– 2 –

TABLE OF CONTENTS

1. SERVICING NOTES .................................................. 3

2. GENERAL

Index to Parts and Controls ............................................... 5

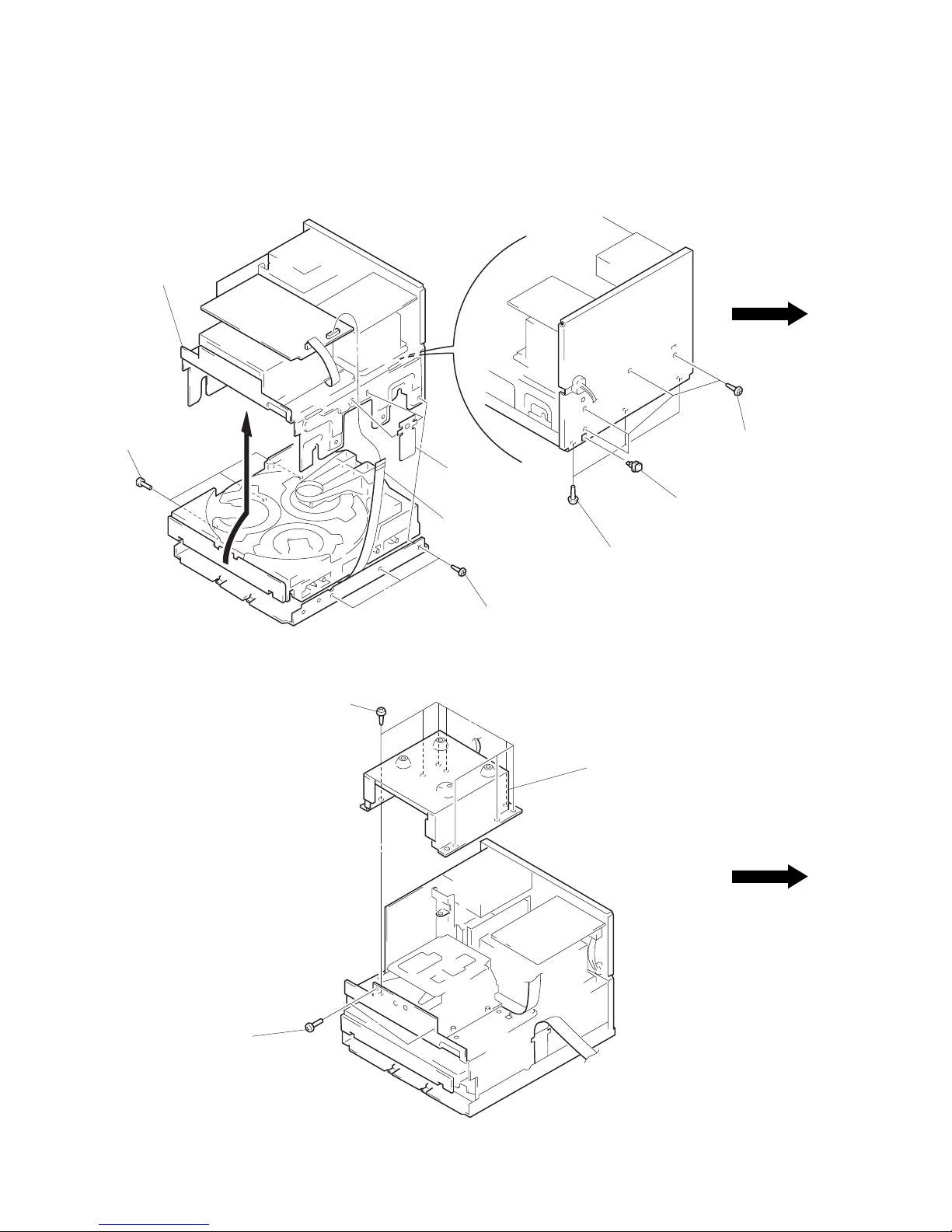

