Sonatest Sitescan D-10 User manual

Sitescan D-10 & D-20Sitescan D-10 & D-20

User’s GuideUser’s Guide

Sitescan D-10 & D-20 User’s GuideSitescan D-10 & D-20 User’s Guide

Page iPage i

Copyright © 2008 Sonatest LimitedCopyright © 2008 Sonatest Limited

All rights reserved. All rights reserved.

No part of this publication may be reprNo part of this publication may be repr

oduced, stored in a retrievaloduced, stored in a retrieval

system or transmitted in any form or system or transmitted in any form or

by any means, electronic, mechanical, photocopying,by any means, electronic, mechanical, photocopying,

recording or otherwise, without the recording or otherwise, without the

prior written permission of Sonatest Limited.prior written permission of Sonatest Limited.

Sonatest Sonatest

Limited Limited

Sonatest Sonatest

Inc.Inc.

Dickens Dickens

Road Road

12775 12775

CogburnCogburn

Milton Milton

Keynes Keynes

San San

AntonioAntonio

MK12 MK12

5QQ 5QQ

TexasTexas

England 78249England 78249

Phone: Phone:

+44 +44

(0)1908 (0)1908

316345 316345

USAUSA

Fax: Fax:

+44 +44

(0)1908 (0)1908

321323 321323

Phone: Phone:

+1 +1

(210) (210)

697 697

03350335

e-mail:e-mail:

Fax: Fax:

+1 +1

(210) (210)

697 697

07670767

Web:Web:

www.sonatest.comwww.sonatest.com

e-mail: e-mail:

Document Number: 147320Document Number: 147320

Sitescan D-10 & D-20 User’s Guide ~ ContentsSitescan D-10 & D-20 User’s Guide ~ Contents

Page iiPage ii

ContentsContents

11

How to Use How to Use

This User’s GuideThis User’s Guide

....

................................................................................................................................................................................

11

1.11.1

TypogTypog

raphiraphi

cal Convencal Conven

tionstions

....

................................................................................................................................................................

11

22

Disclaimers and Notices..Disclaimers and Notices..

....................................................................................................................................................................................................

22

2.12.1

SpeciSpeci

fic fic

WarnWarn

ingsings

....

................................................................................................................................................................................................

22

2.22.2

GenerGener

al Warningal Warning

ss

....

................................................................

..........................................................................

......................................................

22

2.32.3

Operator Training..Operator Training..

................................................................................................................................................................................................

22

2.42.4

TestinTestin

g Limitatiog Limitatio

nsns

....

............................................................................................................................................................................................

33

2.52.5

CritiCriti

cal Operacal Opera

ting Facting Fac

torstors

....

......................................................................................................................................................................

33

2.5.12.5.1

Calibration of Calibration of

the Sound the Sound

VelocityVelocity

....

....................................................................................................................................

33

2.5.22.5.2

Transducer Transducer

(Probe) Zero (Probe) Zero

ProcedureProcedure

....

............................................................................................................................

33

2.5.32.5.3

Flaw Detection Calibration..Flaw Detection Calibration..

..........................................................................................................................................................

33

2.5.42.5.4

Effects of Temperature on Calibration..Effects of Temperature on Calibration..

......................................................................................................................

44

2.5.52.5.5

TransTrans

duceduce

r Conditionr Condition

....

........................................................................................................................................................................

44

2.5.62.5.6

Use of Couplant..Use of Couplant..

..............................................................

..........................................................................

....................................................

44

2.62.6

Disclaimer of Liability..Disclaimer of Liability..

....................................................................................................................................................................................

55

2.72.7

Electromagnetic Compatibility..Electromagnetic Compatibility..

........................................................................................................................................................

55

33

Quick Start..Quick Start..

..................................................................

........................................................................

..........................................................................

..........................

66

3.13.1

FroFro

nt Pnt P

aneane

ll

....

................................................................................

..............................................................................

......................................................

66

3.23.2

Flaw Detection...Flaw Detection...

....................................................................................................................................................................................................

1212

3.33.3

ThickThick

ness ness

GaugGaug

inging

......

