Sonic Air Systems Sonic 150 User manual

L10028_RevK

Page i

Operation and Maintenance Manual

Sonic 150 / 150C

Sonic Air Systems

1050 Beacon Street

Brea, California 92821

Tel: 714-255-0124 Fax: 714-255-8366

www.sonicairsystems.com

L10028_RevK

Page ii

Table of Contents

1Sonic 150 / Sonic 150C ....................................................................................................................................... 1

1.1 Introduction ..................................................................................................................................................... 1

1.2 Blower Performance ........................................................................................................................................ 1

1.3 Product Profile ................................................................................................................................................ 2

1.4 Typical Applications ....................................................................................................................................... 3

2Initial Inspection................................................................................................................................................. 4

3Safety Instructions ............................................................................................................................................. 5

3.1 Electrical ......................................................................................................................................................... 5

3.2 Mechanical ...................................................................................................................................................... 5

4Installation and Adjustments ............................................................................................................................ 6

4.1 Lifting and Handling ....................................................................................................................................... 6

4.2 Blower Location .............................................................................................................................................. 6

4.3 Belt Installation ............................................................................................................................................... 8

4.4 Blower Head Mounting Adjustment .............................................................................................................. 11

4.5 Retro Kit Installation (Assemble Sonic blower to existing motor) ................................................................ 15

5Electrical Wiring, and Start-Up ...................................................................................................................... 18

5.1 Motor Wiring................................................................................................................................................. 18

6Blower Specifications ....................................................................................................................................... 19

6.1 Blower Specification Sheet ........................................................................................................................... 19

6.2 Assembly Drawing ........................................................................................................................................ 20

6.3 Parts List ........................................................................................................................................................ 21

6.4 Motor Reference ............................................................................................................................................ 28

6.5 Pulley / Belt Cross Reference ........................................................................................................................ 28

7Periodic Maintenance ...................................................................................................................................... 29

7.1 Maintenance Schedule ................................................................................................................................... 29

7.2 Torque Specifications .................................................................................................................................... 29

7.3 Belt Replacement Procedure ......................................................................................................................... 29

7.4 Belt Tensioner Service .................................................................................................................................. 32

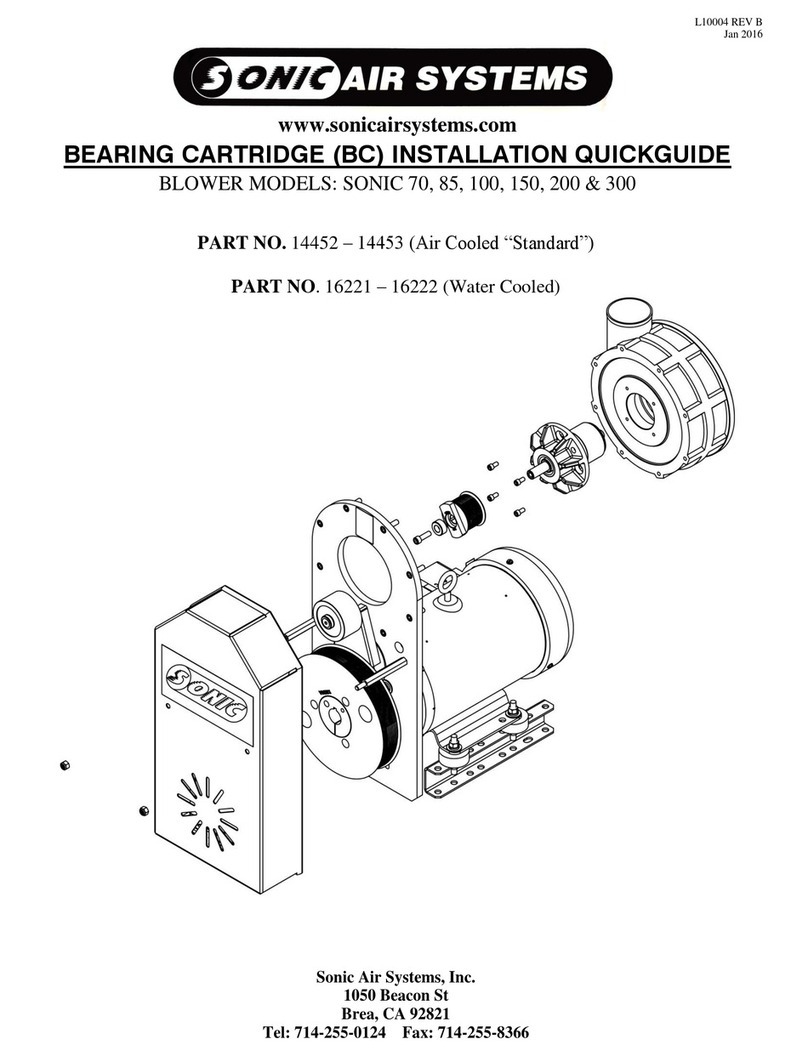

7.5 Bearing Cartridge Replacement Procedure ................................................................................................... 36