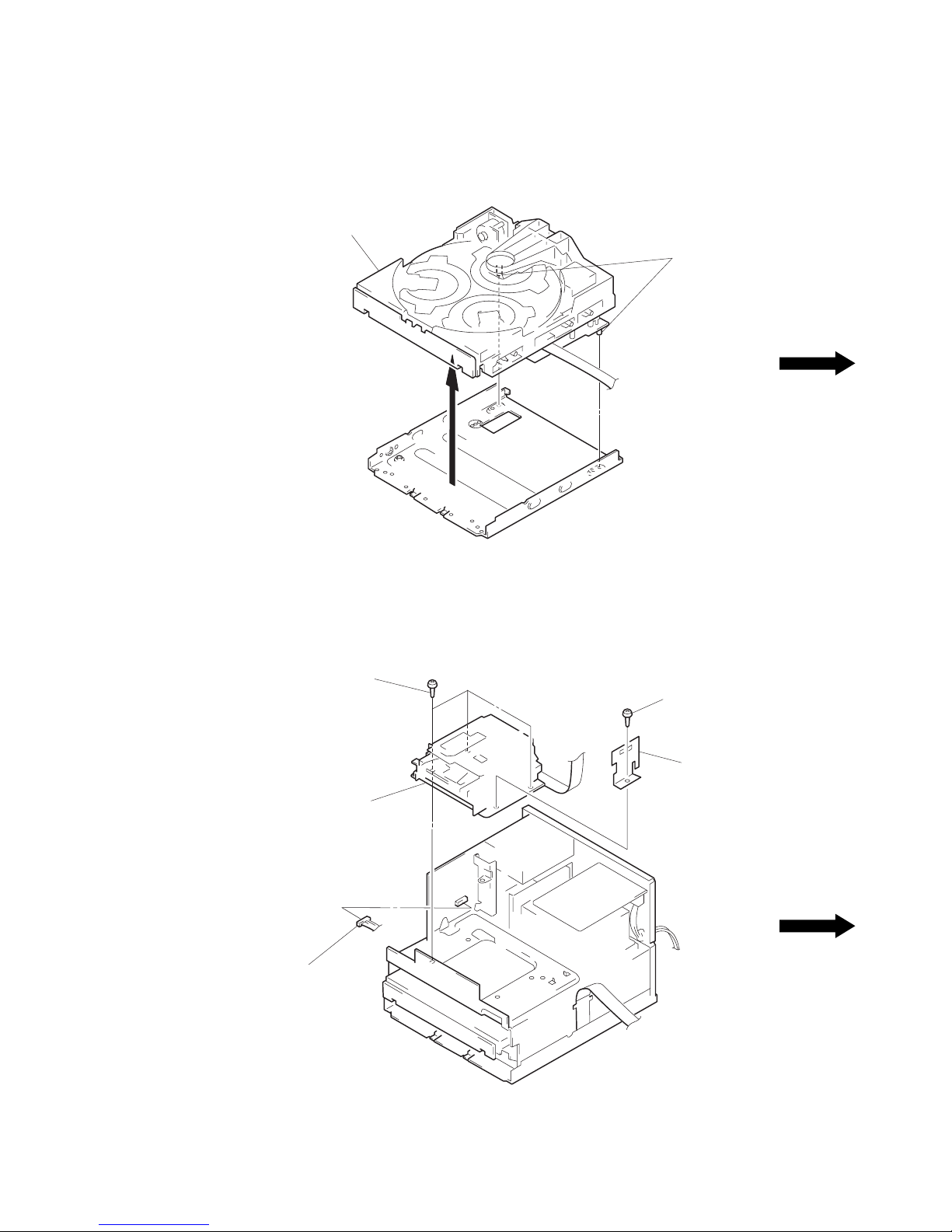

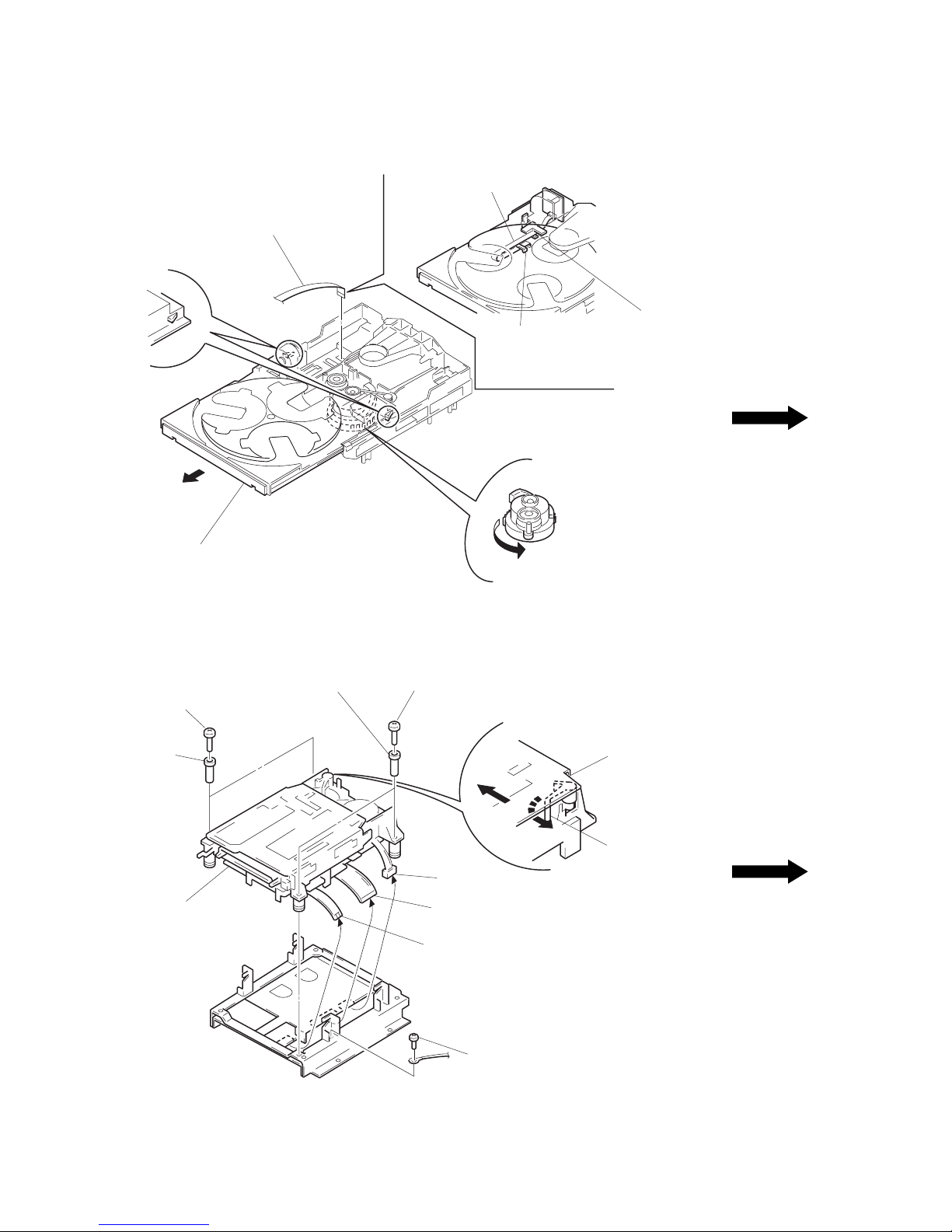

3. DISASSEMBLY............................................................ 7

4. TEST MODE ................................................................. 14

5. ELECTRICAL ADJUSTMENTS

MD Section........................................................................ 20

Tuner Section..................................................................... 25

