5

POWER BLOWER

OPERATOR'SMANUAL

EXTENDED OPERATION/EXTREME CONDITIONS

Vibration and Cold --

It is believed that a condition called Raynaud’s Phenomenon, which

affects the fingers of certain individual may be brought about by

exposure to vibration and cold. Exposure to vibration and cold may

cause tingling and burning sensations, followed by loss of color and

numbness in the fingers. The following precautions are strongly

recommendedbecause the minimumexposure which mighttriggerthe

ailmentisunknown.

• Keep your body warm, especially the head, neck, feet, ankles, hands,

and wrists.

• Maintain good blood circulation by performing vigorous arm

exercises during frequent work breaks, and also by not smoking.

• Limit the hours of operation. Try to fill each day with jobs where

operating the blower or other hand-held power equipment is not

required.

• If you experience discomfort, redness and swelling of the fingers

followed by whitening and loss of feeling, consult your physician

before further exposing yourself to cold and vibration.

Repetitive Stress Injuries --

It is believed that overusing the muscles and tendons of the fingers,

hands, arms, and shoulders may cause soreness, swelling, numbness,

weakness, and extreme pain in those areas. Certain repetitive hand

activities may put you at a high risk for developing a Repetitive Stress

Injury(RSI).AnextremeRSIconditionisCarpalTunnelSyndrome

(CTS), which could occur when your wrist swells and squeezes a vital

nerve that runs through the area. Some believe that prolonged exposure

to vibration may contribute to CTS. CTS can cause severe pain for

months or even years.

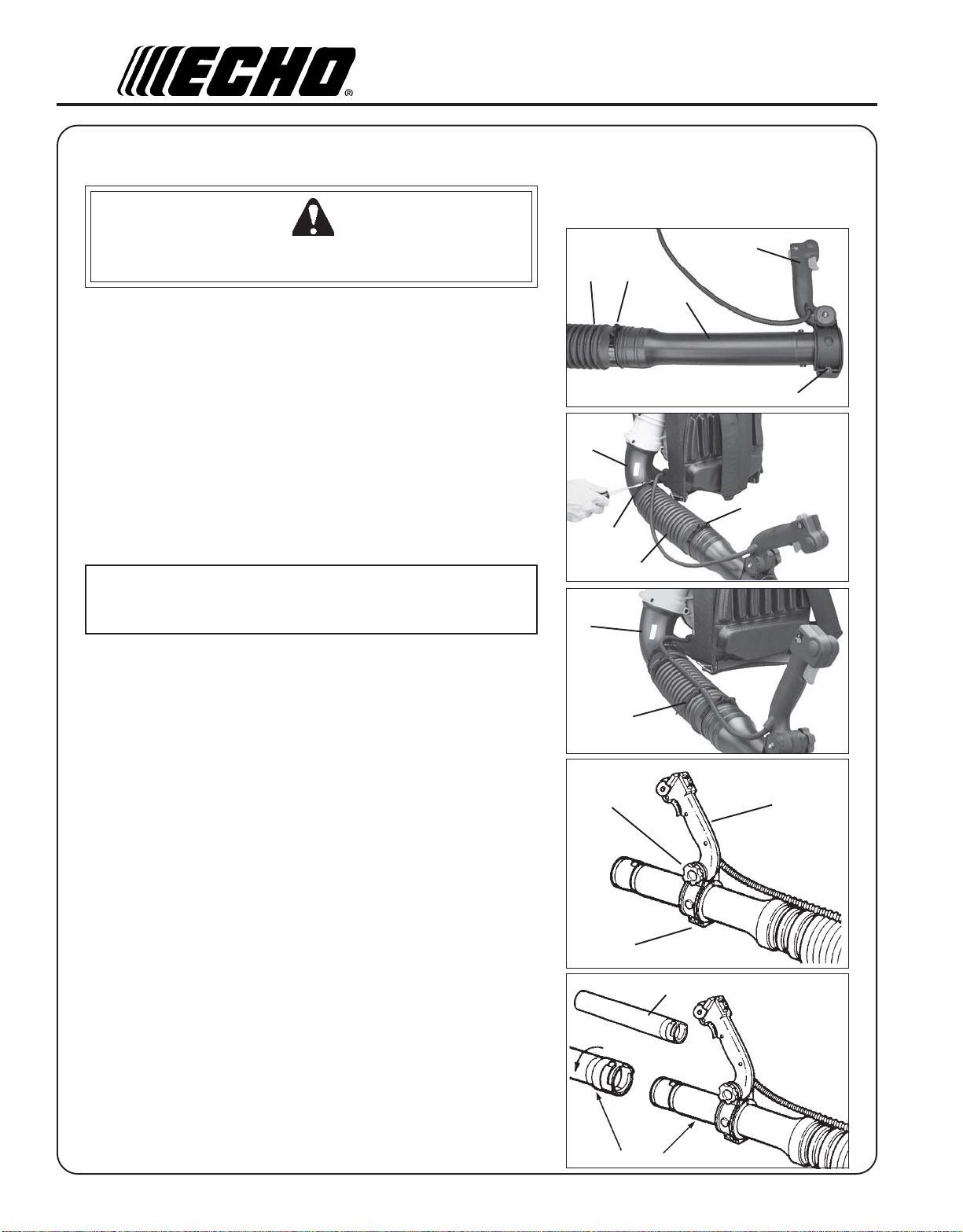

EQUIPMENT

Before operation a complete check of the unit must be performed:

• Check unit for loose/missing nuts, bolts and screws. Tighten and/or

replace as needed.

• Inspect fuel lines, tank and area around carburetor for fuel leaks. DO

NOT operate unit if leaks are found.

• Keep exhaust area clear of flammable debris. Avoid contact during

andimmediatelyafteroperation.

To reduce the risk of RSI/CTS, do the

following:

• Avoid using your wrist in a bent,

extended, or twisted position. Instead try

to maintain a straight wrist position.

Also, when grasping, use your whole

hand, not just the thumb and index finger.

• Takeperiodicbreakstominimizerepeti-

tion and rest your hands.

• Reduce the speed and force with which

you do the repetitive movement.

• Do exercises to strengthen the hand and

armmuscles.

• Immediately stop using all power

equipment and consult a doctor if you

feel tingling, numbness, or pain in the

fingers, hands, wrists, or arms. The

sooner RSI/CTS is diagnosed, the more

likelypermanentnerveand muscle

damage can be prevented.