SOMMY TC-*-M1 User manual

Features:

KKTCC02A-A/0-20151231

TC Series

23

Intellegient Temperature Controller

User Manual

Various of TC/RTD signal type are supported

⊙

⊙

⊙

⊙

Using fuzzy PID control algorithm and auto-tuning

without overshoot impulse

Different control modes for selection, kindly refer to

OT parameter for details

Switch RUN/STOP function with one key

The instruction explain instrument settings,

connections,name and etc,please read carefully

before you use the temperature controller. Please

keep it properly for necessary reference.

Model Illustration

TC 6 R 2 D

4: 48W*48H*100L 6:48W*96H*100L 7:72W*72H*100L

8:96W*48H*100L 9:96W*96H*100L(mm)

D: Version

TC Series Temperature Controller

R: relay output Q: SSR output M: relay and SSR output

K: SCR output (need to be ordered)

1: one alarm 2: 2 alarms Blank: No alarm

Note: If need heating and cooling control mode , also need alarm function , please choose model

with 2 alarms relay output.

Model Control output Alarms

TC-□-M1

TC-□-Q2

TC-□-R1

TC-□-R2

Models Example

relay and SSR output

SSR output

relay output

1

2

1

2

relay output

1.Specifications

AC/DC 100 ~240V(85-265V)

< 6VA

Technical Parameters

Sample rate

2 times/per second

Relay capacity AC 250V /3A Life of rated load>100,000 times

Power supply

Power consumption

Environment 0 ~50℃no condensation,Humidity:<85%RH,altitude<2000m

Storage enenvironment -10 ~60℃, no condensation

IEC/EN61000-4-2 Contact ±4KV /Air ±8KV perf.Criteria B

IEC/EN61000-4-4 ±2KV perf.Criteria B

IEC/EN61000-4-5 ±2KV perf.Criteria B

IEC/EN61000-4-29 0% ~70% perf.Criteria B

IP65(IEC60529)

SSR output DC 24V pulse voltage,load<30mA

Insulation impedance Input, output, power VS meter cover >20MΩ

ESD

Pulse traip

anti-interference

Safety Standard IEC61010-1 Overvoltage category Ⅱ,pollution level 2,

levelⅡ(Enhanced insulation)

Panel Protection level

Power failure memory 10 years,times of writing: 1 million times

Surge immunity

Voltage drop & short

interruption immunity

Dielectric strength

Signal input /output /power 1500VAC,between lower than 60V circuits,

DC500V1min

Shell material The shell and panel frame PC/ABS (Flame Class UL94V-0)

Total weight About 400g

Panel material PET (F150/F200)

2.Isolation diagram

Power supply

Control output Measure input Relay alarm output

1

K

J

E

PT100

-50 ~999

-50 ~400

-200 ~600

0~999

0~850

T

1℃

1℃

1℃

1℃

1℃

0.5%F.S±3digits

0.5%F.S±3digits

0.5%F.S±3digits

0.5%F.S±3digits

0.5%F.S±2℃

>500kΩ

>500kΩ

>500kΩ

>500kΩ

0.2mA

CU50

CU100

-50 ~150

-50 ~150

1℃

1℃

0.5%F.S±3℃

0.5%F.S±1℃

0.2mA

0.2mA

3.Measured signal specifications:

Input impedance/auxiliary current

Accuracy

Resolution

Range

Symbol

Input type

Operation & menu

1. Factory default menu procedure (pid heating mode)

SET

measure and control mode

LCK=33

PV

SV

PV

SV

PV

SV

PV

SV

SV

PV

PV

SV

PV

SV

(uncommon menu)

PV

SV

PV

SV

PV

SV .

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV .

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

SV

PV

.

PV

SV

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

Press “SET”>3seconds

Press “SET”>3s

Press “SET”>3s

1st alarm value

1st alarm

hystersis

1st alarm mode

Amend

Input signal

control mode

password

OUT1 control cycle

Overshoot limit

Proportional

band

Integral time

Differential time

Control output

mode

auto-tuning

Speed fine-tuing

1st alarm

extended function

Display low limit

software version

Display fuzzy

tracking value

Temperature unit

Digital filter

coefficient

Decimal point

setting

Display high limit

(common menu)

Note: Meter will hide non-related parameters based on selected OT working mode. Please set

OT parameter well when using the meter.

