SOR 651 K9 RF Instruction manual

Form 759 (04.16) SOR Inc.

1/16

Remove the housing cover.

Place the instrument on an insulated surface or support

so the sensor does not touch a conductive surface.

Apply 12 to 28VDC, and observe the LED. (See on page 2)

NOTE: When the LED is on, it indicates the output is in the normal state 16-20mA.

Turn the sensitivity adjustment clockwise (up to 25 turns) to increase sensitivity until

the LED goes out.

NOTE: Do not turn the sensitivity adjustment past 25 turns! Damage to the unit could result.

Turn the sensitivity adjustment counterclockwise to decrease sensitivity until the

LED illuminates.

Pre-Installation I/O Test and Calibration

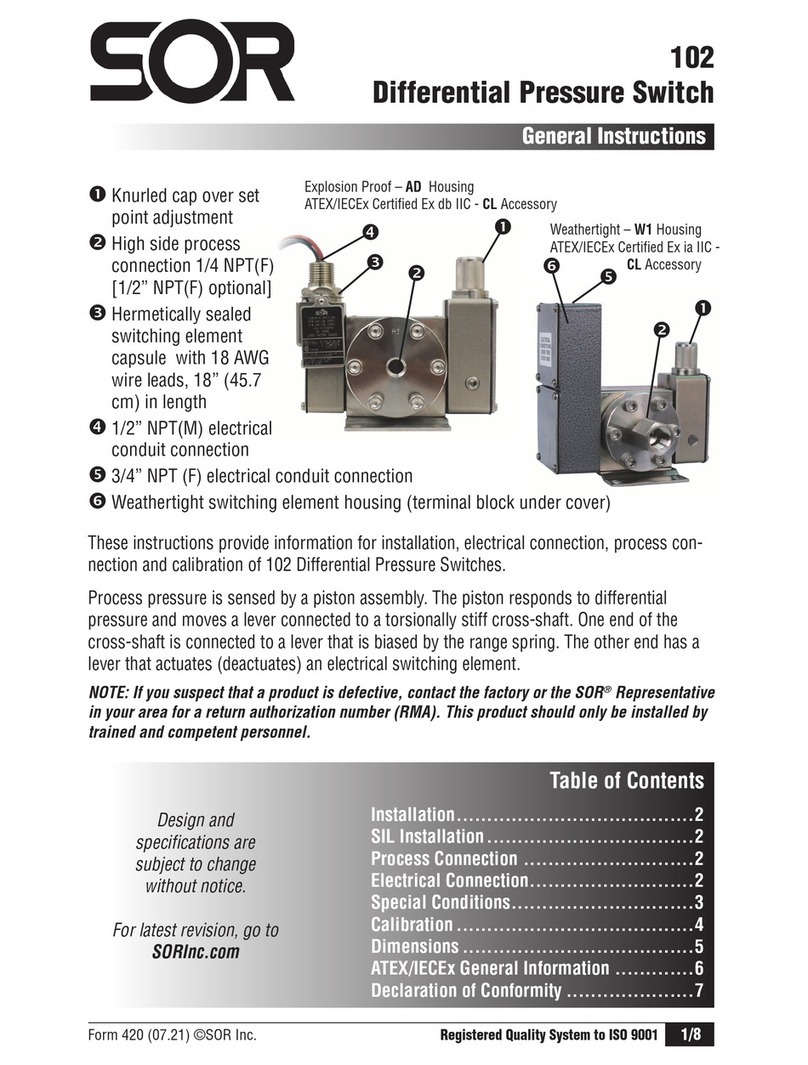

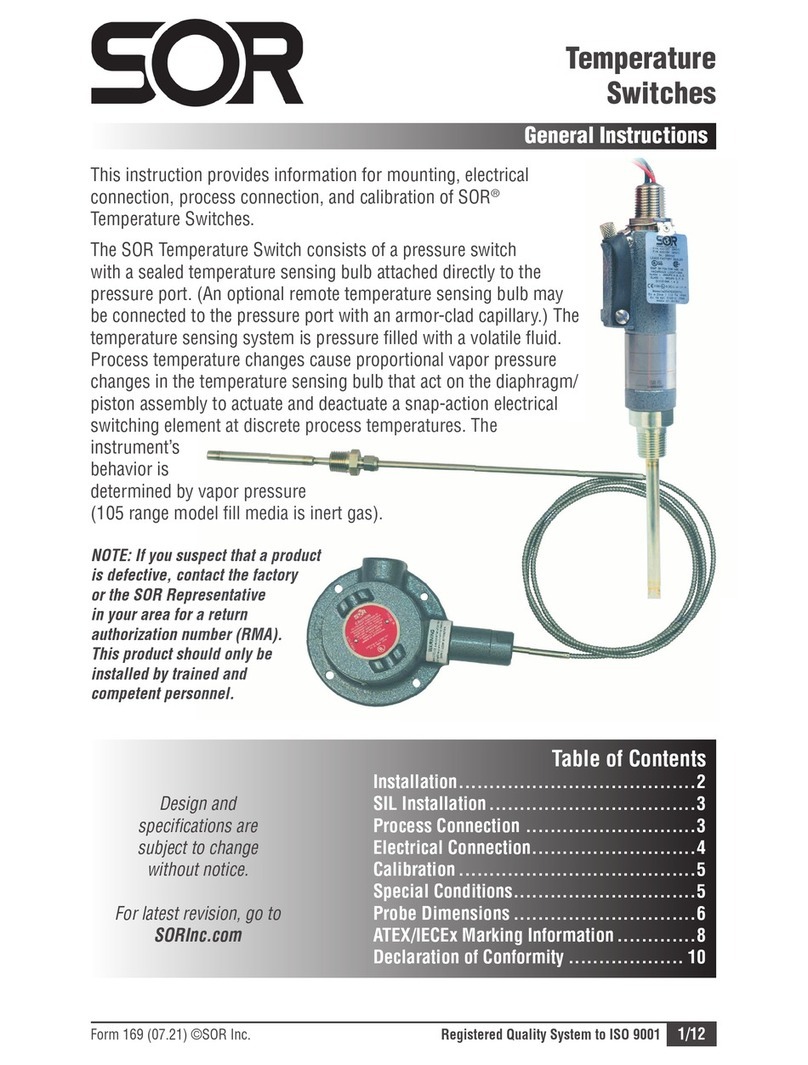

651 K9 RF Admittance

Two Wire Point Level Control

General Instructions

Registered Quality System to ISO 9001

Design and

specifications are

subject to change

without notice.

For latest revision, go to

SORInc.com

Table of Contents

Pre-Installation I/O and Calibration....... 1-2

Installation.......................................3

Electrical Connections .........................4

Post-Installation Calibration ..................4

SOR RF Probe Grounding Screen ............5

Control Drawings ............................ 6-9

Instructions for EMC.......................... 10

Spare Parts .................................... 10

Information for IEC-Listed Product ......... 10

Maintenance and Troubleshooting ......... 11

Dimensions ................................ 12-13

ATEX and IECEx Marking Details ........... 14

Declaration of Conformity ................... 15

These instructions provide specific information for installation,

electrical connection, calibration and troubleshooting for the

