SOR 701 Series User manual

Form 712 (06.10) ©2010 SOR Inc.

1/12

The Ultrasonic Point Level Detector energizes/

de-energizes a DPDT relay to indicate liquid

presence/absence within the sensor cavity. Two

piezoelectric crystals face each other across the

cavity. The transmitter crystal sends an ultrasonic

signal to the receiver crystal. When liquid fills the

cavity, the receiver crystal detects a strong signal

because liquids are good conductors of ultrasonic

waves. When the cavity is empty, the receiver

crystal detects a weaker signal because air is

a poor conductor of ultrasonic waves.

Series 701

Ultrasonic Point Level Detector

General Instructions

Registered Quality System to ISO 9001:2008

Design and

specifications are

subject to change

without notice.

For latest revision, go to

www.sornc.net

NOTE: If you suspect that a product is defective, contact the factory or the SOR®

Representative in your area for a return authorization number (RMA). This product

should only be installed by trained and competent personnel.

Table of Contents

PC Board Arrangement.........................2

Sensor Installation .......................... 2-3

Remote Cable Connection.................. 4-5

Electrical Connection........................ 5-6

Fail Safe Detector...............................6

Sensor Test Procedure .........................7

Time Delay.......................................7

Installation Drawings ....................... 8-9

Dimensions .................................... 10

Troubleshooting ............................... 11

Field Replacement - PC Board.............. 11

Replacement Fuses .......................... 12

Spare Parts .................................... 12

n

ic

t

h

e

g

nal

s

onic

e

r

s

n

i

c

P

o

General Ins

t

r

u

c

t

i

o

nt

ac

t

th

e

factory or the S

OR

®

R

R

R

MA

)

T

hi

s product

2/12

Form 712 (06.10) ©2010 SOR Inc.

