2

1. GENERAL

The counter is used to count the number of cycles of injection molds, stamping tools, dies

or other devices performing cyclic operations.

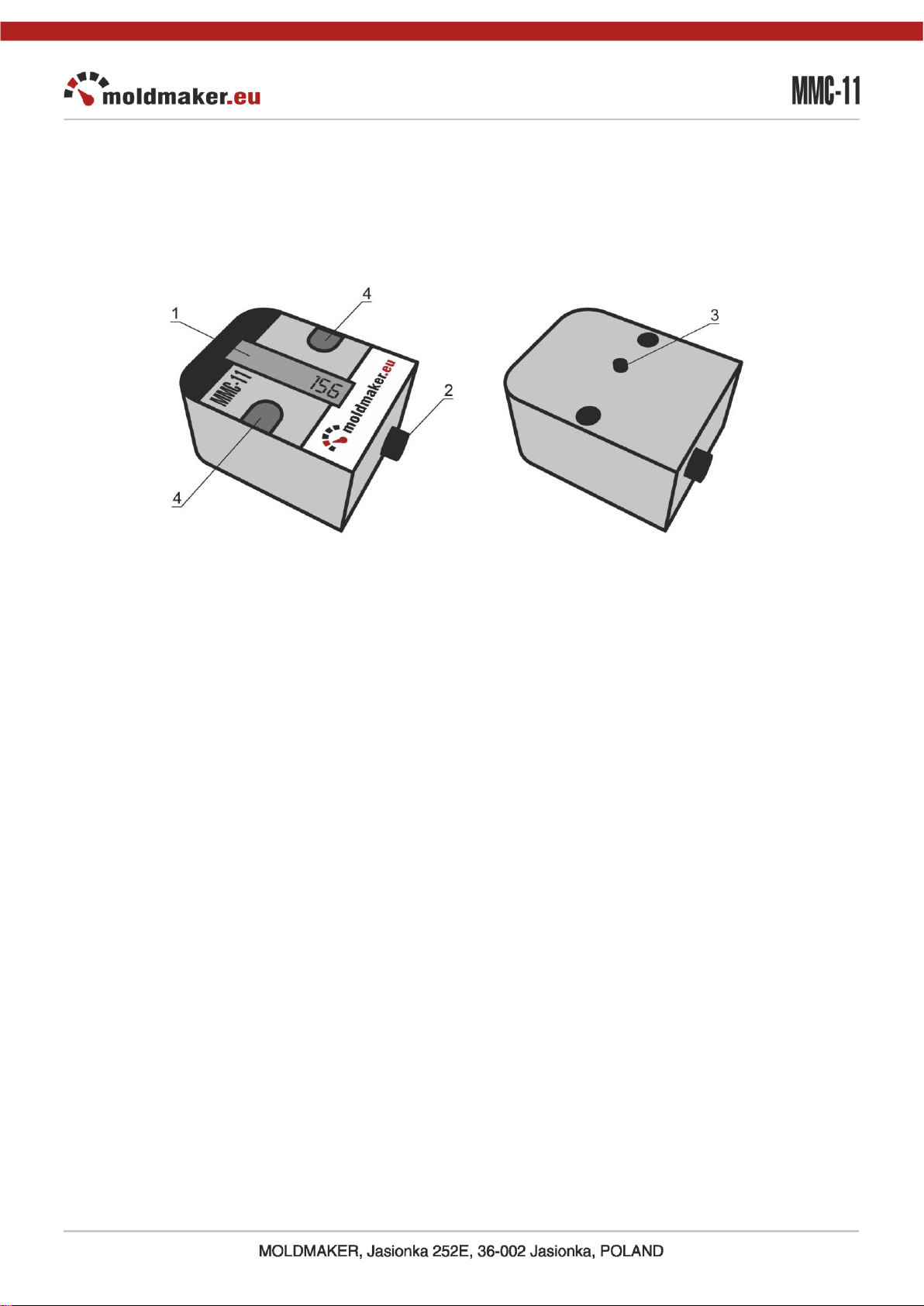

Description of main elements:

1. LCD display

2. Cycle button

3. Disassembly sensor

4. Mounting holes

Techical parameters:

Power supply 3,6V built-in lithium battery.

Bettery lifetime 5 years.

Maximum LCD indication 99 999 999.

Maximum counting value is 4 000 000 000 (available wirelessly only)

Working temperature -20 do +85 °C.

