SOR 1710 Instruction manual

Form 916 (06.18) ©SOR Inc.

1/8

1710 Side Mounted

Level Switch

General Instructions

Registered Quality System to ISO 9001

Design and

specifications are

subject to change

without notice.

For latest revision, go to

SORInc.com

Table of Contents

Physical Installation............................2

Electrical Installation ..........................3

SIL Installation Requirements ................3

Dimensions ......................................4

Replacement Switch Assemblies ............4

ATEX Information ...............................5

Declaration of Conformity .....................7

Maintenance.....................................8

Troubleshooting .................................8

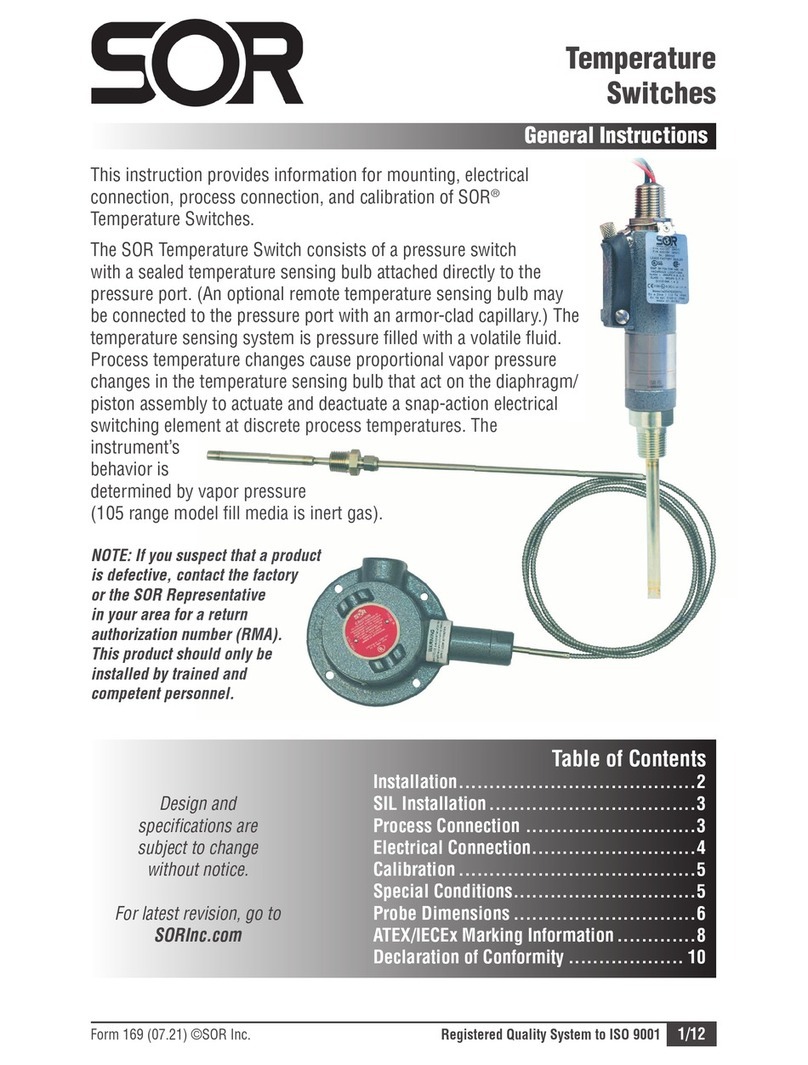

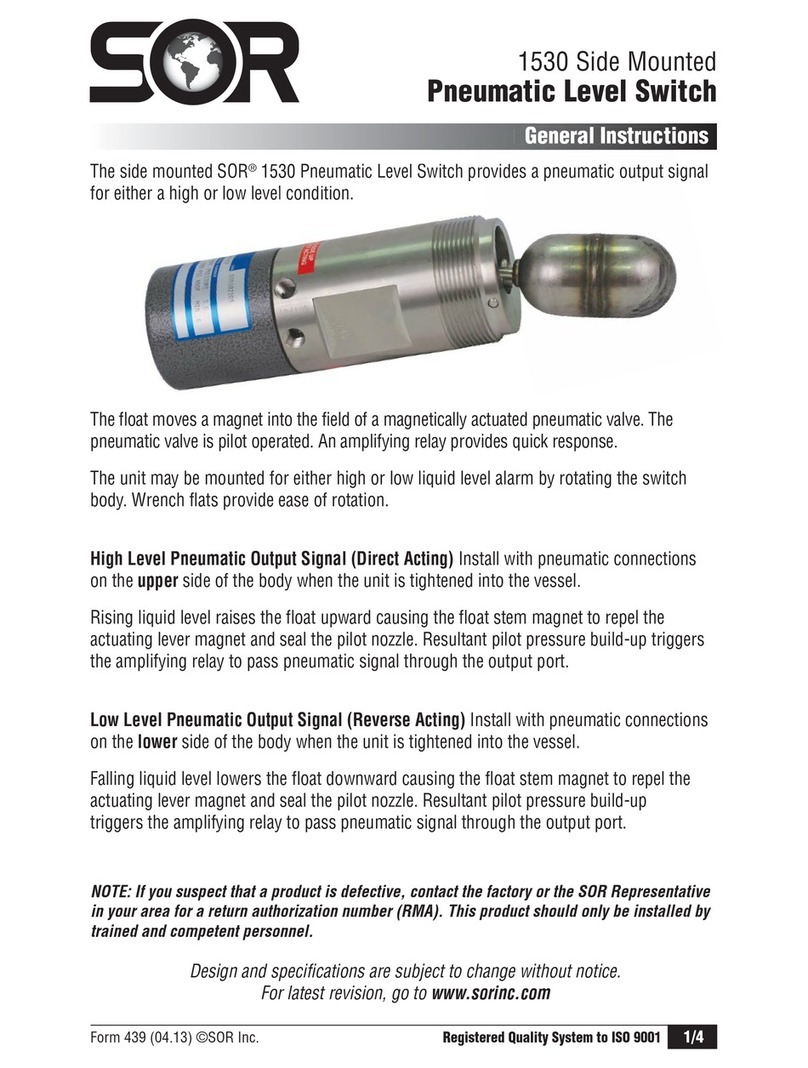

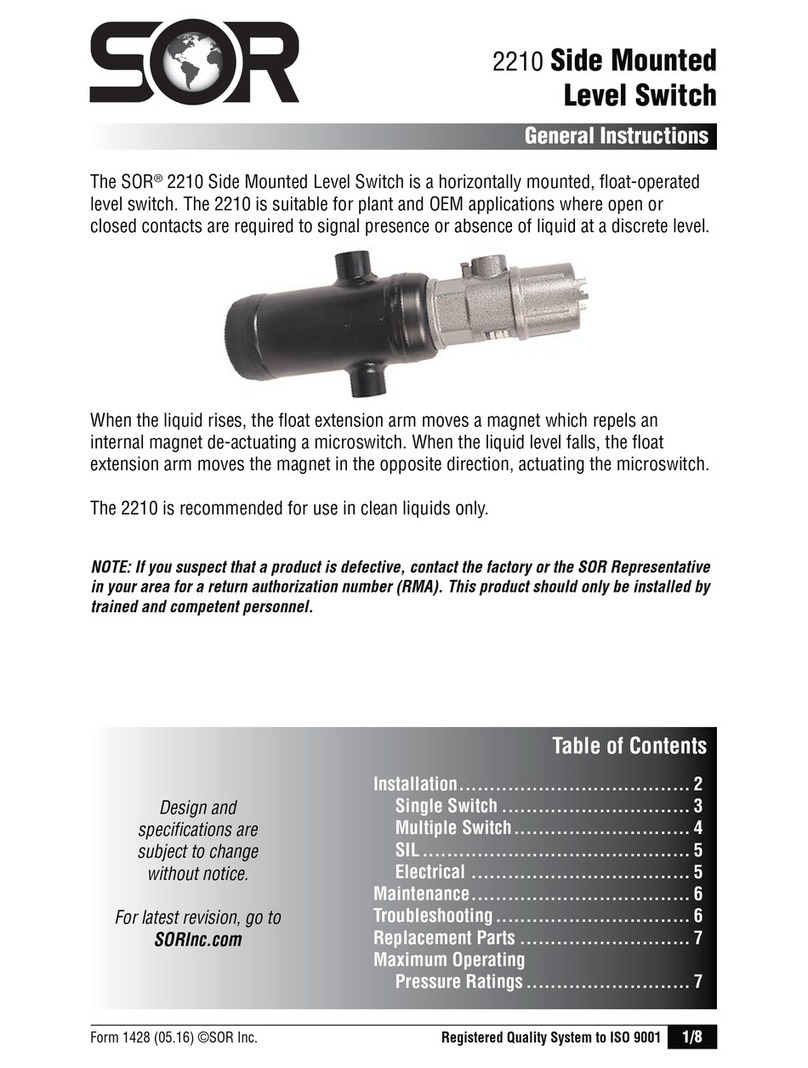

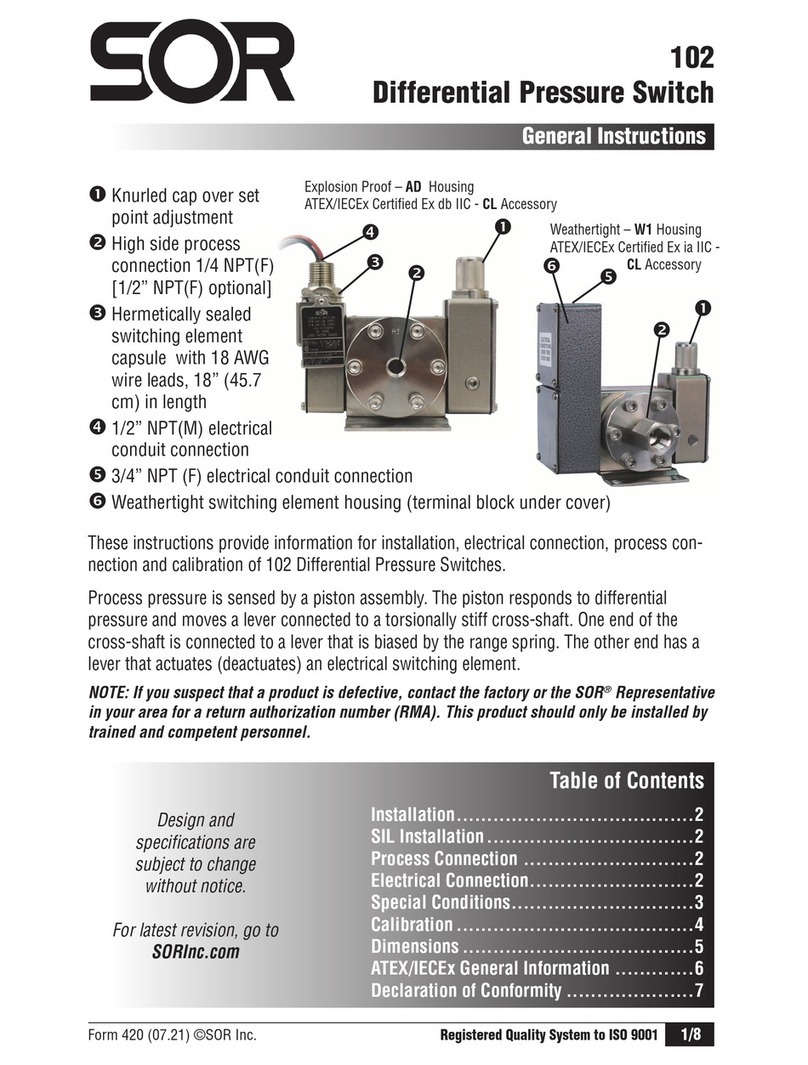

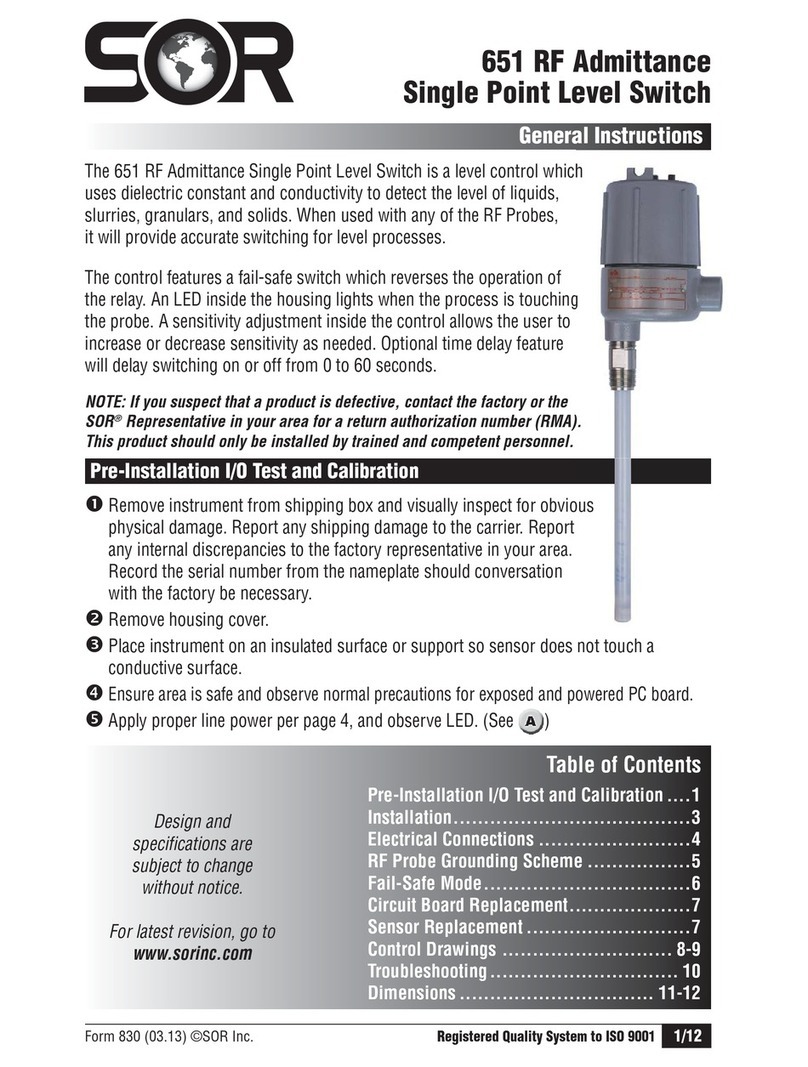

The SOR®1710 Side Mounted Level Switch is a horizontally mounted, float-operated

level switch. The 1710 is suitable for plant and OEM applications where open or closed

contacts are required to signal presence or absence of liquid at a discrete level.

When the liquid rises, the float extension arm moves a magnet which repels an internal

magnet de-actuating a microswitch. When the liquid level falls, the float extension arm

moves the magnet in the opposite direction, actuating the microswitch.

The 1710 is recommended for use in clean liquids only.

NOTE: If you suspect that a product is defective, contact the factory or the SOR Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

2/8

Form 916 (06.18) ©SOR Inc.

Physical Installation

The 1710 must be mounted so that the centerline is within 3º of horizontal. The

conduit connection centerline must be within 3° of vertical and the nameplate at 12

o’clock. Switch actuation cannot be reversed by rotating the unit 180°.

Pipe support hangers or stands should be used where necessary.

All isolation valves must be fully open during service, as restricted valves may

cause erroneous level switching.

Remember external chamber piping should be short, straight and unrestricted.

Pipe must be of a diameter equal to or greater than the process connection

diameter.

Valves and other equipment between the chamber and process must be of the same

diameter or larger than the process connection diameter to allow adequate liquid

flow into the chamber.

Installation shall be carried out by suitably-trained personnel in accordance with the

applicable code of practice e.g. EN 60079-14.

Not following these installation instructions, including pipe and valve

diameter and pipe lengths can affect operation of the switch, including

differential.

Form 916 (06.18) ©SOR Inc.

