— 3 —

TABLE OF CONTENTS

SELF-DIAGNOSIS FUNCTION

1. Self-diagnosis Function ················································ 5

2. Self-diagnosis display··················································· 5

3. Service Mode Display ·················································· 5

3-1. Display Method ···························································· 5

3-2. Switching of Backup No. ············································· 5

3-3. End of Display······························································ 5

4. Self-diagnosis Code Table ············································ 6

1. GENERAL

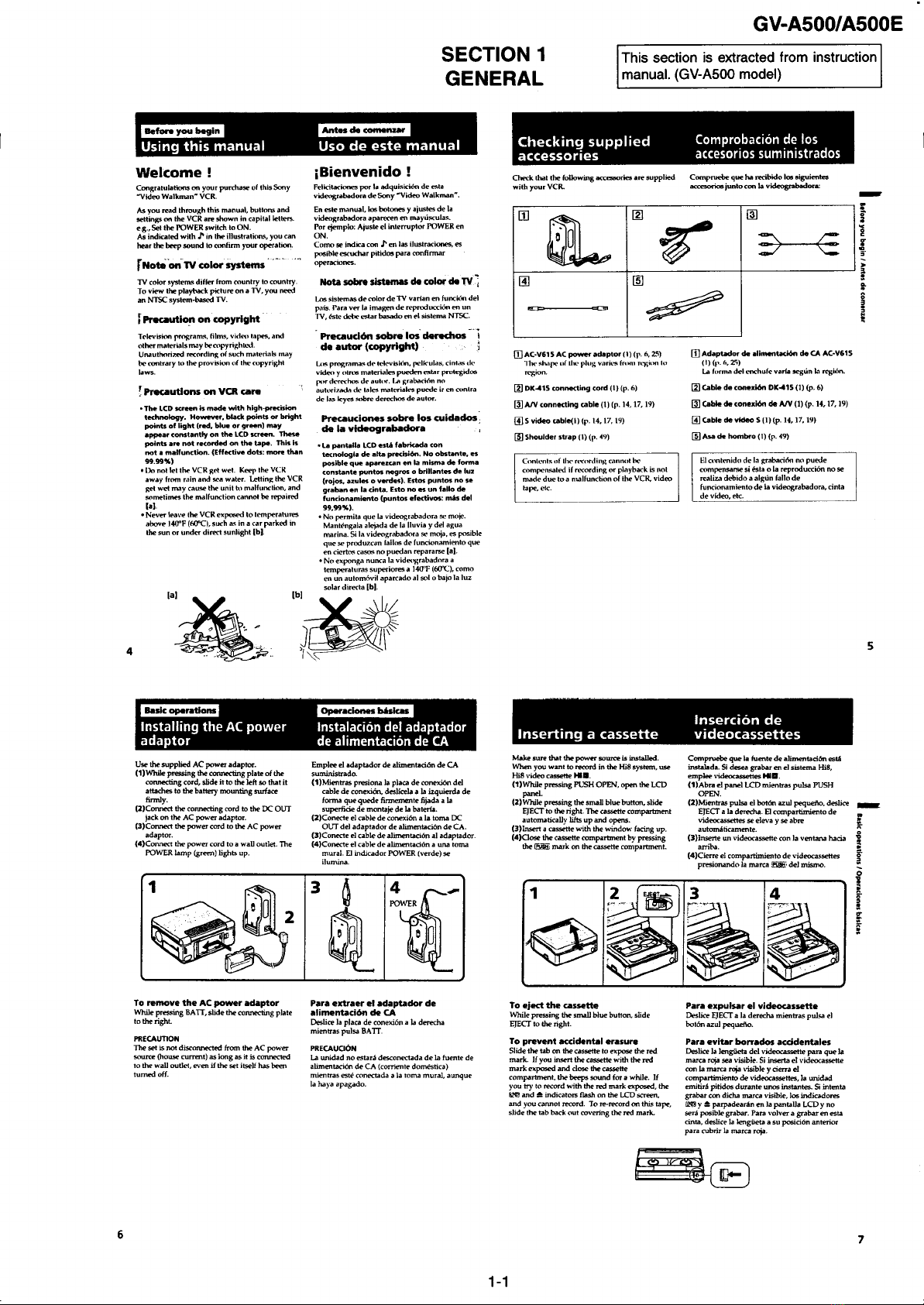

Before you begin

Using this manual ······························································· 1-1

Checking supplied accessories ··········································· 1-1

Basic operations

Installing the AC power adaptor ········································· 1-1

Inserting a cassette ······························································ 1-1