......................................................................................................................................................................................

1414

3.43.4

SitesSites

can D-10 & D-2can D-10 & D-2

0 Memory0 Memory

......

..................................................................................................................................................

1616

3.4.13.4.1

Reset to factReset to fact

ory defauory defau

lts:lts:

......

..........................................................................................................................................................

1616

3.4.23.4.2

Clearing the Memory...Clearing the Memory...

......................................................................................................................................................................

1616

44

Detailed Menu Description...Detailed Menu Description...

....................................................................................................................................................................................

1818

4.14.1

MenMen

u Tu T

reeree

......

......................................................................

..............................................................................

............................................................

1818

4.24.2

Main Menu...Main Menu...

....................................................................

........................................................................

....................................................................

2020

44

.2.1.2.1

Main Menu Selection...Main Menu Selection...

......................................................................................................................................................................

2020

4.34.3

CAL CAL

MenMen

uu

......

..........................................................

....................................................................

....................................................................

................

2121

4.3.14.3.1

Calibration Menu...Calibration Menu...

..................................................................................................................................................................................

2121

4.3.24.3.2

Amplifier MenuAmplifier Menu

......

........................................................................................................................................................................................

2121

4.3.34.3.3

TX MTX M

enuenu

......

..............................................................

..........................................................................

....................................................................

2222

4.3.44.3.4

GATEGATE

1 & GATE2 Men1 & GATE2 Men

usus

......

............................................................................................................................................................

2222

44

.3.5.3.5

Auto-Cal MenuAuto-Cal Menu

......

................................................................

........................................................................

..................................................

2323

4.44.4

MEAS Menu...MEAS Menu...

....................................................................

..........................................................................

................................................................

2424

4.4.14.4.1

Measurement Menu...Measurement Menu...

..........................................................................................................................................................................

2424

4.4.24.4.2

TRIG...TRIG...

..................................................................

........................................................................

........................................................................

........

2525

4.4.34.4.3

PROBPROB

E ME M

enuenu

......

..............................................................................................................................................................................................

2626

4.4.44.4.4

AGC (Automatic AGC (Automatic

Gain Control)Gain Control)

......

......................................................................................................................................

2626

4.4.54.4.5

TCG Time CorTCG Time Cor

rectrect

ed Gain Menued Gain Menu

......

................................................................................................................................

2727

Sitescan D-10 & D-20 User’s Guide ~ Contents

Page iii

4

.4.6

Distance A

mplitude Correct

ion (DAC)

Menu

...

.............................................

28

4.5

MEM

ORY M

enu

...

..................................

....................................

..........................

29

4.5.1

PANEL Memory Menu...

..................................................................................

29

4.5.2

A-LOG Memory Menu

...

..................................................................................

30

4.5.3

REF Menu...

................................

.....................................

................................

30

4.5.4

T-

FN

..

.

....................................

.....................................

....................................

31

4.5.5

T-LOG Menu Numeric Mode...

.......................................................................

31

4.5.6

T-LOG

Menu D

elete Mo

de

...

..........................................................................

32

4.6

UTIL Me

nu

...

.................................

....................................

...................................

33

4.6.1

ME

NU M

enu

...

................................................................................................

33

4.6.2

VIDEO Menu...

................................................................................................

33

4.6.3

MISC

Menu

...

................................

.....................................

.............................

34

4.6.4

PRINT Menu...

................................

....................................

.............................

34

4.6.5

CLOCK Menu...

...............................................................................................

35

4.6.6

U-KEYS Menu...

...............................................................................................

35

4.7

Storage & Recall of Calibration Setups...

.............................................................

36

4.7.1

To sto

re a panel

set:

...

....................................................................................

36

4.7.2

To recall a panel set:...

....................................................................................

37

4.7.3

To del

ete a p

anel se

t:

...

..................................................................................

37

4.7.4

Adding NOTES to PA

NEL and A-LOG set

s

...

...................................................

37

5

Fla

w Test

ing

...

...................................

.......................................

......................................

.

40

5.1

Basic

Flaw

Testi

ng

...

............................................................................................

40

5.2

Flaw Testing Calibration...

