Soundoff Signal pinnacle Quick start guide

OWNER’S MANUAL &

INSTALLATION INSTRUCTIONS

EPL9000 9.10

TABLE OF CONTENTS

PAGE CONTENT

3 TECHNICAL SPECIFICATIONS

4 PRE-INSTALLATION

5 PINNACLE BASICS

6 FIXED HEIGHT BRACKETS AND HOOK MOUNTING

7 FIXED HEIGHT BRACKETS PERMANENT MOUNTING

8-10 ADJUSTABLE HEIGHT BRACKETS AND HOOK MOUNTING

10-11 ELECTRICAL INSTALLATION

12-13 BREAKOUT BOX

13 FLASH PATTERNS AND CONNECTOR INSTRUCTIONS

14 CONTROLLER AND WIRE HARNESS INSTRUCTIONS

15 PINNACLE TROUBLESHOOTING

16 REPLACEMENT PARTS

17 PRODUCT MAINTENANCE

BACK WARRANTIES AND POLICIES

Page 2

Technical SPECIFICATIONS

Input Voltage 10-16Vdc

Current Draw (Amps)

Average Peak Power Consumption

(Watts)

Inboard Module (ea): 0.5Amps @ 12.8Vdc 1.0Amps @ 12.8Vdc 6.4

Corner Module (ea): 1.0Amps @ 12.8Vdc 2.0Amps @ 12.8Vdc 12.8

Takedown Module (ea): 0.5Amps @ 12.8Vdc 1.0Amps @ 12.8Vdc 6.4

Alley Light Module (ea): 0.33Amps @ 12.8Vdc 0.65Amps @ 12.8Vdc 4.2

Average = Flashing Peak = 100% Steady ON

Reverse Polarity: Fuse Protected

Load Dump: Protected

Wiring: Power Cable 15ft 10AWG Wires, (+) RED, (-) BLK

Data Cable 15ft RJ-45 Type

Number of LEDs:

Inboard Module (ea) 6 Gen3 LEDs

Corner Module (ea) 12 Gen3 LEDs

Takedown Module (ea) 6 Gen3 LEDs

Alley Light Module (ea) 1 Multi Chip Gen3 LED

Operating Temperature: -40°C to +65°C

Light output:

Blue LED 30 Lumens minimum per LED

Red LED 50 Lumens minimum per LED

White LED 100 Lumens minimum per LED

White Multichip LED 400 Lumens minimum per LED

Amber LED 45 Lumens minimum per LED

Green LED 40 Lumens minimum per LED

Life: 50K+ hours

Optical Distribution:

Inboard Module (ea) 20° Vert. x 90° Horiz. Angle

Corner Module (ea) 20° Vert. x 120° Horiz. Anle

Takedown Module (ea) 20° Beam Angle

Alley Light Module (ea) 20° Beam Angle

Moisture Protection: IP66 sealed construction

Outer Lens: Polycarbonate with UV Protection

Mounting Bolt: n3/16” Stainless / A2

Dimensions:

36” Lightbar 35.4“L x 10.0”W x 2.9“H (end), 2.2”H (interior)

42” Lightbar 41.7“L x 10.0”W x 2.9“H (end), 2.2”H (interior)

48” Lightbar 48.0“L x 10.0”W x 2.9“H (end), 2.2”H (interior)

54” Lightbar 54.3“L x 10.0”W x 2.9“H (end), 2.2”H (interior)

60” Lightbar 60.7“L x 10.0”W x 2.9“H (end), 2.2”H (interior)

72” Lightbar 73.5“L x 10.0”W x 2.9“H (end), 2.2”H (interior)

*Based on configuration see page 12.

Page 3

Unpack box:

1. Remove the light bar and packaging.

2. Save packaging for later shipping.

3. Check components/contents.

4. Please reference this instruction manual for

proper wiring and installation.

Tools Required for Installation:

5/32” Allen Driver

7/16” Socket with ratchet

T-25 Torx Driver

Phillips Head Screwdriver

Electric Drill with #30 (.128 dia.) drill bit

1 1/4” Hole Saw

Components/Contents

Standard Equipment

1- PINNACLE Lightbar

1- Roof Side Cable Grommet (cable specific)

Controller

1- Breakout Box (DSC Option)

1- Wire Harness

Optional Mounting Kits

2- Adjustable Height Mounting Brackets (OR)

2- Fixed Height Mounting Brackets

1- Specific Vehicle Hook w/ Hardware Kit (OR)

1- Specific Mounting Hardware Kit

**Kits will vary with each bar

WARNING - DRILLING ANY HOLES INTO THE LIGHTBAR IS NOT RECOMMENDED! THE

RISK OF DAMAGING INTERNAL COMPONENTS AND THE RESULTING FAILURE OF THE

LIGHTBAR WILL VOID ANY WARRANTY OF THIS PRODUCT.

