Solvimus MBUS-M13 Series User manual

HARDWARE

MANUAL

MBUS-M13

solvimus GmbH – Ratsteichstr. 5 – 98693 Ilmenau – Germany

Phone: +49 3677 7613060 – Fax: +49 3677 7613069 – Email: info@solvimus.de

...we solve. www.solvimus.de

M-BUS MASTER OEM MODULE

MBUS-M13

Version 1.08

Date: 2018-04-05

Author:

Remo Reichel

solvimus GmbH

Ratsteichstr. 5

98693 Ilmenau

Germany

Hardware Manual MBUS-M13

Page 2/15 Version 1.08 reichel@solvimus.de, 2018-04-05

HWM_MBUS-M13_1.08_W_EN.docx Draft © solvimus GmbH

This page intentionally left blank.

Hardware Manual MBUS-M13

reichel@solvimus.de, 2018-04-05 Version 1.08 Page 3/15

© solvimus GmbH Draft HWM_MBUS-M13_1.08_W_EN.docx

Table of contents

1General hints and conventions....................................................................................................................................4

1.1 About this document.............................................................................................................................................4

1.2 Legal bases .................................................................................................................................................................4

1.2.1 Copyright ..........................................................................................................................................................4

1.2.2 Personnel qualifications .............................................................................................................................4

1.2.3 Technical condition of specified devices ............................................................................................4

1.3 Symbols........................................................................................................................................................................4

1.4 Font conventions.....................................................................................................................................................5

1.5 Number notation.....................................................................................................................................................5

1.6 Safety guidelines......................................................................................................................................................5

1.7 Scope.............................................................................................................................................................................6

1.8 Abbreviations ............................................................................................................................................................6

1.9 Versions........................................................................................................................................................................6

2General Information .........................................................................................................................................................7

2.1 Structure of the module .......................................................................................................................................7

2.2 Variants.........................................................................................................................................................................7

2.3 Pin assignment .........................................................................................................................................................8

2.3.1 Terminals at the edge for pin headers .................................................................................................8

2.3.2 Connector X1...................................................................................................................................................8

2.4 Dimensions.................................................................................................................................................................8

2.5 Ordering information.............................................................................................................................................9

3Operation ........................................................................................................................................................................... 10

3.1 Wiring diagrams .................................................................................................................................................... 10

3.2 Reference circuit with collision indication and EMC precautions................................................... 11

3.3 Technical data ........................................................................................................................................................ 11

3.4 Timing and performance diagrams.............................................................................................................. 12

4Option wireless M-Bus.................................................................................................................................................. 13

4.1 Structure of the module .................................................................................................................................... 13

4.2 Pin assignment ...................................................................................................................................................... 13

4.2.1 Terminals at the edge for pin headers .............................................................................................. 13

4.2.2 Connector X1................................................................................................................................................ 13

4.3 Dimensions.............................................................................................................................................................. 13

4.4 Ordering information.......................................................................................................................................... 13

4.5 Wiring diagrams .................................................................................................................................................... 13

4.6 Parametrization of the wM-Bus module .................................................................................................... 14

4.7 Reference circuit with collision indication and EMC precautions................................................... 15

4.8 Altered technical data......................................................................................................................................... 15

Hardware Manual MBUS-M13

Page 4/15 Version 1.08 reichel@solvimus.de, 2018-04-05

HWM_MBUS-M13_1.08_W_EN.docx Draft © solvimus GmbH

1General hints and conventions

1.1 About this document

This manual provides guidance and procedures for a fast and efficient installation and start-up of

the units described in this manual. It is imperative to read and carefully follow the safety guidelines.

1.2 Legal bases

1.2.1 Copyright

This manual, including all figures and illustrations, is copyright-protected. Any further use of this

manual by third parties that violate pertinent copyright provisions is prohibited. Reproduction,

translation, electronic and photo-technical filing/archiving (e. g.: photocopying) as well as any

amendments require the written consent of solvimus GmbH.

Non-observance will involve the right to assert damage claims.

The solvimus GmbH reserves the right to provide for any alterations or modifications that serve to

increase the efficiency of technical progress. All rights arising from the granting of patents or from

the legal protection of utility patents are owned by the solvimus GmbH. Third-party products are

always mentioned without any reference to patent rights. Thus, the existence of such rights cannot

be excluded.

