Sorotec Basic Line User manual

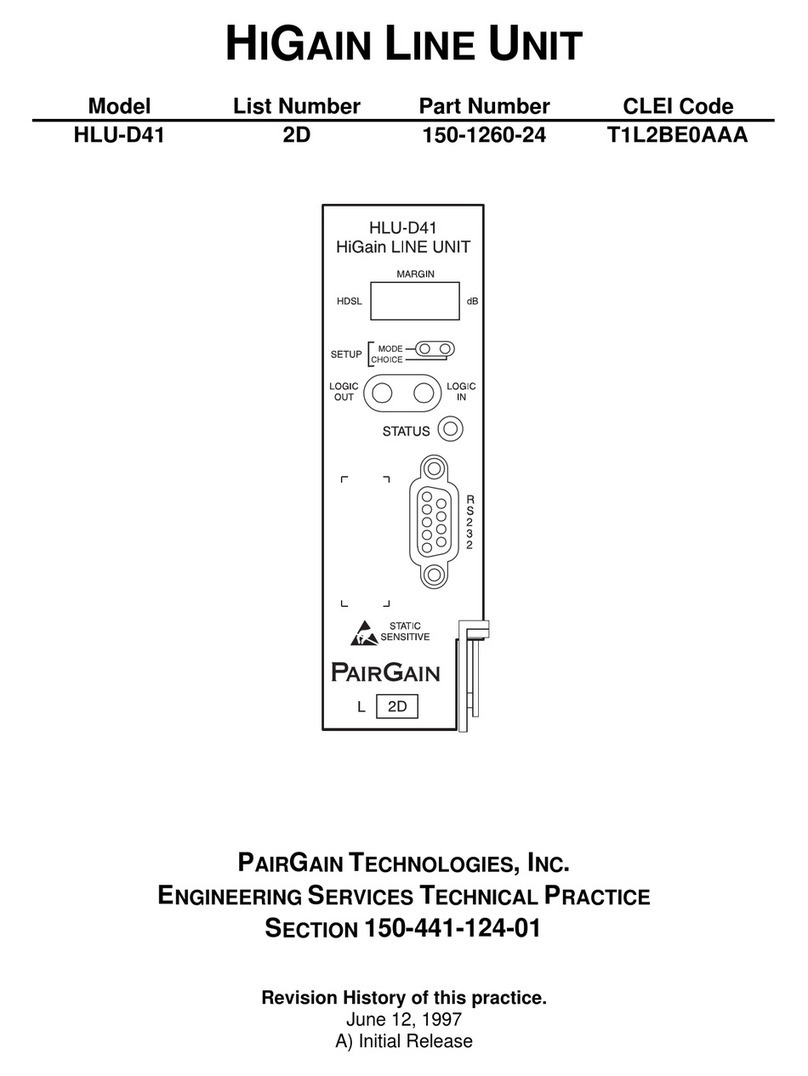

Other Sorotec Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

MKS

MKS Ophir FluxGage user manual

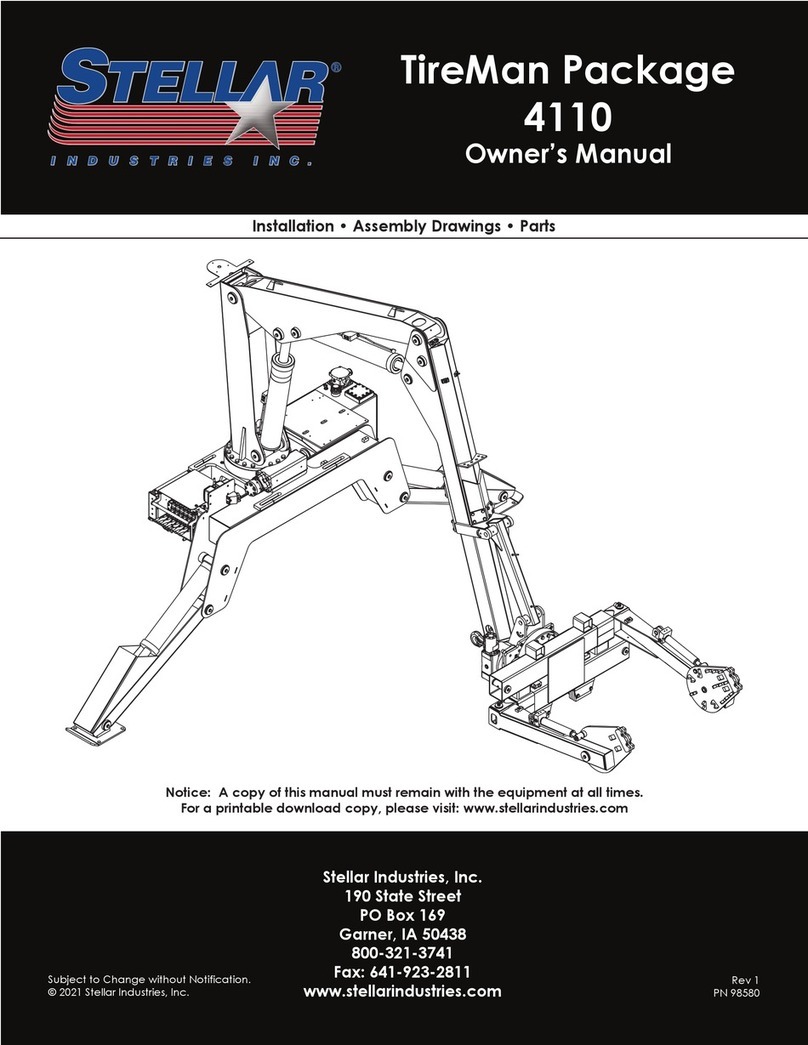

stellar labs

stellar labs TireMan 4110 owner's manual

Reich Kupplungen

Reich Kupplungen ARCUSAFLEX AC F2 Series English translation of the original German Operating Manual

