LAB964R, Issue 4, May 2014

Page 4

1General description

1.1 The Silavent CMX appliance is a key part of a whole house ventilation system specifically designed to

improve indoor air quality in dwellings. The system is designed to remove polluted, stale air from all

bathing, cooking and washing areas at a constant gentle rate. Fresh replacement air is supplied

through background ventilators installed in all living areas (supplied separately – see section 1.5).

1.2 A manual boost switch can be used to increase the ventilation rate, e.g. when cooking or showering

thereby maintaining a comfortable indoor environment (supplied separately – see section 1.6).

1.3 The boost facility can also be triggered from a lighting circuit or by a range of sensors, including

humidity control and PIR movement detection (supplied separately – see section 1.7).

1.4 This product is listed in the Products Characteristics Database (PCDB), therefore part of the installation

process requires that an installation checklist is completed and submitted to the Building Control Body

(BCB). Blank checklists are available at www.ncm-pcdb.org.uk/SAP. The NCM (SAP) identifier for this

product is Silavent CMX.

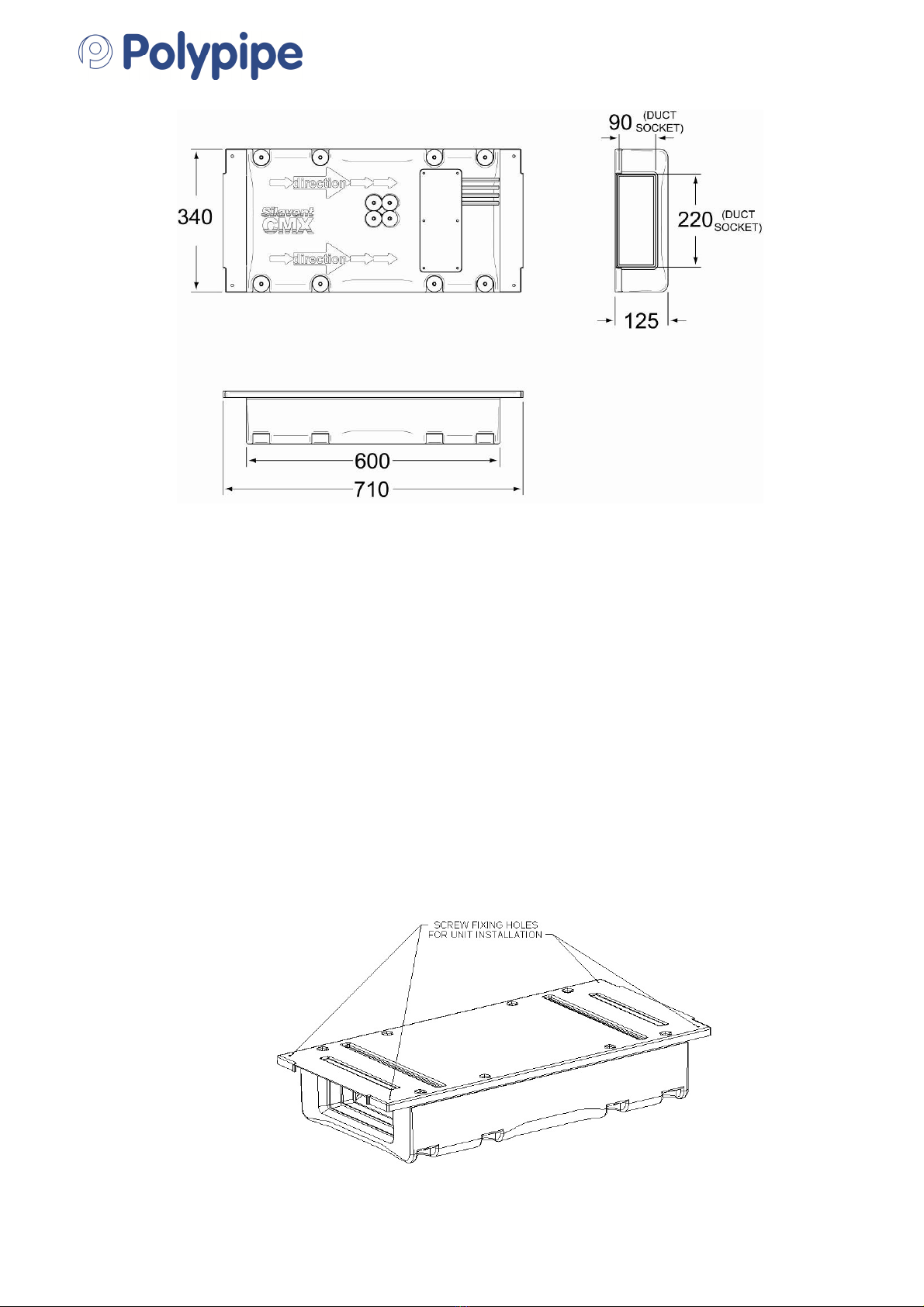

1.5 Ancillary items required:

•Domus 220mm x 90mm rectangular or Ø150mm round rigid duct system (adaptor req) (see 5.2)