1.2.2 Personnel qualifications

The use of the product described in this manual requires special personnel qualifications. All

responsible persons have to familiarize themselves with the underlying legal standards to be

applied, e. g.:

•Valid standards

•Handling of electronic devices

The solvimus GmbH does not assume any liability whatsoever resulting from improper handling

and damage incurred to both, solvimus own and third-party products, by disregarding detailed

information in this manual.

1.2.3 Technical condition of specified devices

The supplied components are equipped with hardware and software configurations, which meet

the individual application requirements. Changes in hardware, software and firmware are permitted

exclusively within the framework of the various alternatives that are documented in the specific

manuals. The solvimus GmbH will be exempted from any liability in case of changes in hardware or

software as well as to non-compliant usage of components.

Please send your request for modified and new hardware or software configurations directly to the

solvimus GmbH.

1.3 Symbols

Danger: Always observe this information to protect persons from injury.

Warning: Always observe this information to prevent damage to the device.

Attention: Marginal conditions that must always be observed to ensure smooth and

efficient operation

ESD (Electrostatic Discharge): Warning of damage to the components through electrostatic

discharge. Observe the precautionary measure for handling components at risk of

electrostatic discharge.

Note: Make important notes that are to be complied with so that a trouble-free and efficient

device operation can be guaranteed.

Hardware Manual MBUS-M13

reichel@solvimus.de, 2018-04-05 Version 1.08 Page 5/15

© solvimus GmbH Draft HWM_MBUS-M13_1.08_W_EN.docx

Additional information: References to additional literature, manuals, data sheets and

internet pages.

1.4 Font conventions

Names of paths and data files are marked in italic-type. According to the system, Slashes or

Backslashes are used.

e. g.:

D:\Data\

Menu items are marked in italic-type, bold letters.

e. g.:

Save

Sub-menu items or navigation steps within a web browser are marked by using an arrow between

two menu items or tabs.

e. g.:

File

→

New

Pushbuttons or input fields are marked with bold letters.

e. g.: Input

Keys are marked with bold capital letters within angle brackets.

e. g.: <F5>

The print font for program codes is Courier.

e. g.: END_VAR

Names of variables, designators and configuration fields are marked in italic-type.

e. g.:

Value

1.5 Number notation

Numbers a noted according to this table:

Number code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C Notation

Binary

'100'

in quotation marks

'0110.0100'

nibbles separated with dot

Table 1: Numbering systems

1.6 Safety guidelines

All power sources to the device must always be switched off before carrying out any

installation, repair or maintenance work.

Replace any defective or damaged device/module (e. g.: in the event of deformed contacts), as the

functionality of the device in question can no longer be ensured on a long-term basis.

The components are not resistant against materials having seeping and insulating properties.

Belonging to this group of materials is: e. g. aerosols, silicones, triglycerides (found in some hand

creams).

If it cannot be ruled out that these materials appear in the component environment, then the

components must be installed in an enclosure that is resistant against the above mentioned

materials.

Clean tools and materials are generally required to operate the device/module.

Only use a soft, wet cloth for cleaning. Soapy water is allowed. Pay attention to ESD.

Do not use solvents like alcohol, acetone etc. for cleaning.

Do not use contact sprays, which could possibly impair the functioning of the contact area

and may cause short circuits.

Hardware Manual MBUS-M13

Page 6/15 Version 1.08 reichel@solvimus.de, 2018-04-05

HWM_MBUS-M13_1.08_W_EN.docx Draft © solvimus GmbH

Components, especially OEM modules, are designed for the mounting into electronic

housings. Those devices shall not be touched when powered or while in actual operation.

The valid standards and guidelines applicable for the installation of switch cabinets shall be

adhered to.

The devices are equipped with electronic components that may be destroyed by

electrostatic when touched. It is necessary to provide good grounding to personnel,

working environment and packing. Electro-conductive parts and contacts should not be

touched.

1.7 Scope

This manual describes the devices mentioned in the title, supplied by solvimus GmbH, Ilmenau.