7.6 Required Tools .............................................................................................................................................. 37

7.7 Bearing Cartridge Replacement Procedure ................................................................................................... 37

7.8 Recommended Spares ................................................................................................................................... 41

8Troubleshooting ............................................................................................................................................... 42

9Performance Guarantee .................................................................................................................................. 43

10 Warranty Policy ............................................................................................................................................... 44

11 24/7/365 Service Program ................................................................................................................................ 45

12 Sonic Repair Policy .......................................................................................................................................... 46

L10028_RevK

Page iii

Table of Figures

Figure 1 - Sonic 150 ...................................................................................................................................................... 1

Figure 2 - Sonic 150C .................................................................................................................................................... 1

Figure 3 - Sonic Nameplate ........................................................................................................................................... 4

Figure 4 – Blower Serial Number .................................................................................................................................. 4

Figure 5 - Blower Lifting Point...................................................................................................................................... 6

Figure 6 - Remove Belt Guard ....................................................................................................................................... 9

Figure 7 - Install Belt ..................................................................................................................................................... 9

Figure 8 – Verify Belt Gap ............................................................................................................................................ 9

Figure 9 - Loosen Bracket Bolts .................................................................................................................................... 9

Figure 10 – Adjust Belt Gap to ¾” .............................................................................................................................. 10

Figure 11 - Blower Rotations ....................................................................................................................................... 11

Figure 12 - Remove Belt Guard ................................................................................................................................... 13

Figure 13 - Remove Belt .............................................................................................................................................. 13

Figure 14 - Remove Motor Pulley ............................................................................................................................... 13

Figure 15 - Remove Bracket Hardware ....................................................................................................................... 13

Figure 16 - Rotate Bracket ........................................................................................................................................... 14

Figure 17 - Install Bracket Hardware ........................................................................................................................... 14

Figure 18 - Remove Blower Hardware ........................................................................................................................ 14

Figure 19 - Move Water-Cooling Plugs ....................................................................................................................... 14

Figure 20 - Reinstall Blower Head .............................................................................................................................. 14

Figure 21 - Reinstall Belt ............................................................................................................................................. 14

Figure 22 - Adjust Belt Gap to 3/4" ............................................................................................................................. 14

Figure 23 - Final Position ............................................................................................................................................ 14

Figure 24 - Install Uni-mounts ..................................................................................................................................... 16

Figure 25 - Mount Bracket to Motor ........................................................................................................................... 16

Figure 26 - Prepare Bushing ........................................................................................................................................ 16

Figure 27 - Install Bushing .......................................................................................................................................... 16

Figure 28 – Install Bushing Hardware ......................................................................................................................... 16

Figure 29 - Bushing Installation................................................................................................................................... 16

Figure 30 – Install Set Screw ....................................................................................................................................... 16

Figure 31 - Install Motor Pulley................................................................................................................................... 17

Figure 32 - Install Belt ................................................................................................................................................. 17

Figure 33 - Set Belt Gap to ¾” .................................................................................................................................... 17

Figure 34 - Check Alignment ....................................................................................................................................... 17

Figure 35 - Motor Rotation Sticker .............................................................................................................................. 18

Figure 36 - Remove Belt Guard ................................................................................................................................... 30

Figure 37 - Remove Existing Belt ................................................................................................................................ 30

Figure 38 - Install New Belt......................................................................................................................................... 31

Figure 39 – Verify Belt Gap ........................................................................................................................................ 31

Figure 40 - Loosen Bracket Hardware ......................................................................................................................... 31

Figure 41 - Adjust Belt Gap to ¾” ............................................................................................................................... 31

Figure 42 - Remove Belt Guard ................................................................................................................................... 33

Figure 43 - Remove Belt .............................................................................................................................................. 33

Figure 44 - Remove Motor Pulley ............................................................................................................................... 33

