5

HCD-GTR6/GTR6B/GTR7/GTR8/GTR8B

TABLE OF CONTENTS

1. DISASSEMBLY

1-1. Case (Top)............................................................................ 7

1-2. Tape Mechanism Deck......................................................... 7

1-3. Loading panel ...................................................................... 8

1-4. Front Panel Section.............................................................. 8

1-5. MIC Board, USB Board, MICRV Board,

Headphone Board................................................................ 9

1-6. Display Board, STR Board, CD SW Board......................... 9

1-7. Tuner pack ......................................................................... 10

1-8. Subtrans Board .................................................................. 10

1-9. DC Fan, Power Transformer (T1200)................................ 11

1-10. Main Board, Front Boars Section...................................... 11

1-11. Front Board, GTH Subwoofer Board ............................... 12

1-12. Back Panel Section, DC Fan.............................................. 12

1-13. CD Block Section .............................................................. 13

1-14. DMB-19 Board, GTH HUB Board.................................... 13

1-15. Driver MT Board, SW MT Board ..................................... 14

1-16. Optical Pick-up.................................................................. 14

1-17. Sensor Board...................................................................... 15

1-18. Motor(TB) Board............................................................... 15

1-19. Motor (LD) Board ............................................................. 16

2. TEST MODE .............................................................. 17

3. MECHANICAL ADJUSTMENTS .........................19

4. ELECTRICAL ADJUSTMENTS ..........................20

5. DIAGRAMS

5-1. Block Diagram — USB Section —................................... 22

5-2. Block Diagram — RF/Servo Section — ........................... 23

5-3. Block Diagram — Tape/Tuner Section —......................... 24

5-4. Block Diagram — Main Section — .................................. 25

5-5. Block Diagram — AMP/Subwoofer Section —................ 26

5-6. Block Diagram — Display/Power Section —................... 27

5-7. Circuit Boards Location..................................................... 28

5-8. Printed Wiring Board — Display Board —....................... 30

5-9. Schematic Diagram — Display Board — ......................... 31

5-10. Printed Wiring Boards — DMB19 Board — .................... 32

5-11. Schematic Diagram — DMB19 Board (1/4) —................ 33

5-12. Schematic Diagram — DMB19 Board (2/4) —................ 34

5-13. Schematic Diagram — DMB19 Board (3/4) —................ 35

5-14. Schematic Diagram — DMB19 Board (4/4) —................ 36

5-15. Printed Wiring Board — Front Board — .......................... 37

5-16. Schematic Diagram — Front Board — ............................. 38

5-17. Printed Wiring Board — Main Board —........................... 39

5-18. Schematic Diagram — Main Board (1/5) —..................... 40

5-19. Schematic Diagram — Main Board (2/5) —..................... 41

5-20. Schematic Diagram — Main Board (3/5) —..................... 42

5-21. Schematic Diagram — Main Board (4/5) —..................... 43

5-22. Schematic Diagram — Main Board (5/5) —..................... 44

5-23. Printed Wiring Board — MIC and MIC RV Board —...... 45

5-24. Schematic Diagram — MIC and MIC RV Board —......... 46

5-25. Printed Wiring Board — STR and CD_SW Board — ...... 47

5-26. Schematic Diagram — STR and CD_SW Board — ......... 48

5-27. Printed Wiring Board — Trans and Sub Trans Board — .. 49

5-28. Schematic Diagram — Trans and Sub Trans Board —..... 50

5-29. Printed Wiring Board — Sub Woofer Board — ................ 51

5-30. Schematic Diagram — Sub Woofer Board —................... 52

5-31. Printed Wiring Boards —

Headphone and USB CD Board —................................... 53

5-32. Schematic Diagram —

Headphone and USB CD Board —................................... 54

5-33. Printed Wiring Board — HUB Board —........................... 55

5-34. Schematic Diagram — HUB Board — ............................. 56

5-35. Printed Wiring Board — DRIVER Board — .................... 57

5-36. Printed Wiring Board — DRIVER Board — .................... 58

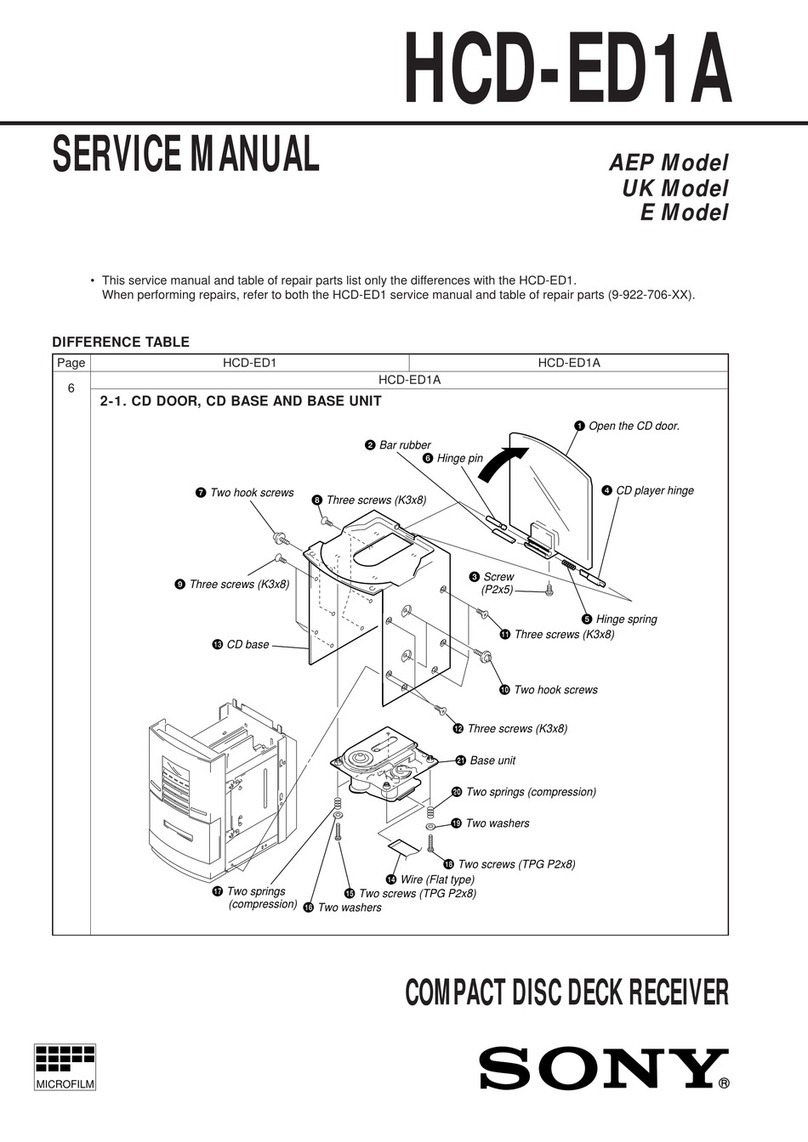

6. EXPLODED VIEWS

6-1. Main Section...................................................................... 66

6-2. Back Panel Section ............................................................ 67

6-3. Front Panel Section (1) ...................................................... 68

6-4. Front Panel Section (2) ...................................................... 69

6-5. Chassis Section .................................................................. 70

6-6. CD Mechanism Section (1) ............................................... 71

6-7. CD Mechanism Section (2) ............................................... 72

7. ELECTRICAL PARTS LIST ................................. 73