– 2 –

TABLE OF CONTENTS

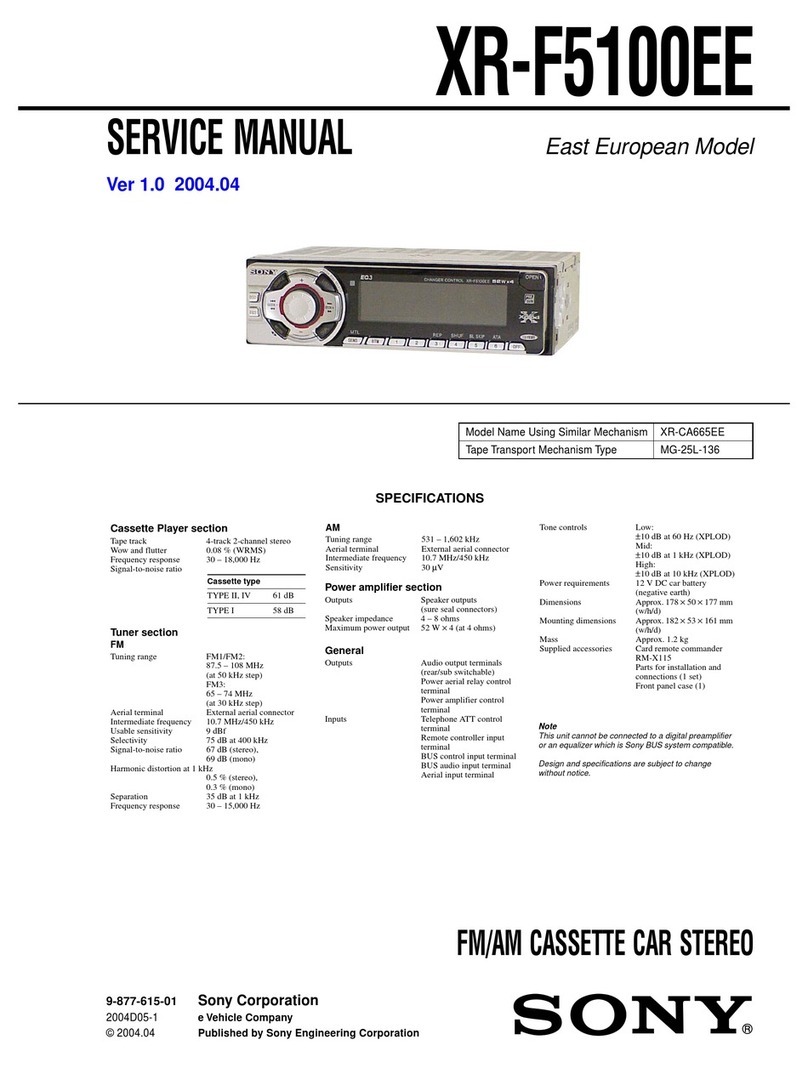

1. GENERAL

Location of Controls ........................................................ 3

Installation ....................................................................... 4