IMPORTANT NOTICE TO INSTALLER: Make sure to read and understand all instructions and warnings before

proceeding with the installation of this product. Ensure that the manual and any warning cards are delivered to

the end user of this equipment. Proper installation of the lightbar requires the installer to have a thorough

knowledge of automotive electronics, systems, and procedures. Lightbars provide an essential function of an

effective visual warning system. The use of the lightbar does not insure that all drivers can or will abide by or

react to an emergency warning signal, especially at high rates of speeds or long distances. The operator of the

vehicle must never take the right of way for granted and it is the operator’s responsibility to proceed safely.

The effectiveness of the this lightbar is highly dependant on the correct mounting and wiring. The installer

must read and follow the manufacturer’s installation instructions and warnings in the manual. The vehicle

operator should verify daily that the lightbar is securely fastened to the vehicle and properly functioning before

operating vehicle. The lightbar is intended for use by authorized personnel only. It is the user’s responsibility

to ensure they understand and operate the emergency warning devices in compliance with the applicable city,

state and federal laws and regulations. (SoundOff Signal assumes no liability for any loss resulting from the

use of this warning device.)

PRE-INSTALLATION

At anytime during your installation process, feel free to call our technical support line at

1-800-338-7337. Press #4 to skip automated message. You can also visit our website at