1.8 Abbreviations

Abbreviation

Meaning

AE,AI

Analog Input, Analog Input terminal

AA,AO

Analog Output,Analog Output terminal

DE,DI

Digital Input, Digital Input terminal

DA,DO

Digital Output, Digital Output terminal

ESD

Electro-Static Discharge

I/O

Input / Output

ID

Identification, Identifier, unique identification mark

M-Bus

Meter-Bus (EN 13757, part 2 - 3)

OEM

Original Equipment Manufacturer

wM-Bus

Wireless Meter-Bus (EN 13757, par t 3 - 4)

Table 2: Abbreviations

1.9 Versions

Version

Date

Editor

Changes

1.00

2013-04-30

Remo Reichel

Initial translation, derived from German v 1.04

1.01

2013-08-09

Remo Reichel

Additional technical data,fixed reference schematic

1.02

2014-06-17

Sebastian Bauer

Fixed schematics of MBUS-M13-G

1.07

2015-01-09

Remo Reichel

Amendment of technical data, synchronization to the German version tag

1.08

2018-04-05

Sven Ladegast

Updated document to actual corporate design.

Table 3: Versions of this document

Hardware Manual MBUS-M13

reichel@solvimus.de, 2018-04-05 Version 1.08 Page 7/15

© solvimus GmbH Draft HWM_MBUS-M13_1.08_W_EN.docx

2General Information

The module MBUS-M13 and its variants are compact M-Bus (Meter-Bus) masters. It is responsible for

the power supply of the connected slaves and also for the communication with them.

Especially in the scope of smart metering M-Bus is used for automated meter reading.

Additional information on M-Bus can be found here:

http://www.m-bus.com/

2.1 Structure of the module

The module MBUS-M13 and its variants are populated single-sided. Pin headers with a spacing of

2.54 mm can be used for connecting the corresponding pads.

The following figure shows the module:

Figure 1: The module MBUS-M13

The module is integrating all necessary components for the operation of the M-Bus. The internal

power supply generates the bus voltages 24 V and 36 V as well as 3.3 V for internal use and also for

connecting some external logic (e. g.: a microcontroller).

2.2 Variants

There are 3 variants available.

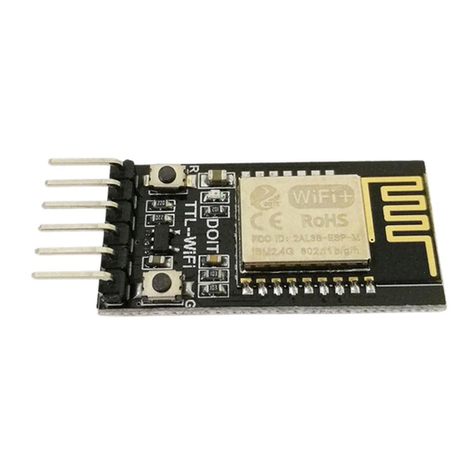

The variant MBUS-M13-S is the standard version, serving as a fully integrated M-Bus master and the

level converter. The connection of the control logic is realized by using a simple TTL UART interface,

which is galvanically isolated from the M-Bus levels. The connection is established through the pads

at the edge of the module.

The variant MBUS-M13-G has no unit for electrical isolation. It is suitable for simple systems. The

connection is established through the connector X1.

The variant MBUS-M13-M has no internal 3.3 V power supply and no electrical isolation. The

connection is only established through connector X1.

With the variants -S and –G, the internal 3.3 V power supply can also be used for direct connection

of small logic modules (e. g.: a microcontroller with LCD display). In that way, certain compact

applications such as a gateway or a data logger only need a single 24 VDC.

The internal 3.3 V supply can handle loads with a maximum current consumption of 50 mA.

Hardware Manual MBUS-M13

Page 8/15 Version 1.08 reichel@solvimus.de, 2018-04-05

HWM_MBUS-M13_1.08_W_EN.docx Draft © solvimus GmbH

2.3 Pin assignment

The module MBUS-M13 is made for connection via pin headers with a spacing of 2.54 mm. The

following figure shows the top view:

Figure 2: Top view of MBUS-M13 with its pads

The function of each pin will be explained in following tables.

