EN 4

A - SAFETY INSTRUCTIONS

In our efforts to continually improve our products,

we reserve the right to make any changes to the

technical, functional, or aesthetic characteristics

related to their development.

This automatic gate opening mechanism, and its

manual, were designed to enable a gate to be

motorised in compliance with current European

standards.

WARNING

Important safety instructions. A automatic gate

opening mechanism is a product that can cause

injury to people and animals and damage to

property. It is important for people’s safety to follow

these instructions.

Keep these instructions.

1 - OPERATING PRECAUTIONS

• This apparatus may be used by children over

the age of 8 and by persons with reduced

physical, sensory or mental abilities or lack of

experience or familiarity, if they are correctly

supervised or if the instructions relating to the

safe use of the apparatus have been given to

them and the possible hazards are understood.

Children must not play with the device. Cleaning

and user maintenance must not be conducted

by children without supervision.

• This apparatus should only be used for its

intended purpose, that is, to motorise a one- or

two-panel gate for vehicle access. Any other use

will be considered dangerous.

• The opening or closing manoeuvre control must

be used with perfect visibility of the gate. Should

thegatebeoutsidetheuser’seldofvision,the

installation must be protected by a photocell

type safety device, and its operation must be

checked every six months.

• All potential users must be instructed in the use

of the motorised gate by reading this manual. It

must be ensured that no persons who have not

been instructed in the use of the device may set

the gate into motion.

• Before setting the gate into motion, ensure that

there is no person in the area in which the gate

moves.

• Do not let children play with the gate control

devices. Keep the remote controls out of the

reach of children.

• Avoid any natural obstacles (branch, stone, high

grass, etc.) impeding the gate’s movement.

• Do not manually activate the gate when the

motor drive is not disengaged from the gate.

Avidsen cannot be held liable for any use that does

not comply with the instructions in this manual and

causes damage.

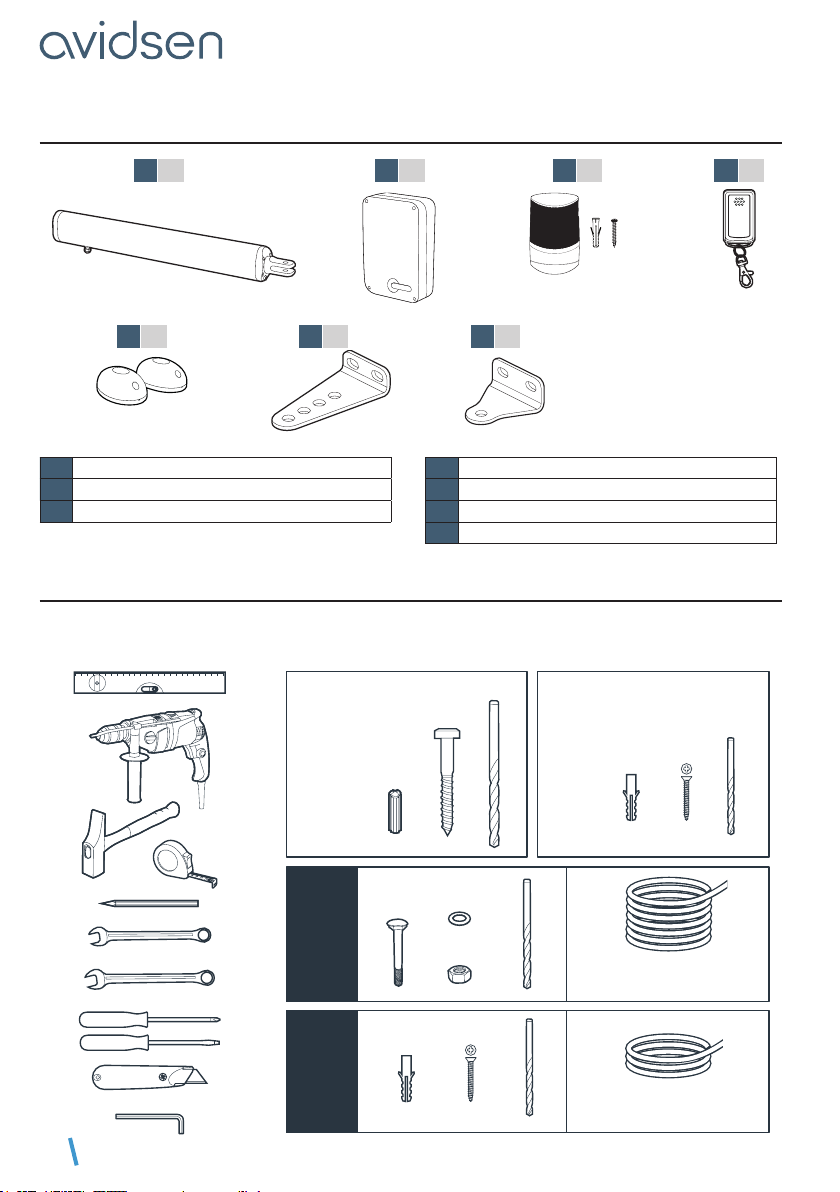

2 - INSTALLATION PRECAUTIONS

• Read this entire manual before starting the

installation.

• The electrical installation of the motorised gate

must meet current standards (NF C 15-100) and

shouldbeundertakenbyaqualiedperson.

• The 230VAC mains supply must be protected

against surges with a suitable circuit breaker

which meets current standards.

• All electrical connections must be performed

with the power switched off (safety switch in the

OFF position) and battery disconnected.

• Ensure that crushing and shearing between

the mobile parts of the motorised gate and

the surrounding xed parts due to the gate’s

opening/closing movement are avoided or

signalled on the installation.

• The motorised part must be installed on a gate

accordingtothespecicationsprovidedinthis

manual.

• The motorised gate must not be installed in

an explosive atmosphere (presence of gas,

ammablesmoke,etc.).

• The installer must check that the temperature

range shown on the motor drive is suitable for

the location.

• The wire that acts as an antenna must remain

inside the electronic panel.

• It is strictly forbidden to modify any of the

components provided in this kit, or to use an

additional component not provided for in this

manual.

•

During installation, but above all during adjustment

of the motorised gate, you must ensure that no

person, including the installer, is in the area in

which the gate moves at the start and throughout

the duration of adjustment.

• The ashing light is an essential safety

component.

• If installation does not correspond to one of the

cases shown in this manual, you must contact

us so that we can provide all the components

necessary for smooth installation with no risk of

damage.

• After installation, ensure that the mechanism

is correctly adjusted and that the protection

systems work correctly.

The Avidsen company shall not be responsible in

case of damage if installation is not conducted as

indicated in these instructions.