651 K9 RF Admittance Two-Wire Point Level Control.

NOTE: If you suspect that a product is defective, contact the factory

or the SOR®Representative in your area for a return authorization

number.

This product should only be installed by trained and

competent personnel.

2/16

Form 759 (04.16) SOR Inc.

Turn the sensitivity adjustment slowly clockwise until LED goes off, then

counterclockwise until LED goes on to check the null position to verify that the bridge is

balanced. It is desirable to closely bracket the position where the LED came on.

Turn the sensitivity adjustment one turn counterclockwise from the null position. Next,

slowly move a hand toward the probe to touch it. The LED should stay on until the

probe is touched. If it goes out when the hand is near, turn the sensitivity control

counterclockwise so the LED stays on until the hand touches the probe. Usually,

1-2 turns will locate the new null point.

When practical, use a small container of actual process material to calibrate the control.

If the actual process vessel is metal, use a metal container (coffee can, etc.) and ground

it to the instrument housing. If the actual process vessel is an insulator, such as,

fiberglass, use a plastic container.

Immerse the sensor in the process material; the LED should turn off. If not, rotate the

sensitivity adjustment clockwise until the LED goes off.

To detect an interface, such as oil/water or foam/liquid, the lighter material must be in

contact with the sensor, then tuned out. Then adjust the sensitivity to detect the heavier

process material. (See and )

Oil

Water

Terminal Block

(opposite side)

Fail Safe

Switch

Sensitivity

Adjustment

Banana

Plug

LED Ring

Terminal

Form 759 (04.16) SOR Inc.