2.3.1 Terminals at the edge for pin headers

Terminal

Description

-S

-G

-M

TP_VDD

galvanically isolated logic, positive supply 3,0 V ... 5,0 VDC

VDDiso

nc

nc

TP_RX

galvanically isolated logic, UART Receiver (to RX)

RXiso

nc

nc

TP_TX

galvanically isolated logic, UART Transmitter (from TX)

TXiso

nc

nc

TP_GND

galvanically isolated logic, negative supply (ground)

GNDiso

nc

nc

TP_MR

do not connect

nc

nc

nc

TP_MT

do not connect

nc

nc

nc

TP_PGND

M-Bus-side negative power supply, Ground (0 VDC)

GND

nc

nc

TP_PWR

M-Bus-side positive power supply (24 VDC)

24VDC

nc

nc

TP_ANT

do not connect

nc

nc

nc

TP_BUS-

M-Bus, low-side

M-Bus-

M-Bus-

M-Bus-

TP_BUS+

M-Bus, high-side

M-Bus+

M-Bus+

M-Bus+

Table 4: Function of the terminals for the pin header

2.3.2 Connector X1

Pin

Name

Description

-S

-G

-M

1

MB+

M-Bus, high-side

nc

nc

M-Bus+

2

MB-

M-Bus, low-side

nc

nc

M-Bus-

3

VCC

positive logic power supply 3,3 VDC

nc

VDD

VDD

4

24V

positive M-Bus power supply 24 VDC

nc

24 VDC

24V DC

5

GND

negative power supply,Ground

nc

GND

GND

6

#COL

collision interrupt (see section: 11)

#COL

#COL

#COL

7

WRX

do not connect

nc

nc

nc

8

WTX

do not connect

nc

nc

nc

9

RX

UART Receiver (to RX)

nc

RX

RX

10

TX

UART Transmitter (from TX)

nc

TX

TX

Table 5: Pin assignment of connector X1

2.4 Dimensions

Following drawing shows the dimensions of the module:

Hardware Manual MBUS-M13

reichel@solvimus.de, 2018-04-05 Version 1.08 Page 9/15

© solvimus GmbH Draft HWM_MBUS-M13_1.08_W_EN.docx

Figure 3: Mechanical dimensions and position of pads of MBUS-M13 (values are in mm)

2.5 Ordering information

Item name

Order number

MBUS-M13-S

500325

MBUS-M13-G

500327*

MBUS-M13-M

500328*

MBUS-M13-S1 (all pin headers and X1 assembled at the bottom side)

500336*

MBUS-M13-M1 (X1 assembled at the bottom side)

500339*

MBUS-M13-G1 (X1 assembled at the bottom side)

500340*

*delivery only upon request

Table 6: Ordering information

Hardware Manual MBUS-M13

Page 10/15 Version 1.08 reichel@solvimus.de, 2018-04-05

HWM_MBUS-M13_1.08_W_EN.docx Draft © solvimus GmbH

3Operation

The module MBUS-M13 is a compact M-Bus (Meter-Bus) master. In detail, it is a physical level

converter, allowing the communication between a serial UART interface (TTL) and M-Bus slaves.

3.1 Wiring diagrams

The following examples give a brief overview on how to connect the module MBUS-M13. It should

be noted that nomenclature is chosen according to typical interface transceivers (such as MAX232).

TX

should be therefore

TXin

, data transmitted from the logic to the bus, and

RX

is

RXout

, data

received from the bus to the logic.

Figure 4: Variant MBUS-M13-S with galvanically isolated interface to external logic

Figure 5: Variant MBUS-M13-G with direct interface to external logic

Figure 6: Variant MBUS-M13-G powering the external logic (3.3 VDC) on its own (max. 50 mA)

Hardware Manual MBUS-M13

reichel@solvimus.de, 2018-04-05 Version 1.08 Page 11/15

© solvimus GmbH Draft HWM_MBUS-M13_1.08_W_EN.docx

Figure 7: Variant MBUS-M13-M using only the connector X1

3.2 Reference circuit with collision indication and EMC precautions

Figure 8: Reference circuit for MBUS-M13-S

3.3 Technical data

Parameter

Value

Power supply

24 VDC,+2/-10 %

Current consumption in idle state (without bus load)

approx. 27 mA

Power consumption in idle state (without bus load)