Figure 45 - Remove Bolt ............................................................................................................................................. 33

Figure 46 - Remove Belt Tensioner ............................................................................................................................. 34

Figure 47 - Caution Loose Springs .............................................................................................................................. 34

Figure 48 - Correct Position ........................................................................................................................................ 34

Figure 49 - Verify Belt Gap ......................................................................................................................................... 34

Figure 50 - Loosen Bracket Hardware ......................................................................................................................... 35

Figure 51 - Adjust Belt Gap to 3/4" ............................................................................................................................. 35

Figure 52 - Remove Belt Guard ................................................................................................................................... 38

Figure 53 - Remove Belt .............................................................................................................................................. 38

L10028_RevK

Page iv

Figure 54 – Remove Water Cooling Tubing ................................................................................................................ 38

Figure 55 – Remove Filter or Inlet Screen ................................................................................................................... 38

Figure 56 – Remove Cover .......................................................................................................................................... 39

Figure 57 – Remove Impeller ...................................................................................................................................... 39

Figure 58 – Remove Blower Pulley ............................................................................................................................. 39

Figure 59 – Remove Thermocouple ............................................................................................................................ 39

Figure 60 – Remove Compression Fitting ................................................................................................................... 40

Figure 61 – Remove Bearing Cartridge Hardware....................................................................................................... 40

Figure 62 – Remove Bearing Cartridge ....................................................................................................................... 40

Figure 63 – Blower w/ Bearing Cartridge Removed .................................................................................................... 40

Page 1

1Sonic 150 / Sonic 150C

Figure 1 - Sonic 150

Figure 2 - Sonic 150C

1.1 Introduction

Thank you for the recent purchase of a Sonic 150 or Sonic 150C centrifugal blower or

retro-kit. Sonic Air Systems is confident that the blower unit is the best available in this

performance range. Sonic manufactures blowers using the finest components available,

assembles using only highly trained and qualified personnel, and inspects each unit 100%

for quality and performance.

The following manual is intended to:

Identify safety hazards

Familiarize personnel with the equipment performance

Demonstrate typical installation and usage

Identify maintenance schedule and typical spare components

Provide Sonics’ Performance Guarantee and Warranty information

1.2 Blower Performance

The Sonic 150 series blower is a single stage centrifugal blower and has been designed in

accordance with fan engineering laws. Horsepower demand increases in proportion to

increased air volume (motor amperage draw increases). As the air volume decreases

(valve closes or filter clogs), the amp draw decreases. Always check a fully installed

system to ensure that the motor is not overloaded.

Page 2

Sonic air blowers have some of the largest turndown ratios of any blower in their

performance range. At 10:1, a Sonic 150’s range is from 120 cfm 57 (lps) to 1,200 cfm

(566 lps) without overheating or surging. Outside of those ranges the air surging is mild

and continuous operation may shorten the bearing life.

The blower inlet must also be hose coupled to an inlet filter-silencer, inlet air safety

screen or piped to a delivery system. Sonic inlet filter-silencers should be used in every

application where the inlet air is not piped directly to the blower inlet. Sonic standard

filters are rated at 2 microns with a paper element or 5 microns with a polyester element.

Inlet air temperature must not exceed 125°F (52°C) unless a Sonic 150C water-cooled

unit is used. If the blower is in an enclosed space and the inlet air is piped from another

area, make sure that the ambient temperature around the blower / motor does not exceed

110°F (43°C). When air is re-circulated from an air knife zone, in-line filters and water

separators must be used to prevent water from entering the blower.

The blower outlet must always be hose coupled to a discharge silencer, system piping, or

otherwise directed away from personnel. Discharged air should be silenced to levels as

required by applicable occupational safety standards or corporate standards as applicable.

In order to minimize pressure drop and noise transmission, Sonic recommends using

smooth bore tubing (hard plastic or metal).

Flex hose can induce a large pressure drop and should only be used when absolutely

necessary. Flex hose should be rated to handle a pressure of 10 psig (0.7 bar) at 200°F

(93°C). Flex hose can be used for connecting misaligned piping and bend radii that do

not match standard elbows. Be aware that flex hose can collapse inside and should be

inspected if flow problems occur. Short rubber sleeves with band clamps are standard for

blower and piping connections.

Sonic butterfly valves have a wafer design that is designed to regulate flow, but will not

seal when closed. Air will always leak around the wafer to help minimize blower

cavitations.

