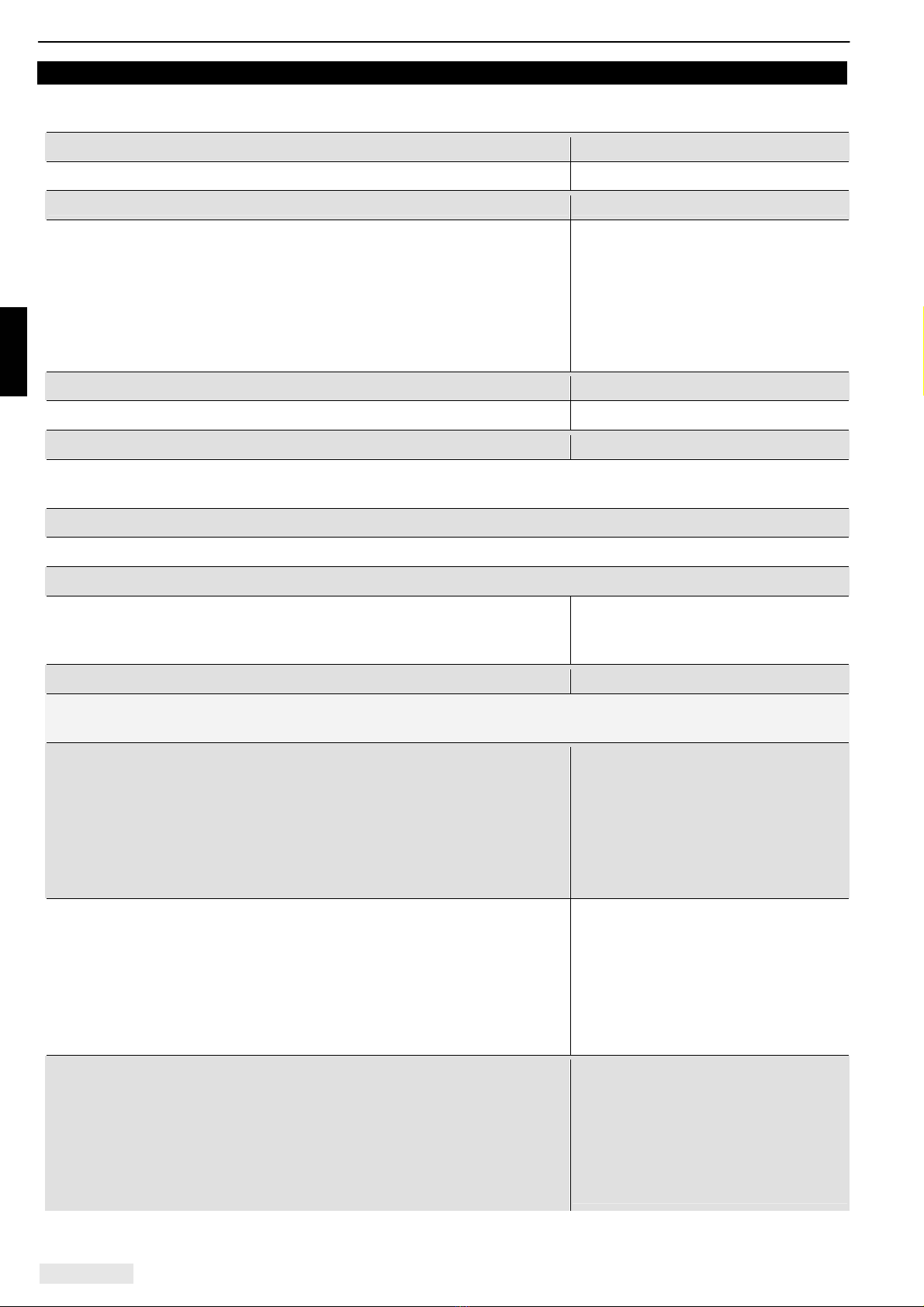

Symbols

The following symbols are used in this manual and

on the product:

Thoroughly read these operating

instructions before undertaking any

maintenance, installation and cleaning

steps

Wear ear defenders and a face shield

before starting the engine

Switching off the engine, stop switch on

"STOP"

Wear protective gloves when handling

and working with the equipment

Wear solid shoes, preferably safety

shoes with a good tread

Danger! Failure to comply with the

instructions could cause accidents with

potentially life-threatening injuries.

Maintain a minimum distance of

15 metres bystanders

Never smoke near the power tool or

where the equipment is refuelled!

Keep open flames away from the power

tool and the fuel can

- This equipment produces exhaust

fumes

and

- fuel vapours are poisonous;

never start or refuel in enclosed spaces

Fuel mixture: symbol above the fuel

mixture tank cap

Choke flap:

Cold start position Îchoke lever up,

towards this symbol

Operation and warm start Îchoke

lever down

Type plate

a: Type designation

b: Serial number

c: Build year (08 Î2008)