3/8

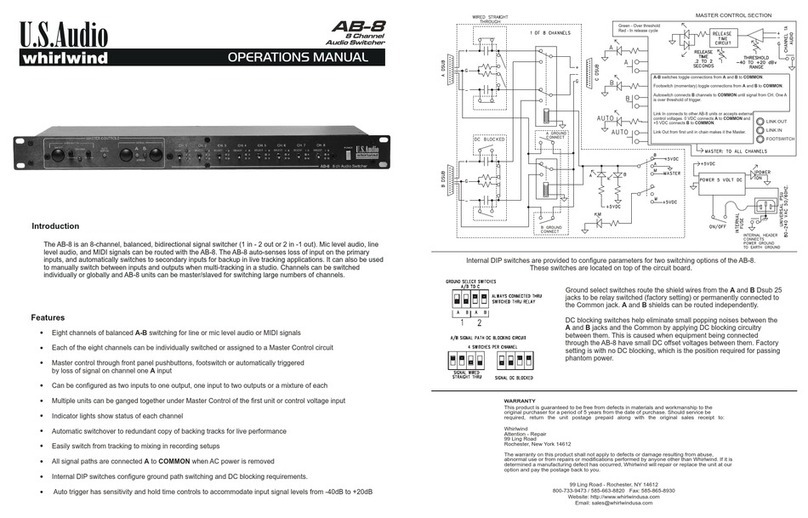

Electrical Installation

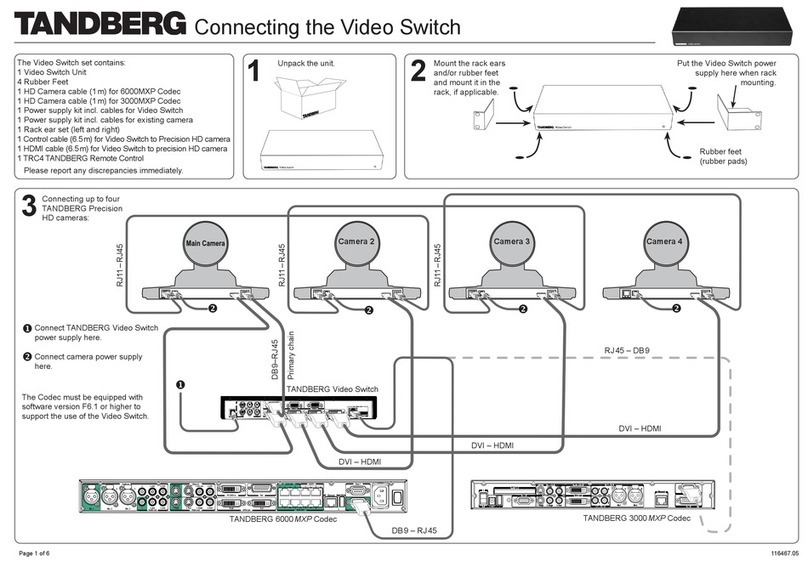

nRemove the end cover to gain acess to the switch mechanism and terminal block.

oFeed the switching wires into the housing through the electrical connection. Wire

to the terminal block(s) as shown in . Select wires which are compatible with

temperature and electrical load required by the application. Keep wire length as

short as possible to prevent damage when cover is installed.

p

Connect the ground wire to the green ground screw located on the outside of the housing.

qReplace the switch cover. Ensure switch cover is screwed on all the way.

rHousing becomes very hot during regular use, high temp. conduit connections are

necessary.

sTest the switch action by varying the liquid level in the chamber or tank.

The cover can become

extremely hot during

operation. Use adequate

protection to prevent

severe personal injury.

LIQUID

LEVEL

LOW

LIQUID

LEVEL

HIGH

SPDT DPDT

WIRING CONTINUITY

1

2

3

4

5

6

SPDT DPDT

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure switches have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration. Form 1538 (03.12) ©2012 SOR Inc.

4/8

Form 916 (06.18) ©SOR Inc.

Dimensions

Linear = mm/inches

Drawing 0390777

Dimensions are for reference only. Contact the factory

for certified drawings for a particular model number.

