- -

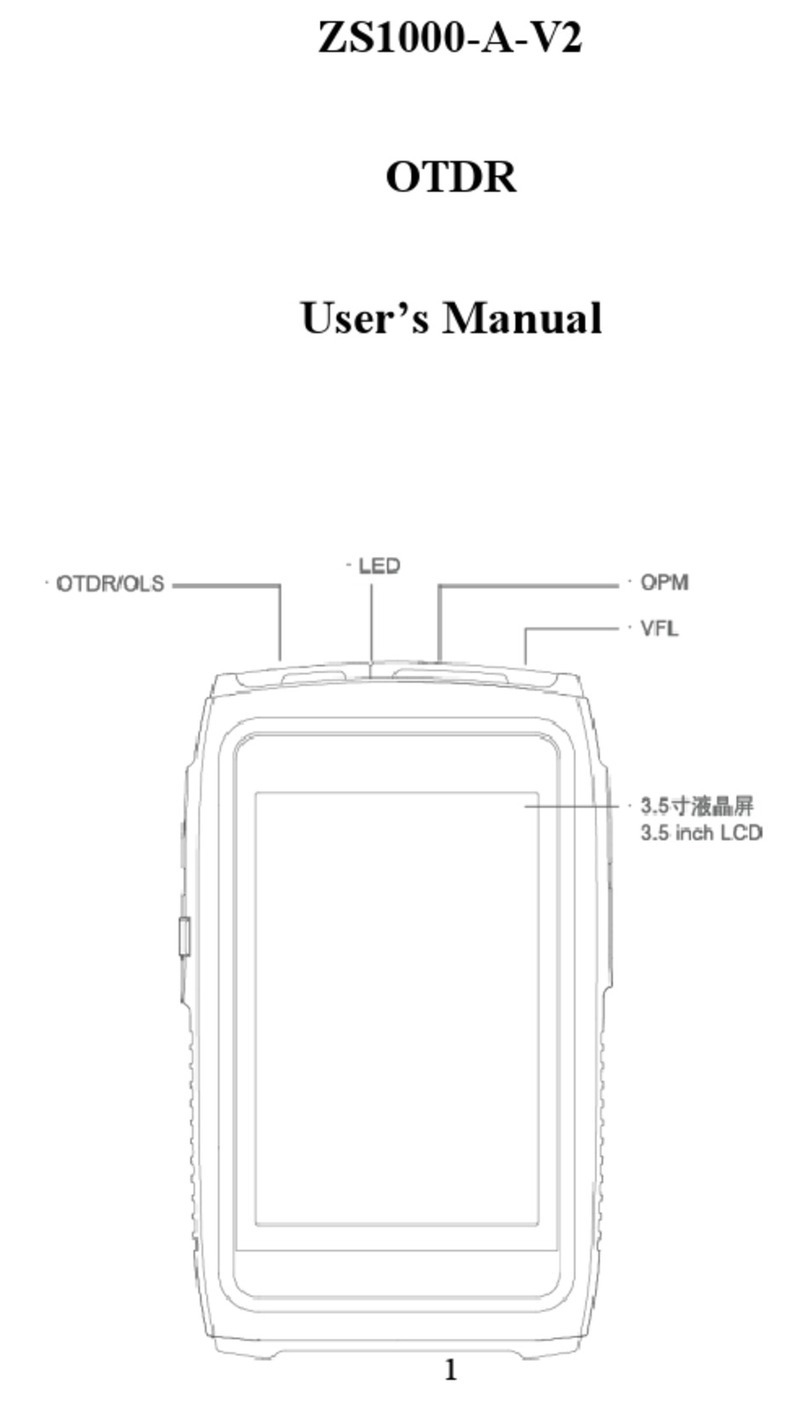

HD2114.2 - HD2134.2 - HD2164.2 - HD2114B.2

1. Input, 8-pole DIN45326 connector. It is possible to connect: a PP471 SICRAM module, a

Pt100 temperature probe fitted with SICRAM module, a direct 4-wire Pt100 temperature probe,

a 2-wire Pt1000 probe or a 2-wire Ni1000 probe.

2. Positive input (+) into the internal pressure sensor. Quick coupling Ø 5mm

3. External auxiliary power supply connector input (positive at centre).

4. Battery symbol: displays the battery charge level.

5. Function indicators.

6. Secondary display line.

7. HOLD/key: freezes the measurement during normal operation; in the menu, increases the

current value.

8. FUNC/ENTER key: during normal operation displays the maximum (MAX), the minimum

(MIN) and the average (AVG) of current measurements; in the menu, confirms the current

selection.

9. REL/key: enables the relative measurement (displays the difference between the current

value and the logged value when the key is pressed); in the menu, decreases the current value.

10. SERIAL/ERASE LOG key: starts and ends the data transfer to the serial communication port.

In the menu, clears the data contained in the instrument's memory.

11. LOG/DUMP LOG key: during normal operation, starts and ends the saving of the data in the

internal memory; in the menu, starts the data transfer from the instrument's memory to the PC.

12. Mini-USB type B connector for USB 2.0. For the connection to PC (with cable CP23).

13. PEAK/MENU key: during normal operation, starts and ends the peak measurement. When

pressed together with the FUNC/ENTER key, allows access to the menu. To exit the menu,

press the key again.

14. C°/F°-ESC key: changes the unit of measurement for temperature from degrees Celsius to

Fahrenheit; in the menu, cancels the operation in progress without making changes.

15. UNIT key: selects the unit of measurement for the pressure.

16. ON-OFF/AUTO-OFF key: turns the instrument on and off; when pressed together with the

HOLD key, disables the automatic turn off.

17. Peak, MAX, MIN and AVG symbols.

18. Main display line.

19. Multiplication factor -3, 3 or 6: the apex, if present, indicates that the displayed measurement

must be divided by 1000 (apex "-3"), multiplied by 1000 (apex "3") or by 1,000,000 (apex "6").

20. Line for symbols and comments.

21. 8-pole MiniDin connector for RS232C. For the connection to PC (with cable HD2110CSNM or

C206) or printer (with cable HD2110CSNM).

22. Negative input (-) into the internal pressure sensor. Quick coupling Ø 5mm. This input is not

present in the HD2114B.2 model.