Page 4

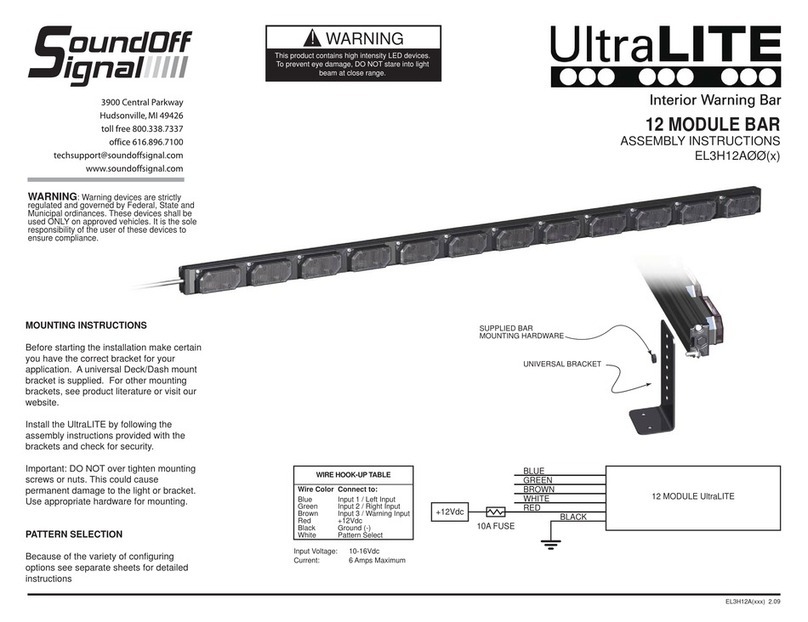

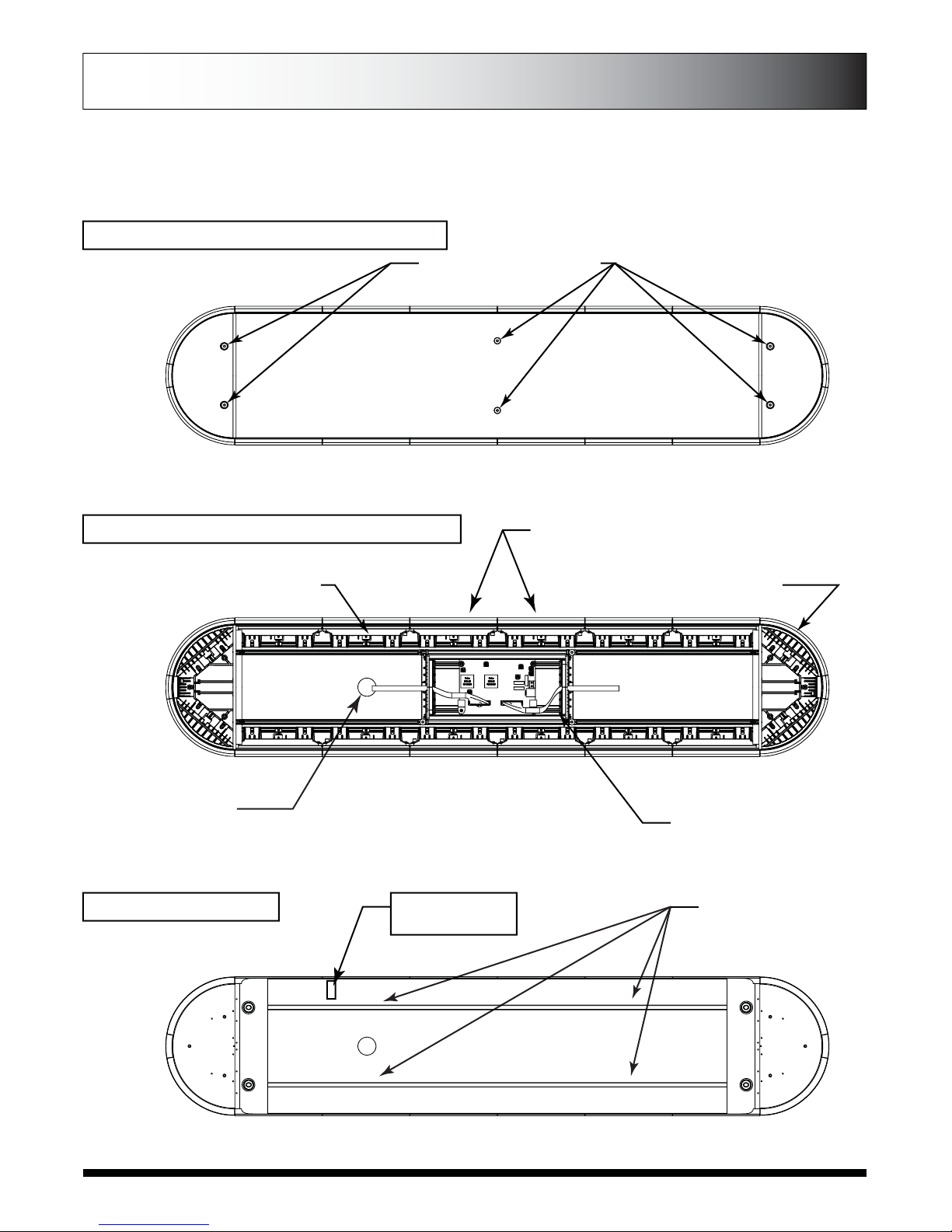

6 TOP COVER SCREWS

FRONT

REAR

MODEL NUMBER

SERIAL NUMBER

This is a basic configuration showing many of the features offered. Your PINNACLE may

have a different configuration. This diagram should only be used as a reference.