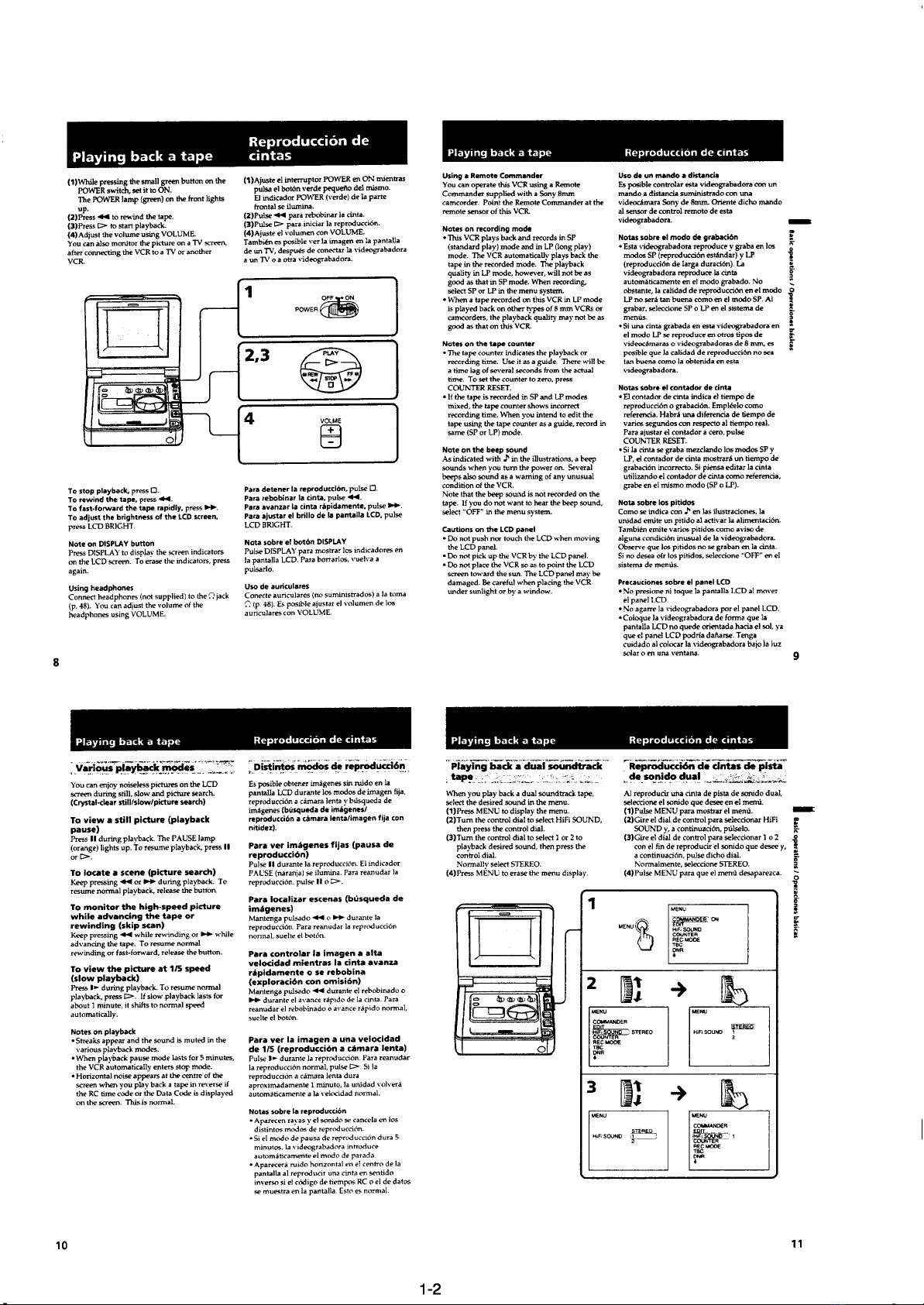

Playing back a tape ····························································· 1-2

Advanced operations

Watching on a TV screen ···················································· 1-3

Editing onto another tape···················································· 1-4

Recording from a VCR or TV ············································ 1-4

Changing the mode settings················································ 1-5

Using alternative power sources ········································· 1-6

Additional information

Charging the vanadiumlithium battery in the VCR ············ 1-7

Usable cassettes and playback modes································· 1-7

Notes on “InfoLITHIUM” battery pack ····························· 1-7

Maintenance information and precautions·························· 1-8

Using your VCR abroad ····················································· 1-9

Trouble check ········································································· 1-9

Self-diagnosis display····························································· 1-10

Identifying the parts································································ 1-10

Warning indicators·································································· 1-11