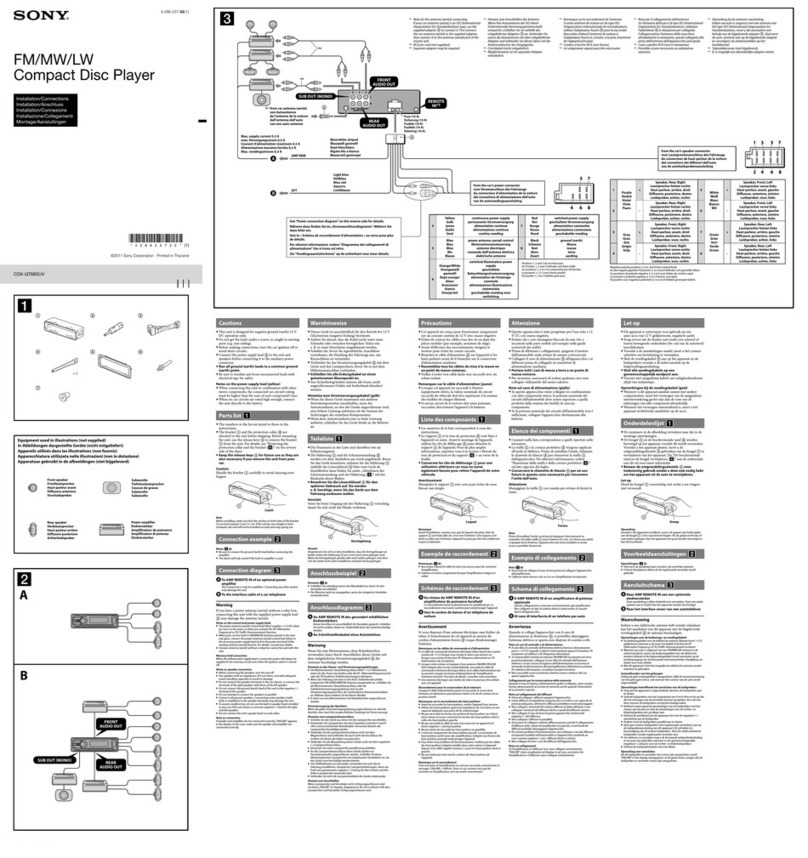

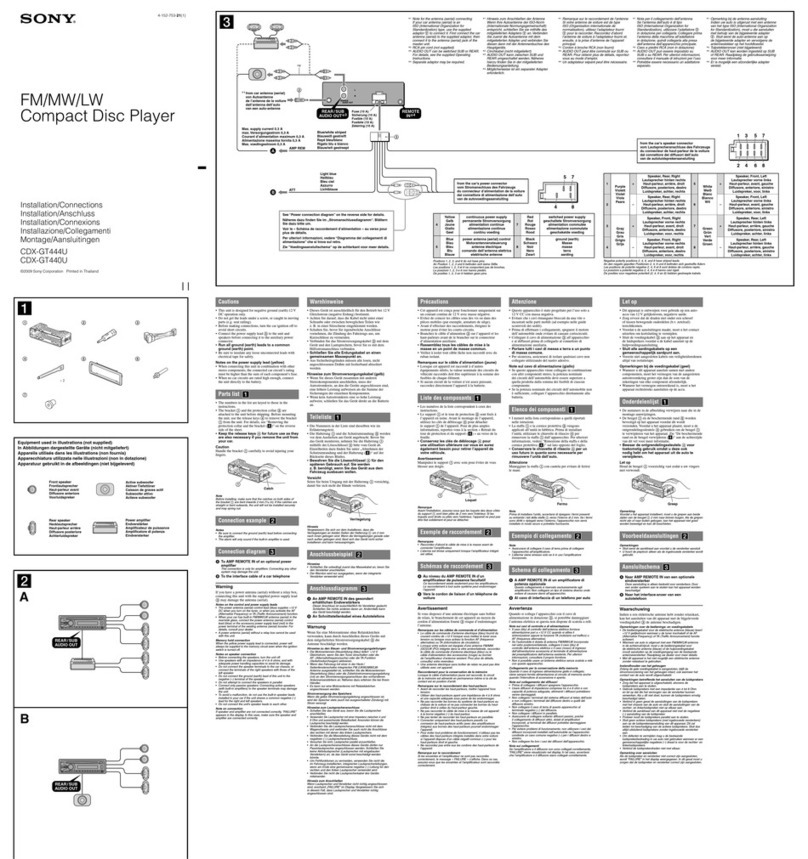

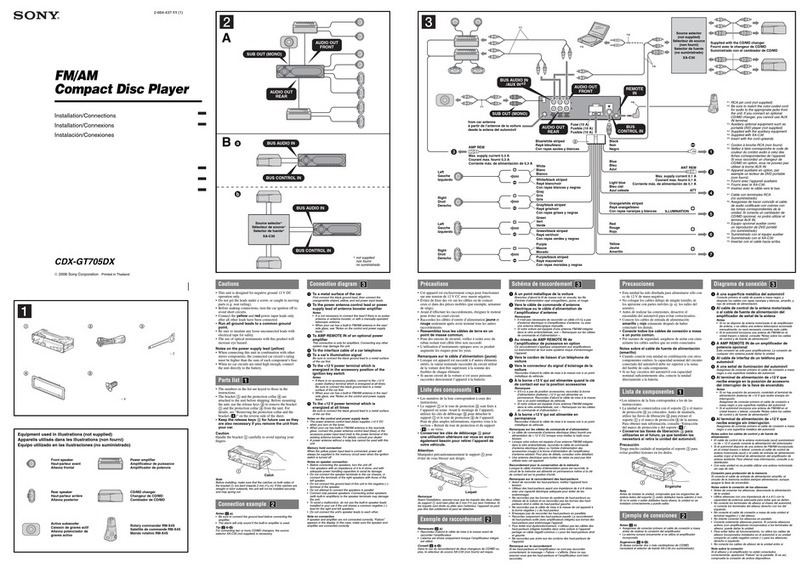

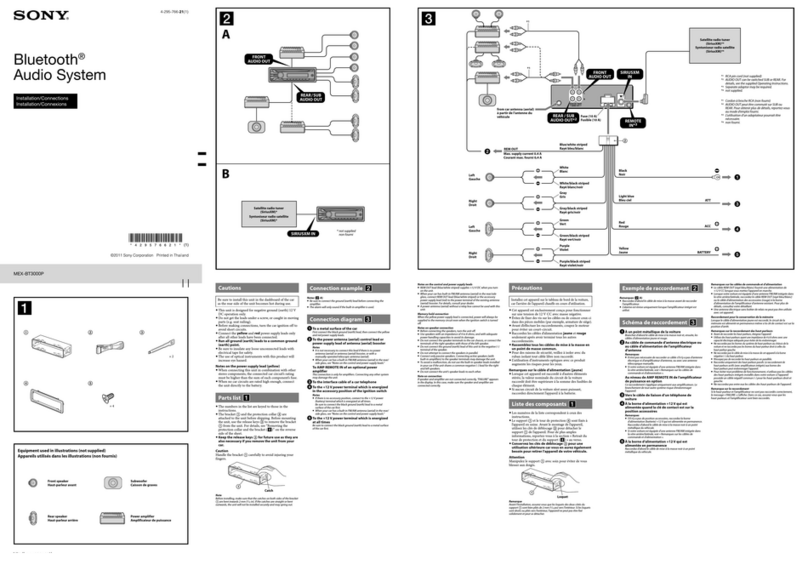

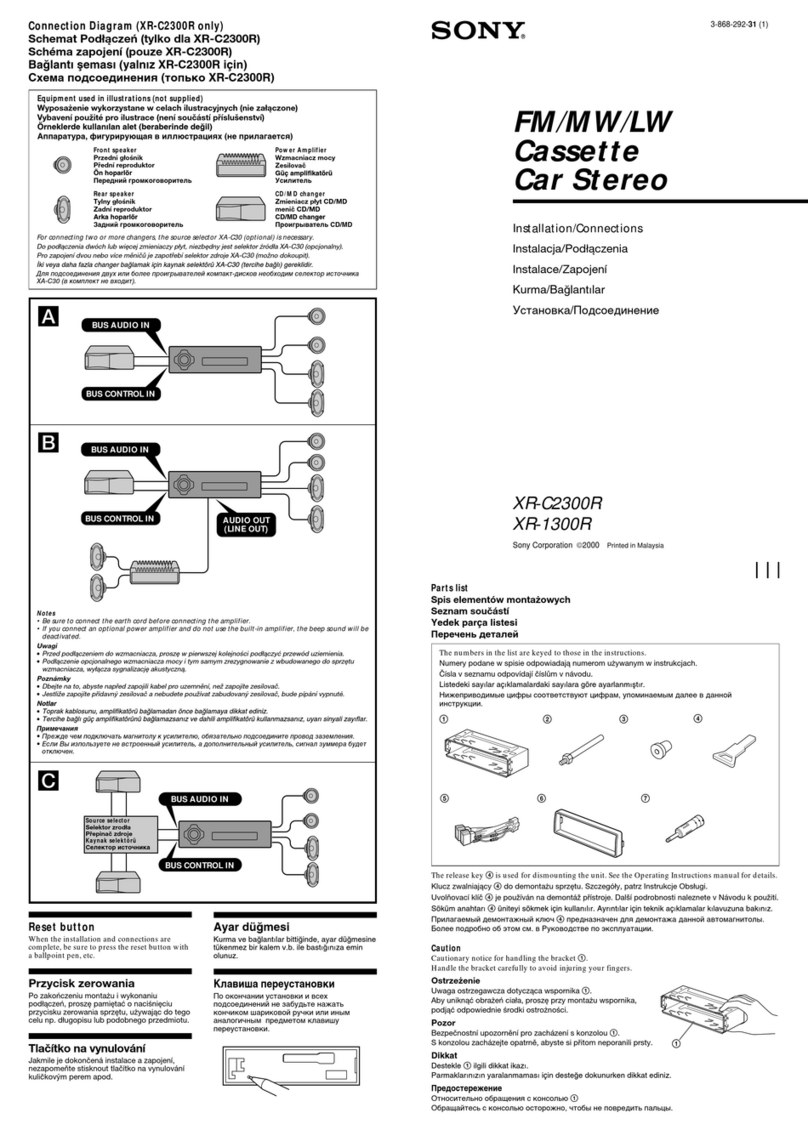

Connections ..................................................................... 5

2. DISASSEMBLY.......................................................... 8

3. ASSEMBLY OF MECHANISM DECK ........... 11

4. MECHANICAL ADJUSTMENTS ....................... 17

5. ELECTRICAL ADJUSTMENTS

Test Mode ........................................................................ 17

Tape Deck Section ........................................................... 18

Tuner Section................................................................... 18

6. DIAGRAMS

6-1. IC Pin Function Description ............................................ 22

6-2. Printed Wiring Boards – MAIN Section – ..................... 25

6-3. Schematic Diagram – MAIN Section –........................... 29

6-4. Printed Wiring Board – POWER Section – .................... 34

6-5. Schematic Diagram – POWER Section –........................ 37

6-6. Printed Wiring Board – CONTROL Section – ............... 41

6-7. Schematic Diagram – CONTROL Section –................... 43

7. EXPLODED VIEWS ................................................ 47

8. ELECTRICAL PARTS LIST................................ 51

SERVICING NOTES

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

•Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

•Be careful not to apply force on the conductor when soldering

or unsoldering

Notes on chip component replacement

•Never reuse a disconnected chip component.

•Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.