MoldMaker

MoldMaker MMC-11 user manual

KTR-Group

KTR-Group CLAMPEX KTR 125 Operating & assembly instructions

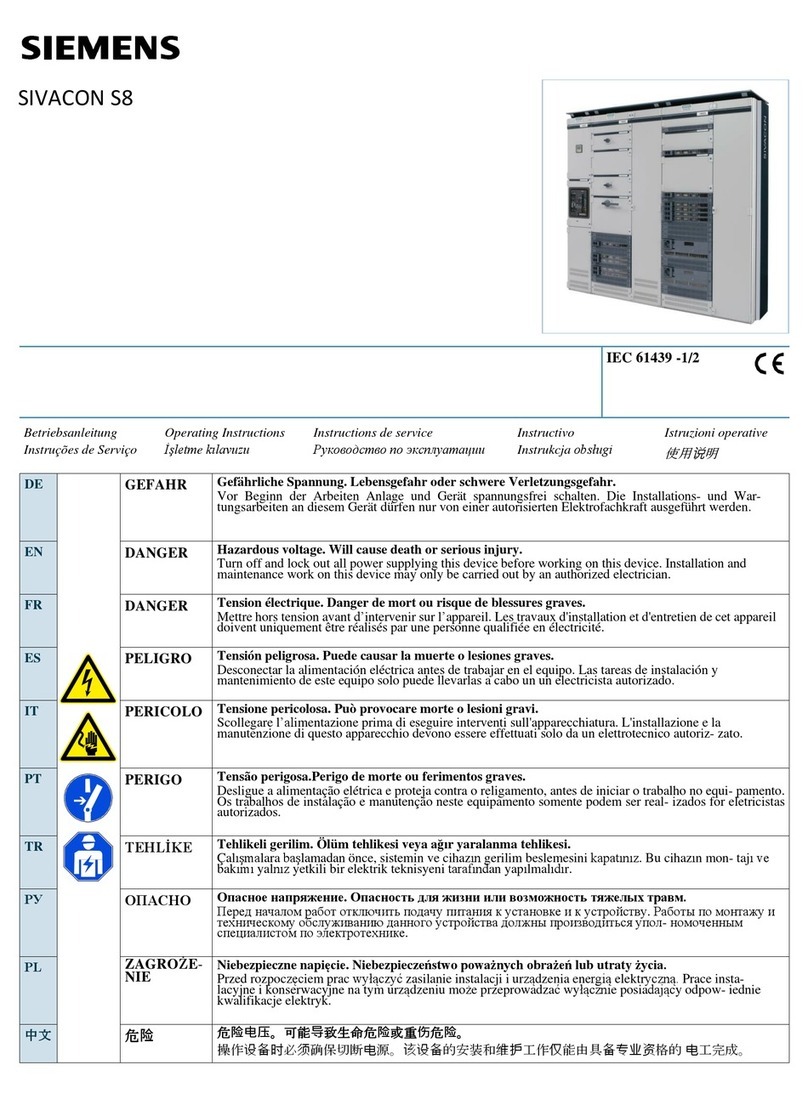

Siemens

Siemens Sivacon S8 operating instructions

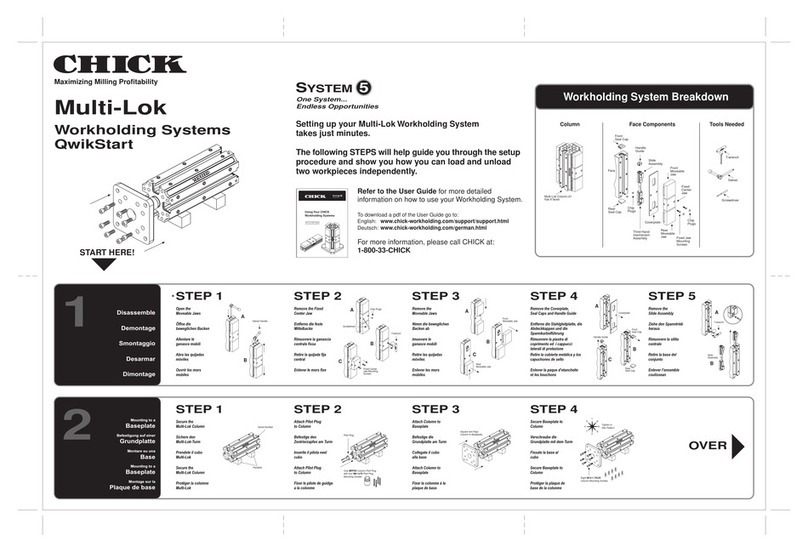

