CS-Lab CSMIO-ENC User manual

© copyright CS-Lab s.c. 2019: Rev 3.1 (20/12/22)

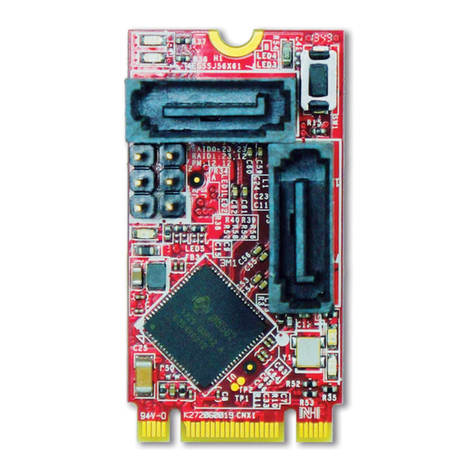

CSMIO-ENC

Encoder module for

threading

www.cs-lab.eu

CS-Lab s.c. | CSMIO-ENC module for threading

2

CONTENT

1. CSMIO-ENC general ...................................................................Błąd! Nie zdefiniowano zakładki.

1.1 Signs used in this guide ....................................................................................................... 3

1.2 Standards compliance ......................................................................................................... 3

2. CSMIO-ENC module signals connector ....................................................................................... 4

2.1 Encoders connector ............................................................................................................ 4

2.2 Connector for CSMIO/IP control connection....................................................................... 5

2.3 Expansion modules connector ............................................................................................ 5

3. VisualBasic® macro use............................................................................................................... 6

3.1 GetInput – position (16 bit) and angle read out.................................................................. 6

3.2 GetUserDRO – position read out (32 bit) ............................................................................ 6

4. CSMIO-ENC module installation and configuration .................................................................... 7

4.1 Installation and connection of CSMIO-ENC module............................................................ 7

4.2 CSMIO-ENC module configuration ...................................................................................... 7

www.cs-lab.eu

CS-Lab s.c. | CSMIO-ENC module for threading

3

1. General

The CSMIO-ENC is an expansion module for threading and it’s used to connect spindle encoder. It can

be used with CSMIO/IP-S (step/dir) and CSMIO/IP-A (+/-10V) Ethernet Motion Controllers.

1.1 Signs used in this guide

Potential danger, possible risk of injury.

Useful information, tips

Warning, failure to comply with these warnings may lead to inappropriate functioning or

damage to the device

1.1 Content of the package

In the CSMIO-ENC module package you will get:

1x DB25 flat cable

1x DB9 flat cable

1x DB25 connector -> terminal block.

1x terminator

1.2 Standards compliance

CSMIO-ENC modules were designed and made in accordance with the national and international

standards for industrial control systems based on electronic components:

•Detailed requirements for programmable controllers: working characteristics, shock

resistance, safety etc. EN61131-2 (IEC1131-2), CSA 22.2, UL508

•Compliance with European Guidelines (low voltage, the level of electromagnetic interference

Electromagnetic Compability), the CE marking.

•Electrical and non-combustible properties of insulation materials: UL 746C, UL 94, etc.

•The Product made in lead-free technology, RoHS compliant.

www.cs-lab.eu

CS-Lab s.c. | CSMIO-ENC module for threading

4

2. CSMIO-ENC module signals connector

2.1 Encoders connector

PIN number

Description

1

+5V

2

encoder 0 - IN A+

3

encoder 0 - IN B+

4

encoder 0 - IN I+

5

+5V

6

encoder 1 - IN A+

7

encoder 1 - IN B+

8

encoder 1 - IN I+

9

+5V

10

encoder 2 - IN A+

11

encoder 2 - IN B+

12

encoder 2 - IN I+

13

NC

14

GND

15

encoder 0 - IN A-

16

encoder 0 - IN B-

17

encoder 0 - IN I-

18

GND

19

encoder 1 - IN A-

20

encoder 1 - IN B-

21

encoder 1 - IN I-

22

GND

23

encoder 2 - IN A-

24

encoder 2 - IN B-

25

encoder 2 - IN I-

To use the CSMIO-ENC module on a lathe we use only encoder channel 0.

The encoder needs to have 5V

differential outputs.

The maximum total load of encoder power supply outputs is 500mA.

www.cs-lab.eu

CS-Lab s.c. | CSMIO-ENC module for threading

5

2.2 Connector for CSMIO/IP control connection

2.3 Expansion modules connector

PIN no.

