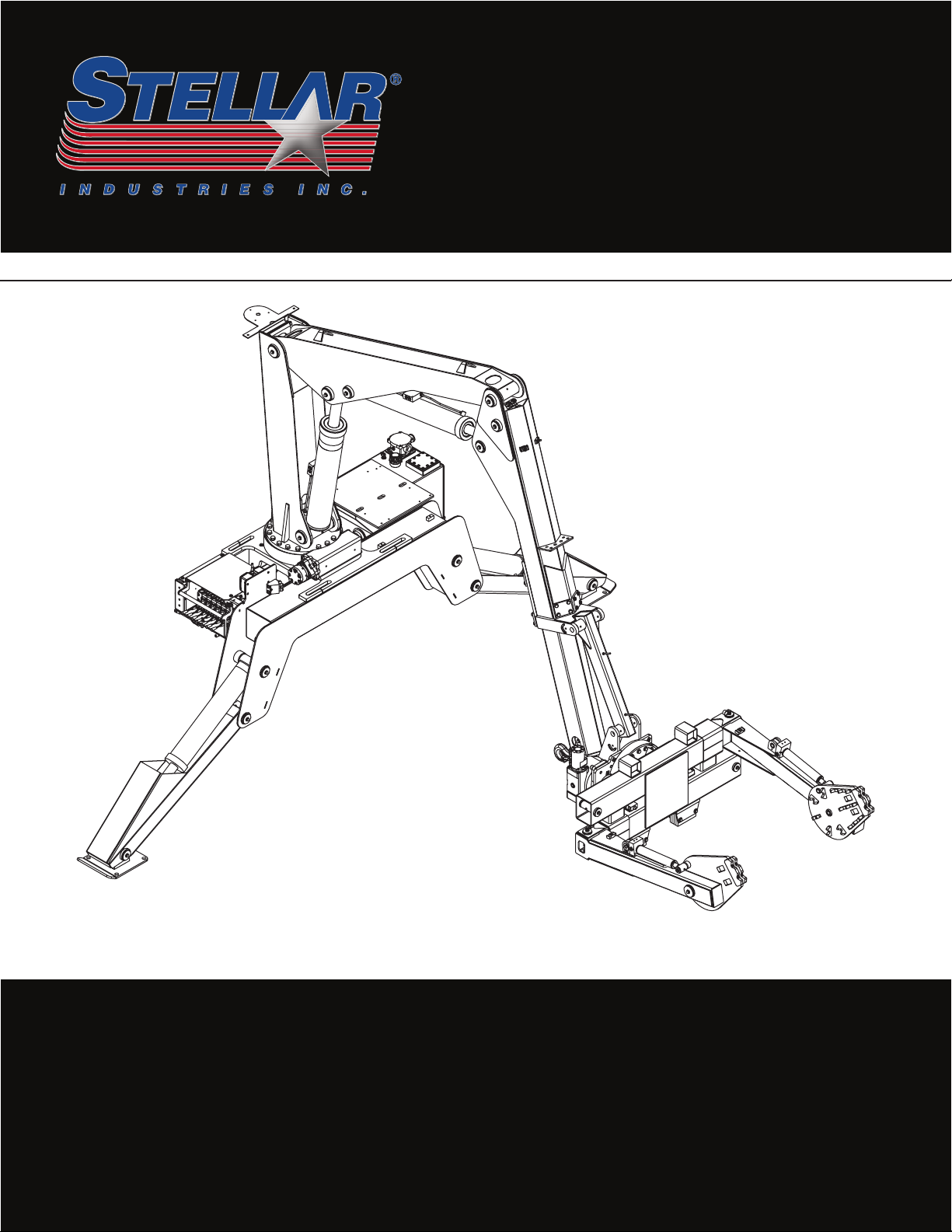

Stellar®TMP4110 Owner’s Manual | Page iii

Table of Contents

Introduction ............................................................................................................................................iv

Chapter 1 - Specifications......................................................................................................................... 1

Model TM4110 Capacity ....................................................................................................................... 1

Model TM4110 Specifications ............................................................................................................... 1

TM4110 Dimensional Layout.................................................................................................................. 2

Chapter 2 - Installation .............................................................................................................................. 3

General Installation................................................................................................................................ 3

Installer Notice ..................................................................................................................................... 3

Torque Data Chart .............................................................................................................................. 4

Installation Overview .......................................................................................................................... 5

Mounting Kit Drawing ......................................................................................................................... 5

Hydraulic Installation.............................................................................................................................. 6

Hydraulic Pressure Settings.................................................................................................................... 7

Face Seal/O-Ring Size Chart................................................................................................................. 7

Main Hydraulic Kit - PN 61547 ............................................................................................................... 8

TireMan Hydraulic Kit - PN 67411 ........................................................................................................ 10

Control Kit - PN 92663........................................................................................................................... 12

Grease Kit - PN 61641........................................................................................................................... 13

Main Decal Placement - PN 98660 .................................................................................................... 14

TireMan Decal Placement - PN 35432 ............................................................................................... 15

Chapter 3 - Assembly Drawings ............................................................................................................. 17

Base Assembly - PN 94131 ................................................................................................................... 17

Base Assembly Rear Mount Australia Stop - PN 94132..................................................................... 18

Stabilizer Assembly - PN 61089 ............................................................................................................ 19

Gear Bearing - PN 63815 ..................................................................................................................... 20

Valve Bank - PN 51658 ......................................................................................................................... 21

Outrigger Valve Bank - PN 61642........................................................................................................ 22

Valve Assembly - PN 66286.................................................................................................................. 23

Mast Assembly - PN 29350................................................................................................................... 24

Main Cylinder Assembly - PN 29352 ................................................................................................... 25

Main Boom Assembly - PN 29354 ....................................................................................................... 26

Outer Cylinder Assembly - PN 29356.................................................................................................. 27

Extension Boom Assembly - PN 61204................................................................................................ 28

Extension Cylinder Assembly - PN 73499............................................................................................ 29

TireMan Assembly - PN 61223 ............................................................................................................. 30

TireMan Assembly (cont.) - PN 61223................................................................................................. 31

TireMan w/Rotation Pads Assembly - PN 61386................................................................................ 32

TireMan w/Rotation Pads Assembly (cont.) - PN 61386................................................................... 33

Mounting Kit - PN 61401....................................................................................................................... 34

Optional Pad Extensions - PN 35434................................................................................................... 35

Optional Pad Extensions - PN 58288................................................................................................... 36

Optional Pad Extensions - PN 81015................................................................................................... 37

Reservoir Assembly - PN 100786.......................................................................................................... 38

Compressor Mounting - PN 64165 ...................................................................................................... 39

Reservoir Assembly - PN 86510............................................................................................................ 40

Radio Transmitter - PN 89149/93084 ................................................................................................... 41

Chapter 4 - Replacement Parts .............................................................................................................. 43