CHICK

CHICK Multi-Lok quick start guide

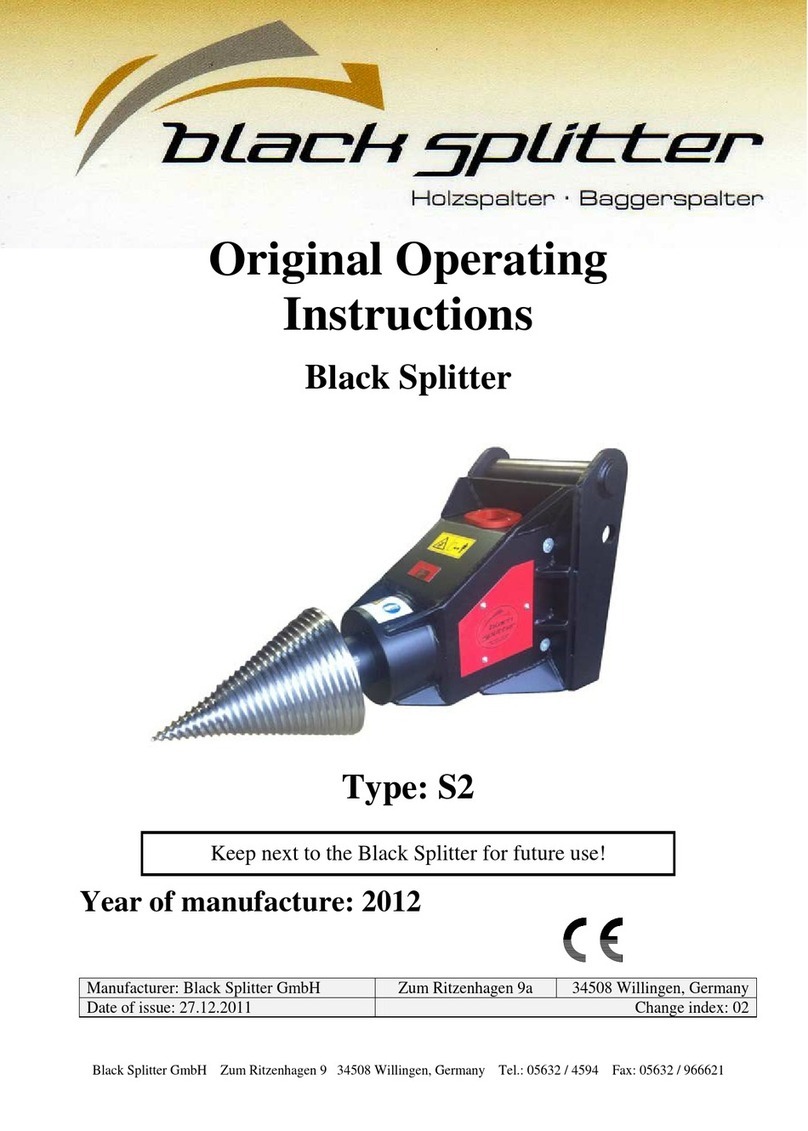

Black Splitter

Black Splitter S2 Original operating instructions

Wintriss

Wintriss SmartPAC PRO installation manual

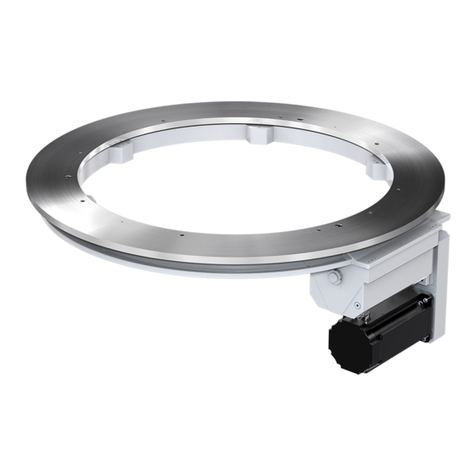

