Somerdata AROW Series Programming manual

This manual suits for next models

3

Table of contents

Popular Network Hardware manuals by other brands

Honeywell

Honeywell 35 Series user guide

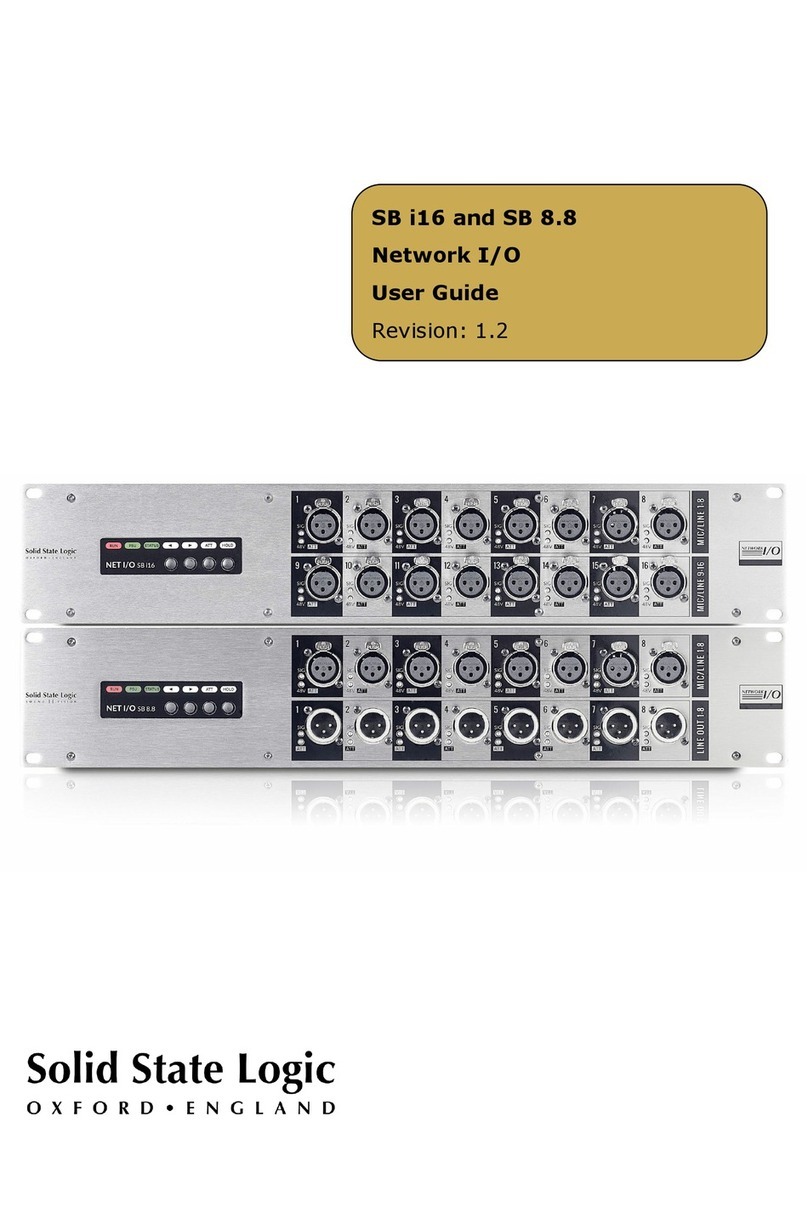

Solid State Logic

Solid State Logic SB i16 user guide

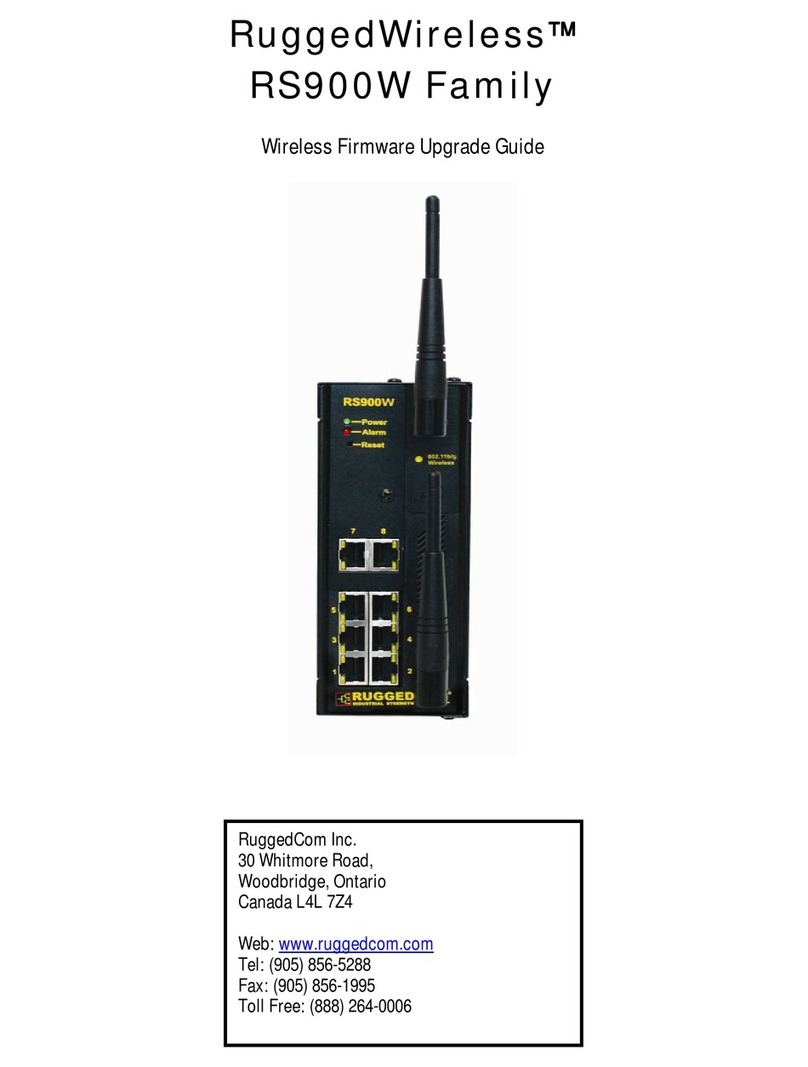

RuggedCom

RuggedCom RuggedWireless RS900W Family Upgrade guide

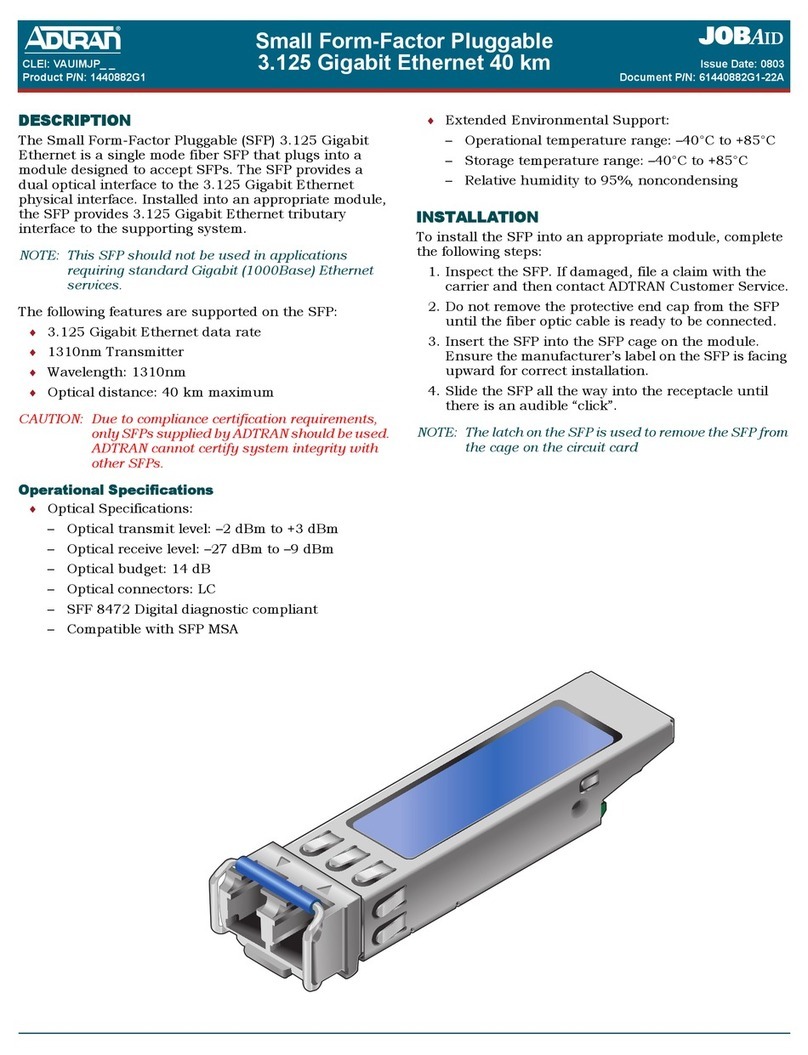

ADTRAN