3/16

Installation

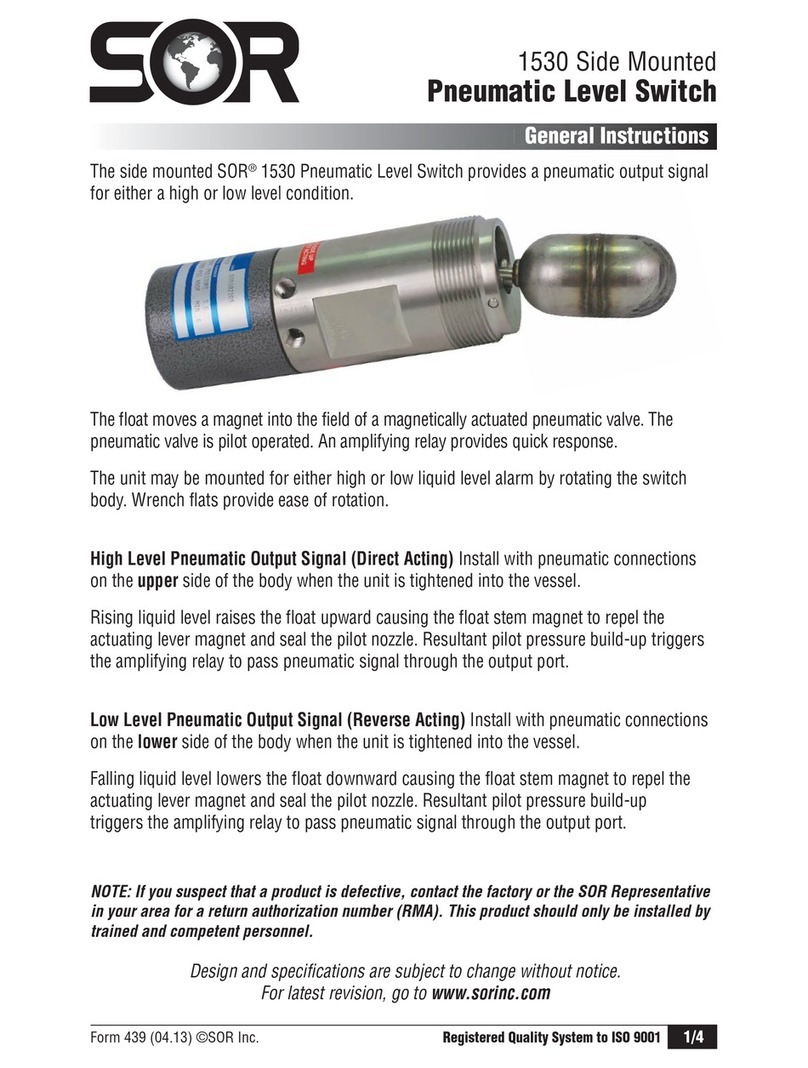

Output Signal

Failsafe Hi Lo

Absence of Process 16-20mA 4-8mA

Presence of Process 4-8mA 16-20mA

Standard conguration is a 3/4” NPT(M) pipe nipple that threads into a 3/4” NPT(F) vessel

nozzle or half coupling. Allow a 4” turn radius (See and ). Sometimes open tanks,

vats, sumps or basins require a locally-made bracket mount similar to that shown in.

(See ).

Optional conguration is a raised face or flat face ANSI flange. See Form 1100 for

selection. (See

g

and )

Orientation. The control can be mounted in any position. Sensitivity is optimized when the

greatest surface area of the sensor is parallel to the process level. (See

p

and )

4/16

Form 759 (04.16) SOR Inc.

Electrical Connections

When the process is adhesive, i.e. it tends to coat the sensor, it may be desirable to mount

it on a 45° angle to reduce product build-up and to increase its effective surface area. (See

and )

Placement and orientation of the sensor in a vessel is frequently determined by available

nozzles. The sensor should be away from fill points to avoid false trips. The insulator

bushing on the sensor should protrude a minimum of 1” from the inner wall of the vessel.

The sensor must not touch any metal, nor should conductive product build-up be allowed

to bridge between the sensor and a grounded metal tank wall.

This product must be installed with an explosion proof breather vent per

Agency requirements and the National Electric Code-Article 501, Section F,

paragraph 3.

Electrical power must be disconnected from explosion proof/intrinsically

safe models before the cover is removed. Failure to do so could result in

severe personal injury or substantial property damage.

Remove the housing cover. Ensure that all wiring conforms to all applicable local and

national electrical codes and install unit(s) according to relevant national and local

safety codes.

Connect the positive loop power wire to the terminal marked “+”.

Connect the negative loop power wire to the terminal marked “-”.

Replace the cover.

Apply power.

Post-Installation Calibration

Units in Hazardous Locations — Prior to calibration, make certain that the

work area is declassied before removing the explosion proof cover to

calibrate the unit. Failure to do so could result in severe personal injury

and/or substantial property damage.