•Domus CMX-ASK1 or Domus 2404 air supply kits with filter (see 1.1)

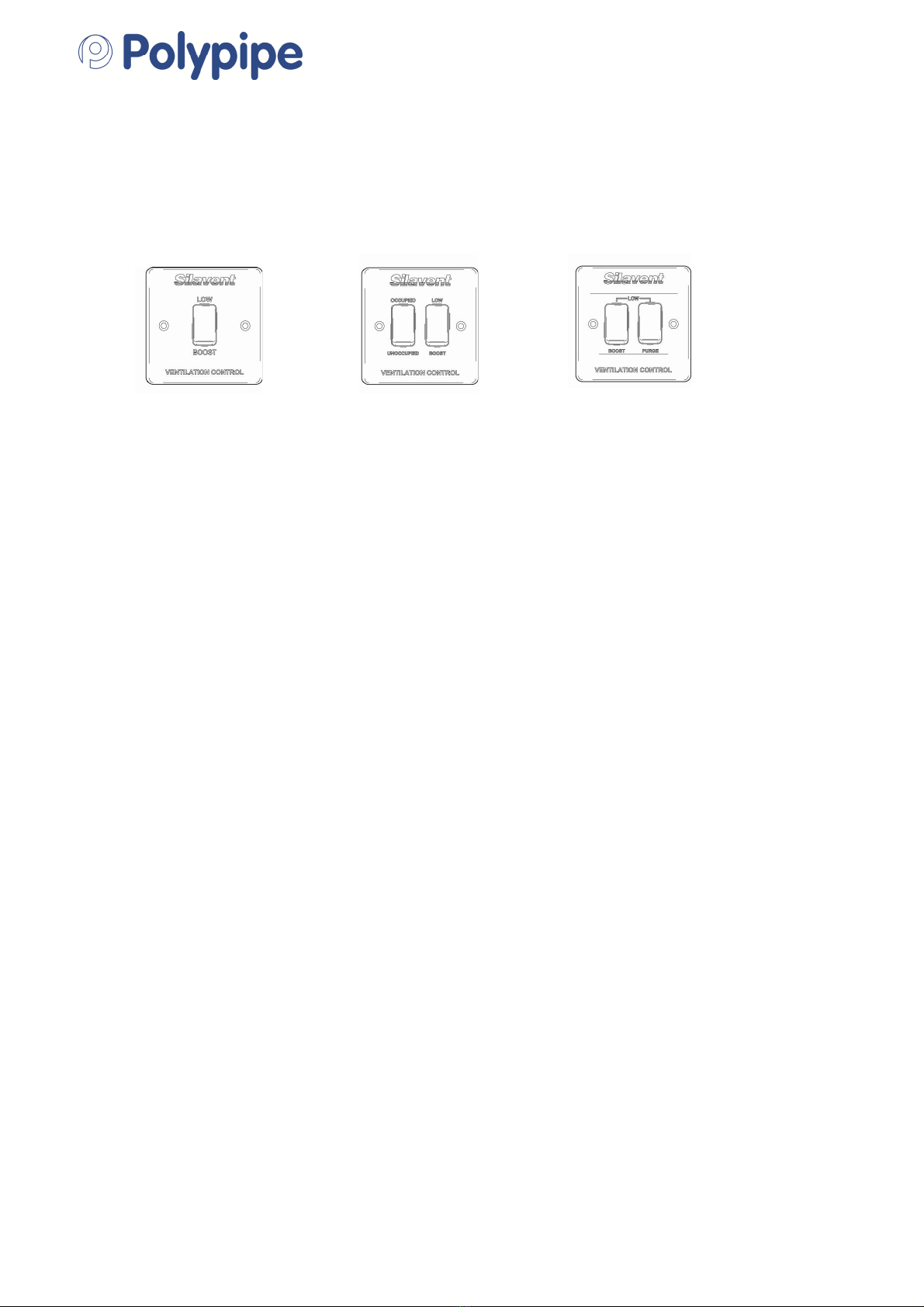

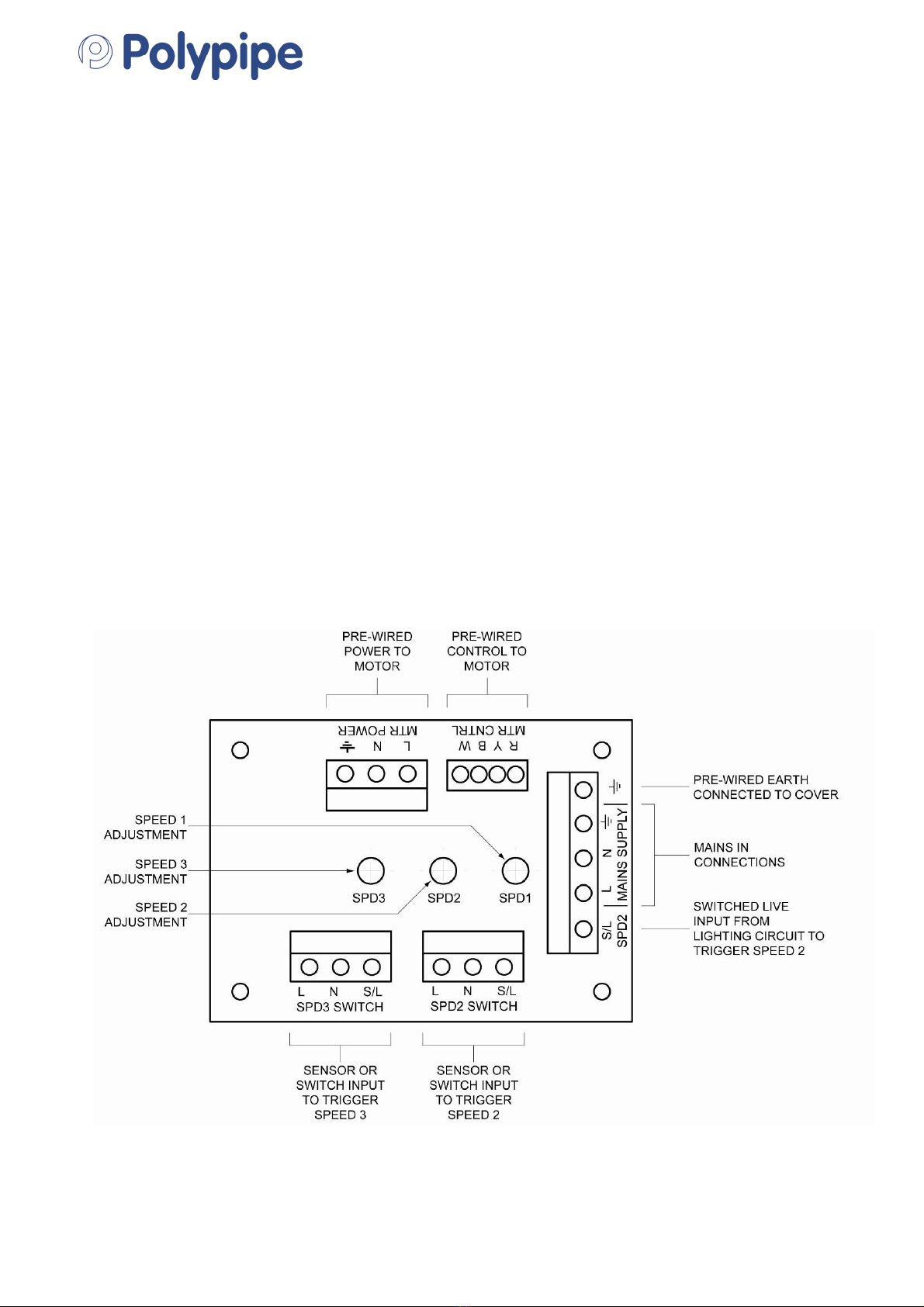

1.6 Control switch options – supplied separately (wiring - see page 6)

•Silavent manual LOW/BOOST switch, code ANC848A

Manual BOOST selection switch. LOW speed is engaged upon connection of mains supply.

Both speeds are manually adjustable at the wiring centre to facilitate Building Regulation

commissioning speeds.

•Silavent manual OCCUPIED/UNOCCUPIED - LOW/BOOST switch, code ANC849A

Manual BOOST and UNOCCUPIED selection switches. OCCUPIED/LOW speed is engaged

upon connection of mains supply. UNOCCUPIED speed is intended to be lower than the

OCCUPIED/LOW Building Regulation commissioning speed and should only be selected when

the property is vacant for extended periods such as holidays in order to save energy but keep

the property ‘fresh’. There is no requirement or value in the Building Regulations for this speed,

so it should be set to suit the individual client’s requirement. All three speeds are manually

adjustable at the wiring centre to facilitate Building Regulation commissioning speeds.

•Silavent manual LOW/BOOST/PURGE switch, code ANC850A

Manual BOOST and PURGE selection switches. LOW speed is engaged upon connection of

mains supply. PURGE speed is intended to be higher than the BOOST Building Regulation

commissioning speed and should be selected during periods when exceptional levels of indoor

pollution are encountered such overcooked food or paint fumes. The Building Regulations

recommend a 4ach (air change per hour) air flow rate for this speed but should be set to suit

the individual client’s requirement. All three speeds are manually adjustable at the wiring centre

to facilitate Building Regulation commissioning speeds.

1.7 Remote/automatic control options – supplied separately (wiring - see page 7)

•Silavent adjustable overrun timer, code ANC108A

•Silavent humidity control with adjustable overrun timer, code ANC802A

•Silavent humidity control with adjustable overrun timer and remote sensor, code ANC846A

•Silavent humidity control with adjustable overrun timer and manual override with neon indicator, code

ANC808A

•Silavent PIR movement control with adjustable overrun timer, code ANC813A

•Silavent 6-Switched live backfeed protected junction box, code ELE150R