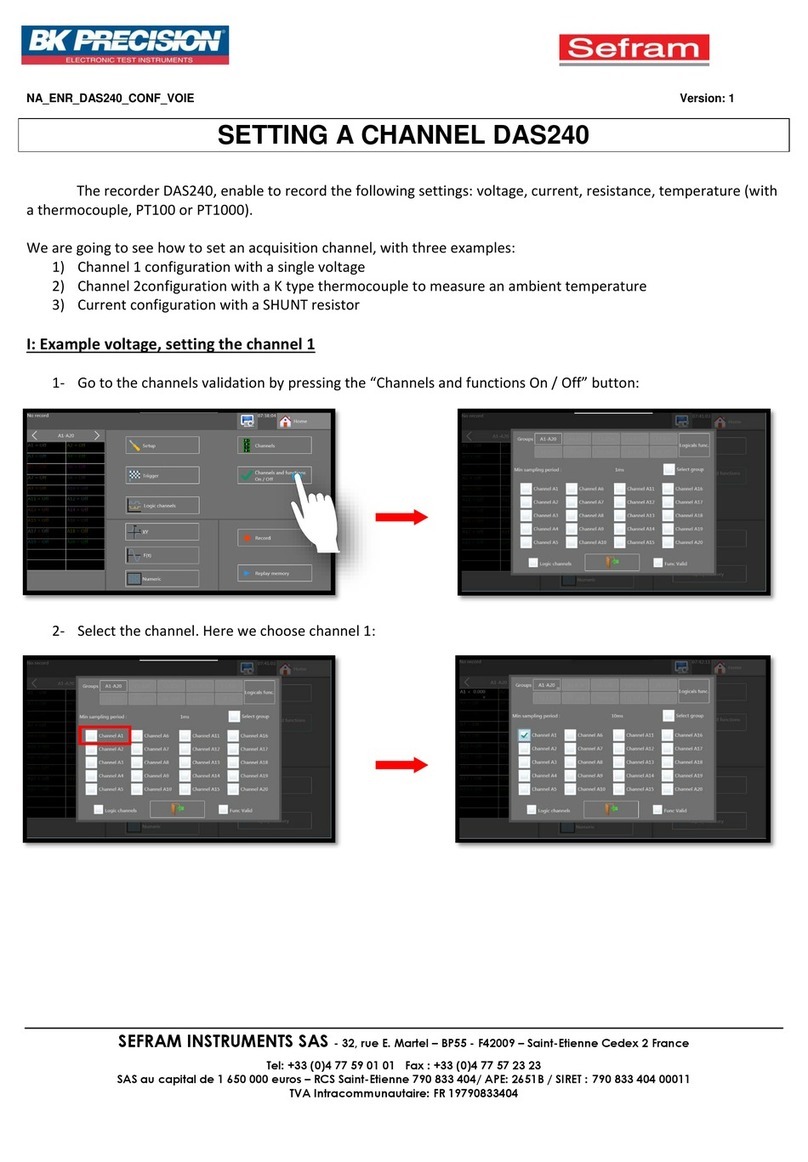

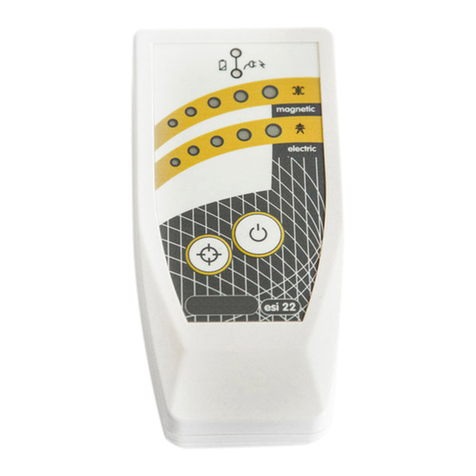

PC Board Arrangement

Sensor Installation (Applies to all models)

Series 701 Ultrasonic Level Sensors can be mounted by inserting the sensor through a

fitting in a vessel, or the sensor may be suspended over an open sump or basin. Keep the

sensor cavity out of the direct flow of liquid fill to prevent false readings. Install a baffle to

divert liquid flow if necessary.

DO NOT weld any part of this instrument.

9 Position Terminal Block (Reverse Side)

Ground (Earth)

Power Supply

DPDT Level Indication

Relay Contact

Failsafe Slide Detector

(optional)

Sensor Lead Connection

Sensor Lead Connection

Replaceable Fuse(s)

Power LED

Wrench Flat

No Obstructions

Housing Hub

Apply thread sealant

Tank or Vessel

Make sure that the sensor can be fully inserted and tightened without interference from

obstructions inside the tank or vessel.

Apply suitable sealant to the process

connection to prevent process leakage.

Use an open end wrench to tighten

the sensor into the process connection.

Do not use the sensor housing as a

handle to tighten the process connection.

Form 712 (06.10) ©2010 SOR Inc.

3/12

Horizontal Mounting

When tightened securely, the sensor

cavity must be positioned vertically for

optimum drainage when process liquid

level drops below the sensor cavity.

An alignment mark X stamped on a

wrench flat (or on the dry face of a

flange below the housing) shows

sensor cavity orientation.

Optimum drainage occurs when the X

mark is located at 6 or 12 o’clock.

Level is detected when the sensor

cavity is filled with process liquid.

The sensor must project through a tank

fitting so that the sensor cavity is at least

1” beyond the inner wall of the tank.

Sensor Cavity

1 inch

minimum

Top View

Alignment mark

X on wrench flat

at 12 o’clock

Housing

Hub

Alternate position

for alignment

mark X: 6 o’clock

Open Sump or Basin

Do not suspend the unit by rigid

conduit installed in the electrical hub.

When installing the unit over an open

sump or basin use a suitable bracket

to support the instrument.

NOTE: The instrument must be

positioned so that overow does

not ood the electrical housing.

Bracket

4/12

Form 712 (06.10) ©2010 SOR Inc.

