SOR GI169 Instruction manual

Form 169 (07.21) ©SOR Inc.

1/12

This instruction provides information for mounting, electrical

connection, process connection, and calibration of SOR®

Temperature Switches.

The SOR Temperature Switch consists of a pressure switch

with a sealed temperature sensing bulb attached directly to the

pressure port. (An optional remote temperature sensing bulb may

be connected to the pressure port with an armor-clad capillary.) The

temperature sensing system is pressure filled with a volatile fluid.

Process temperature changes cause proportional vapor pressure

changes in the temperature sensing bulb that act on the diaphragm/

piston assembly to actuate and deactuate a snap-action electrical

switching element at discrete process temperatures. The

instrument’s

behavior is

determined by vapor pressure

(105 range model fill media is inert gas).

NOTE: If you suspect that a product

is defective, contact the factory

or the SOR Representative

in your area for a return

authorization number (RMA).

This product should only be

installed by trained and

competent personnel.

ent at

d

i

scre

t

e process

t

empera

t

ures.

T

h

e

vapor pressure

del fill media is inert gas

)

.

s

pe

ct that a

pr

oduc

t

ntact the factory

resentativ

e

a return

umber

(

RM

A)

.

ould only b

e

ned and

onnel.

Design and

specifications are

subject to change

without notice.

For latest revision, go to

SORInc.com

Table of Contents

Installation.......................................2

SIL Installation ..................................3

Process Connection ............................3

Electrical Connection...........................4

Calibration .......................................5

Special Conditions..............................5

Probe Dimensions ..............................6

ATEX/IECEx Marking Information .............8

Declaration of Conformity ................... 10

Temperature

Switches

Registered Quality System to ISO 9001

General Instructions

2/12

Form 169 (07.21) ©SOR Inc.

Installation

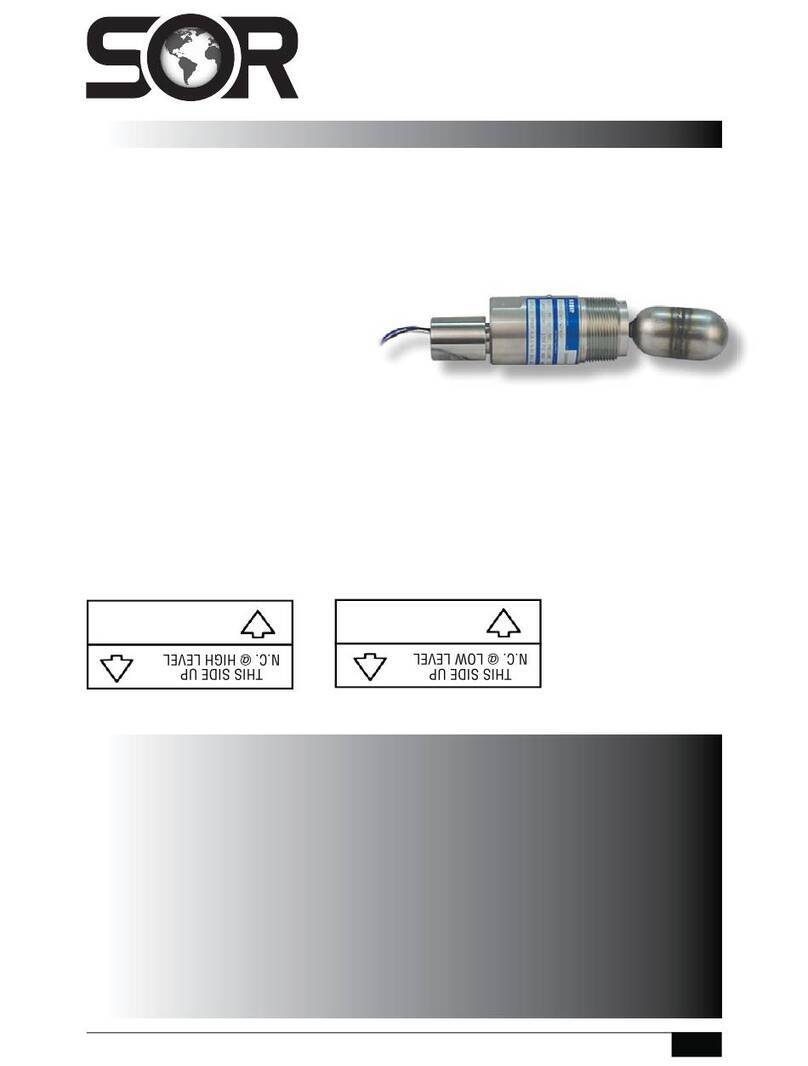

Direct-Mount Probe

The temperature sensing probe is rigidly attached to the instrument’s body/housing.

nCarefully insert the sensing probe into the process through a suitable fitting or

thermowell. The standard process connection is 1/2-inch NPT(M).

oEnsure that ample clearance exists before rotating the instrument housing to make

threaded connection.

pTighten the probe hex fitting with 1-1/8-inch open-end wrench for a leak free fit.