...................................................................................

41

5.3

TCG Op

eratio

n

...

.................................................................................................

45

5.4

DAC

Opera

tion

...

.................................................................................................

47

5.5

Weld Inspection Using Trigonometr

y Mode

...

....................................................

50

5.6

A-LOG, A-Scan Storag

e

...

......................................................................................

52

5.6.1

To Stor

e An A-Sca

n:

...

.....................................................................................

52

5.6.2

To Recall an A-Scan:...

.....................................................................................

53

5.6.3

To Delete a Stor

ed A-Sc

an

...

...........................................................................

53

5.6.4

REF, Reference

Waveform Comparison

s

...

.....................................................

54

5.6.5

To Recall an

A-Scan as a Referen

ce Waveform:

...

...........................................

54

5.6.6

Peak Echo & Hold Dynamics...

.......................................................................

55

6

Thick

ness Gaug

ing

...

...................................

.......................................

.............................

57

6.1

Basic Thick

ness Gaugin

g

...

..................................................................................

57

6.2

A-Cal

...

....................................

....................................

....................................

......

60

6.3

TCG for Reliable Gauging...

.................................................................................

61

6.4

T-LOG Thi

cknes

s Storage

...

.................................................................................

62

6.5

T-Log Ed

iting an

d Print

ing

...

...............................................................................

64

6.5.1

To dele

te a single lo

cation

:

...

.........................................................................

64

6.5.2

To delete all L

ocations in a single

File:

...

.......................................................

64

Sitescan D-10 & D-20 User’s Guide ~ Contents

Page iv

6.5.3

To delete all Files

and all Locations:

...

...........................................................

64

6.5.4

To print thick

ness logs

...

................................................................................

65

7

Bat

ter

y

...

......................................

.......................................

.......................................

......

66

7.1

Batte

ry Cautio

ns

...

...............................................................................................

66

7.2

Battery Charging...

...............................................................................................

68

7.2.1

Charg

ing

Cautio

n

...

........................................................................................

68

8

Interface Connections...

................................

.....................................

.............................

70

8.1

USB...

.................................

.....................................

....................................

.........

70

8.2

Comp

osite Vid

eo

...

..................................

..................................

..........................

70

9

Features of the Sit

escan D-10 &

D-20

...

..........................................................................

71

9.1

Functional Testing Methods...

.............................................................................

71

10

Specifications...

.................................

........................................

.....................................

..

72

11

Warranty

...

.......................................

........................................

.....................................

...

76

12

In

de

x

..

.

...................................

.....................................

....................................

................

77

Sitescan D-10 & D-20 User’s Guide ~ How to Use This User’s Guide

Page 1

1

How to Use This User’s Guide

This user’s guide has been designed so that a person with a good knowledge of the

basics of

ultrasonic non-destructive testing may understand the operation and use of the

features

offered by the S

itescan D-10 &

D-20.

The user is advised, however, of

the important natur

e

of ultrasonic non-destructive testing and is referred to

Section 2 for important information

on the proper use of this technology.

Section

1

:

How to Use This User’s Guide

is this section.

Section

2

:

Disclaimers and Notices

contains important information that must be

understood

by users of the Sitescan D-10 & D-20

Section

3

:

Quick Start

provides a user familiar with ultrasonic testing a means to operate the

instrument’s basic functions and to quickly achieve familiarity without

having to

understand all of its features in

detail.

Section: 4:

Detailed Menu Description

is an in-depth description of the menu items found in

the Sitescan D-10 & D-20 with brief descriptions of each item.

Section 5:

Flaw Testing

gives guidelines on

performing flaw testing

with examples of how

to calibrate the Sitescan D-10 & D-20 and how to set up the unit for DAC and

TCG and how to use the A-Scan storage facilities.

Section 6:

Thickness Gauging

gives guidelines on performing thickness measurements

including the calibration of the Sitescan D-10 & D-20, using TCG and how to use

the thickness measurement memory functions.

Section 7:

Battery

describes important aspects of using and caring for the battery.

Section

8

:

Interface Connections

is for users who desire to operate the Sitescan D-10 & D-20

with ancillary equipment.