PINNACLE BASICS

INBOARD LED MODULES CORNER LED MODULES

WIRE EXIT

TAKE DOWN MODULES

ELECTRICAL ENCLOSURE

CARRIAGE BOLTS

FOR MOUNTING

BRACKETS IN CHANNELS

BOTTOM VIEW

TOP VIEW WITH COVER OFF

TOP VIEW WITH COVER ON

Page 5

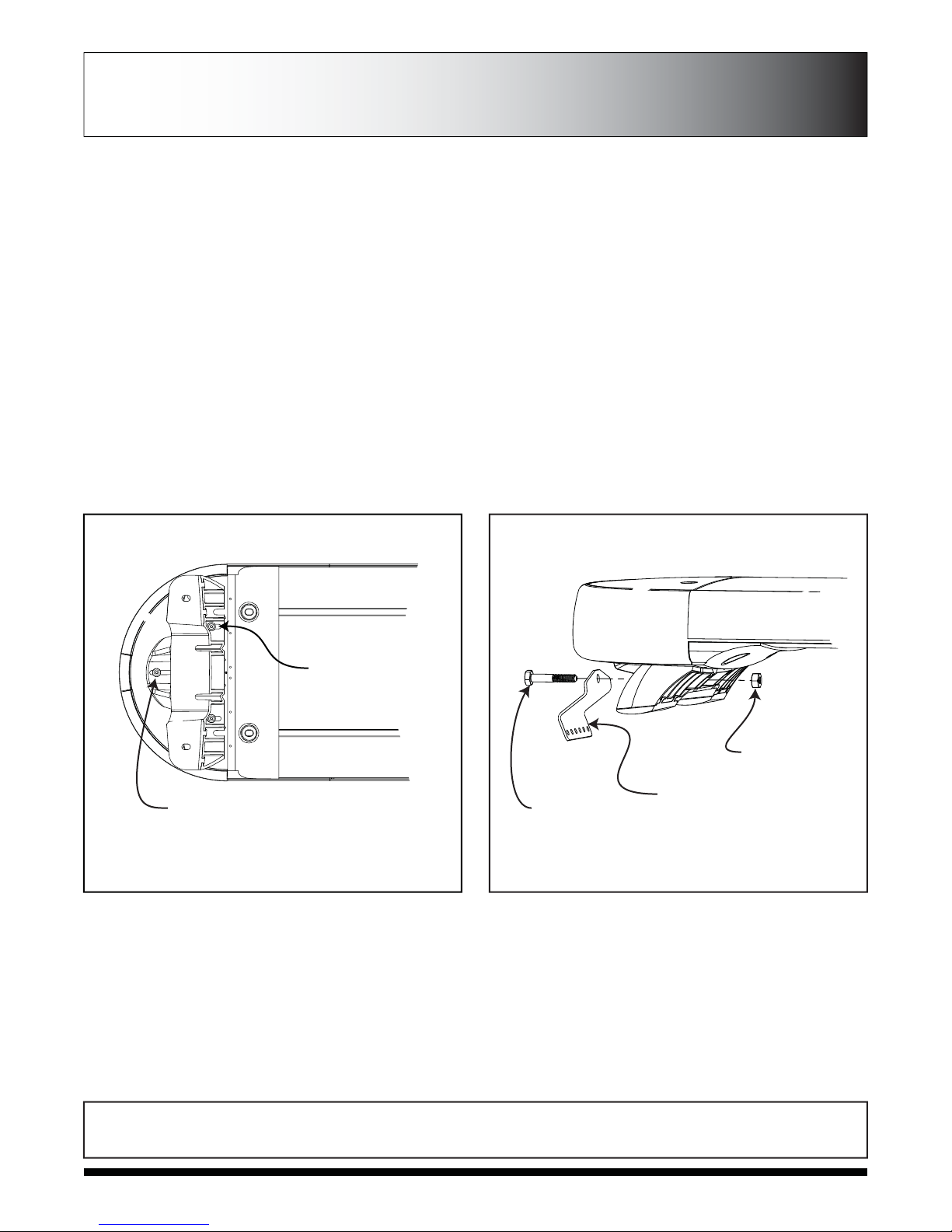

1. Mount fixed height brackets (See Figure 1) using supplied (3) T25 torx screws on each side. Temporarily place the lightbar in

it’s correct position on the roof of the vehicle. The bar should be positioned about the center line of the “B” pillar.

2. Based on the bar’s position, determine wire entry into vehicle. Mark location for later use. Note: Take into consideration the

location of any structural, airbag, or heating and cooling system components that can be in the way of the the wire entry point

or wire routing.

3. Install supplied vehicle specific hook brackets using supplied 1/4”-20 x 2.5 Hex Head bolts and Nylon Locking Nuts onto the bar

mounting foot as shown in Figure 2. Nut will nest into molded socket to prevent turning and improve ease of installation. It’s

recommended that you position the nut into the foot and tap it slightly with a hammer to seat it into the cast foot prior to placing

the bar on the roof. This will make installation easier.

4. Adjust fixed height bracket position on the Lightbar by loosening the (3) T25 Torx Screws on each side (See Figure 1). Be sure

that there is enough clearance between fixed height brackets and vehicle specific brackets to allow for tensioning to roof. When

the correct position is found, tighten T25 torx screws that attach fixed height bracket to lightbar base end plates.

5. Using the vehicle specific hook brackets as a template, drill 4 pilot holes using a #30 (.128 dia.) drill bit on each side of the

vehicle.

6. Secure each vehicle specific hook bracket by using the 8 supplied #8 x 1/2” Truss Head Sheet metal screws on each side.

7. Tighten each vehicle specfic hook bracket by turning the 1/4”-20 x 2.5 Hex head bolt clockwise until bar is snug and no side to

side or fore to aft movement occurs.

8. Route cables into vehicle. Use supplied rubber grommet in roof for sealing/protection of wires. It is recommended that silicone

be placed around grommet to ensure roof sealing.

WARNING - ROUTE WIRES ONLY IN LOCATIONS THAT ARE NOT SUBJECTED TO POTENTIAL WEAR. MAKE SURE TO

AVOID ROUTING WIRES IN THE DEPLOYMENT AREA OF YOUR AIR BAG. REFER TO YOUR VEHICLE’S OWNER’S

MANUAL FOR AIR BAG DEPLOYMENT ZONES.