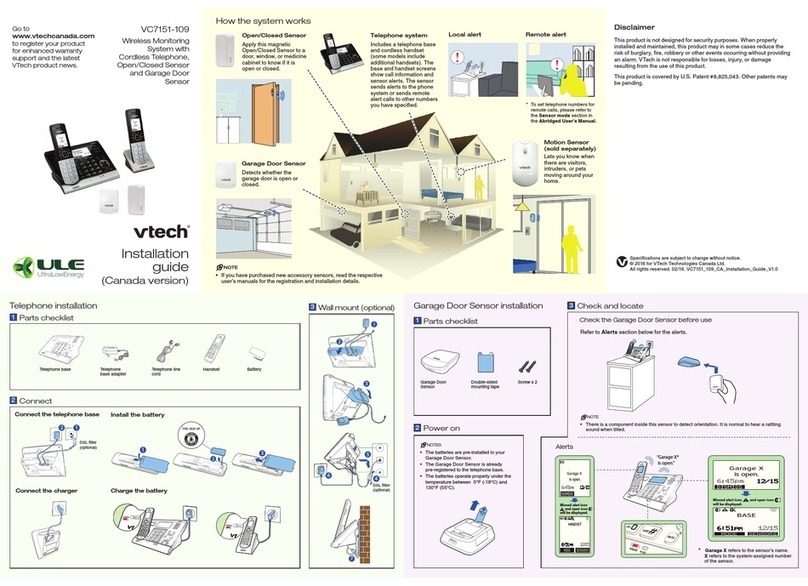

Control Board (See Page 2)

Electronics

Housing

Conduit

Must Meet

Class 1 Group C & D;

Class II Groups E, F & G;

Division 1 & 2

Sensor Base

Protect

Factory-

Installed Plugs

Remote

Interconnect

Board

(See Below)

Conduit must be installed between the

sensor base and the electronics housing

to provide a raceway for sensor

extension cables. The sensor base and

the electronics housing are suitable for

use in Class I Group C & D; Class II

Groups E, F, & G; Division 1 & 2

Hazardous Locations. All conduit and

fittings used for the installation must

equal or exceed this rating to maintain

the explosion proof integrity of

the assembly.

Ensure that wiring conforms to all

applicable local and national electrical

codes and install unit(s) according to

relevant national and local safety codes.

Remote Cable Connection (Applies to remote units only - R Housing)

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Short

each center conductor

to the shell to discharge

sensor crystals.

Use care to avoid damaging the factory

installed mini-phono connectors while

fishing the sensor extension cables through

the conduit. Pull cables from the sensor base

so that the free ends follow the fish through

the conduit.

Discharge the Sensor Temperature changes

which occur during shipment may result in

a small electrical charge inside the sensor

crystals. This charge is harmless to humans, but may result in damage to the electronics

if the sensor is plugged in before it is discharged. To discharge the sensor, touch a wire to

each sensor connector so that the center conductor and outside shell make contact.

Fishing the Sensor Extension Cables

Two sensor extension cables are supplied. Both ends of the cables are

terminated and labeled at the factory.

Form 712 (06.10) ©2010 SOR Inc.

5/12

Electrical Connection (Applies to all models)

Sensor Connections Inside Sensor Base

Inside the sensor base, a remote interconnect board rests in a plastic holder.

Slide the interconnect board up. Attach the sensor coax connectors to the

interconnect board as follows:

Remote

Interconnect

Board located

inside sensor

base

OUT connections are located on the opposite

side of the board from the IN connections.

Do not use positions 3 and 4 to connect wires.

Connect one sensor cable to IN 1.

Connect the other sensor cable to IN 2.

Attach the extension cables to the

interconnect board as follows:

Connect cable A to OUT 1.

Connect cable T to OUT 2.

Plug in Connections Inside

Electronics Housing. Plug sensor

extension cables onto the PC

board as follows:

Connect cable A and cable T to the

Sensor Lead Connections. See PC Board

Arrangement on page 2 to locate Sensor

Lead Connections.

Tip-sensitive sensor connections are not sensitive to position. Sensor Lead Connection

wires may be interchanged without affecting the performance of the instrument.

A nine-position terminal strip provides connections for DPDT Liquid Level Relay Contacts,

Line Power and Ground. Terminal positions are labeled on the green insulator card as

shown on Page 6.

A. Liquid Level Relay Contact Terminals

On units without OD, OF, or FS accessories, there is no fail-safe detector. The normal

operation of the unit is fail-safe hi. When the sensor is dry, the relay is de-energized; the

normally closed position (NC) and common (C) are in contact. When the sensor is wet, the

relay is energized; the normally open position (NO) and common (C) are in contact.

On units with OD, OF, or FS accessories, there is a fail-safe detector. The fail-safe detector is

located on the upper right hand corner of the circuit board with contact terminals facing

away from you (see circuit board illustration on the front cover). Refer to Page 6 for

detector options.