Dimensions: 48x38x25 mm

Mounting screws M4 x 35 allen with cylinder head or No.8-32 0.164".

General informations:

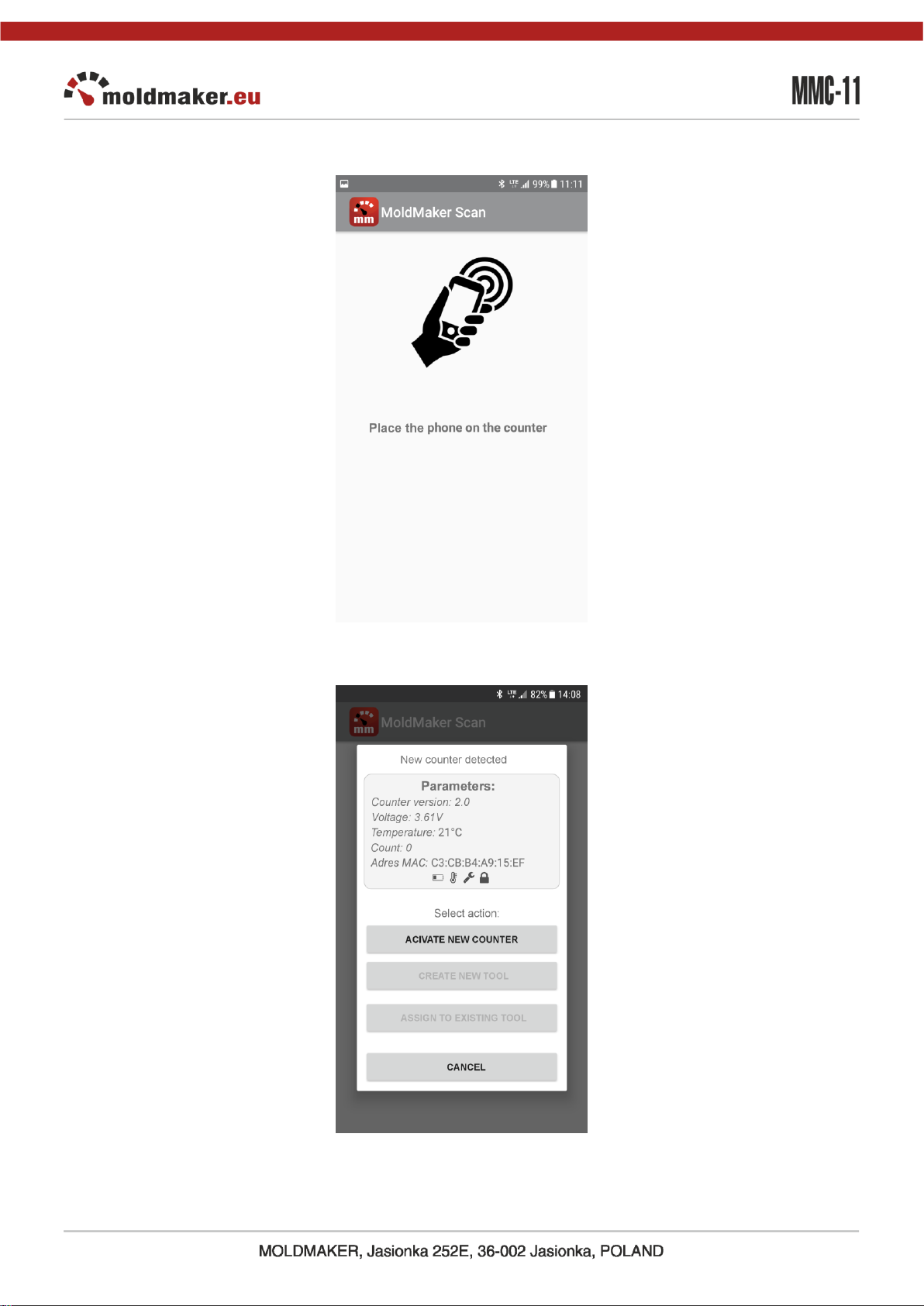

The counter is delivered as inactive. After pressing the main button "Inactive" appears on

the LCD display. Activation can be done using the MoldMaker Scan application, which can

be downloaded from Google Play for Android devices. For more information please follow

this manulal.

Requirements for the MoldMaker Scan application:

android 4.2 or newer

Bluetooth 4.0 LE module

NFC communication interface