Turn the set-point adjustment to the full clockwise position. The LED should be off

(in Hi Level Fail-safe mode).

Turn the adjustment slowly counter-clockwise until the LED just changes state (on).

Raise the material level until it is above the sensing element. The LED should be off.

Turn the adjustment slowly counter-clockwise until the LED illuminates. Then turn the

adjustment 1/2 turn clockwise (LED off) to complete the calibration.

Form 759 (04.16) SOR Inc.

5/16

SOR RF Probe Grounding Scheme

Critical Grounding Path =

Circuit

Board

Line

Neutral

Ground

Electronics

Housing

Power Supply

Line

Neutral

Ground

Process

Connection

SOR Supplied

Stilling Well

(optional)

Probe Center

Conductive Element

IMPORTANT! Do not

provide separate earth

grounding for the process

connection. This can create

a parallel grounding circuit

that will impair operation

and calibration.

Do not provide separate

earth grounding for the

process connection. This can

create a parallel grounding circuit

that will impair operation and calibration.

6/16

Form 759 (04.16) SOR Inc.

Control Drawing

Drawing 9093008

Form 759 (04.16) SOR Inc.

7/16

Control Drawing

Drawing 9093010

8/16

Form 759 (04.16) SOR Inc.

Control Drawing

Drawing 9093011

Form 759 (04.16) SOR Inc.

9/16

Control Drawing

Drawing 9093009

10/16

Form 759 (04.16) SOR Inc.

Instructions for EMC

651K9

When subjected to an RF Interference, the

651K9 will maintain the +1% accuracy in

all frequency ranges. In order to achieve

the stated accuracy for the 651K9, a

shielded cable, cable gland, shield bead

and the probe should be mounted in a

metallic vessel. SOR recommends using

a shielded cable made of PVC

Insulation around a tinned copper braid

shield (Olflex CY cable or equivalent).

Refer to illustrations for installation of

shield bead onto the probe wire.

Short/Fat Bead

Certificate Number: IECEx BAS 05.0054X, Issue 2

Standards: IEC 60079-0:2011, Ed 6 and IEC 60079-11:2011, Ed 6

Listing: Ex ib IIB Tx Gb (-40°C < Ta < +80°C)

Certificate Number: Baseefa 12ATEX0084X

Standards: IEC 60079-0:2011, Ed 6 and EN60079-11:2012

Condition of Safe Use: This apparatus may not be capable of

withstanding the insulation test required by Clause 6.4.12 of

IEC 60079-11:1999. This must be taken into account when installing the apparatus.

To order a new circuit board assembly, use the following part number:

99-414

Spare Parts

Instructions for IEC-Listed Product

Parameters: Ui = 28V

Ii = 100mA

Pi = 0.75W

Li = 0

Ci = 0

NOTE: Replacement of circuit boards not allowed on agency listed units.

Form 759 (04.16) SOR Inc.

11/16

Sympton/Problem

Possible Cause Corrective Action

LED stays illuminated,

even at maximum

sensitivity setting (full

clockwise 25 turns).

1. Banana plug is loose or

disconnected

2. Probe lead is shorted to

case or ground

3. Faulty sensing circuit

1. Plug banana plug

securely into sensor

jack.

2. Check that the bare end

of the probe is not

touching any metal

part. Clean, repair or

replace the sensor

assembly.

3. Call the factory.

LED stays off, even at

minimum sensitivity

setting (full counter-

clockwise, 25 turns).

No power to the circuit or

excessive loop resistance.

Check the voltage at the

terminal block. It should

be a minimum of 12V.

Device will not detect

process material.

1. Bad circuit switch

2. The oscillator is not

working

Call the factory.

Calibration drifts 1. Sensitivity improperly set

2. Highly conductive

product

3. Heavy conductive

build-up on the sensor

1. Recalibrate according to

Post-Installation

Calibration Instructions

on page 3.

2. Use sheather sensor.

3. Use sheather sensor and

periodically remove

build-up.

Corroded sensor Process material has

chemically attacked sensor

Use sheather sensor to

provide corrosion

resistance.

Eroded or abraded

sensor

Fast flowing or agitated

process has physically

attacked sensor.

Consider other sensor

material or design,

relocating sensor or a

stilling well in liquid

process.

Output current exceeds

23 mA

Bad current switch Call the factory.

Output current is below

3.5 mA

The oscillator is not

working.

Call the factory.

NOTE: Agency certied units, (FM, CSA, IEC) must be returned to SOR for repairs.