NOTE: A locally customized mounting bracket may be used if more support is desired.

Housings L, S, TA, V1, V2, LC, SC, BA, B3, B4, B5 and B6 are not recommended for direct

mount where vibration is expected. These housings should be securely mounted to a at

surface (bulkhead or panel rack) or pipe stanchion.

Remote-Mount Probe — Capillary

nSecure the housing-mounting pad to bulkhead, panel rack or pipe stanchion with

suitable 1/4-inch (6.35 mm) bolts.

oMounting by electrical conduit connection is NOT recommended.

p

Suggested mounting orientation is electrical conduit connection at 3 or 9 o’clock

and sensing body at 6 o’clock. However, the device is not position sensitive and

may be mounted in any position. If a breather drain is installed, it must be

oriented at 6 o’clock (pointing down) so condensation will drain. It must be kept

clear of paint and foreign matter.

q

Carefully insert the sensing probe into the process through a suitable fitting or

thermowell. Adjust the desired insertion length. Tighten the probe hex fitting with

a 7/8” open-end wrench. Tighten 9/16” hex nut to fingertight. Then hold the 7/8”

fitting with a wrench and tighten the 9/16” hex nut an additional 1-1/4 turns from

finger tight. Avoid sharp bends in capillary.

When mounting to an irregular or uneven surface, install rubber washers on

bolts between the housing and mounting surface (except for high vibration

applications) to prevent deformation of housing, which could change relative

positions of internal parts and affect calibration or render device inoperative.

Form 169 (07.21) ©SOR Inc.

3/12

Process Connection

The temperature sensing probe is 300 series stainless steel. If the process is

compatible, it may be directly inserted into the process without the use of a thermowell.

Best results are obtained when the probe is completely immersed in the process.

A thermowell increases response time (lag). A thermowell filled with thermal transfer

media reduces lag.

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure switches have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration. Form 1538 (03.12) ©2012 SOR Inc.

4/12

Form 169 (07.21) ©SOR Inc.

Electrical Connection

When making electrical connections, use care to apply minimal strain to the electrical

switching element. Refer to wiring schematic below for terminal and wire codes.

Ensure that wiring conforms to all applicable local and national electrical codes and

install unit(s) according to relevant national and local safety codes.

The Switching Element Assembly has been precisely positioned in the

housing at the factory for optimum performance. Any inadvertent movement

or replacement in the eld will degrade performance and could render the

device inoperative, unless factory authorized procedures are followed.

Housing Type Conduit

Connection

Contact

Termination

Contact

Identication

Open Bracket None

Screw terminals Stamped on

insulation

Wire leads Color coded and

marked

All others

3/4” NPT(F), M

20 x 1.5 (F), or

1/2” NPT(M)

unless optional

adapter is

specified

Screw terminals Stamped on

insulation

Wire leads Color coded and

marked

Terminal strip Stamped on

insulation

Wiring Schematics

Wiring Lead Code Colors

SPDT

Blue (C)

Black (NO)

Red (NC)

Temperature Green (GND)

DPDT (2-SPDT)

Blue (C)

Black (NO)

Red (NC)

Yellow (C2)

Brown (NO2)

Orange (NC2)

Temperature

NO1 NO2

Green (GND)

Form 169 (07.21) ©SOR Inc.

5/12

The permanently attached cables are to be suitably terminated and protected

from impact and UV light.

To minimize the risk of electrostatic discharge, clean only with a damp cloth.

The switch capsule has an expected life cycle of 1x105, therefore end user shall

ensure that the switch capsule does not exceed the stated life cycle.

Flameproof joints are not intended to be repaired

Special Conditions for Safe Use for ATEX/IECEx Certied

Mini-Hermet Temperature Switches only

Calibration

Disconnect electrical power to the temperature switch.

NOTE:

It is not necessary to disconnect electrical power with the Big Hermet series or models

in B3, B4, B5 and B6 housings provided that only the cover fastened with four captive screws

over Set Point adjustment is removed.

Remove the housing cover (or weathertight cap).

Units in Hazardous Locations – Prior to calibration, make sure that the work

area is declassied before removing the explosion proof cover to calibrate

the unit. Failure to do so could result in severe personal injury or

substantial property damage.