Section

9

:

Features of the Sitescan D-10 & D-20

is a quick reference listing the pertinent

characteristics of the instrument and the

various functional testing methods that

may be used with the

instrument.

The function keys are shown throughout this

manual as shown in Section

3.1

,

Front Panel

.

1.1

Typographical Conventions

When describing front pan

el buttons the text is

éêáåíÉÇ áå íÜáë Ñçåí

.

When describing settings in the S

itescan D-10 & D-20 the text is.

printed in this

font

Sitescan D-10 & D-20 User’s Guide ~ Disclaimers and Notices

Page 2

2

Disclaimers and Notices

The following information must be read a

nd understood by users of the

Sonatest Sitescan

D-10 & D-20

ultrasonic flaw detector

and thickness

gauge.

Failure to follow these

instructions can lead to serious errors in test results or damage to the flaw detector.

Decisions based on erroneous results can lead

to property damage, personal injury or

death.

Anyone using this instru

ment should be fully qu

alified by their organization in the

theory and practice of ultrasonic testing, or

under the direct supervision of such

a person.

2.1

Specific Warnings

The Sitescan D-10 & D-20

contains a high-energy, precision pulser allowing optimum testing

results to be

obtained by mat

ching the pulse width

to the probe character

istics.

This

circuitry may be damaged

by voltage spikes.

It is recommended that the instrum

ent be

switched

off,

or

the

pulser

stopped

(by

pressing

the

key)

before

changing

transducers

(probes).

2.2

General Warnings

Proper use of the

ultrasonic test equipment requires three essential elements:

•

Knowledge of the specific

test or inspection and applicable test equipment.

•

Selection of the correct test

equipment based on knowledge of the

application.

•

Competent training of the instrument operator.

This user’s guide provides instruction in the basic operation of the Sitescan D-10 & D-20

flaw detector.

In addition to the methods included, m

any other factors can affect the use of

this flaw detector.

Specific information

regarding these factors is

beyond the scope of

this

manual.

The user should refer to appropriate textbooks on t

he subject of ultrasonic testing

and thickness gauging for more detailed

information.

2.3

Operator Training

Operators must receive adequate training before using this

ultrasonic flaw detector.

Operators must be trained in general ultrasonic testing procedures and

in the set-up and

performance required b

y each specific test or inspection.

Operators must understan

d:

•

Sound wave propagation theory.

•

Effects of the velocity of sound in the test material.

•

Behaviour of the sound wave at the interface of two different materials.

•

Sound wave spread and mode conversion.

Sitescan D-10 & D-20 User’s Guide ~ Disclaimers and Notices

Page 3

More specific information about operator training, qualification, certification

and test

specifications can be obtained from technical societies,

industry groups and government

agencies.

2.4

Testing Limitations

In ultrasonic testing, information is obtained only from

within the confines of the

sound

beam as it propagat

es into the test mater

ial.

Operators must

exercise great caution

when

making inferences about the nature of the test material outside the limits of the sound

beam.

The condition of materials can vary significan

tly and the results can be erratic

if

operators don’t exercise good judgment.

2.5

Critical Operating Factors

The following procedures must be observed

by all users of this

ultrasonic flaw detector in

order to obtain proper and accurate results.

2.5.1

Calibration of the Sound Velocity

An ultrasonic flaw detec

tor operates on the principle of measuring

the time of flight of a

burst of high frequency sound through the test piece as well as evaluating the amplitude of

reflected or transmitted

echoes.

The sound velocity of the test piece multiplies

this time in

order to obtain an accurate d

istance or thickness reading.

Since the actual sound velocity

in

materials can vary from the published values,

the best result is

obtained when the

instrument is calibrated on a reference block made from the same material as the test piece.

This block should be flat, smooth and as thick as the maximum thickness expected of the

test piece.

Users should also be aware that the sound velocity might not be constant throughout the

test piece due to effects such as heat-treating.

This must be taken into con

sideration when

evaluating the resul

ts of ultrasonic thic

kness testing.

The calibration should alway

s be

checked after testing to minimize errors.