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

6/12

Form 712 (06.10) ©2010 SOR Inc.

B. Line Power Terminals

Terminals are provided for incoming power leads on the nine-position PC board terminal strip.

Supply voltage for each PC board is printed on the green insulator card. Make sure that the

available line voltage matches device’s power supply.

C. Ground Terminals

The housing and the PC Board must be connected to ground. Ground (earth) screws are

provided on the nine-position PC board terminal strip and on the housing floor.

If extra clearance is required for connection to the ground screw on the housing floor, the

PC board can be removed and reinstalled according to Field Replacement–PC Board on

page 11.

C

Nine-Position Terminal Strip

NC1 C1 NO1 NO2 C2 NC2 L1 N GND

BA

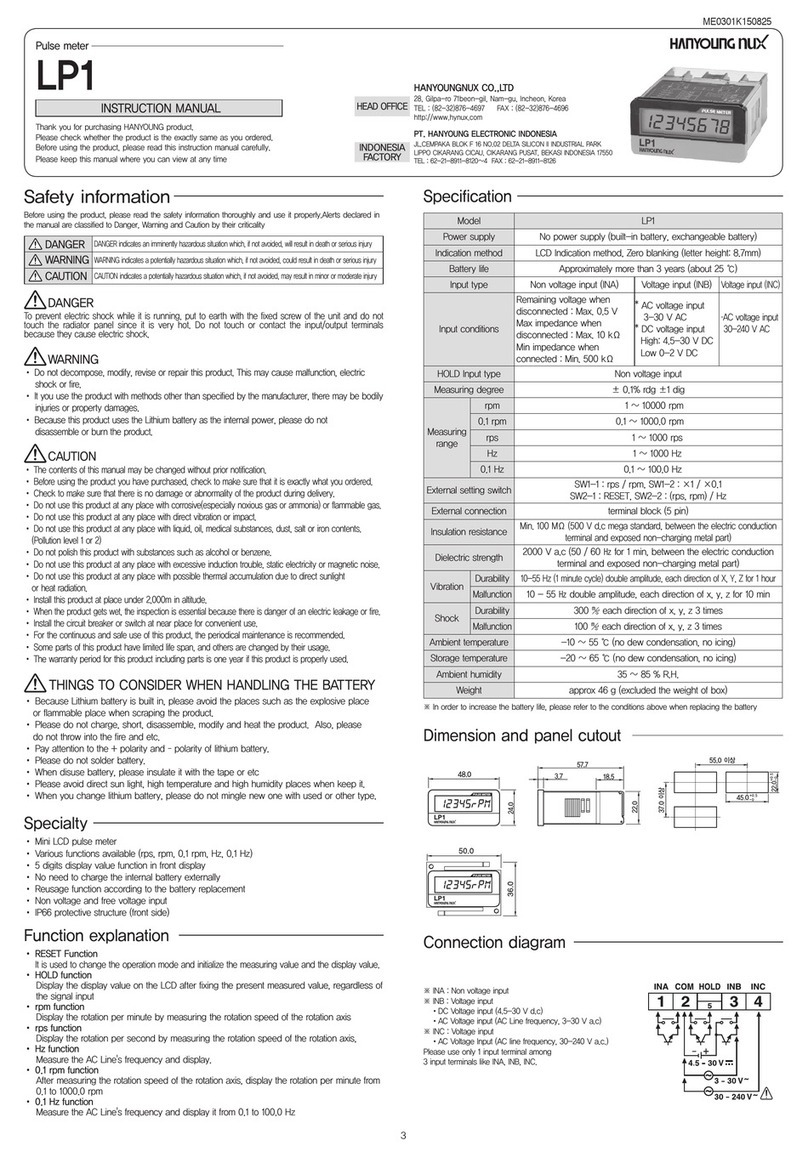

Fail-Safe Detector (Models with OF, OD, or FS accessories only)

Fail-safe

Mode

Detector Position

Sensor

Condition

Liquid Level

Relay Contact A

Continuity Chart

Relay

energized on

high level

Liquid above sensor

Liquid below sensor

Liquid above sensor

Liquid below sensor

NC1 C1 NO1 NO2 C2 NC2

Relay Energized

NC1 C1 NO1 NO2 C2 NC2

Relay De-energized

NC1 C1 NO1 NO2 C2 NC2

Relay De-energized

NC1 C1 NO1 NO2 C2 NC2

Relay Energized

Relay

energized on

low level

HI/LO HI/LO

Form 712 (06.10) ©2010 SOR Inc.