Parameters will keep displaying all the time for all the model and all the setting

Parameters will be hided based on model and menu setting

1

2

3

6

7

Name of universal panel

Menu key/confirm key, to enter or exit modified mode or confirm modified parameters

Increase key/R/S

Display window (red)

Decrease key Decrease key

Setting value/parameters display window,display “STP” =stop control

measured value/parameters code display window

No Symbol Name Function

1

2

Alarm1# indicate light(red)

Alarm2# indicate light(red)

Alarm3# indicate light

3

AT indicate light(green)

Shift/AT key

SET function key

5

4

7

6

out1 indicate light(red)

out2 indicate light(red)

Main control output indicate light, it lights when the output is ON

Cooling output indicate light,it lights when output is ON

1st alarm output indicate light

2nd alarm output indicate light

3rd alarm output indicate light (can be ordered)

Auto-tuning indicate light,it indicates auto-tuning status when lighting on

Display window (green)

*

*

AL1

AL2

AL3

OUT1

OUT2

AT

SET

SV

PV

R/S

▲

▲

AT

▲

Activation/shift key/AT auto-tuning key,long press to enter/exit auto-tuning under measure control mode

Increase key, long press it to shift RUN/STOP mode under measure control mode.

4:(48*48)

6:(96*48)

7:(72*72)

8:(48*96)

9:(96*96)

80:(80*160)

16:(160*80)

48

48

72

96

96

160

80

Model

3:(72*36) 72 36 70.5 6.5 64 32 68 25 33 25

AH(Min)

GB C D E F

J

48

96

72

48

96

80

160

101

100

100

100

100

102

102

10

6

10

6

10

10

10

91

94

90

94

91

92

92

45.5

45.5

68

91.5

91

154

76.5

25

25

25

25

25

30

30

45.5

91.5

68

45.5

91

76.5

154

45

91

67.5

45

90.5

76

153.5

K

(Min)

25

25

25

25

25

30

30

+0.5

H

G

K

J

A

B

C

E

D

F

-0

+0.5

-0

Dimension and installation size

front size side size Hole size

4

1

2

3

6

5

7

OUT1

SV

PV

OUT2 AL1 AL2 AL3 AT

SET R/S

AT

▲

▲

▲

2. Common use menu explanation 3. Uncommon use menu explanation

TC4

TC9

TC7

16

SSR

OUT1

17

-

+

14

SSR

OUT1

13

-

+

TC6

Note:

17

SSR

OUT1

18

-

+

Model with “M”, ssr output terminal

TC8

17

SSR

OUT1

18

-

+

Model with “M”, ssr output terminal

Note:

13

SSR

OUT1

11

-

+

NC

7

6

45

Lock function; 001: SV value can not be modified,

010:menu setting value only can be checked ,cannot modified.

033: If set it as 033 ,it can enter to uncommon menu .

123: reset to factory defalut setting

Control type,0:ON/OFF control; related pararmeter: DB

1:PID heating control , related parameter: P , I , D, OVS, CP, ST, SPD

2:compressor cooling , parameter: DB , PT

3:PID heating & cooling control . related parameters: P, I, D, OVS,DB,

CP, CP1, PC, ST, SPD

0~999 0

8

9

10

11

12

13

14

15

16

17

18

K~CU100

0~3

K

1

0~999 30

0 ~ 999 120

0 ~ 999 30

0 ~ 999 5

0~100 5

1~200 20

4~200 20

1~100 10

Description

1

2

3

4

5

6

7

FL ~FH

0~100

0~12

FL ~FH

0~100

0~6

-199 ~999

10

1

3

5

1

4

0

No. symbol

1st alarm value, note: the minus is dealed as absolute value when it is

as a deviation value .

Set range Factory setting

1st alarm hystersis

1st alarm mode . Note: when 1st alarm is used as OUT2 , should set

as 0. When setting as 0, it close alarm function. When set value >6,

should set AD2 as 0. (refer to alarm output logic diagram on page 6)

2nd alarm value,note:the minus is dealed as absolute value when it is as

a deviation value .

2nd alarm hystersis

2nd alarm mode. Note: When AD1>6, should set this value as 0 to

close the alarm function.(refer to alarm output logic diagram on page 6)

Amend value,display value=actual measured value+ amend value

Optional input measured signal type:refer to input signal parameters

table.Note:it need to change the relevant parameters after changing.

Proportional band,the lower of setting value,the faster of system heating .