2.5.2

Transducer (Probe) Zero Procedure

The transducer calibrat

ion procedures must be perform

ed as described in this manual.

The

calibration block must be c

lean, in good condition and free of n

oticeable wear.

Failure to

perform the transducer zero and calibration procedure will cause inaccurate thickness

readings.

2.5.3

Flaw Detection Calibration

When performing flaw detection, it is im

portant to note that the amplitude of ind

ications is

not only related to the size of the discontinuity; the depth of a discontinuity below the test

piece surface will also have an effect on the amplitude due to characteristics of the sound

beam spread and near field zone of t

he transducer.

In addition, the characteristics of the

discontinuity such as orientation and classification can alter the

expected amplitude

Sitescan D-10 & D-20 User’s Guide ~ Disclaimers and Notices

Page 4

response.

For these reasons, calibration

should be performed

on test blocks

made of the

same material as the test piece with artificial discontinuities within the range of size and

depth in the mater

ial to be detected

.

The user is again c

autioned to refer

to reference

books which are beyond the scope of this manual.

2.5.4

Effects of Temperature on Calibration

The sound velocity in test pieces and the transducer wear face changes with temperature

variations.

All calibrations should be perfor

med on site with test blocks at or near t

he same

temperature as that expected on the test piece, to minimize errors.

2.5.5

Transducer Condition

The transducer used for testing must be

in good condition, without noticeable wear of

the

front surface.

The specified range of the transducer mu

st encompass the complete ran

ge of

the thickness to

be tested and/or the

types of discontinu

ities to be investigated.

The

temperature of the material to be tested must be within the transducer’s specified

temperature range.

2.5.6

Use of Couplant

Operators must be familiar w

ith the use of ultrasonic couplant.

Testing skills must be

developed so that couplant is used and

applied in a consistent manner to

eliminate

variations in couplant thickn

ess which can cause errors an

d inaccurate readings.

Calibration

and actual testing should be performed under similar coupling conditions, using a

minimum amount of couplant and applying consistent pressure to the transducer.

Sitescan D-10 & D-20 User’s Guide ~ Disclaimers and Notices

Page 5

2.6

Disclaimer of Liability

All statements, technical in

formation and recommendation

s contained in this manual or any

other information supplied by Sonatest Limited in connection with

the use, features and

qualifications of the Sitescan D-10 & D-20 are based on tests believed to be reliable, but the

accuracy or completeness thereo

f is not guaranteed.

Before using the product you

should

determine its suitability for your intended use

based on your knowledge of

ultrasonic

testing and the characteristics of materials.

You bear all risk in conn

ection with the use of

the product.

You are reminded that all w

arranties as to merchantability and fitness for pu

rpose are

excluded from the contract under which the

product and this manual have been supplied

to

you.

The Seller’s only obligation in this respect is

to replace such quantity of the produ

ct

proved to be defective.

Neither the seller nor the manufacturer shall be liable either in contract or in tort for any

direct or indirect loss or damage (whether for loss of profit or otherwise), costs, expenses or

other claims for consequential or indirect compensation whatsoever (and wh

ether caused

by the negligence of the company, its employees or agents or otherwise).

2.7

Electromagnetic Compatibility

This product conforms to the following European Directives:

Directive 2002/95/EC on the Restriction of the

Use of certain Hazardous Substances in

Electrical and Electronic Equipment (RoHS)

Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE)

Low Voltage Directive (LVD)

73/23/EEC

CE Marking Directive

93/68/EEC

EMC Directive 89/336/E

EC.

However, in order to

ensure the equipmen

t meets the

requirements, the following should be read:

WARNING!

This is a “CLASS

A” product.

In a domestic environ

ment, this prod

uct

may cause rad

io interference.

In which case the

user may be r

equired to

take adequate measures.

Note:

This

product

should

not

be

connected

to

cables

greater

than

three

(3)

meters in length.

If this is necessary,

the installation may

require further

EMC testing to ensure conformity.

The Sitescan D-10 & D-20 also

complies with EN 12668-1, Non-destructive testing and

verification of ultrasonic examination

equipment – Part 1: Instrument

s.

