– 2 –

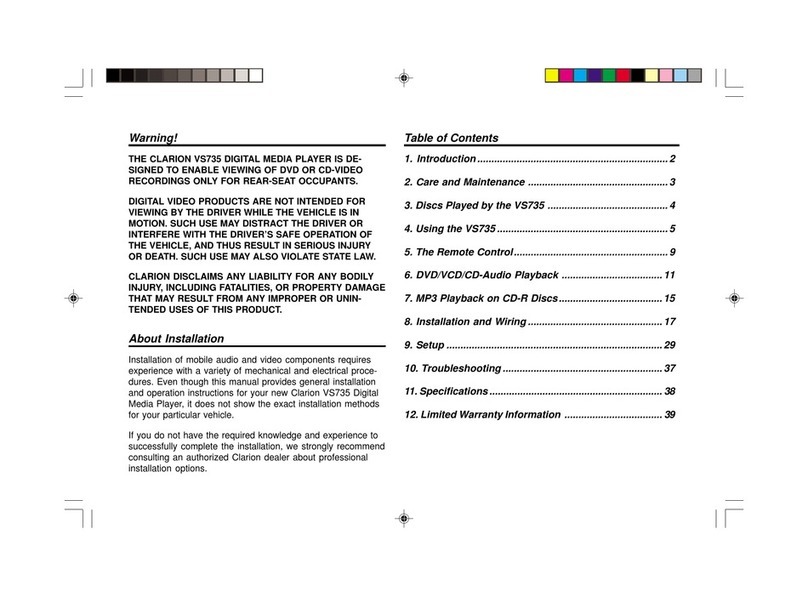

TABLE OF CONTENTS

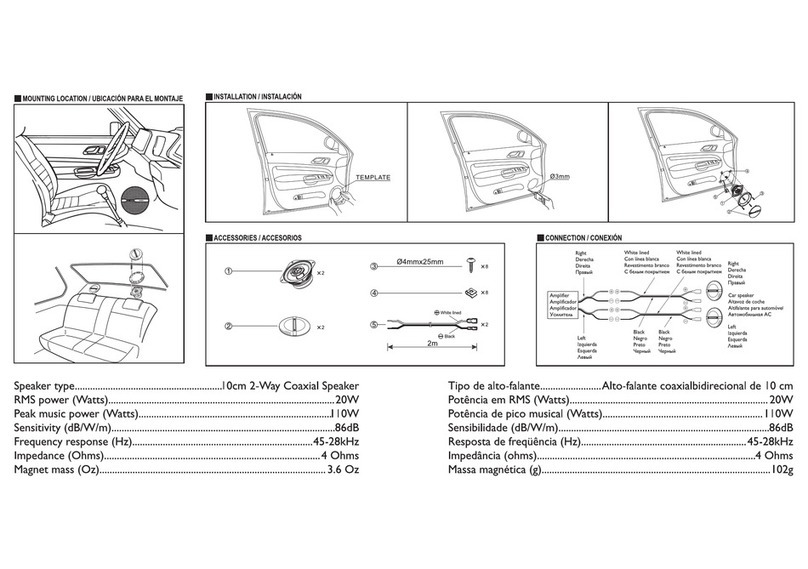

1. GENERAL

Location of Controls ....................................................... 3

Installation....................................................................... 4

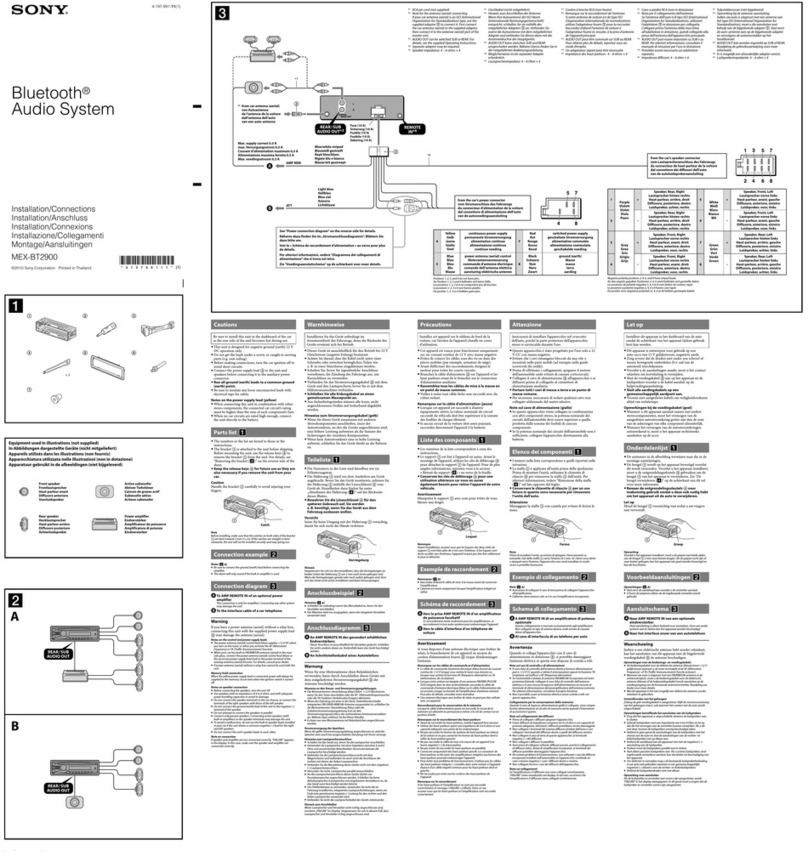

Connections ..................................................................... 5

2. DISASSEMBLY ......................................................... 8

3. ASSEMBLY OF MECHANISM DECK........... 10

4. MECHANICAL ADJUSTMENTS ....................... 13

5. ELECTRICAL ADJUSTMENTS

Test Mode ........................................................................ 13

Tape Deck Section .......................................................... 13

Tuner Section .................................................................. 14

6. DIAGRAMS

6-1. IC Pin Function Description ........................................... 17

6-2. Note for Printed Wiring Boards and

Schematic Diagram ......................................................... 20

6-3. Printed Wiring Board – MAIN Section – ...................... 21

6-4. Schematic Diagram – MAIN Section (1/2) –................ 23

6-5. Schematic Diagram – MAIN Section (2/2) –................ 25

6-6. Printed Wiring Board – PANEL Section – .................... 27

6-7. Schematic Diagram – PANEL Section – ....................... 29

7. EXPLODED VIEWS................................................ 33

8. ELECTRICAL PARTS LIST ............................... 36

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.