Somati system s.r.o., Jihlavská 510/2c, 664 41 Troubsko

ID: 29260159, Tax ID: CZ29260159

www.somati-system.cz

List of documentation:

1WIRING EXAMPLE............................................................................................ 1

2MECHANICAL INSTALLATION .......................................................................... 2

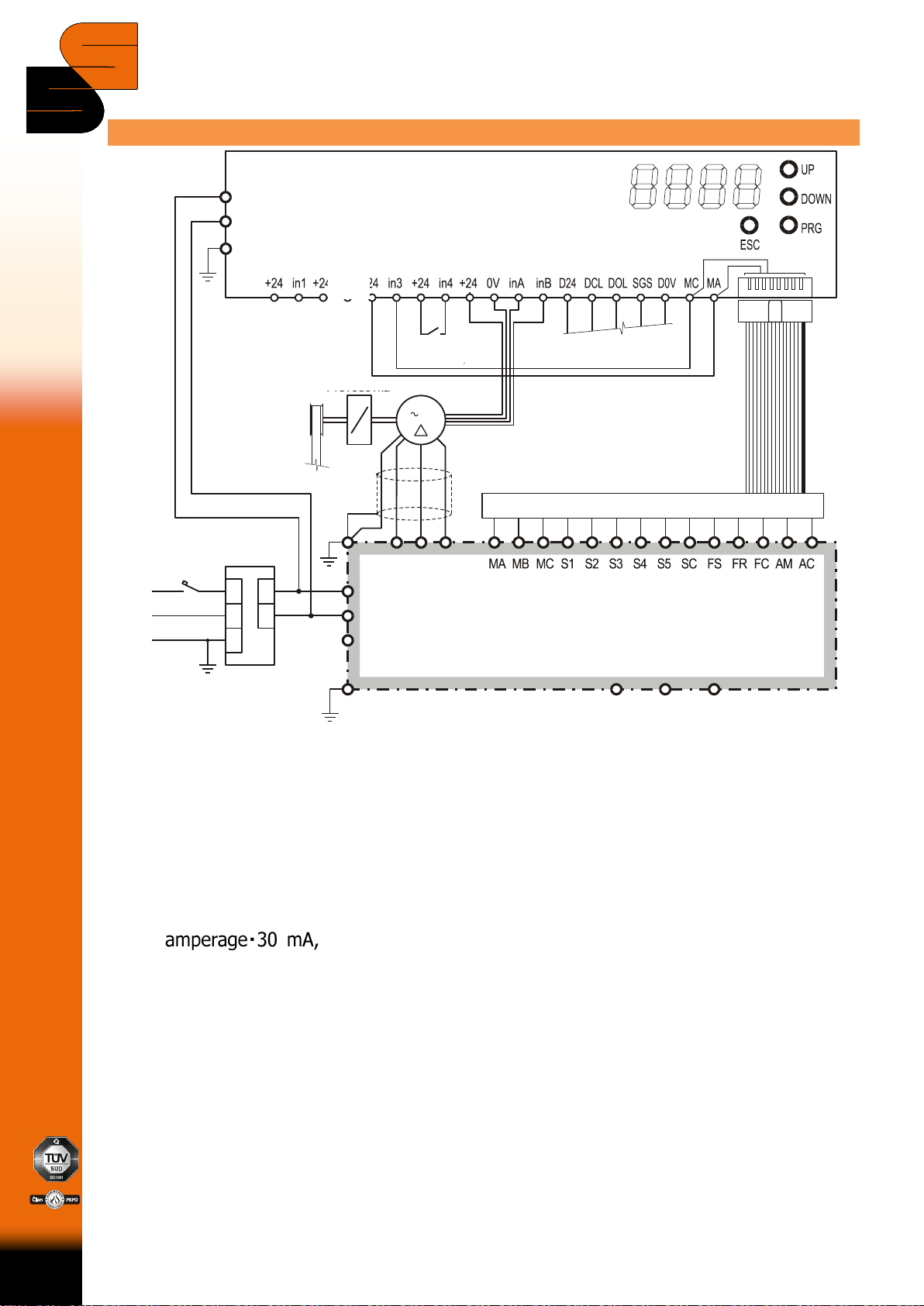

3ELECTRICAL WIRING ....................................................................................... 3

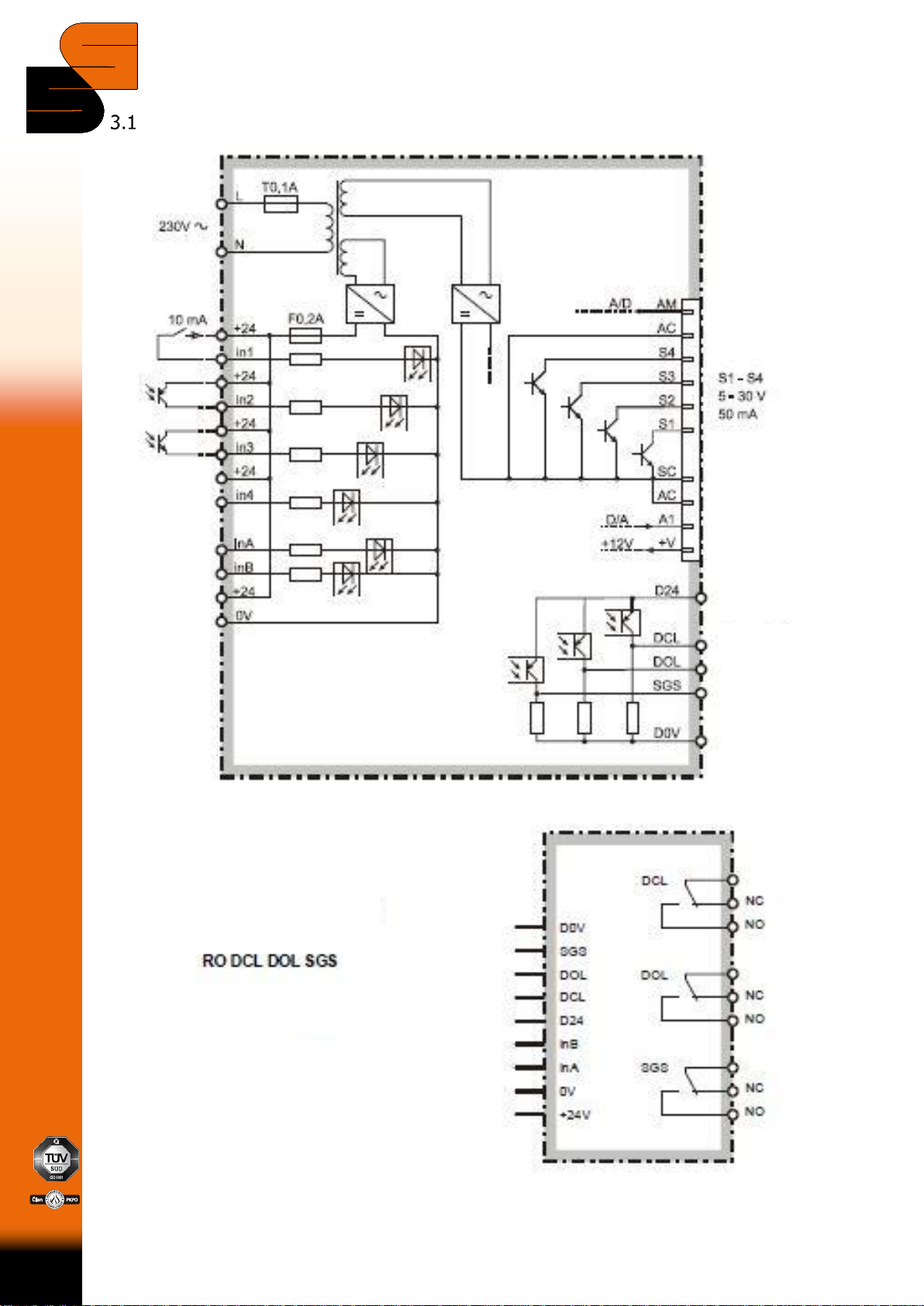

3.1 Input/output connection diagram of VJ002v........................................................ 4

4REFERENCE SEARCHING .................................................................................. 5

4.1 Motor phase conductors matching ...................................................................... 5

4.2 Reference searching without limit switch............................................................. 5

4.4 Reference searching via limit switch ................................................................... 6

5OPENING .......................................................................................................... 6

6CLOSING........................................................................................................... 8

7OVERLOAD EVALUATION ...............................................................................10

7.1 Evaluation by speed difference......................................................................... 10

7.2 Evaluation by current excess ............................................................................ 10