For any questions

relating to the proper use

of this product, please

contact the manufacturer at the number

indicated on page i.

Sitescan D-10 & D-20 User’s Guide ~Quick Start

Page 6

3

Quick Start

3.1

Front Panel

The main control on the front of the unit is the scroll-wheel that is

used to navigate through

the menus and to adjust parameters this, along with the

lh

key in the middle of the wheel

allows quick and intuitive navigation.

Moving your finger in a clockwise direction moves the top line menu selection to the right

and increases a sel

ected parameter.

Moving your finger

in an anticlock

wise direction moves

the top line menu

selection to the left an

d decreases a

selected parameter.

The right arrow

moves the top menu selection right by one increment at a time, the left arrow moves it left

by one increment.

The down arrow moves down t

he four parameter boxes on the right of

the display while the

up arrow mov

es up.

When a parameter is select

ed using the

lh

button the up and down arrows change the

value by small increments while the

right and

left arrows change the value by a bigger increment.

The remaining front panel controls consist of a series sealed, pressure sensitive, tactile

buttons that have specific functions assigned to them; the exception to this are the four

"user" buttons that can be assign

ed to any menu item or a list of u

seful features.

A more

detailed description of each button is shown below followed by an overview of the front

panel:

When the term “highlighted” is used, it refers to text with a b

right background and dark

letters which is the selected item.

Power on & off push button for switching the instrument on and off.

Operates as a toggle.

N.B Random lines or characters may be displayed for a second or two after

switch on, before the memory is initialized, this is normal.

This button is used to select one of the main menu items (

CAL

,

MEAS

,

MEMORY

and

UTIL

) once they have been highlighted using the arrows.

It is

also used to select a parameter that has been highlighted using the arrows

– A

short press will show the drop-down list (if available) while a long press will

select the parameter so that it can be changed using the arrows.

Sitescan D-10 & D-20 User’s Guide ~ Quick Start

Page 7

These buttons move the highlighted cursor along the top of the screen left

and right to the sub menu to be selected, they are also used to make large

increment changes to

a selected parameter.

These are momentary

buttons

with no repeat.

The parameter boxes along the right hand side of the screen

change as the sub menu is selected.

This button moves the selection of the parameter boxes on the right of the

screen up, it is also used make small increment changes to a selected

parameter.

In the

case of

transducer

Zero

or

Delay

, it moves the signals to

the right.

This is a m

omentary b

utton with

no repeat.

This button moves the selection of the parameter boxes on the right of the

screen down, it is also used make small increment changes to a selected

parameter.

In the

case of

transducer

Zero

or

Delay

, it moves the signals to

the left.

This is a

momentary bu

tton with

no repeat.

jbkr

This button is u

sed to navigate "up"

through the menu

structure.

If a

parameter is selected then pressing the MENU button once will take you back

to the major menu item while pressing it twice will display the 4 main menu

levels (

CAL

,

MEAS

,

MEMORY

and

UTIL

) on the right hand side of the

screen. The

jbkr

button can be pressed at any time

d^qb

This button takes you directly to the

GATE

menu and turns on the gate in

positive trigger mode and highlights the

START

parameter box.

Ç

_

This button caused the

GAIN

parameter to be highlighted so that the

scroll-

wheel can then adjust the value.

Pressing the button again highlights the

REF

parameter, pressing for a third time selects the gain step size.

Press this button

once to select freeze

mode for the A

-Scan display.

This is a

useful feature for holdin

g an echo for ev

aluation.

When in this mode,

a box is

highlighted showing

FREEZE

below the graticule.

Pressing the button a second time selects peak mode, which holds and

updates all echoes on

the display during

inspection.

This feature allows an

envelope or echo dynamic pattern to be drawn on the screen with the "live"

signal shown within, which is useful for angle beam inspection to locate the

peak signal.