CD Section......................................................................... 26

6. DIAGRAMS

6-1. Block Diagrams

CD Section......................................................................... 29

Tuner Section..................................................................... 31

MD Section........................................................................ 35

Main Section...................................................................... 39

6-2. Schematic Diagram – Tuner Section –

(AEP, G, UK model).......................................................... 44

6-3. Printed Wiring Board – Tuner Section –

(AEP, G, UK model).......................................................... 46

6-4. Printed Wiring Board – Tuner Section –

(EXCEPT AEP, G, UK model).......................................... 47

6-5. Schematic Diagram – Tuner Section –

(EXCEPT AEP, G, UK model).......................................... 48

6-6. Printed Wiring Board – CD Section – ............................... 50

6-7. Schematic Diagram – CD Section – .................................. 53

6-8. Printed Wiring Board –MD Section – ............................... 56

6-9. Schematic Diagram –MD Section – .................................. 59

6-10. Schematic Diagram – Digital Section – ............................ 63

6-11. Printed Wiring Boards – Digital Section – ........................ 67

6-12. Schematic Diagram – Relay Section – .............................. 70

6-13. Printed Wiring Board – Relay Section – ........................... 73

6-14. Printed Wiring Board – Main Section – ............................ 76

6-15. Schematic Diagram – Main Section – ............................... 79

6-16. Schematic Diagram – Power Section – ............................. 83

6-17. Printed Wiring Boards – Power Section – ......................... 87

6-18. Schematic Diagram – PowerAMP Section – .................... 92

6-19. Printed Wiring Boards – PowerAMP Section –................ 95

6-20. Schematic Diagram – Panel Section –............................... 99

6-21. Printed Wiring Boards – Panel Section – ........................ 103

6-22. IC Pin Function Description ............................................ 109

7. EXPLODEDVIEWS ................................................. 123

8. ELECTRICAL PARTS LIST .................................. 132

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

Tourist model: 76.0 – 108.0 MHz (50 kHz step)

Other models: 87.5 – 108.0 MHz (50 kHz step)

Aerial FM lead aerial

Aerial terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

German model:

AM: 522 – 1,611 kHz

(with the interval set at 9 kHz)

AEP, UK models:

MW: 522 – 1,611 kHz

(with the interval set at 9 kHz)

LW: 144 – 288 kHz

(with the interval set at 3 kHz)

Tourist model:

AM: 531 – 1,602 kHz

(with the interval set at 9 kHz)

530 –1,710 kHz

(with the interval set at 10 kHz)

Malaysia, Singapore,

Saudi Arabia,

Hong Kong models:

MW: 531 – 1,602 kHz

(with the interval set at 9 kHz)

530 – 1,710 kHz

(with the interval set at 10 kHz)

SW: 5.95 – 17.90 MHz

Aerial AM loop aerial

External aerial terminals

Intermediate frequency 450 kHz

General

Power requirements 220 – 230 V AC, 50/60 Hz

(AEP, German model)

110 – 120 V or 220 – 240 V AC,

50/60 Hz Adjustable with the

voltage selector (Other model)

Power consumption 85 watts (Tourist model)

130 watts (Other models)

Dimensions

Amplifier/Tuner/MD/CD section:

Approx. 280 ×240 ×360 mm

(11 1/8×9 1/2×14 1/4in) (w/h/d) incl.

projecting parts and

controls

(U.K., Hong Kong model)

Approx. 280 ×240 ×350 mm

(11 1/8×9 1/2×13 7/8in) (w/h/d) incl.

projecting parts and

controls (Other models)

Mass

Amplifier/Tuner/MD/CD section:

Approx. 9.4 kg

(20 lb 12 oz)

Supplied accessories: AM loop aerial (1)

Remote RM-S5MD (1)

Sony SUM-3 (NS)

batteries (2)

FM lead aerial (1)

Speaker cords (2)

Design and specifications are subject to change without notice.