Increase proportional band can reduce vibration,but it may increase control

bias.Reduce proportional band reduce control bias, may cause vibration

Integral time the lower of the value,the stronger of integral action,the more

tendency to eliminate and deviation of set value.If integral action is too weak,

it may not eliminate the deviation. Unit: Second

Differential time,reduce effect of differential time to proper value,which prevent

system oscillation.The higher value,the stronger function of differential.Unit:s

Overshoot limit,in the process of PID control,when PV>SV+OVS,it force off

output; The lower value,the lower PID adjusted range,the worse control

stability;please set a proper value according actual state.

On-off control backlash(nagetive backlash on-off control) or cooling control

and compressor cooling control dead zone. please change value according

to decimal position,when you change input sigal type type.

OUT1 heating control cycle, 1:SSR control output,

4-200: relay control output. (Unit:second)

OUT2 control cycle,cooling relay output cycle.Unit:second

OUT2 cooling proportionality coefficient,the higher of value,the stronger of

cooling

19

20

21

22

0~1

0~1

0

0

N

999

-50

0

10

℃

0~999 180

0~5

0~6

0

0~5

0~1

0

23

24

25

26

27

28

29

30

31

0.0~2.0 1.0

V1.0

0~255

℃、℉

AT

▲

Control output : 0: relay output 1: single SSR output

Power on auto-tuning setting. 0: normal control after power on

to exit the auto-tuning.

Control speed fine tuning,optional 0(N)no function,1(slow),2(ss)medium slow,

3(SSS)very slow,4(F)fast,5(FF)medium fast,6(FFF)express

Compressor starting delay ,unit:s

1st alarm extended function

2nd alarm extended function

Measure range low limit, setting value must be less than measure

range high limit

Measure range high limit, setting value must be more than measure

range low limit.

Decimal point setting

filter coefficient ,the higher of value,the stronger of filter function

Temperature unit

PV fuzzy tracking value,it can get stable control display value in some status.

Note:when the alarm setting value is equal with SV setting value after setting

the DTR value,operation of alarm output is subject to actual measured value.

Setting 0 to close the function.

Software version cannot modified

refer to input signal table

refer to input signal table

1: meter enter into pid auto-tuning status after power on. long press

Key function operation

1. Run/stop operation

1)Under the measure mode,press “ ” into monitoring mode;and on the SV window display “STP” . Long Press “ ” to exit.

2)It can modify SV value and shift mode operation even if displaying STP.

3)Under the monitoring mode, main control output will stop

2. PID Parameter confirmation and auto-tuning operation:

1)Factory default PID may not be suitable to usage occasion;please use auto-tuning function to get suitable PID setting.

2)The meter will make control output after power on a short period. User can set the meter to monitor mode to make sure

auto-tuning effect, or switch off the power of control output load at temporary . No matter how to operate, it should guarantee

the set value is larger than the present measured value, it is better if much larger.

3)In order to avoid the effect of alarm output,please set the proper alarm value,or remove the alarm effect.

4)Set proper SV value .

5)Set OT as 1 (PID control).

6)Under the condition of PV value at normal room temperature, exit the monitoring mode or switch on load power,and

long press “ ” to enter auto-tuning mode, and AT indication light will flashing.

7)Auto-tuning need a period, to ensure the auto-tuning result,please don`t modify parameters or power-off during auto tuning.

8)When AT light is off , it will exit the auto-tuning. PID will update automatcially, and can get good control result.

9)During auto-tuning, long press “ ” key, measure beyond the range,display abnormally, shift to “STP” status,power-off

ect will stop the auto-tuning.

10)Experienced users can set a proper PID parameter according to their experience.

3. PID & Cooling control operation (suitable for injection molding machine , extruding machine ect)

1) Please set OT parameter as 3

2)PID control act on main control output OUT1;Cooling control act on OUT2.

3)AL1 alarm relay will be used as OUT2 control output.

4)Please set the cooling start offset DB to a value bigger than 5,to ensure the cooling would not affect the PID control impact.

5)Please set cooling control cycle CP1 to a proper value,and modify the cooling proportional coefficient to a a proper value.

6)When PV value > SV+DB value,the cooling control start to effect;the bigger value of PV,the longer output time of OUT2

R/S

▲

R/S

▲

AT

▲

AT

▲

Wire Connection

Model with “M”, ssr output terminal

Model with “M”, ssr output terminal

Model with “M”, ssr output terminal

Note:

Note:

Note:

Display

LLLL/HHHH

Methods

Check whether the input disconnection, check the FH and FL value, Check working

environment temperature , Check whether input signal is selected correctly.