FIXED HEIGHT BRACKETS AND HOOK MOUNTING

1/4”-20 x 2.5”

Hex Head Bolt

Vehicle Specific Hook Bracket

1/4”-20 Nylon

Locking Hex Nut

Slots for

adjustablitlity

for correct roof fit

Loosen T25 Torx Screws

to adjust brackets

FIGURE 1 FIGURE 2

Page 6

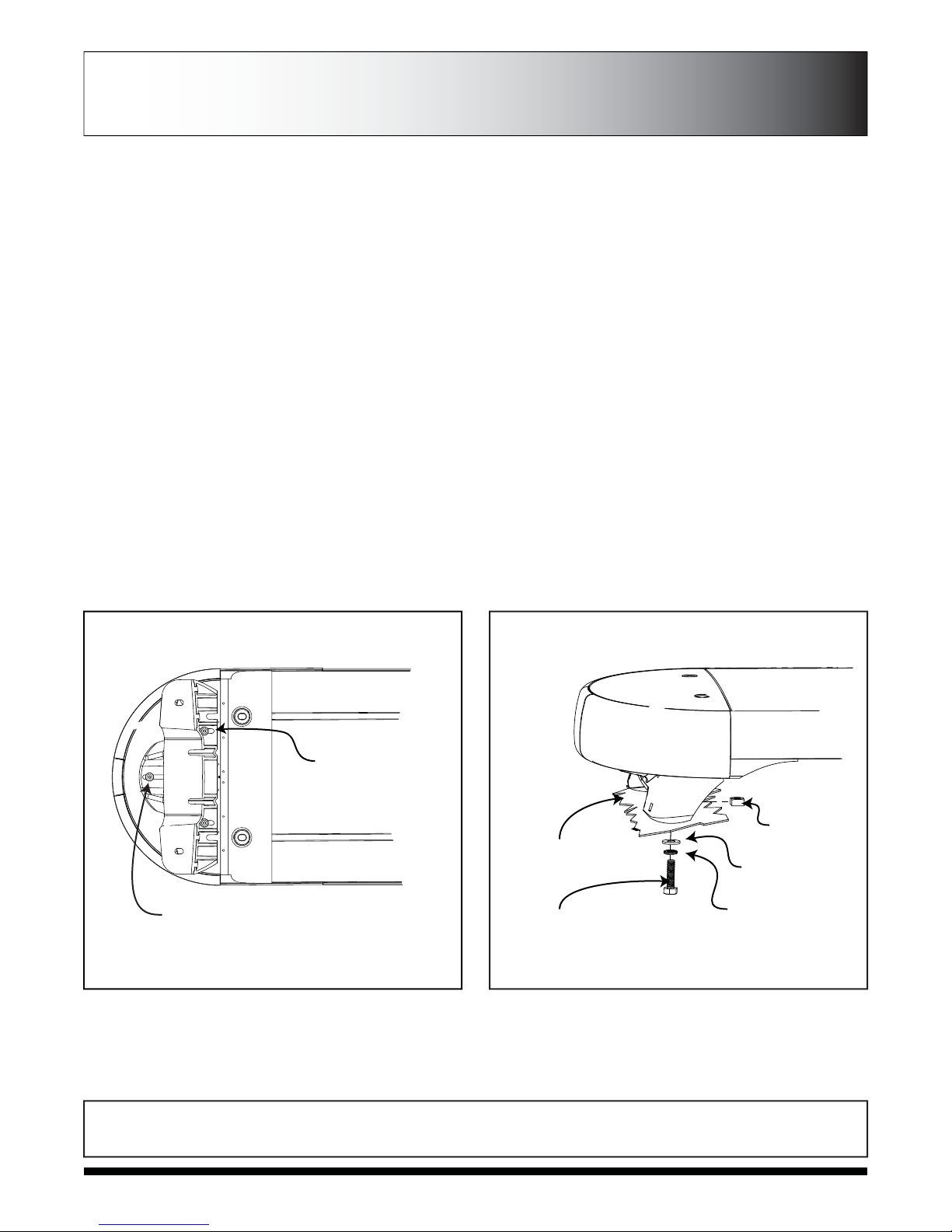

FIXED HEIGHT BRACKETS PERMANENT

MOUNTING

1. Locate the permanent hardware kit that is included. Kit will include (4) 1/4”-20 x 1“ hex head screws, (4) flat washers, (4) lock

washers, (4) square nuts, and (6) T25 Torx Screws.

2. Attach fixed height brackets to lightbar using T25 Torx Screws. Brackets should be adjusted to identical positions at both ends

of lightbar. See Figure 1.

3. Position the lightbar on the vehicle roof in the desired mounting location. The recommended location is directly above the B-

Pillars. This is the strongest part of the roof. Make sure that the bar is centered on the vehicle left to right. Adjust bracket

location on lightbar base end castings if needed.

4. Mark the location for the (4) holes that need to be drilled through the roof that will attach the fixed height brackets to the roof.

5. Determine the best location for cable entry depending on the configuration of your bar. Using a 1-1/4” hole saw, drill hole in the

marked location. Be mindful that you do not drill through any roof support members or the interior headliner.