When in this

mode, a box

is highlighted showing

PEAK

below

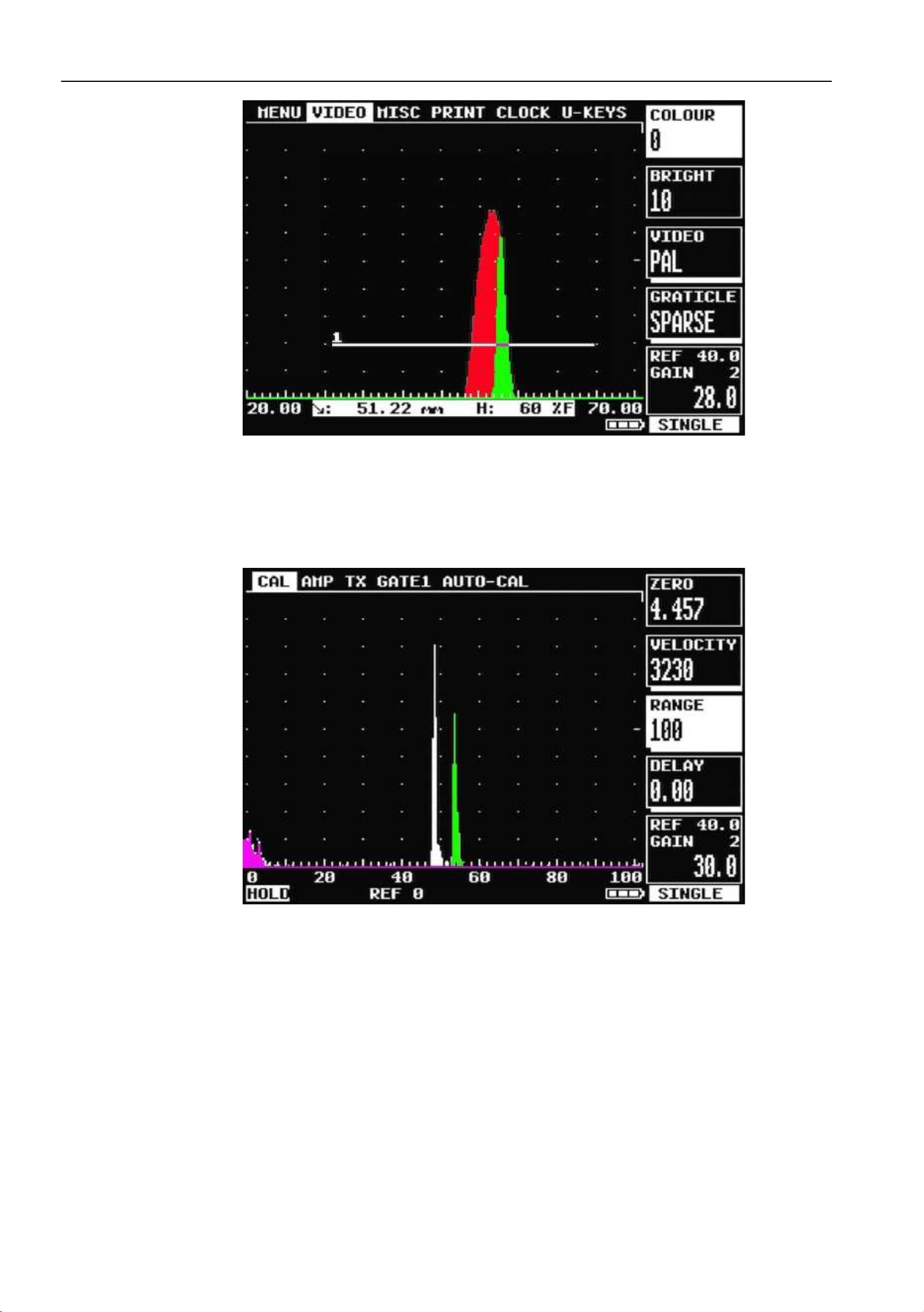

the graticule as sown below:

Sitescan D-10 & D-20 User’s Guide ~Quick Start

Page 8

Pressing the key again invokes the Hold mode that captures the current A-

Scan in white allowing a comparison to be made with the live A-Scan that is

shown in green.

When this mode is selected

a box is highlighted s

howing

HOLD

as shown below:

Pressing the button a fourth time

returns the A-Scan display to normal mode.