Kitagawa

Kitagawa TT150AE-04 instruction manual

SCHUNK

SCHUNK TENDO Turn DKE Assembly and operating manual

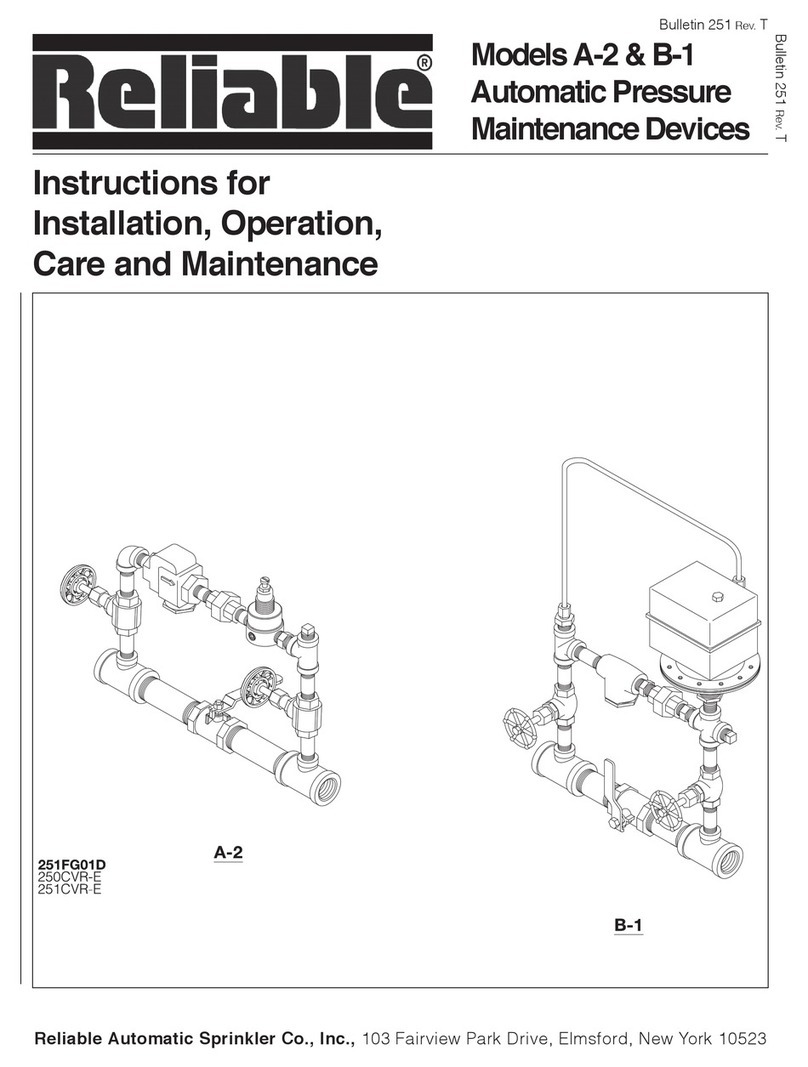

Reliable

Reliable A-2 Instructions for installation, operation care and maintenance