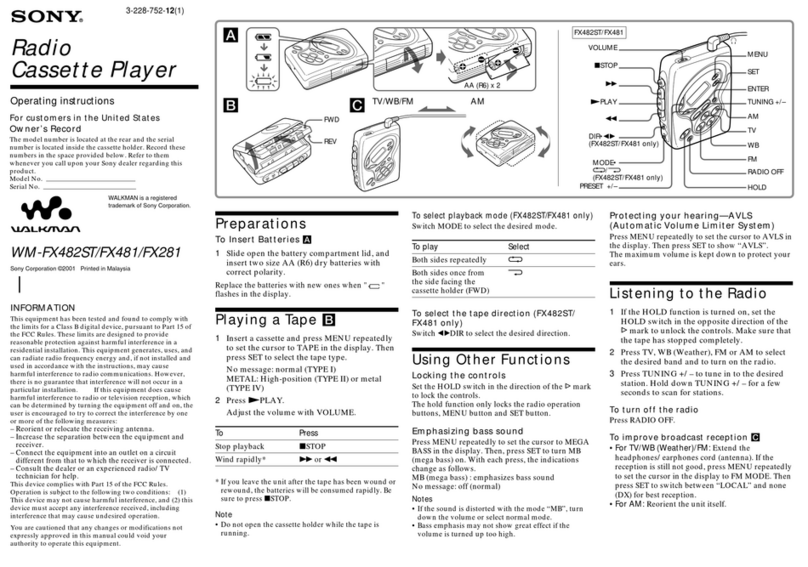

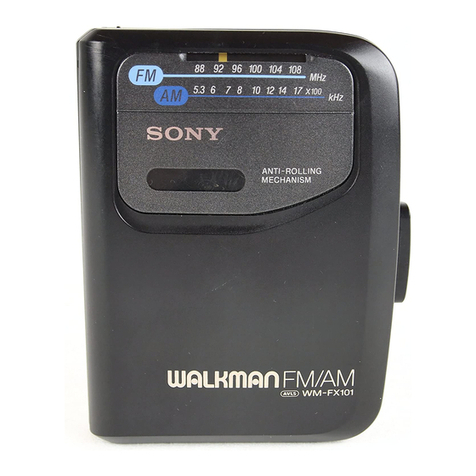

WM-DDm

Replacing chip components

All

chip components should be connected and disconnect-

ed, using a tapered soldering iron [temperature

of

the

iron

tip: less than 280°C

(536°F)],

a pair

of

tweezers and braid-

ed

wire.

Precautions for replacement

1.

Do

not

disconnect

the

chip component forcefully.

Otherwise, the pattern may peel off.

2. Never re-use a disconnected chip component. Dispose

of

all old chip components.

3.

To protect the chip component, heating time for attach-

ing the component should be within 3 seconds.

o Removing chip components

(l)

Removing solder at electrode

Remove the solder

at

the

electrode, using a thin

braided wire. Do not remove the solder

of

the part

(chip component) attached adjacent

to

the electrode.

Braided wire

(2) Disconnecting chip components

Turn the tweezers with

the

soldering iron alternately

applied

to

both

electrodes, and the chip component

will be disconnected. Take careful precautions while

disconnecting, because

if

the

chip component is force-

fully removed the land may peel off.

Never re-use a disconnected chip component.

(3)

Smoothing the soldered surface

After disconnecting the chip component, remove the

solder

by

using a braided wire

to

sinooth

the

land

surface.

o Connecting chip components

The value

of

chip components

is

not

displayed

on

the

main body. Take due precautions to avoid mixing new

chip components with other ones.

(1) Applying

s<>lder

to

land

on

one side

Apply a thin layer

of

solder

to

the land

on

one side

where

the

chip component

is

to

be connected. Too

much solder may cause bridging.

(2) Speedy soldering

Hold the chip component at the desired position,

using tweezers, and apply the soldering iron in the

arrow-marked direction. To protect

the

chip compo-

nent,

heating time should be within 3 seconds.

~~~,~-------------

\

~

I \

Land

Printed

circuit

board

(3) Speedy soldering

of

electrode

on

the other side

Solder

the

electrode on the other side in the same

way as in

(2)

above.

-2-