For instruments with 3/4-inch hex set point adjustment:

Use 3/4-inch open-end wrench to turn hex adjusting nut clockwise (in) to increase

set point, and counterclockwise (out) to decrease set point.

Approximate set point can be obtained by sighting across top of adjusting nut to

calibration scale on the housing floor.

If precise set point calibration is required, it will be necessary to use a regulated

thermal bath and suitable continuity tester. Consult factory.

For instruments with dead band adjustment:

Use the fixed dead band procedure (above) to calibrate the desired decreasing

temperature set point. The increasing temperature set point can then be adjusted by

turning the white thumbwheel on the electrical switching element. Setting Ayields the

smallest possible dead band. Setting Fyields the widest possible dead band. Settings

above Emay degrade repeatability.

Do not unthread the adjusting screw more than two threads below the ush

point of housing as calibration could be adversely affected.

For instruments with 1/8” hex Allen wrench set point adjustment under weathertight cap:

Use 1/8” hex Allen wrench to turn adjusting screw to achieve desired set point.

Turn the adjusting screw clockwise (in) to increase set point and counterclockwise

(out) to decrease set point.

A calibration scale is not installed, so external measurement of the process

temperature is necessary. Consult the factory.

6/12

Form 169 (07.21) ©SOR Inc.

See Housing

Dimensions

52.3

2.06

Armored Capillary

300 Series SS

Sensing Bulb

Extension 316 SS

1/2” NPT (M)

Temperature Sensing Bulb

347 SS for Range 105

316 SS For all Others

263.4 Max

10.37

308.3

12.06

Approximate Range of Adjustment

Remote Mount

Probe Dimensions

Linear = mm/inches

Drawings are for reference only. Contact the factory for certified drawings for a

particular model number.

For “V” Series, see

Housing Dimensions

For All Others, subtract .29

from Housing Dimensions

12.7

.50

1/2” NPT (M)

22.6

.89

Sensing Bulb 316 SS

Direct Mount

Linear = mm/inches

Form 169 (07.21) ©SOR Inc.

7/12

Feature

Range Probe 201 203 205 207 209

AAll m NA 1.8 3.0 4.5 6.0

ft NA 6.0 10.0 15.0 20.0

B

*235,

125,

115

mm 105.7 112.0 124.7 162.8 194.6

in. 4.16 4.41 4.91 6.41 7.66

105 mm - 148.3 148.3 148.3 148.3

in. - 5.84 5.84 5.84 5.84

B with

NB opt.

*235,

125

mm 107.2 112.0 112.0 112.0 112.0

in. 4.22 4.41 4.41 4.41 4.41

C

*235,

125,

115

mm 128.3 135 to 396 147 to 409 185 to 447 216 to 480

in. 5.05 5.3 to 15.6 5.8 to 16.1 7.3 to 17.6 8.5 to 18.9

105 mm - 170 to 433 170 to 433 170 to 433 170 to 433

in. - 6.7 to 17.1 6.7 to 17.1 6.7 to 17.1 6.7 to 17.1

D dia.

*235,

125,

115

mm 9.7 9.7 9.7 9.7 9.7

in. 0.38 0.38 0.38 0.38 0.38

105 mm - 16.0 16.0 16.0 16.0

in. - 0.63 0.63 0.63 0.63

*235 range has same dimensions as the discontinued 135 range.

8/12

Form 169 (07.21) ©SOR Inc.

Drawing 0720044

Manufacturer’s

Registered

Trademark

ATEX/IEXEx

Listing

Information

Product

Model

Identification

Serial Number

(First Two

Numbers

Indicate

Year of

Manufacture)

NOTE: The unit conforms to the requirements of clause 6.3.12, EN 60079-11: 2007. The unit

is capable of withstanding a 500 Vrms isolation test between circuit and enclosure.

ATEX/IECEx Marking Information

For Mini-Hermet ATEX/IEXEx Certied Models

For R-Series ATEX/IEXEx Certied Models

8304108

Serial Number

(First Two Numbers Indicate

Year of Manufacture)

Manufacturer’s

Registered Trademark

ATEX/IECEx Listing

Information

Thread Form

Information

Product Model

Identification

Drawing 8304108

Form 169 (07.21) ©SOR Inc.

9/12

For ATEX/IECEx Certied Models

Declaration of Conformity

Form 1382 (06.20) ©SOR Inc.

14685 West 105th Street, Lenexa, KS 66215-2003

913-888-2630 • 800-676-6794 USA • 913-888-0767 FAX

Engineered to Order with Off-the-Shelf Speed

EU Declaration

of Conformity

A Mini Hermet Pressure or Temperature Switch

SOR Inc.