Simple TroubleShooting Method

(1)Alarm parameters and output logic diagram:

Symbol description:“☆” means alarm hystersis , “▲” means alarm value,“ ” means SV value

△

No. Type

High limit absolute value alarm1

2

3

4

5

6

※High limit deviation value alarm

※Low limit deviation value alarm

※High/low limit deviation value alarm

※High/low limit interval value alarm

Low limit absolute value alarm

Alarm output(AL1、AL2 is independent of each other)

Image:the hatched section means the alarm action

SV+AL

SV+AL

SV-AL

SV

SV

SV-AL SV

SV+AL

SV-AL

AL

AL

☆

☆

☆

☆

☆☆

▲

▲

▲

☆

▲

▲

▲

☆

▲

▲

△

△

△

△

△

△

※When the alarm value with deviation alarm set to a negative number,it will deal with it as an absolute value.

7

8

9

10

11

12

High/low limit absolute value alarm

※High/low limit deviation value alarm

High/low absolute value alarm

※High/low limit deviation alarm

※Alarm between high limit absolute

value and low limit deviation value .

※Alarm between high limit deviation

value and low limit absolute value.

The following two group of alarm parameters(AL1、AL2) used in

combination,AL1 alarm output , AD2 must set to 0

SV

SV

SV

SV

SV

SV

SV-AL1

SV-AL1

SV-AL1

SV+AL2

SV+AL2

SV+AL2

AL2

AL2

AL2

AL1

AL1

AL1

☆

▲

☆

▲

☆

▲

☆

▲

☆

▲

☆

▲

☆

▲

☆

▲

☆

▲

☆

▲

☆

▲

☆

▲

△

△

△

△

△

△

No. Type

(2)Alarm extension function table

0

1

2

5

3

4

AE1/AE2 value Alarm handling mode when show HHHH/LLLL

Forced alarm output

Forced alarm close

Forced alarm output

Forced alarm close

Remark

The state when alarm keep HHH/LLL in previous time

The state when alarm keep HHH/LLL in previous time

Power on alarm, alarm does not inhibit

(As long as meet the requirement

of alarm , make alarm output)

Power on alarm , alarm inhibits.

(Before PV value reach the set value at the

first time ,the alarm does not output)