Description

1

CAN H

2

-

3

-

4

-

5

GND

6

CAN L

7

RS485 B-

8

RS485 A+

9

-

PIN no.

Description

1

CAN H

2

RS232 RxD

3

RS232 TxD

4

-

5

GND

6

CAN L

7

RS485 B-

8

RS485 A+

9

-

The connectors are designed only for extension modules by CS-Lab s.c. They

cannot be used to connect any other devices, PC etc.

For correct module operation it is enough to connect the lines (CAN H ; CAN L ;

GND). Lines (RS485 B- ; RS485A+) are used in other CSMIO modules and it may be

required to connect them for correct operation of following modules.

www.cs-lab.eu

CS-Lab s.c. | CSMIO-ENC module for threading

6

3. VisualBasic® macro use

3.1 GetInput – position (16 bit) and angle read out

With this command you can read position counter for each encoder inputs as well as the spindle angle

(encoder channel 0).

Syntax:

GetInput (addr)

Parameters:

addr - register addresses (look at the table below)

Register no.

Description

84

Spindle angle multiplied x10 (range 0-3600)

85

Encoder channel 0 position counter (spindle)

86

Encoder channel 1 position counter

87

Encoder channel 2 position counter

3.2 GetUserDRO – position read out (32 bit)

With this command you can read position counter in 32bit format.

Syntex:

GetUserDRO (addr)

Parameters:

addr - register address (look at the table below)

Register no.

Description

1501

32 bit encoder channel 0 position counter

1502

32 bit encoder channel 1 position counter

1503

32 bit encoder channel 2 position counter

www.cs-lab.eu

CS-Lab s.c. | CSMIO-ENC module for threading

7

4. CSMIO-ENC module installation and configuration

4.1 Installation and connection of CSMIO-ENC module

An encoder should be mounted this way to get encoder- spindle ratio 1:1. The encoder most be firmly

mounted and parts used for driveline must be finely made.

For instance if we have to use a belt drive for the encoder's drive we need to pay attention if gears

and toothed belts are good quality.

Poorly made gears and toothed bars can distort spindle's current position readout what can directly

affect on Z axis feed during threading.

It is not recommended to use an encoder of a servo motor that drives the spindle to avoid spindle

position readout error.

CSMIO-ENC module connection

−The module should be connected to a motion controller (CSMIO/IP-S or CSMIO/IP-A) with the

flat cable included.

−A power supply of the module should be connected the same way as the head controller's

power supply.

−Spindle encoder signals should be connected to inputs described as "encoder 0" as only these

inputs are supported by an algorithm for threading and revs reading.

During an encoder connection remember to keep proper signals' order.

4.2 CSMIO-ENC module configuration

The encoder module configuration is very easy and it comes down to only to operations:

a) Encoder pulses number configuration

Go to „Config\Config Plugins\Config\Special Functions\Spindle” and enter encoder pulses

number incl. all edges in the „Spindle Encoder (CSMIO-ENC)” area.

b) Encoder pulses counting direction configuration

Sometimes it can be necessary to change encoder pulses counting direction. To verify if

current direction is correct you should go to „PlugIn Control\CSMIO_IP plugin\Expansion

modules\CSMIO-ENC\”. Then - activate a spindle with M3 command and verify if RPM value is

positive. If it will be negative you should go to „Config\Config Plugins\Config\Special

Functions\Spindle” and select (check) „Inv. Direction” option.

CSMIO-ENC for proper operation requires all encoder signals (A+/A-/B+/B-/I+/I-).

A shield of an encoder's wire should be connected only from one side to PE or in case of

high noises to GND (0V). CSMIO-ENC power connector can be the place of connection.

Table of contents

Other CS-Lab Control Unit manuals

Popular Control Unit manuals by other brands

Keysight

Keysight N3304A Component level information

Armstrong

Armstrong 425 Installation and Maintenance

Mitsubishi Electric

Mitsubishi Electric CC-Link IE TSN user manual

Watts

Watts 909 Series Installation, maintenance & repair

TECH

TECH Sinum PS-08m 230 quick start guide

Bardiani Valvole

Bardiani Valvole BBZO Instruction, use and maintenance manual

Automated Logic

Automated Logic LGE Technical instructions

Digi

Digi XBee SX 868 user guide

Duemmegi

Duemmegi Domino DFCKIII manual

YASKAWA

YASKAWA DO-A3 installation manual

GEM

GEM 563 Installation, Operating and Maintenance Instructions for the Installer and the User

SMC Networks

SMC Networks IL201 Series Operation manual