423.2±14.2

16.66±0.56

423.2±14.2

16.66±0.56

COUNTERBALANCE

FLOAT

Designator

Replacement switch assemblies include: bracket, terminal block, magnet, and

microswitch(es). Choose the appropriate switch mechanism and order it using the

part number shown.

The switch designator is located in the empty position of the sample model number below:

1710A - G2A - C - - H1

Replacement Switch Assemblies

Part Number Description (see back page for specifications)

A 1

380801 SPDT

General Purpose

A 4

380310 DPDT

S 1

380381 SPDT

Hermetically Sealed,

Gold Contacts

S 4

380570 DPDT

NOTES:

112.8

1. ADD MINIMUM CLEARANCE

4.44

REQUIRED TO REMOVE HOUSING COVER

1

Components to be incorporated into or used as replacement parts of the equipment

shall be fitted by suitably-trained personnel in accordance with the manufacturer’s

documentation (or inform of contracting manufacturer or their stockist or specify no

replaceable component parts).

93.7

3.69

10-32 EXTERNAL

GROUND SCREW

ELECTRICAL CONN

1 INCH NPTF

1

112.6

4.43

104.2±11.1

4.10±0.44

79.6

3.13

2 IN NPT(M)

PROCESS CONNECTION

Form 916 (06.18) ©SOR Inc.

5/8

ATEX Information

For ATEX Certied Models

Product Type IdentificationATEX Listing InformationManufacturer’s

Registered Trademark

Location of Product Model

Identification Drawing 0720558

The certification of this equipment relies upon the following material used in its

construction:

ENCLOSURE MATERIAL:

ALUMINUM 356.0-T6 (COVER AND HOUSING, ASTM B 108)

O-RING COMPOUND: SILICONE, PARKED COMPOUND S1224

The equipment may be used with flammable gases and vapours with apparatus groups

IIC or IIB + Hydrogen (see product nameplate) and with temperature class T5 in the

ambient temperature range -40ºC to +80ºC.

The equipment is only certified for use in ambient temperatures in the range -40ºC to

+80ºC and should not be used outside this range.

6/8

Form 916 (06.18) ©SOR Inc.

Special Conditions for Safe Use

To minimize the risk of electrostatic discharge, clean only with a damp cloth.

When the equipment is installed particular precautions must be taken to ensure the

process temperature does not affect the ambient temperature range -40°C to 80°C

of the overall liquid level control switch assembly.

If the equipment is likely to come into contact with aggressive substances, than it

is the responsibility of the end user to take suitable precautions that prevent it from

being adversely affected, thus ensuring that the type of protection provided by the

equipment is not compromised. If in doubt contact the manufacturer.

Flamepath joints are not intended to be repaired.

Process

Connection

Description

Pressure at Listed Temperature in psig (bar)

100°F

(38°C)

200°F

(93°C)

300°F

(149°C)

400°F

(204°C)

500°F

(260°C)

600°F

(316°C)

700°F

(371°C)

G2A 2” NPT(M) 1500

(103)

1500

(103)

1500

(103)

1500

(103)

1500

(103)

1500

(103)

1500

(103)

G3C

3” 150#

RF Flange

(316SS)

275

(19)

235

(16)

215

(15)

195

(13)

170

(12)

140

(10)

110

(8)

G3D

3” 300#

RF Flange

(316SS)

720

(50)

620

(42)

560

(39)

515

(36)

480

(33)

450

(31)

435

(30)

G4C

4” 150#

RF Flange

(316SS)

275

(19)

235

(16)

215

(15)

195

(13)

170

(12)

140

(10)

110

(8)

G4D

4” 300#

RF Flange

(316SS)

720

(50)

620

(42)

560

(39)

515

(36)

480

(33)

450

(31)

430

(30)

Maximum Operating Pressure Ratings

Chamber

Designator

Description

Pressure at Listed Temperature in psig (bar)

100°F

(38°C)

200°F

(93°C)

300°F

(149°C)

400°F

(204°C)

500°F

(260°C)

600°F

(316°C)

700°F

(371°C)

EE 4” S40

Carbon Steel

1500

(103)

1500

(103)

1397

(96)

1282

(88)

1196

(82)

1129

(78)

1081

(75)

EG 4” S40

316/316L SS

1435

(99)

1435

(99)

1435

(99)

1435

(99)

1435

(99)

1435

(99)

1378

(95)

With External Chamber

Electrical and Pressure Paramaters

Switch Rating

A 6A, 125/250 VAC

S 1/2A, 28 VDC

Form 916 (06.18) ©SOR Inc.