2. DISASSEMBLY

2-1. CASSETTE LID ASSEMBLY ····································· 2-1

2-2. LCD CABINET···························································· 2-1

2-3. CRYSTAL INDICATION MODULE,

FLUORESCENT COLD CATHODE TUBE,

PD-88 BOARD····························································· 2-2

2-4. CABINET (BOTTOM) ASSEMBLY··························· 2-3

2-5. MD BLOCK ASSEMBLY ··········································· 2-3

2-6. CONTROL (FK-71) SWITCH BLOCK,

DD-100 BOARD ·························································· 2-3

2-7. VC-197 BOARD ·························································· 2-4

2-8. B MECHANISM DECK ·············································· 2-4

2-9. CABINET (R) BLOCK ASSEMBLY,

FP-571 BOARD ··························································· 2-4

2-10. EX-34 BOARD ···························································· 2-4

2-11. IO-62, IR-29, FP-572, FP-573, FP-574,

FP-575 BOARDS SPEAKER ······································ 2-5

2-12. CABINET (UPPER) ASSEMBLY ······························· 2-5

2-13. CIRCUIT BOARDS LOCATION ································ 2-6

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM ································· 3-1

3-2. VIDEO BLOCK DIAGRAM 1 ···································· 3-4

3-3. VIDEO BLOCK DIAGRAM 2 ···································· 3-7

3-4. SERVO BLOCK DIAGRAM ······································· 3-10

3-5. SYSTEM CONTROL BLOCK DIAGRAM ················ 3-13

3-6. AUDIO BLOCK DIAGRAM ······································· 3-15

3-7. MODE CONTROL BLOCK DIAGRAM ···················· 3-17

3-8. LCD BLOCK DIAGRAM ··········································· 3-20

3-9. POWER SUPPLY BLOCK DIAGRAM ······················ 3-23

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM····························· 4-1

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS ········································· 4-4

• VC-197 (MAIN) PRINTED WIRING BOARD ······· 4-5

• VC-197 (REC/PB HEAD AMP)

SCHEMATIC DIAGRAM ··························· 4-11

• VC-197 (EVR) SCHEMATIC DIAGRAM ··············· 4-16

• VC-197 (VIDEO PROCESS)

SCHEMATIC DIAGRAM ··························· 4-19

• VC-197 (Y/C PROCESS)

SCHEMATIC DIAGRAM ··························· 4-23

• VC-197 (TBC/CNR) SCHEMATIC DIAGRAM ······ 4-27

• VC-197 (VIDEO IN/OUT)

SCHEMATIC DIAGRAM ··························· 4-30

• VC-197 (RGB DECODER)

SCHEMATIC DIAGRAM ··························· 4-33

• VC-197 (IR DRIVER), IR-29 (TRANSMITTER)

SCHEMATIC DIAGRAM ··························· 4-37

• IR-29 (TRANSMITTER)

PRINTED WIRING BOARD ······················ 4-40

• VC-197 (SERVO/SYSTEM CONTROL)

SCHEMATIC DIAGRAM ··························· 4-41

• VC-197 (SERVO) SCHEMATIC DIAGRAM ·········· 4-44

• VC-197 (MODE CONTROL)

SCHEMATIC DIAGRAM ··························· 4-47

• VC-197 (AUDIO) SCHEMATIC DIAGRAM ·········· 4-51

• IO-62 (AV IN/OUT) SCHEMATIC DIAGRAM ······ 4-55

• EX-34 (MULTI CONNECTOR)

SCHEMATIC DIAGRAM ··························· 4-59

• EX-34 (MULTI CONNECTOR)

PRINTED WIRING BOARD ······················ 4-63

• IO-62 (AV IN/OUT) PRINTED WIRING BOARD · 4-65

• PD-88 (LCD DRIVER)

SCHEMATIC DIAGRAM ··························· 4-68

• PD-88 (LCD DRIVER)

PRINTED WIRING BOARD ······················ 4-71

• DD-100 (POWER SUPPLY)

PRINTED WIRING BOARD ······················ 4-73

• DD-100 (POWER SUPPLY)

SCHEMATIC DIAGRAM ··························· 4-75

5. ADJUSTMENT

5-1. PREPARATIONS ························································· 5-1

1-1. PREPARATIONS BEFORE ADJUSTMENT ·············· 5-1

1-1-1.List of Service Tools····················································· 5-1

1-1-2.Adjusting Remote Commander ···································· 5-2

1. Using the adjusting remote commander ······················· 5-2

2. Precautions upon using the adjusting

remote commander ······················································· 5-2

1-1-3.Page D Address ···························································· 5-3

1-1-4.Page F Address ····························································· 5-4

1-1-5.Page E Address ····························································· 5-7

1-2. INITIALIZATION OF D, E, F PAGE DATA ··············· 5-8

1. Initialization of D, E, F Page Data ······························· 5-8

2. Modification of D Page Data········································ 5-8

3. Modification of F Page Data ········································ 5-9

4. Modification of E Page Data ········································ 5-10

1-3. Data Processing ···························································· 5-10

5-2. MECHANICAL SECTION ADJUSTMENT ·············· 5-11

2-1. OPERATING WITHOUT A CASSETTE···················· 5-11

2-2. TAPE PATH ADJUSTMENT······································· 5-11

1. Preparations for adjustments ········································ 5-11