ADTRAN 3.125 Gigabit Ethernet Job aid

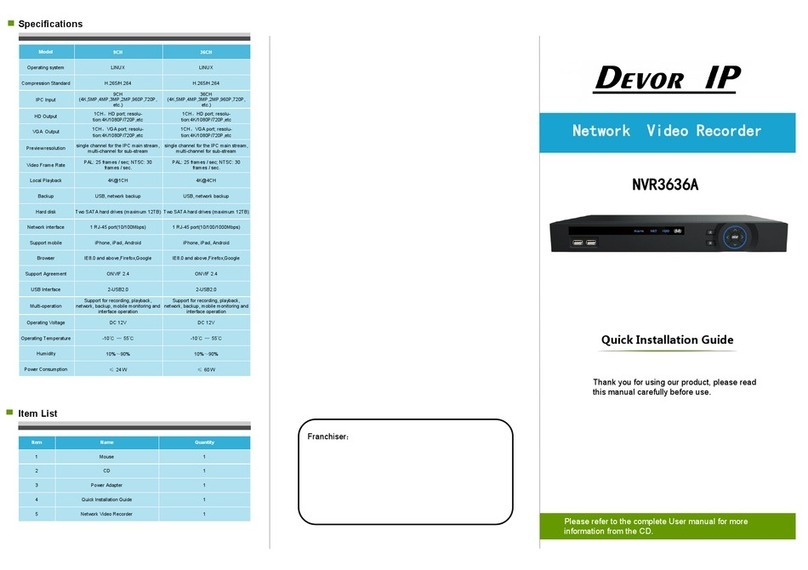

Devor IP

Devor IP NVR3636A Quick installation guide

Extreme Networks

Extreme Networks NetSight NS-A-20 installation guide

Huawei

Huawei LUNA2000-97KWH-1H1 Maintenance manual

Riverbed

Riverbed SteelHead CX xx70 Series Upgrade and Maintenance Guide

Televes

Televes TOX Series User instructions

Grandstream Networks

Grandstream Networks UCM6510 How to configure

Bull