7/8

Declaration of Conformity

For ATEX Certied Models

Form 1386 (12.17) ©SOR Inc.

Product

Manufacturer

Date of Issue

We declare that the above

products conform to

the following specifications

and directives

Carries the marking

Reference document

ATEX Notified Body

Person responsible

Michael J. Bequette

14685 West 105th Street, Lenexa, KS 66215-2003

s53!s&!8

Engineered to Order with Off-the-Shelf Speed

EC Declaration

of Conformity

1710 Side Mounted Level Switch

SOR Inc.

14685 West 105th Street

Lenexa, Kansas 66215-2003

5NITED3TATESOF!MERICA

December 4, 2017

!4%8$IRECTIVE%5%QUIPMENT)NTENDEDFORUSEIN

0OTENTIALLY%XPLOSIVE!TMOSPHERES

%.!)%#

%. )%#

%. )%#

Ex db IIC T5 Gb; Ex tb IIIC T90°C Db;

(Nonchambered); Ex d IIB + H2 T5 Gb;

Ex tb IIIC T90°C Db (Chambered)

Ta=-40°C <Tamb <+80°C

EC-Type Examination Certificate

SIRA 13ATEX1306X

IECEx CSA 13.0024X

)SSUED-ARCH

Baseefa Ltd..OTIlED"ODY.O

2OCKHEAD"USINESS0ARK3TADEN,ANE

"UXTON$ERBYSHIRE3+2:

5NITED+INGDOM

"ASEEFA#USTOMER2EFERENCE.O

-ICHAEL*"EQUETTE60OF%NGINEERING

8/8

Form 916 (06.18) ©SOR Inc.

14685 West 105th Street, Lenexa, KS 66215

913-888-2630

800-676-6794 USA

Fax 913-888-0767

Registered Quality System to ISO 9001

Printed in USA SORInc.com

Maintenance

Troubleshooting

Keep the cover tightly secured to the housing.

Prevent moisture or dirt from entering the housing when the cover is off.

Check all screw terminal connections periodically. Vibration may loosen the screw terminals.

Clean the float and counterweight mechanism periodically to assure continued free movement.

Make no adjustments to the switch mechanism. It is factory calibrated for optimum

performance.

Apply petroleum jelly or anti-seize compounds to cover threads periodically to

prevent seizing.

Inspection and maintenance of this equipment shall be carried out by suitibly-trained

personnel in accordance with the applicable code of practice e.g. EN 60079-17.

Repair of this equipment (as applicable) shall be carried out by suitably-trained

personnel in accordance with the applicable code of practice e.g. EN 60079-19.

Do not remove the cover when the unit is energized.

Symptom Probable Cause

The float is in the actuated

position but the switch

does not actuate.

a. The terminal block is wired incorrectly. Check wiring.

b. The unit is installed upside-down. Rotate housing so

that the nameplate faces up.

c. The switch is damaged. Contact the factory.

The float is in the de-actuated position

but the switch remains actuated.

a. The terminal block is wired incorrectly. Check wiring.

b. The switch is damaged. Contact the factory.

The control will not function when

installed but operates when

removed from process connection.

a. Float travel is inadequate. Check for internal

vessel obstructions. See Mounting Requirements.

Liquid is in the vessel at the actuation

level but the unit does not respond.

a. The float pivot pin is bound up or dirty. Clean the

float pivot pin.

b. The unit is installed upside-down. Rotate housing

so that the nameplate faces up.

c. The specific gravity of the liquid is not sufficient

to lift the float.

d.

The float is leaky or collapsed. Contact the factory.

Table of contents

Other SOR Switch manuals