The Patent Pending Sonic Belt Tensioner is used to maintain a constant low tension on

the drive belt and reduces the maintenance schedule for the blower unit. Belt life is

optimized and belt replacement typically takes only 5 to 10 minutes to perform.

Typical blower noise is approximately 80db to 95db. Sonic Blower Acoustical

Enclosures can be used to reduce blower noise to within 75 db to 85 db depending on the

blower model. Additional noise reduction is available; contact Sonic for details.

1.3 Product Profile

The Sonic 150 blower with the Sonic Automatic Belt Tensioning assembly requires no

periodic belt adjustment. The blower shaft and impeller assembly is supported by two

duplex pair (4 bearings) ABEC 9 permanently greased packed bearings. With operating

speeds of 11,000 to 20,000 RPM, a single Sonic 150 head assembly can be powered by a

15 to 25 horsepower (11.2 to 18.6 kW) motor. The inter-connecting support bracket

Page 3

joining the blower and motor has a belt guard completely enclosing the drive assembly

and completing this integral design.

With air / gas delivery up to 1,200 CFM (566 lps), this unit is well suited for any

application with pressures to 4.5 psi (0.31 bar). As a result of the high-speed operation,

the total envelope of the blower / motor assembly is one of the most compact and

lightweight within its performance range.

1.4 Typical Applications

The following is a list of typical applications for using a Sonic 150 centrifugal blower

assembly. This is only a partial list of the possible uses for supplying low cost, clean air

to a particular application. Please consult a Sonic Application engineer to design a

system to meet any request.

Parts drying

Engine exhaust sampling

Hydrocarbon vapor recovery

Environmental test chambers

Gas boosting

Tank / Pond aeration

Concrete grinding vacuum

Gas meter testing

Cooling

Vacuum hold down

Oil spill containment booms

Air bearings

Special applications and options are available for the Sonic 150 blower unit:

Corrosion resistant electroplating

Air flow control valves

316 Stainless Steel Material Option

Acoustical enclosure

Welded inlet and outlet flanges

In-Line filters and water separators

Water cooling of the bearing housing

Filter Silencers

Operation to 400°F inlet air temperature

Explosion Proof motors

Thermocouple monitoring of bearings

Wash Down duty motors

Discharge silencers

Premium Efficiency (PE) motors

IEC motor compatibility

Hydraulic motors

Sonic also provides a full line of air / gas handling accessories:

Complete drying systems

Air wipe collars

Air blowers from 3 to 50 horsepower

HEPA filters to 1,000 CFM

High efficiency aluminum air knives

Acoustical enclosures

High efficiency stainless steel air knives

Piping accessories

Sonic services four main industries:

Food and Beverage

Wire and Cable

Electronics

Metal and Sheet Fabricators

Please contact a local Sonic representative or a Sonic application engineer to discuss any special

considerations or applications.

Page 4

2Initial Inspection

Upon receipt of your Sonic Air Centrifugal Blower, make sure that all components listed on

the packing slip are present. Check to see that the serial number on the blower housing

matches the packing slip (See Figure 4). Inspect the blower / motor to ensure that they are

mounted with the correct outlet position and that the motor is the correct horsepower,

voltage and enclosure. If you have any shortages, discrepancies, or shipping damage, please

call your Sonic Distributor or Sonic Air Systems immediately.

Figure 3 - Sonic Nameplate

The serial number of the blower identifies the blower model, pulley size, belt size, mounting

position, and the motor specifications. Please use this number for any correspondence with

the Sales / Customer Service Department at Sonic Air Systems.

Blower Serial Number

Figure 4 – Blower Serial Number

Sonic Nameplate

Sonic Serial

Number

Identification

Grooves

Page 5

3Safety Instructions

3.1 Electrical

Always use qualified electrical and mechanical personnel for installation and maintenance

of Sonic air blowers.

No work should be performed on a Sonic air blower until the power has been turned off

and an isolation device has been applied. Disconnect the electrical power at the motor

starter, fuse box, or circuit breaker before working on the blower / motor. Double check

to be sure that the power is off and that it cannot be turned on while you are working on

the blower / motor assembly.

Use proper electrical installation, wiring, and controls consistent with local and national

electrical codes. A lockable isolation switch should be provided.

Refer to the motor nameplate data for the proper power supply requirements. Be sure the

junction box connections are tight and well insulated to prevent shorts and to assure

maximum protection against moisture.