6. Using a 5/16” drill bit, drill the 4 holes in the locations that you marked in step 4. Clean and debur each hole.

7. Attach the lightbar to the vehicle using the supplied hardware. Use (1) flat washer and locking nut for each bolt. You should

have a total of 4 bolts attaching the lightbar to the roof of the vehicle. See Figure 2 for details. It is recommended that you add

silicone around the hole to ensure roof sealing.

8. Route cables into vehicle. Use supplied rubber grommet in roof for the sealing/protection of wires. It is recommended that

silicone be placed around the grommet to ensure roof sealing.

WARNING - ROUTE WIRES ONLY IN LOCATIONS THAT ARE NOT SUBJECTED TO POTENTIAL WEAR. MAKE SURE TO

AVOID ROUTING WIRES IN THE DEPLOYMENT AREA OF YOUR AIR BAG. REFER TO YOUR VEHICLE’S OWNER’S

MANUAL FOR AIR BAG DEPLOYMENT ZONES.

Slots for

adjustablitlity

for correct roof fit

Loosen T25 Torx Screws

to adjust brackets

FIGURE 1

Roof Cut-away

4x 1/4”-20 x 1”

Hex Head Screw

4x 1/4” Lock

Washers

4x 1/4” Flat

Washers

4x 1/4” -20

Square Nuts

FIGURE 2

Page 7

ADJUSTABLE RUBBER FEET

HEIGHT ADJUSTMENT

SCREWS

HEIGHT & ROOF ANGLE ADJUSTMENT SCREWS

VEHICLE SPECIFIC BRACKET

ADJUSTMENT SCREW

VEHICLE

SPECIFIC

BRACKET

PIVOT

ARM

FRONT TO BACK TILT ADJUSTMENT SCREWS

ADJUSTABLE HEIGHT BRACKETS AND HOOK MOUNTING

Page 8

1. Attach vehicle specific bracket to adjustable mounting bracket. 1 1/2” Allen drive screw must be placed “underneath” djustable

mounting bracket (See Figure 1). Allen drive screw will be accessible through hole in front of adjustable bracket. Square nut

must be placed in front of vehicle specific bracket. Place 1/4“ lockwasher between square nut and vehicle specific hook

bracket. See Figure 1 for details. To hold bracket in place, use provided hardware: 1 flat washer, 1 lock washer and 3/8” Allen

drive screw per slot (as shown in Figure 1).

2. Attach mounting brackets to bar using the carriage bolts pre-installed on the bar. Use two lockwashers and a acorn nut per bolt.

Leave acorn nuts loose so that the bracket has the ability to slide to fit your specific vehicle application. When choosing the

placement for the mounting bracket, consider the cable routing and the risk of pinching wires or anything that can lead to cable

failure. See Figure 2 for details.

3. Position bar on roof about center line of “B” pillar. Determine final location of adjustable mounting brackets for vehicle

application and ensure bar is centered about brackets and vehicle. Determine and mark off locations for mounting screws

through vehicle specific bracket into roof. Determine location for wire entry into vehicle.

4. Determine the height of bar in relationship to the roof that best suits your application. Height of bar can be adjusted by

loosening 4 allen drive screws that fasten pivot arm to either end. To simplify this procedure we recommend cutting 2 wood

blocks to your preferred height to set gap height between roof and bar. Also be sure that adjustable height bracket feet are

sitting flat on vehicle roof. See Figure 3.

5. After position of bar is determined. Tighten tilt and height adjustment screws (shown on page 5). Also tighten acorn nuts

attaching adjustable mounting bracket to bar.

6. Drill 4 holes using a #30 (.128 dia.) drill bit on each side of vehicle that were marked in Step 5. Be careful not to damage

weather stripping on vehicle.

7. Using 1 1/4” hole saw, drill hole in marked location on roof for cable routing. Be mindful that you do not drill through any roof

support members or interior head liner. Clean and debur hole.

8. Secure each vehicle specific bracket by using 4 supplied #8 x 1/2” truss head screws.

9. When required, adjust front to back tilt to make bar parallel with road for best optical range. 5/32“ allen drive adjustment

screws are located above each mounting foot in the mounting bracket base. Adjustment screws must be turned

counter-clockwise to raise either front or back of bar.

SQUARE NUT

1/4-20 X 1.5” SCREW

FIGURE 1

VEHICLE SPECIFIC BRACKET

1/4-20 X 3/8 SCREW

1/4” TOOTH LOCKWASHER

1/4” FLAT WASHER

TOOTH LOCKWASHER

LOCKWASHER

ACORN NUT

GASKET

FIGURE 2

ADJUSTABLE HEIGHT BRACKETS AND HOOK MOUNTING

Page 9

10. Tighten vehicle attachment brackets to roof by turning 5/32” Allen driver in COUNTER-CLOCKWISE ROTATION. Depending on

your desired height, you may need to cut down your allen wrench to fit between the bar and the mounting bracket. Or use a micro

drive gear wrench and 1/4” shank with 5/32” allen bit.