14685 West 105

th

Street

Lenexa, Kansas 66215-2003

United States of America

June 18, 2020

ATEX Directive (2014/34/EU) Equipment Intended

for use in Potentially Explosive Atmospheres

EN 60079-0:2012 + A11:2013 IEC 60079-0:2011

EN 60079-1:2014 IEC 60079-1:2014-06

II 2 G Ex db IIC T6/T5 Gb

T6 (-40°C < Ta < +60°C)

T5

(-40°C < Ta < +75°C)

EC-Type Examination Certificate

Baseefa03ATEX0582X Issued October 31, 2003

IECEx BAS 15.0047X Issued June 1, 2016

SGS Fimko Oy (Notified Body No. 0598)

Takomotie 8

Helsinki, 00380

Finland

Michael J. Bequette (VP of Engineering)

Michael J. Bequette

Product

Manufacturer

Place of Issue

Date of Issue

We declare under our sole

responsibility that the

above products conform to

the following specifications

and directives

Carries the marking

Reference document

ATEX Notified Body

Person responsible

10/12

Form 169 (07.21) ©SOR Inc.

Declaration of Conformity

For ATEX/IECEx Certied Models

R Series Pressure Switches

SOR Inc.

14685 West 105th Street

Lenexa, Kansas 66215-2003

United States of America

June 18, 2020

ATEX Directive (2014/34/EU) Equipment Intended for use

in Potentially Explosive Atmospheres

EN 60079-0:2012 + A11:2013 IEC 60079-0:2011

EN 60079-11:2012 IEC 60079-11:2011

II 2 G Ex ia IIC T6...T4 Gb

T6

(-40°CTa +75°C)

T5

(-40°CTa +90°C)

T4

(-40°CTa +125°C)

EC-Type Examination Certificate

Baseefa11ATEX0125 Issued February 16, 2012

IECEx BAS 15.0150 Issued April 19, 2016

SGS Fimko Oy (Notified Body No. 0598)

Takomotie 8

Helsinki, 00380

Finland

Michael J. Bequette (VP of Engineering)

Form 1539 (06.20) SOR Inc.

Product

Manufacturer

Place of Issue

Date of Issue

We declare under our sole

responsibility that the

above products conform to

the following specifications

and directives

Carries the marking

Reference document

ATEX Notified Body

Person responsible

EU Declaration

of Conformity

14685 West 105th Street, Lenexa, KS 66215-2003

913-888-2630 • 800-676-6794 USA • 913-888-0767 FAX

Engineered to Order with Off-the-Shelf Speed

Michael J. Bequette

Form 169 (07.21) ©SOR Inc.

11/12

12/12

Form 169 (07.21) ©SOR Inc.

14685 W. 105th St., Lenexa, KS 66215

913-888-2630

800-676-6794 USA

SORInc.

