5

HCD-DX150/DX170/DX250

SECTION 1

SERVICING NOTE

NOTES ON HANDLINGTHE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pick-

up block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment”and check

that the S curve waveform is output several times.

DISC SLOT LOCK

The disc slot lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the ?/1 button to turn the set on.

2. Press the [FUNCTION] button to set DVD function.

3. Insert a disc.

4. Press the x stick and the A button simultaneously for five

seconds.

5. The message “LOCKED” is displayed and the slot is locked.

Releasing Procedure :

1. Press the x stick and the A button simultaneously for five

seconds again.

2. The message “UNLOCKED” is displayed and the slot is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the ?/1 button.

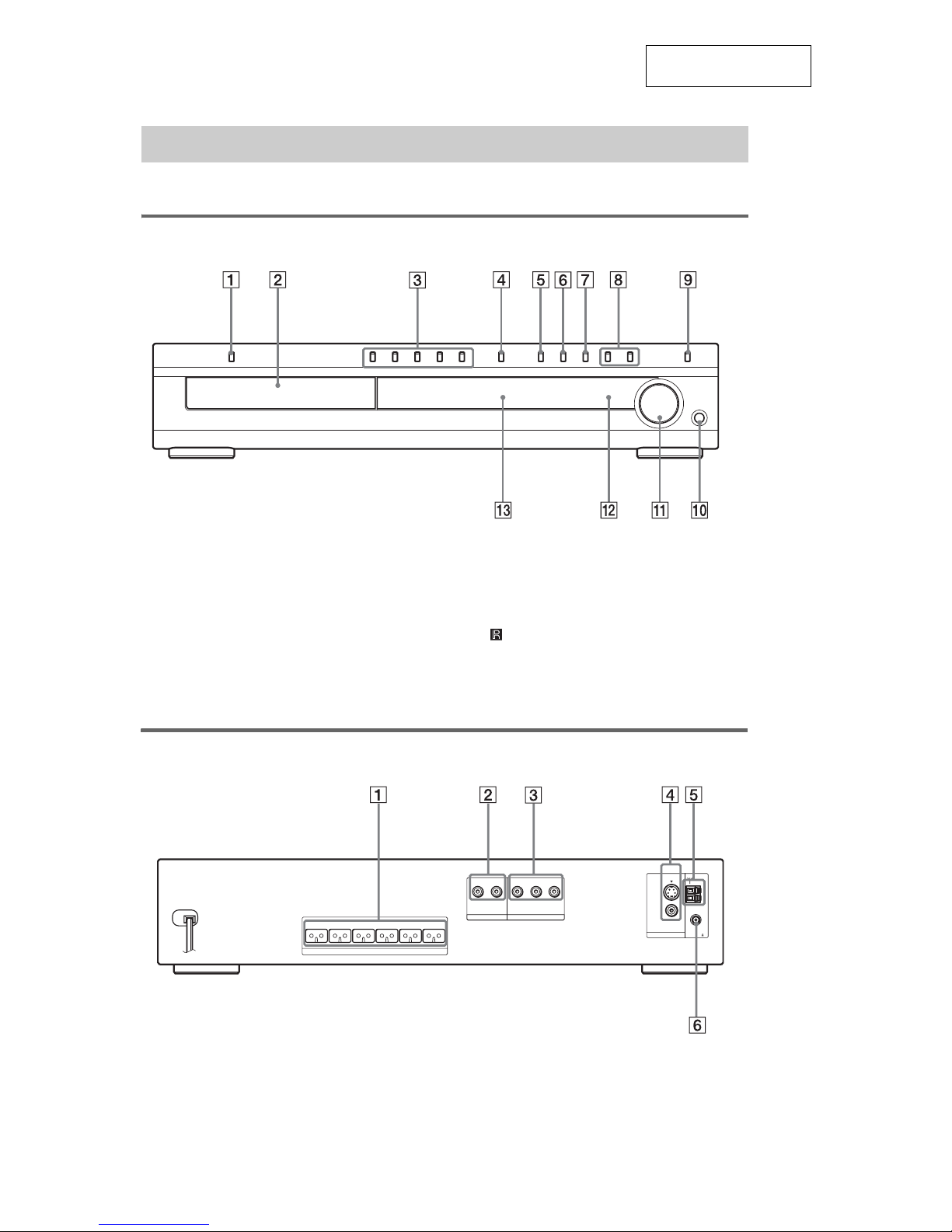

Note 1: Regarding the notification symbol “R”

Because the number of the operating buttons of this product

are limited, some operations require use of the operating

buttons of the remote commander, When a specific operation

requires use of the operating buttons of the remote commander,

“R” is added to the specific operating procedure in this manual.

Example MENU/NO “R” The MENU/NO button of remote

commander.

Note 2: Incorrect operations may be performed if the test mode ia not

entered properly.

In this case, press the ?/1 button to turn the power off, and

retry to enter the test mode.

Note 3: If the disc tray does not open and the message “LOCKED”

appears, press the x tick and the Abutton simultaneously for

5 seconds or longer.

Then remove your fingers from the above stick and the button.

The message “UNLOCKED” appears for 2 seconds and the disc

tray opens.

Note on DMB10 board or DMB11 board replacement

New part of EEP ROM (IC103) on the DMB10 board or DMB11

board cannot be used. Therefore, if the mounted DMB10 board

(A-1088-070-A, etc.) is replaced, exchange new EEP ROM (IC103)

with that used before the replacement.

When the self-diagnosis function is activated to

prevent the system from malfunctioning, a 5-

character service number (e.g., C 13 50) with a

combination of a letter and 4 digits appears on

the screen and the front panel display. In this

case, check the following table.

Self-diagnosis Function

(When letters/numbers appear in the

display)

First 3

characters of

the service

number

Cause and/or corrective action

C 13 The disc is dirty.

,Clean the disc with a soft cloth

(page 80).

C 31 The disc is not inserted correctly.

,Restartthe system, then re-insert

the disc correctly.

E XX

(xx is a number) To prevent a malfunction, the

system has performed the self-

diagnosis function.

,Contact your nearest Sony

dealer or local authorized Sony

service facility and give the 5-

character service number.

Example: E 61 10

C:13:50

Ver. 1.2