7/12

Sensor Test Procedure (Applies to all models)

Disconnect a sensor cable from the PC board. Measure capacitance across the two

conductors of the sensor cable.

Capacitance from 2,000 to 3,000 pf indicates circuit is okay. Plug the sensor cable

back into the PC board. Go to step 2.

Capacitance lower than 2,000 pf or higher than 3,000 pf indicates circuit is bad.

Go to step 3.

Repeat step 1 for the other sensor cable.

A replacement sensor can be ordered from the factory or the SOR Representative in

your area. Required order information: model and serial numbers stamped on the

sensor nameplate.

Units in Hazardous Locations - Prior to calibration, make sure that the

work area is declassied before removing the explosion proof cover to

calibrate the unit. Failure to do so could result in severe personal injury

or substantial property damage.

Time Delay (Models with OD or OF accessories only)

On and off delay timers are fixed to a customer specified constant The timers are not field

adjustable.

On Delay Timer

On delay is an integral timer that starts when process liquid is detected in the sensor cavity.

If the liquid level falls before the On timer completes its cycle, the timer resets to zero and

waits for the sensor cavity to fill again. When the On timer completes its cycle, the Liquid

Level Relay changes state to indicate liquid has filled the sensor. Fail-safe detector (page 6)

is included with the delay timer option.

Off Delay Timer

Off delay is an integral timer that starts when the process liquid evacuates the sensor

cavity. If the liquid level rises into the sensor cavity before the off timer completes its cycle,

the timer resets to zero and waits for the liquid to fall again. When the off timer completes

its cycle, the Liquid Level Relay changes state to indicate liquid has evacuated the sensor

cavity. Fail-safe detector (page 6) is included with the delay timer option.

8/12

Form 712 (06.10) ©2010 SOR Inc.

Installation Drawings

CSA Probe/Electronics Combinations

Form 712 (06.10) ©2010 SOR Inc.

9/12

Installation Drawings

FM Probe/Electronics Combinations

10/12

Form 712 (06.10) ©2010 SOR Inc.