Bull Escala Power7 Series installation guide

CAMBRIONIX

CAMBRIONIX TS2-16 user manual

CTC Union

CTC Union STE-10 Operation manual

Patton electronics

Patton electronics RocketLink-G 3088 Series user manual

Oracle

Oracle Acme Packet 4600 Hardware installation and maintenance guide

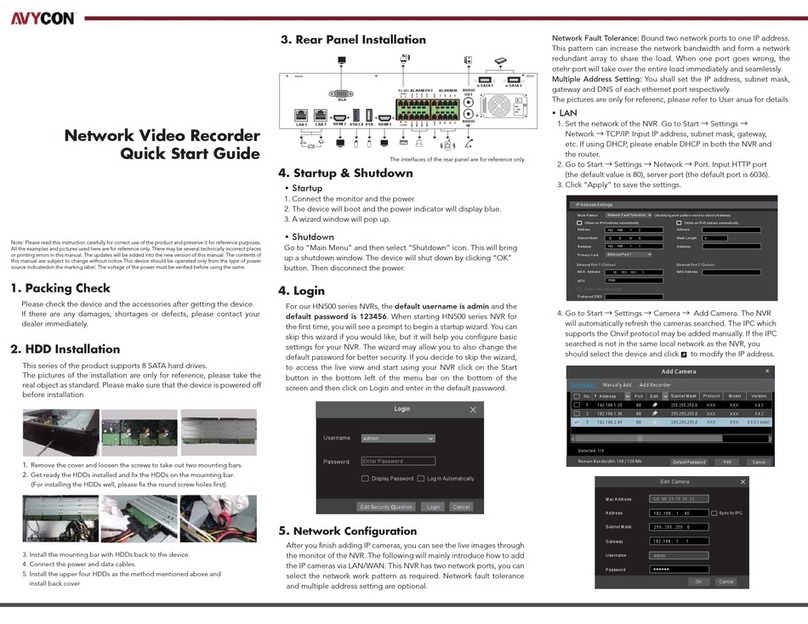

AVYCON

AVYCON HN500 Series quick start guide

Comtrol

Comtrol InterChangeVS 1000 Installation reference guide

websense

websense V10000 Getting started