8PUSHING IN END POSITIONS........................................................................ 11

9END POSITIONS REGULATION ...................................................................... 11

10 SIGNALS TO DOOR CONTROL SYSTEM ........................................................ 11

11 IMPORTANT CONTROL AND DSETTINGS INVERTER COMPONENTS AND

CONSTANTS....................................................................................................13

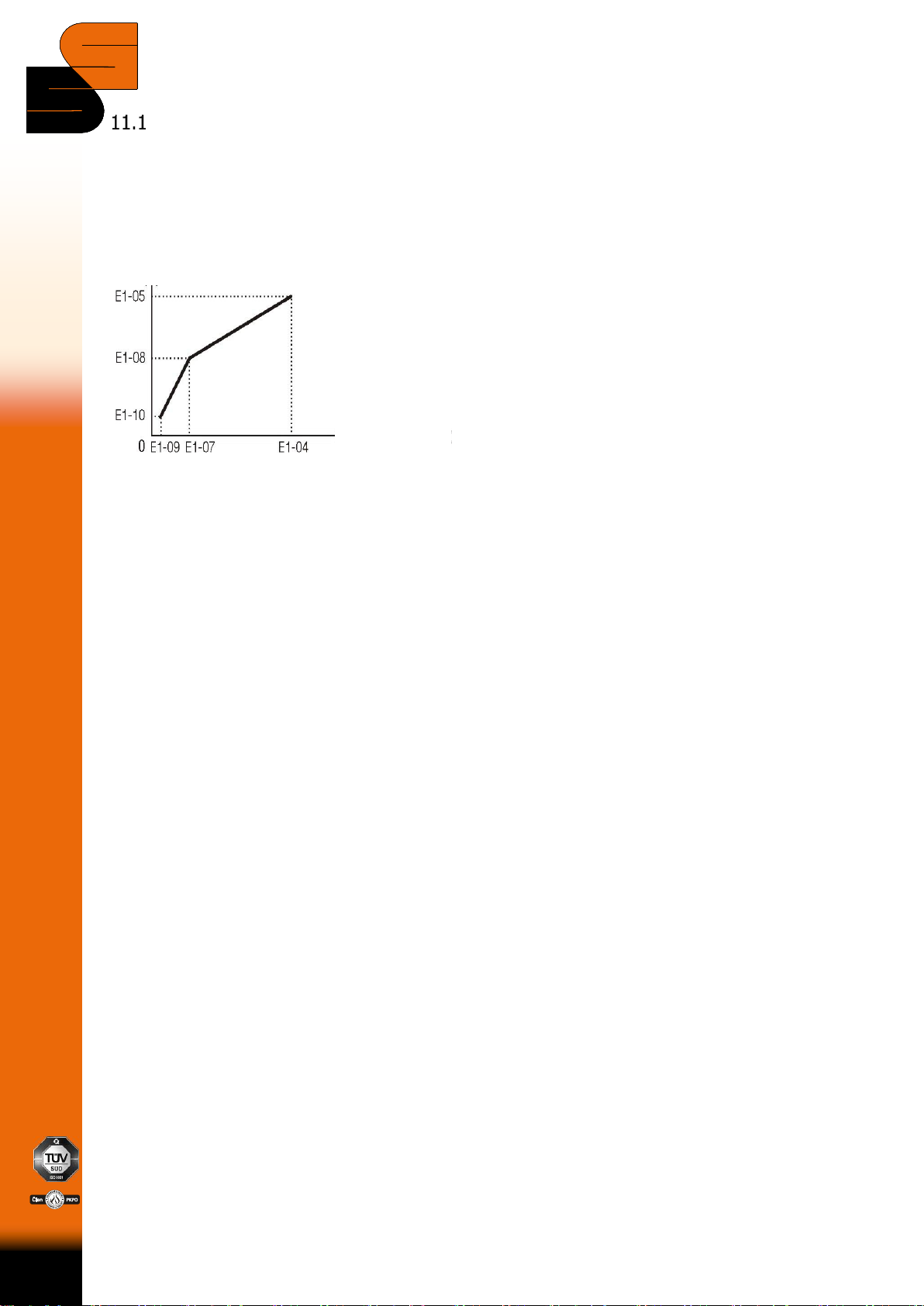

11.1 V/f pattern .................................................................................................. 15

11.2 Ramps and S-curve pattern.......................................................................... 16

11.3 Programmable inputs S3, S4 ........................................................................ 16

11.4 Over-torque detection.................................................................................. 16

11.5 Overload detection - IOL.............................................................................. 16

11.6 Fault Diagnoses........................................................................................... 17

12 SET 1RM1 ..................................................................................................... 18

13 PROGRAMMABLE RELAY ZEN .......................................................................23

14 PERIODICAL INSPECTIONS .........................................................................25

14.1 Inverter ...................................................................................................... 25

14.2 Cabinet ....................................................................................................... 25

14.3 UPS –required user maintenance................................................................. 25

15 CIRCUMFERENTIAL SCHEMATICS................................................................ 26

15.1 Power supply .............................................................................................. 26

15.2 Power unit .................................................................................................. 27

15.3 Frequency converter circuit .......................................................................... 28

15.4 Door unit .................................................................................................... 29

15.5 Programmable relay .................................................................................... 30

15.6 Controls ...................................................................................................... 31

15.7 Photocell, flashlight (signalization)................................................................ 32

15.8 Signalization of door status .......................................................................... 33

15.9 Cabling 1 .................................................................................................... 34

15.10 Cabling 2 .................................................................................................... 35

15.11 Cabling 3 .................................................................................................... 36

15.12 Sensor connection for the drive 1RM1........................................................... 37