Alarm function logic diagram

This manual suits for next models

3

Table of contents

Other SOMMY Controllers manuals

Popular Controllers manuals by other brands

vacuubrand

vacuubrand VACUU-SELECT Instructions for use

Disaster Area Designs

Disaster Area Designs DMC.micro user manual

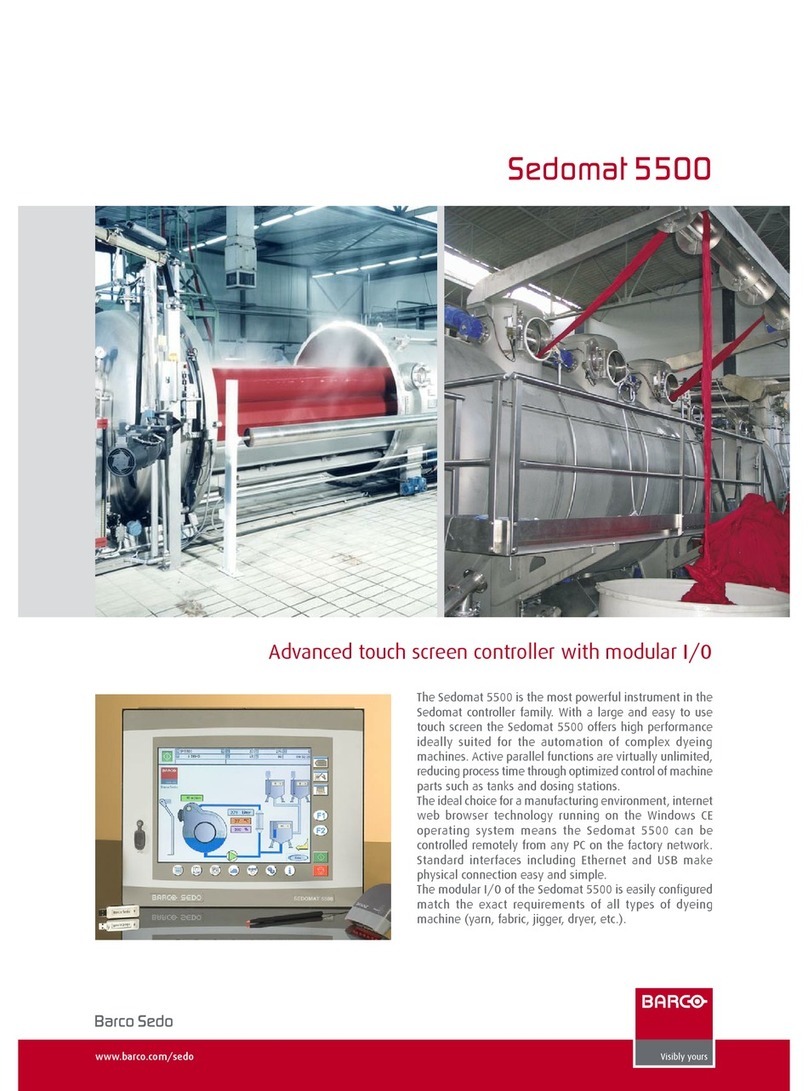

Barco

Barco Sedomat 5500 Specifications

Samlexpower

Samlexpower MSK-10A owner's manual

Siemens

Siemens SSA911.01TH quick guide

Under Control

Under Control MANETTE FILAIRE SWITCH How to connect

Infineon

Infineon IDP2303 Design guide

AMX

AMX NetLinx Integrated Controllers NI-700/900 Hardware reference guide

GARDASOFT

GARDASOFT RC1 Series user manual

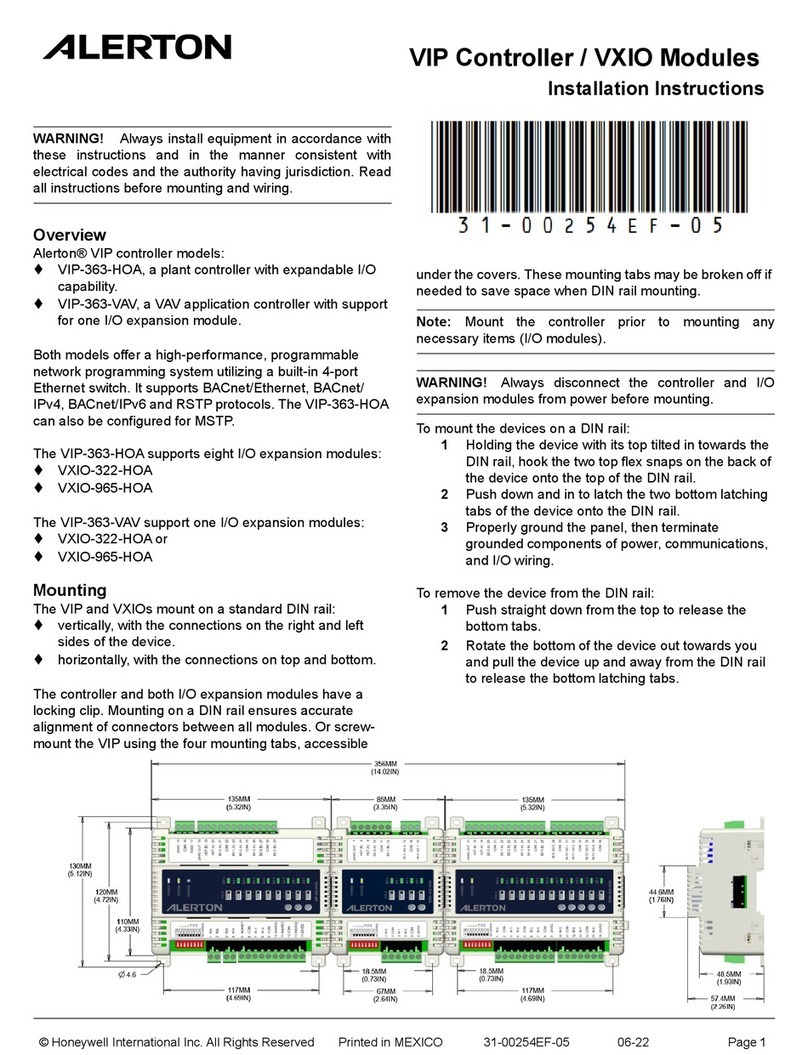

Honeywell

Honeywell ALERTON VIP-363-HOA installation instructions

Philips

Philips Dynalite Revolution Series installation instructions

Cypress

Cypress CY3280-20x66 Universal CapSense quick start guide