3.2 Mechanical

Never run the Sonic air blower without the belt guard installed.

Never run the Sonic air blower with the outlet open to atmosphere as this can cause the

motor to overload.

Never run the Sonic air blower with the inlet open to atmosphere. Always connect your

system piping, Sonic inlet filter, or Sonic Inlet safety screen to the blower inlet to prevent

personal injury or damage to the blower.

Keep tools, clothing and hands away from rotating or moving parts while the unit is

running.

Use safety glasses when working around the blower / motor and / or air knife assembly

while the system is running.

Always use proper lifting techniques and equipment.

Observe good safety habits at all times and use care to avoid injury to personnel and

damage to the equipment.

Page 6

4Installation and Adjustments

The following steps and procedures detail the installation and setup of a typical blower

assembly. Disassembly of a blower unit is the opposite of the assembly procedure.

4.1 Lifting and Handling

Due to the weight of the blower / motor assembly, it should be lifted by a hoist or forklift

using the single eyebolt on the top middle of the motor (See Figure 5). See Section 6.1 -

Component Specification Sheet for weight and dimension details.

Figure 5 - Blower Lifting Point

4.2 Blower Location

4.2.1 Access

Make certain to allow room for proper ventilation and accessibility to remove the

belt guard for belt replacement as well as filter servicing. Never block the

ventilation holes in the belt guard. Mount the blower / motor assembly in a well

ventilated area to prevent motor overheating and premature belt and / or blower

head failure.

Page 7

4.2.2 Temperature

The blower / motor assembly must be placed in an area that prevents hard freezes

or overheating. Ambient temperature conditions should range from a low of

+10°F (-12°C) to +110°F (43°C). The blower / motor assembly is suitable for

outdoor locations, but care should be taken to protect the equipment from

temperature extremes, direct exposure to the sun, rain, snow, and dust so as to

extend the service life of the blower, motor, and filter.

The blower / motor assembly, while running, can increase the ambient

temperature above 110°F (43°C). Always check the running ambient temperature

and do not operate above 110° (43°C).

4.2.3 Moisture and Debris

Sonic air blowers have a high-speed belt drive, close tolerance components and

precision bearings. Do not put the blower where it will be sprayed from a

washing / rinsing zone, from over-spray from an air knife or where dust, dirt, or

other debris will attack the drive belt or clog the filter. If the filter needs cleaning

or replacing more than one time each month, the blower or filter should be moved

to a cleaner, dryer area. A Sonic acoustical blower enclosure will also ensure safe

operation.

4.2.4 Wash Down

In factory locations subject to high-pressure water or caustic wash down cycles,

the blower / motor unit must be protected or relocated to prevent damage. Raising

the blower 1-2 feet (0.3 to 0.6 meters) above the wash zone is recommended.

Wash down duty motors and corrosive resistant blower coatings are available to

allow full exposure should it be needed.

4.2.5 Explosive Environments

The Sonic 150 centrifugal blower is made from non-sparking aluminum and

therefore is suitable for explosive gases and explosive environments. Special

explosion proof motors can also be included for hazardous duty.

4.2.6 Corrosive Environments

The Sonic 150 blower can be protected with special coatings for protection in

corrosive environments. Protection level and life of blower is dependent on the

type of chemical and the concentration level.

4.2.7 Vibration

Due to the low vibration level of the Sonic air blowers, they can be bolted to any

type of foundation or framework without transmitting any significant vibration.

Sonic provides four rubber isolation mounts on most assemblies to prevent other

equipment vibration from damaging the blower bearings.

4.2.8 Water Cooling Circuit

If the inlet air / gas is piped directly to the blower inlet, and the temperature is

over 125°F (52°C), a water-cooled blower head must be used to protect the shaft

Page 8

bearings. The exact water temperature and flow required in the cooling circuit

will vary with each blower configuration and application. Although water

demand for the blower head varies, the common design point in all applications is

that the water exiting from the cooling circuit should never exceed 100°F (38°C).

Typical water demand will range from ¼ to ¾ gallons per minute (1 to 3 liters per

minute) if using tap water (approximately 65°F (18°C)) and will be significantly

lower if chilled water is used.

4.2.9 Thermocouple Option

All Sonic 150 blower heads can be ordered with a thermocouple option. The

thermocouple is in direct contact with the shaft bearing and continuously monitors

the temperature of the bearing. Continuous monitoring of the blower head bearing

temperature can indicate an imminent bearing failure (See Section 12 for Sonics’

repair policy). Predicting and anticipating a bearing failure may save costly

equipment and / or line down time.