<0,7 W

Power dissipation of internal power circuit (at maximum bus load)

<1,3 W

Voltages M-Bus

24 V (space) and 36 V (mark)

Ampacity M-Bus

150 mA (approx. 80 unit loads)

Short circuit protection M-Bus

PTC resettable fuse at MB+

Trip point of resettable fuse (at 25°C ambient temperature),theoretical values in the data

sheet (without taking internal impedance of module into account)

approx. 900 ms@360 mA,

approx. 450 ms@440 mA,

approx. 220 ms@530 mA,

approx. 50 ms@3300 mA

Reset behavior of fuse (at 25°C ambient temperature)

approx. 2,5 s@36 mA

Power supply for logic (isolated side, variant -S only) (TP_VDD)

3,0 ...5,0 VDC

Power supply for logic (non-isolated side) at X1 (VCC)

3,3 VDC

Ampacity of logic power supply (variants -S and -G) at X1 (VCC)

50 mA

Internal pull-up resistor at pin #COL at X1 (open collector)

1 kOhm

Ampacity of pin #COL an X1 (sink current)

10 mA

Maximum baud rate

19200 Bit/s

Dimensions (variant -S,without pin headers)

30 mm x 33 mm x 6,5 mm

Galvanic isolation (variant -S only)

1 kV

Environmental conditions for operation

0 ...50 °C,<95 % humidity

Environmental conditions for storage

-20 ... 85 °C,<95 % humidity

Table 7: Technical data

Hardware Manual MBUS-M13

Page 12/15 Version 1.08 reichel@solvimus.de, 2018-04-05

HWM_MBUS-M13_1.08_W_EN.docx Draft © solvimus GmbH

3.4 Timing and performance diagrams

Bus voltage (blue) at the transition of the TXD signal (purple) on a

load of 10 kOhm between both bus terminals, test at 9600 bps

Bus voltage (blue) at the transition of the TXD signal (purple) on a

load of 200 Ohm between both bus terminals,test at 9600 bps

Bus voltage (blue) at the transition of the TXD signal (purple) on a

load of 10 kOhm in parallel with 1 uF between both bus terminals,

test at 9600 bps

Bus voltage (blue) at the transition of the TXD signal (purple) on a

load of 10 kOhm in parallel with 2.2 uF between both bus

terminals,test at 9600 bps

Table 8: Oscillogram of signal transitions

Condition

10 kOhm

200 Ohm

10 kOhm || 1 uF

10 kOhm || 2.2 uF

Parameter

Bus voltage high

36.8 V

35.6 V

36.8 V

36.8 V

Bus voltage low

24 V

23.6 V

24.1 V

24.3 V

Fall time

<3 us

<1 us

approx. 45 us

approx. 60 us

Rise time

<3 us

<3 us

approx. 25 us

approx. 45 us

Delay at falling edge

approx. 8 us

approx. 8 us

approx. 12 us

approx. 12 us

Delay at rising edge

approx. 4 us

approx. 4 us

approx. 4 us

approx. 4 us

Table 9: Conditions and results of performance measurements

Hardware Manual MBUS-M13

reichel@solvimus.de, 2018-04-05 Version 1.08 Page 13/15

© solvimus GmbH Draft HWM_MBUS-M13_1.08_W_EN.docx

4Option wireless M-Bus

The module MBUS-M13 can be optionally equipped with a wireless M-Bus module made by the

company Amber Wireless (Type AMB8425 / AMB8426). It therefore combines the functionality of an

M-Bus master and a wireless M-Bus device (slave or master).

Further information about the wireless M-Bus extension can be found here:

http://www.amber-wireless.de/

4.1 Structure of the module

The wireless M-Bus extension is going to be surface-mounted on the backside of the MBUS-M13

module. The module is still interfaced through the 2.54 mm pin headers or the appropriate eyelets.

Please be aware of the changed installation height and the space below the module.

An eyelet is designated for connection of the antenna. Optionally, there is also the possibility to

mount an RF connector of the RSP series made by Samtec (RSP-122811-02) to install a standard RF

pigtail to the module.