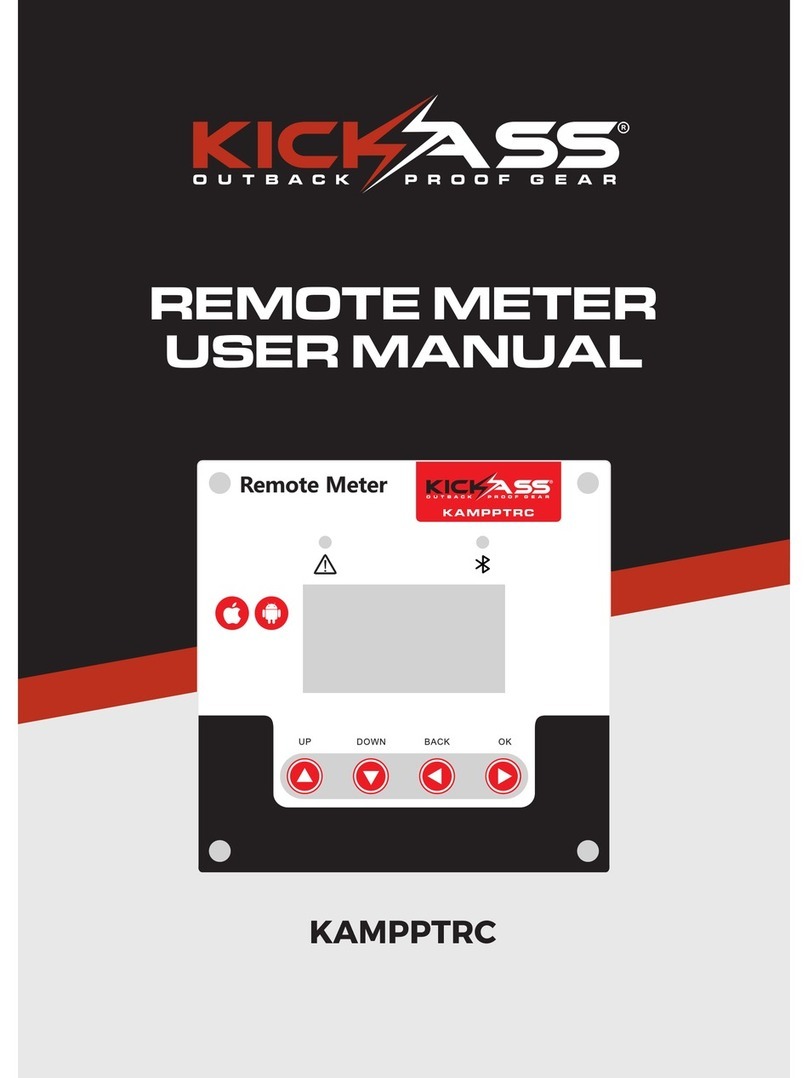

Dimensions

Integral model with threaded process connection shown.

Process Connection *Add to Length

3/4” NPT(M) Shown

1” NPT(M) Add 8.0

.313

1-1/2” NPT(M)

Add 9.5

.375

2” NPT(M)

Linear = mm/inches

Drawing 0390415

Form 712 (06.10) ©2010 SOR Inc.

11/12

Field Replacement - PC Board

Identical replacement printed circuit boards can be ordered by specifying the part number

from the spare parts table on page 12.

De-energize all supply and control conductors that enter the housing. Failure to disconnect

electrical power could result in severe personal injury and substantial plant damage from

ignition of hazardous atmosphere.

Remove the electronics housing cover.

Note existing connections, then disconnect all conductors from the PC board

terminal strip.

Remove the two screws to release the PC board bracket from the housing.

Slide the PC board straight up, then unplug the sensor cables from the PC board.

Slide the old PC board completely out of the housing.

Slide the new PC board into the PC board mounting slots.

Discharge sensor crystals as shown on page 4. Failure to do so may damage the electronics.

Plug the sensor cables into J1 and J2 connectors on the new PC board. The sensor

will function properly regardless of orientation.

Reinstall the two screws to secure the PC board bracket to the housing.

Reconnect all conductors to the PC board terminal strips.

Replace the cover.

Restore power to supply and control circuits.

Troubleshooting

Symptom Possible Causes Solutions

No response

to liquid

level

No power to unit. Restore power. Check fuse(s).

Blown fuse. Replace fuse(s). (See page 12.)

One or both sensor cable(s)

unplugged from PC board.

Replace sensor cable plug(s)

according to the Field Repalcement

procedure. (See above.)

I

nternal or external damage to

sensor. Sensor damage can

be verified using sensor test

procedure. (See page 7.)

If sensor tests okay, replace

circuit board according to field

replacement procedure. (below)

Replace entire instument or contact

factory for replacement sensor. The

factory will request model and serial

numbers to provide replacement

sensor.

12/12

Form 712 (06.10) ©2010 SOR Inc.

14685 West 105th Street, Lenexa, KS 66215

913-888-2630

800-676-6794 USA

Fax 913-888-0767

Registered Quality System to ISO 9001:2008

Printed in USA sorinc.net

Replacement Fuses

Replacement fuses may be ordered from SOR or electronic parts suppliers.

Please note that two fuses are required for 24 volt (P8) units and one fuse is required for

24VDC (P6) and 24 volt (P7) units.

Supplier Part Number

SOR 2806-007

Wickman

19373-035-K

19373-250MA-K

Schurter MSF-250-034.6008

Spare Parts

Model Number

Contact the factory for the correct

replacement board if the model number

has FS, OD, or OF near the end of

the model number.

Replacement PC Board Kit

This kind includes PC mounting bracket

and hardware. Do not use these numbers

if your unit contains fail-safe or time

delays. Contact the factory for the

appropriate part numbers.

701 -U-P6-C 5002-986

701 -U-P7-C 5002-987

701 -U-P8-C 5002-988

Model and Serial Numbers are necessary to ensure receipt of the proper replacement circuit

board. To order the correct PC board for an instrument, find a match for the namplate model

number in the left column below. Ignore characters which fall in a space. Order a part

number from the column to the right of the model number.

Table of contents

Other SOR Measuring Instrument manuals