11. Route cables into vehicle. Use supplied rubber grommet in roof for sealing/protection of wires. It is recommended that silicone

be placed around grommet to ensure roof sealing.

12. Route cable down through the “B” pillar and towards switch panel. Refer to the instructions included with your switch for

switch wiring information.

WARNING - ROUTE WIRES ONLY IN LOCATIONS THAT ARE NOT SUBJECTED TO POTENTIAL WEAR.

MAKE SURE TO AVOID ROUTING WIRES IN THE DEPLOYMENT AREA OF YOUR AIR BAG. REFER TO

YOUR VEHICLE OWNER’S MANUAL FOR AIR BAG DEPLOYMENT ZONES

WARNING - ALL CUSTOMER SUPPLIED POWER WIRES CONNECTING TO THE POSITIVE (+) OR

NEGATIVE (-) BATTERY TERMINAL OR LOCAL CHASSIS GROUND (-) MUST BE SIZED TO SUPPLY AT

LEAST 125% OF THE MAXIMUM CURRENT AND PROPERLY FUSED AT THE POWER SOURCE WITH

APPROPRIATELY RATED FUSE.

Power Cable:

1. Route lightbar power cables as close to vehicles power source (battery) as possible.

ELECTRICAL INSTALLATION

Featured Highlights:

Mode Select: The PINNACLE Lightbar is equipped with 2 selectable pattern configuration modes via the Mode Select Input. Default

is Mode 1 where the input is floating, Mode 2 is in use when the input activated. This feature allows 2 complete sets of patterns to

be programmed into the Lightbar's non-volatile memory. Once programming configuration is complete, the Mode can be changed

“on-the-fly” by an activation switch.

Cruise Mode: Allows the user to program any Light Head Group(s) to “Glow” when this feature is activated.

Directional Arrow Built-in: If the lightbar was purchased with a directional arrow, the directional controller is built-in w/ 4 arrow

patterns for each direction and 9 warning patterns for warming functions.

ELECTRICAL INSTALLATION

LOCATION FOR MOUNTING

SCREWS TO ROOF

FEET MUST SIT

FLAT ON ROOF

TIGHTEN BRACKETS

TO ROOF BY COUNTER

CLOCKWISE ROTATION

REPRESENTS

VEHICLE ROOF

CENTER ABOUT “B” PILLAR

FRONT-BACK

TILT ADJUSTMENT

SCREWS

WARNING - CARE MUST BE TAKEN WHEN DRILLING THROUGH THE ROOF OF THE VEHICLE NOT TO

DRILL INTO ANY EXISTING WIRING AND NOT TO DRILL THROUGH THE HEADLINER OR SUPPORT

MEMBERS OF THE VEHICLE. CHECK BOTH SIDES OF THE MOUNTING SERVICE PRIOR TO DRILLING.

DE-BURR ANY HOLES AND REMOVE ANY METAL SHARDS OR REMNANTS. INSTALL GROMMETS

INTO ALL WIRE PASSAGE HOLES.

FIGURE 3

Page 10

IMPORTANT: When passing cables through firewall or other sheet

metal, insert grommet to protect the cable!

2. Install a 40Amp Fuse (customer supplied) to the end of the RED wire of the Lightbar Power Cable.

a. Remove the fuse before connecting any wires to the battery.

b. DO NOT USE CIRCUIT BREAKER OR FUSIBLE LINK.

3. Connect the other end of the Fuse to the POSITIVE (+) terminal of the battery.

a. Do NOT use any more than 2ft of wire between the battery terminal and the fuse and ensure the wire is protected

and secured from being cut into; this is non-fused wire.

4. Connect the BLACK wire to the factory chassis ground right next to the battery.

Control (Data) Cable:

1. Route Lightbar Control Cable to the location where all controlling equipment will be, i.e. switch box, center console area.

2. Locate the Breakout Box in the same area to connect jumpers from the switching equipment to the breakout box.

NOTE: Power is supplied to Breakout Box through data cable, no additional power connections necessary.

Initial Power up Test:

1. Insert 40Amp Fuse into Fuse Holder.

2. Plug data jack into Data 1 connector of the breakout box (Data 2 may also be used, but is for future use.)

3. Observe the GREEN Data Link indicator LED on the Breakout Box; the LED will turn steady ON about 15 seconds after main

power is connected

4. When GREEN LED is steady ON (see below), the lightbar is ready to be configured.

Low Power (Standby) Mode

If there is no input to the breakout box for 15 seconds, the lightbar will go into a “standby” mode. The standby mode is a low power mode that is

used to extend the life of your battery. The green light will turn off when the lightbar enters standby mode. The red light will flash every five

seconds showing that it has power. The lightbar will awaken from the standby mode if any input is activated on the breakout box.