Registered Quality System to ISO 9001

Table of contents

Other SOR Switch manuals

SOR

SOR 651 K9 RF Instruction manual

SOR

SOR 1510 User manual

SOR

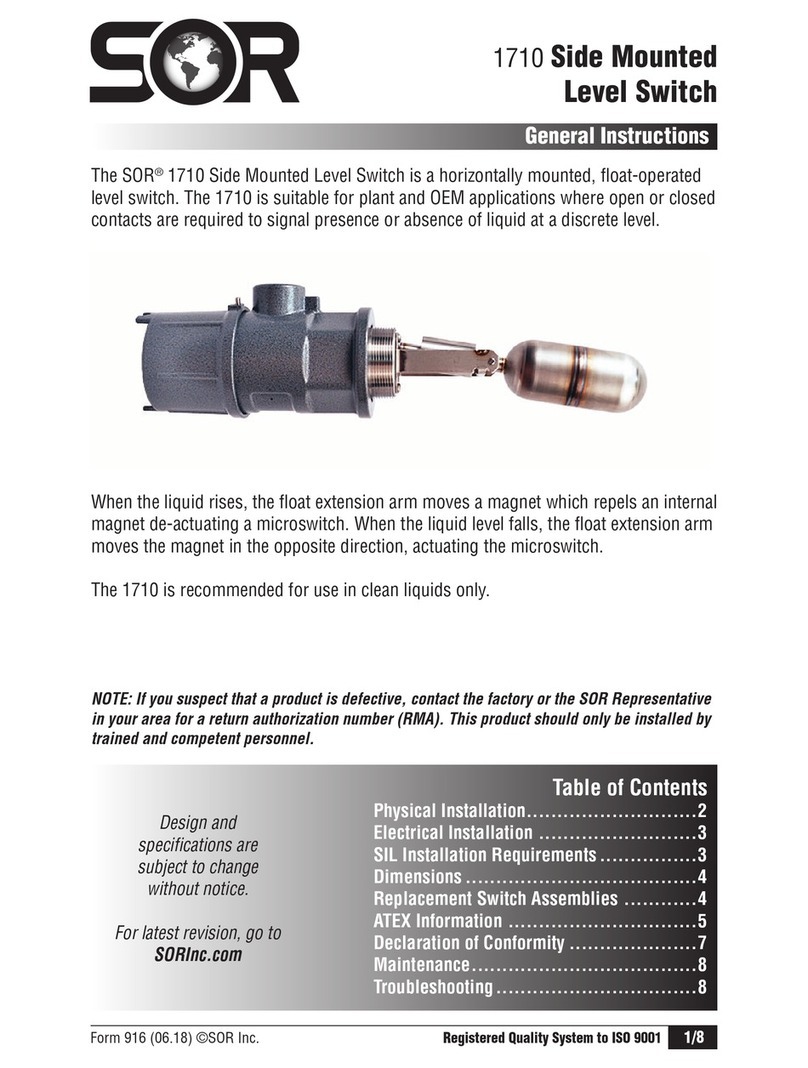

SOR 1710 Instruction manual

SOR

SOR 200 series User manual

SOR

SOR 651 Series Instruction manual

SOR

SOR 1550 Instruction manual

SOR

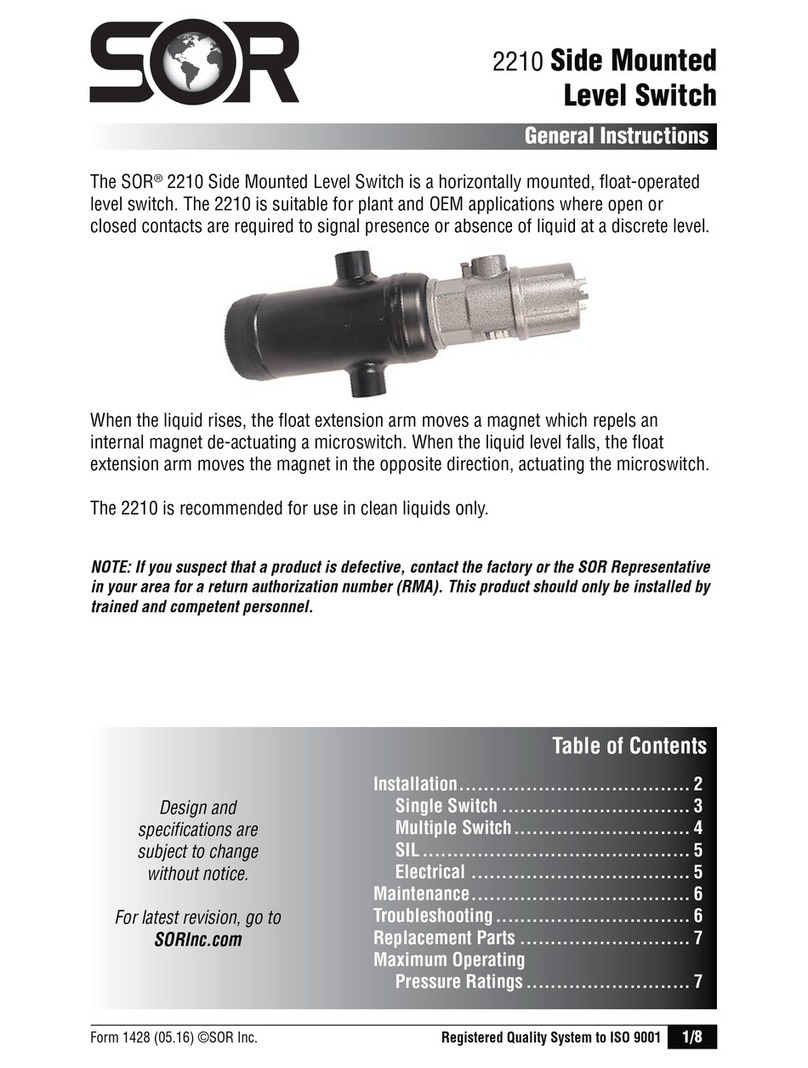

SOR 2210 Instruction manual

SOR

SOR 1530 Instruction manual

SOR

SOR 102 Instruction manual

SOR

SOR T21 Instruction manual