Troubleshooting

12/16

Form 759 (04.16) SOR Inc.

Process Connection

Dim B Dim C

Cable Probe All Other

Probes Cable Probe All Other

Probes

3/4” NPT(M) 87.8

3.46

94.1

3.71

256.0

10.08

262.4

10.33

1, 1-1/2, & 2” NPT(M) 99.7

3.92

97.3

3.83

268.0

10.56

265.6

10.46

Flanged 158.5

6.24

158.5

6.24

326.8

12.87

326.8

12.87

Stilling Well N/A 120.0

4.72 N/A 288.3

11.35

Dimensions - K Housing Conguration (Explosion Proof Integral)

B

C

96.0

3.78

116.7

4.59

A LENGTH

(PER MODEL NUMBER)

19.1

0.75

(INACTIVE SHEATH ONLY)

D

INACTIVE SHEATH LENGTH

(PER MODEL NUMBER)

3/4 NPTF

ELECTRICAL CONNECTION

PROCESS

CONNECTION

SEE TABLE

1

1

Linear = mm/inches

Drawing 0390654

Dimensions are for reference only.

Contact the factory for certified drawings

for a particular model number.

SENSOR STYLE D

BARE 12.7

0.50

SHEATH 15.9

0.63

BARE WITH

STILLING WELL

26.7

1.05

SHEATH WITH

STILLING WELL

26.7

1.05

CABLE 7.90

0.31

INACTIVE SHEATH 15.9

0.63

NOTES:

1. DIMENSION APPROXIMATE AND BASED

ON A FIVE THREAD ENGAGEMENT.

1

Form 759 (04.16) SOR Inc.

13/16

54.0

2.13

31.8

1.25

27.0

1.06

SEE DETAIL A

U

AL CABLE PROBE DETAIL

3/4-16 UNF-

Dimensions - K Housing Conguration (Explosion Proof Integral)

Dual Rigid Probe Detail

50.8

2.00

31.8

1.25 28.4

1.12

SEE DETAIL A

DUAL CABLE PROBE DETAIL

DUAL RIGID PROBE DETAIL

MINIMUM CLEARANCE HOLE

FOR INSTALLATION

54.9

2.16

36.5

1.44

22.2

0.88

D

3/4-16 UNF-2B X 11.1

0.44

Linear = mm/inches

Drawing 0390654

Linear = mm/inches

Drawing 0390654

Dual Cable Probe Detail

Dimensions are for

reference only.

Contact the factory

for certified drawings

for a particular model

number.

14/16

Form 759 (04.16) SOR Inc.

Sample Nameplates

Location of Product

Model Identification

Location of

Serial Number

(First Two Numbers

Indicate Year of

Manufacture)

General Information for ATEX Certied Models

Location of ATEX

Listing Information

Drawing 8924119

Drawing 0720527

Manufacturer’s

Registered

Trademark

Manufacturer’s

Registered

Trademark

Form 759 (04.16) SOR Inc.

15/16

Declaration of Conformity

For ATEX Certied Models

Form 1384 (04.16) ©SOR Inc.

Product

Manufacturer

Date of Issue

We declare that the above

products conform to

the following specifications

and directives

Carries the marking

Reference document

ATEX Notified Body

Person responsible

2 Wire RF Admittance Transmitter Model 651

SOR Inc.

14685 West 105

th

Street

Lenexa, Kansas 66215-2003

United States of America

April 20, 2016

ATEX Directive (2014/34/EU) Equipment Intended for

use in Potentially Explosive Atmospheres

IEC 60079-0: 2011 IEC 60079-11: 2011

EN 60079-11: 2012

II 2G Ex ib IIB T4 Gb

(-40°C Ta +80°C)

EC-Type Examination Certificate

Baseefa 12ATEX0084X

IECEx BAS 05.0054X Issued August 16, 2005

Baseefa Ltd. (Notified Body No. 1180)

Rockhead Business Park, Staden Lane,

Buxton, Derbyshire SK17 9RZ

United Kingdom

Baseefa Customer Reference No. 1021

Michael J. Bequette (VP of Engineering)

14685 West 105th Street, Lenexa, KS 66215-2003

s53!s&!8

Engineered to Order with Off-the-Shelf Speed

EC Declaration

of Conformity

Michael J. Bequette

16/16

Form 759 (04.16) SOR Inc.

14685 West 105th Street, Lenexa, KS 66215

913-888-2630

800-676-6794 USA

Fax 913-888-0767

Registered Quality System to ISO 9001

SORInc.com

Table of contents

Other SOR Switch manuals