This is a momentary button with no repeat action.

Sitescan D-10 & D-20 User’s Guide ~ Quick Start

Page 9

The full screen button is used to toggle between showing the A-Scan on the

full display and showing it wit

h the menus and parameter boxes as

shown

below:

Full display is useful for maximising the size of the A-Scan while performing

inspections.

While in full screen

mode the user can

still change the gain

in

the normal way and use the

cobbwbLmb^h

button; all other buttons are

disabled.

N

.

.

These four

rpbo

buttons can be assigned to any parameter on the Sitescan

D-10 & D-20.

To use this function

simply select

the parameter that you

want

to assign to the button and then hold down the user button until you see the

following message:

In addition the following quick access functions can

be assigned from the

U-KEYS

parameter in the

UTILS

menu:

USER

,

N/A

,

AUTO 80

,

QSAVE-

A

,

WHEEL-LOCK

,

+/- 6Db

,

GAIN UP

,

GAIN DN

,

GAINSTEP

,

SNG/DBL

,

CLR TMIN

and

CLR PEAK

This button is a shortcut to the

PANEL

storage list enabling the

quick recall

or saving of the current panel settings .

Sitescan D-10 & D-20 User’s Guide ~Quick Start

Page 10

This button selects

the help menu

which overlays the display.

The help menu

explains how the Sitescan D-10 & D-20 operate with a choice of three

options:

rpbo

button

N

: Basic operation

rpbo

button

O

: Calibration procedure

rpbo

button

P

: Active menu

Pressing the

jbkr

or

ebim

button again at any point in the help screens

returns the display

to normal mode.

The help screen also

displays the

instrument serial number as well as the

software, FPGA, USB and keyboard

versions.

T/R

BNC or LEMO connector is the

transmitter and receiver socket used for single

transducers or as the transmitter only for

twin or dual transducer operation.

R

BNC or LEMO connector is the receiver socket used for twin or dual

transducer operation.

Sitescan D-10 & D-20 User’s Guide ~ Quick Start

Page 11

Sitescan D-10 & D-20 User’s Guide ~Quick Start

Page 12

3.2

Flaw Detection

Perform the following steps to establish a basic flaw detection mode for the Sitescan D-10 &

D-20.

Units

shown are

in inc

hes.

For inch

units, sel

ect

INCHES

from the

UTIL

menu and

use the corresponding values for the

parameters.

1.

Select a suitable transducer, preferably a 5MHz, 10mm

diameter narrow band.

2.

In the

CAL

menu, set the following parameters:

•

ZERO

to

0.000

•

VELOCITY

should be set the specimen material velocity.

•

RANGE

to

125

or other suitable value to cover the test range of i

nterest.

•

DELAY

to

0.000

•

GAIN

to

50.0

3.

In the

AMP

menu, set the following parameters:

•

FREQ

to

5.0 MHZ

(Sitescan D-20 only)

•

DETECT

to

FULL

•

REJECT-S

to

0

•

SMOOTH

to

OFF

4.

In the TX menu set the following parameters:

•

PRF MAX

to

150Hz

•

DAMPING

to

400

•

TX MODE

to

SINGLE

5.

In the

GATE1

menu, set the following parameters:

•

STATE

to

ON +VE

•

START

to

10.0

•

WIDTH

to

50

or other suitable value to cover the test range of interest.

•

LEVEL

to

50.0

6.

In the

MEAS

menu, set the following parameters:

•

MODE

to

DEPTH

•

TRIGGER

to

FLANK

•

HUD

to

OFF

•

T-MIN

to

OFF

Sitescan D-10 & D-20 User’s Guide ~ Quick Start

Page 13

The Sitescan D-10 or D-20 is now

configured for basic flaw detection.

Using an appropriate

calibration block, adjust the

GAIN

parameter t

o establish

the correct sensitivity.

Adjust

other parameters as n

ecessary to optimize the

calibration.

For more in-depth

features of the

Sitescan D-10 & D-20, see

Flaw Testing

on page

40

.

This manual suits for next models

1

Table of contents