4.3 Belt Installation

Sonic ships all new systems with the drive belt removed. This is to assure that the

electrical starter, soft start and wiring is correct before the blower is started. See Section

5.1 for motor wiring instructions and verify that the wiring and blower rotation is correct

before installation of the drive belt.

4.3.1 Tools Required

Description

Qty.

Description

Qty.

1/2 inch socket

1

#3 Drive Extension

1

9/16 inch box-end wrench

1

¾ inch deep socket (optional)

1

3/8 inch ratchet driver

1

Rubber Mallet (optional)

1

4.3.2 Belt Installation Procedure

1. Remove the belt guard using the 1/2 inch socket. (See Figure 6)

2. Using the 9/16 inch box-end wrench, rotate the belt tensioner arm counter

clockwise (CCW). At the same time wrap the belt around the blower pulley, then

along the right side of the idler pulley, and finally around the motor pulley. (See

Figure 7)

3. Slowly rotate the motor pulley to make sure the belt is seated in the grooves.

4. Verify that the belt gap is approximately ¾ inch ±1/16 inch (Factory Set). (See

Figure 8)

5. If a ¾ inch belt gap was not achieved, use a ¾ inch deep socket to loosen the

bracket mounting screws behind the motor pulley and slide the bracket. (See

Figure 9 and Figure 10)

6. Using the 1/2 inch socket, reinstall the belt guard.

Page 9

Figure 6 - Remove Belt Guard

Figure 7 - Install Belt

Figure 8 – Verify Belt Gap

Figure 9 - Loosen Bracket Bolts

Page 10

Figure 10 – Adjust Belt Gap to ¾”

Page 11

4.4 Blower Head Mounting Adjustment

The blower head position was adjusted at the factory to the application specifications.

Therefore, it should not be necessary to change the position of the blower head outlet

unless the application specifications have changed or the unit is relocated. See Figure 11

for blower head rotation options. Use the following procedure to modify or adjust the

blower head rotation.

Figure 11 - Blower Rotations

4.4.1 Required Tools

Description

Qty.

Description

Qty.

3/8 inch ratchet driver

1

Rubber mallet

1

¾ inch deep socket

1

1/2 inch socket

1

¼ inch allen socket

1

9/16 inch box-end wrench

1

242 Loctite

1

5/16 inch allen socket

1

#3 Drive Extension

1

4.4.2 Blower Head Adjustment Procedure

1. Remove the belt guard using the 1/2 inch socket. (See Figure 12)

2. Disconnect the water-cooling lines at the quick disconnect on the blower head. (If

Applicable)

3. Using the 9/16 inch box-end wrench, rotate the belt tensioner arm counter

clockwise (CCW) and remove the belt. (See Figure 13)

Note: If rotating the blower bracket, follow Steps 4 thru 8. If only rotating the blower

head, skip to Step 7.

4. Use the ¾ inch deep socket to hold the motor pulley in place. Using the 5/16 inch

allen socket, remove the motor pulley screws and motor pulley. (See Figure 14)

5. Using the ¾ inch deep socket, remove the four bracket bolts and washers located

behind the motor pulley. (See Figure 15)

6. Rotate the bracket to the desired position and reinstall the bracket bolts and

washers. Tighten only one bolt temporarily for belt adjustment. (See Figure 16

and Figure 17)

Page 12

7. Using the ¼ inch allen socket, remove the eight screws from the bracket that

secure the blower head. (See Figure 18)

8. Remove the water-cooling plugs from the blower head and rotate as necessary.

(See Figure 19) (If Applicable)

9. Rotate the blower head to desired rotation and reinstall the eight screws to the

proper torque specifications. (See Section 7.2 - Torque Specifications) (See Figure

20)

10. Using the 5/16 allen socket and the 242 Loctite, reinstall the motor pulley.

11. Using the 9/16 inch box-end wrench, rotate the belt tensioner arm counter

clockwise (CCW). At the same time wrap the belt around the blower pulley, then

along the right side of the idler pulley, and finally around the motor pulley. (See

Figure 21)

12. Slowly rotate the motor pulley to make sure the belt is seated in the grooves.

13. Verify that the belt gap is approximately ¾ inch ±1/16 inch. If a ¾ inch belt gap

was not achieved, use a ¾ inch deep socket to loosen the bracket mounting screws

behind the motor pulley and slide the bracket. (See Figure 22 and Figure 23)