Further information regarding the RF connector can be found here:

http://www.samtec.com/

4.2 Pin assignment

The pin assignment of the module does vary in a few points from the standard module:

4.2.1 Terminals at the edge for pin headers

Contact

Description

-S-W

-G-W

-M-W

TP_MR

wM-Bus,UART Receiver (to RX)

RX_WM

nc

nc

TP_MT

wM-Bus,UART Transmitter (to TX)

TX_WM

nc

nc

TP_ANT

wM-Bus, Antenna eyelet

Antenna

Antenna

Antenna

Table 1: Functions of contact eyelets (wireless M-Bus)

4.2.2 Connector X1

Contact

Name

Description

-S-W

-G-W

-M-W

7

WRX

wM-Bus,UART Receiver (to RX)

nc

RX_WM

RX_WM

8

WTX

wM-Bus,UART Transmitter (to TX)

nc

TX_WM

TX_WM

Table 2: Pin assignment of connector X1 (wireless M-Bus )

Please consider the example circuit at section 4.5 for galvanically isolated operation of the serial

interface of the wireless M-Bus module.

4.3 Dimensions

The dimensions of the module do differ slightly only at the installation height. The wireless M-Bus

module has a height of 3.5 mm. The installation height will be increased by this size.

4.4 Ordering information

Article

Article No.

MBUS-M13-S-W

500319

MBUS-M13-G-W

*

MBUS-M13-M-W

*

* available on request

Table 3: Ordering information (wireless M-Bus)

4.5 Wiring diagrams

The following circuit examples give an abstract on how to wire the module:

Hardware Manual MBUS-M13

Page 14/15 Version 1.08 reichel@solvimus.de, 2018-04-05

HWM_MBUS-M13_1.08_W_EN.docx Draft © solvimus GmbH

Figure 1: MBUS-M13-S-W with galvanically isolated logic interface

Figure 2: MBUS-M13-M-W with exclusive use of the X1 connector

4.6 Parametrization of the wM-Bus module

Parameterization of the wireless M-Bus module is done using the protocol according to the

specification of Amber Wireless. This configuration can occur during normal operation through the

connected logic interface (e.g. microcontroller) or with the help of a configuration tool made by

Amber Wireless before the module/device is shipped.

The module saves the configuration to a non-volatile memory and continues operation with its last

configuration after a reset.

Hardware Manual MBUS-M13

reichel@solvimus.de, 2018-04-05 Version 1.08 Page 15/15

© solvimus GmbH Draft HWM_MBUS-M13_1.08_W_EN.docx

4.7 Reference circuit with collision indication and EMC precautions

Figure 3: Reference circuit for the MBUS-M13-S-W

4.8 Altered technical data

Parameter

Value

Active current draw (no M-Bus load, wireless M-Bus active)

ca. 55 mA

Idle current draw (no M-Bus load)

<1,5 W

Continuous current rating (Variants –S and –G) on X1 (VCC)

20 mA

Continuous current delivery (Variants –M) on X1 (VCC)

ca. 30 mA

Baud rate wireless M-Bus

9600 Bit/s

Bit timing wireless M-Bus

8-N-1

Wireless M-Bus modes

S, T, C

Dimensions (Variant -S, without pin headers)

30 mm x 33 mm x 10 mm

Table 4: Technical data (incl. wireless M-Bus)

Other manuals for MBUS-M13 Series

1

This manual suits for next models

16

Table of contents

Popular Control Unit manuals by other brands

Akva-Stabil

Akva-Stabil Effect-Line Sunriser quick start guide

USR IOT

USR IOT USR-TCP232-E2 Hardware manual

Delta

Delta MultiChoice Ara T27T867 Series owner's manual

Promax

Promax DT-700 Instructions for assembly and connection

Keyautomation

Keyautomation CT1RD Instructions and warnings for installation and use

SimCom

SimCom SIM900B EVB Hardware design

Ublox

Ublox MPCI-L2 series System integration manual

GiBiDi

GiBiDi F/3 PLUS Connecting Instructions

Mini?Cam

Mini?Cam SoloPro+ CCU210 Original instruction manual

Alfalaval

Alfalaval SSV instruction manual

Huawei

Huawei VP9660 quick start guide

Metso

Metso Ball Valves Installation maintenance and operating instructions