14. Using a ¾ deep socket, verify that the bracket bolts behind the motor pulley are

secure. (See Section 7.2 - Torque Specifications)

15. Reinstall the water-cooling lines. (If Applicable)

16. Using the 1/2 inch socket, reinstall the belt guard.

Page 13

Figure 12 - Remove Belt Guard

Figure 13 - Remove Belt

Figure 14 - Remove Motor Pulley

Figure 15 - Remove Bracket Hardware

Page 14

Figure 16 - Rotate Bracket

Figure 17 - Install Bracket Hardware

Figure 18 - Remove Blower Hardware

Figure 19 - Move Water-Cooling Plugs

Figure 20 - Reinstall Blower Head

Figure 21 - Reinstall Belt

Figure 22 - Adjust Belt Gap to 3/4"

Figure 23 - Final Position

Page 15

4.5 Retro Kit Installation (Assemble Sonic blower to existing motor)

4.5.1 Tools Required

Description

Qty.

Description

Qty.

3/8 inch ratchet driver

1

9/16 inch box-end wrench

1

¾ inch deep socket

1

1/2 inch socket

1

9/16 inch open-end wrench

1

¼ inch flat head screwdriver

1

5/16 inch allen socket

1

Rubber mallet

1

Calipers

1

24 inch Straight edge

1

242 Loctite

1

7/32 inch allen wrench

#3 Drive Extension

1

4.5.2 Retro Kit Installation

1. Using a 9/16 inch open-end wrench, mount the vibration isolators and uni-mounts

to the motor. (See Figure 24)

2. Mount the bracket assembly to the motor and then tighten only one screw using

the ¾ inch socket temporarily for belt gap adjustment. (See Figure 25)

3. Using a flat head screwdriver and a rubber mallet, wedge the screwdriver into the

front face of the bushing (Do not wedge in flange area) and then slide it onto the

motor shaft. (See Figure 26)

4. Set the bushing to 1.266 ± .005 (32.2 mm) from the bushing flange to the bracket

reference surface and remove the screwdriver. Using the 5/16 inch allen socket

and 242 Loctite, install the two bushing screws. Tighten the screws to the

specified torque, over tightening may damage the bushing. (See Figure 27, Figure

28, Figure 29, and Figure 30)(See Section 7.2 - Torque Specifications)

5. Tighten the bushing set screw using the 7/32 inch allen wrench.

6. Before installing the motor pulley, double check the bushing setting and then

install the pulley and the three pulley screws using 242 Loctite and the 5/16 inch

allen socket. Tighten the three pulley screws to the required torque specifications.

(See Figure 31)(See Section 7.2 - Torque Specifications)

7. Using the 9/16 inch box-end wrench, rotate the belt tensioner arm counter

clockwise (CCW). At the same time wrap the belt around the blower pulley, then

along the right side of the idler pulley, and finally around the motor pulley. (See

Figure 32)

8. Slowly rotate the motor pulley to make sure the belt is seated in the grooves.

9. Using the rubber mallet, adjust the belt gap to ¾ inch ±1/16 inch. (See Figure 33)

10. Using the ¾ inch deep socket, tighten the bracket hardware. (See Section 7.2 -

Torque Specifications)

11. Using a straight edge, check the pulley alignment from the face of the motor

pulley to the face on the blower pulley. Verify that there is no gap and the

alignment must be within ±1/32 inch. (See Figure 34)

12. Using the 1/2 inch socket, install the belt guard.

Page 16

Figure 24 - Install Uni-mounts

Figure 25 - Mount Bracket to Motor

Figure 26 - Prepare Bushing

Figure 27 - Install Bushing

Figure 28 – Install Bushing Hardware

Figure 29 - Bushing Installation

Figure 30 – Install Set Screw

Other manuals for Sonic 150

1

This manual suits for next models

1

Table of contents

Other Sonic Air Systems Blower manuals

Popular Blower manuals by other brands

Schmalz

Schmalz SB-V operating instructions

Mazzoni

Mazzoni FLASH 650M Use and maintenance manual

Black & Decker

Black & Decker FS1610R user manual

Weed Eater

Weed Eater SB180BV Operator's manual

EINHELL

EINHELL GE-CL 18 Li E Kit Original operating instructions

Poulan Pro

Poulan Pro PPB2000 LE instruction manual