*note in standby mode each switch in the down position will contribute to another 0.03A of standby current.

Pattern Selection:

a. First review the Pattern Table (included on pg. 13) before attempting pattern selection to familiarize yourself with patterns

available for the different Functions

i. Depending on the Lightbar configuration purchased, the Arrow Pattern Table may or may not be applicable.

b. Select the Input Function(s) on breakout box (pg. 12) and apply +12V to activate.

i. To change patterns on more than one input function, simply connect desired input functions together. Before doing

this, make sure all the inputs are using the same pattern table and are on the same pattern to make pattern

identification easier.

c. Momentarily apply +12V to the pattern select input on breakout box to advance to the next pattern. See Flash Pattern

Table (pg .13).

i. Once the last pattern is reached, the next pattern advance will cycle back to Pattern #1.

d. Once the desired pattern is reached, simply disconnect the Input Function(s) and proceed to the next Input Function(s)

to be configured.

i. The pattern is saved in non-volatile memory every time it is advanced.

Mode Configuration: See Mode Input on Function Description Table (attached sheet) for more details about this feature.

a. Mode 1 (Default): the Mode Select Input will be floating (no-connection)

i. Continue on to Pattern Selection instructions below to set the patterns for this Mode

b. Mode 2: apply +12V to activate Mode 2. This will need to be activated to configure the Lightbar in Mode 2

i. Continue on to Pattern Selection instructions below to set the patterns for this Mode

ii. Once patterns have been setup, connect Mode Select Input to switching system.

iii. When the Mode Select Input is activated, the Mode 2 Patterns will flash.

Cruise Mode Configuration: See Cruise Mode Input on Function Description Table (attached sheet) for more details about this

Feature.

a. Apply +12V to activate Cruise Mode for configuration setup.

b. Determine what Input Function(s) are desired to use Cruise Mode.

c. Apply +12V to the Input Function(s) desired.

i. NOTE: Lights will flash preset flash pattern

d. With both the Cruise Mode Input and the Input Function(s) activated, momentarily apply +12V to

the pattern select wire to toggle the Cruise Mode to ON (default is OFF).

e. Observe the OFF sequence of the flash pattern is ON dim.

f. Disconnect the Input Function wire(s) (while leaving cruise mode input active) and observe the lightbar is NOT flashing, but

the output function(s) recently set are glowing steady.

ELECTRICAL INSTALLATION

Page 11

PIN#24 - Light Green/White

PIN#23 - Red Black

PIN#22 - Orange/White

PIN#21 - Yellow/White

PIN#20 - Brown

PIN#19 - Red/White

PIN#18 - Pink

PIN#17 - Red

PIN#16 - Orange

PIN#15 - Yellow

PIN#14 - Green

PIN#13 - Blue

Pink/White - PIN#12

Purple/White - PIN#11

Gray/White - PIN#10

Black/White - PIN#09

White - PIN#08

Purple - PIN#07

Brown/White - PIN#06

Light Green - PIN#05

Black - PIN#04

Gray - PIN#03

GreenWhite - PIN#02

Blue/White - PIN#01

Light Green/White 24 Left Turn Signal* Discrete Output #4*

Red/Black 23 Right Turn Signal* Discrete Output #3*

Orange/White 22 Rear Inboard 3 Discrete Output #2*

Yellow White 21 Rear Inboard 2 Discrete Output #1 (L)*

Brown 20 Front Takedown Front Takedown

Red/White 19 Alley Flash Alley Flash

Pink 18 Alley Driver Alley Driver

Red 17 Alley Passenger Alley Passenger

Orange 16 Front Inboard 3 Front Inboard 3

Yellow 15 Front Inboard 2 Front Inboard 2

Green 14 Front Inboard 1 Front Inboard 1

Blue 13 Front Corners Front Corners

Pink/White 12 Arrow, Left* Discrete Output #8 (R)*

Purple/White 11 Arrow, Center* Discrete Output #7*

Gray/White 10 Arrow, Right* Discrete Output #6*

Black/White 9 Arrow,Warning Discrete Output #5*

White 8 Pattern Select* Pattern Select*

Purple 7 Low Power Low Power

Brown/White 6 Front Takedown Flash Front Takedown Flash

Light Green 5 Auxiliary* Auxiliary*

Black 4 Cruise Lights* Cruise Lights*

Gray 3 Mode Select* Mode Select*

Green/White 2 Rear Inboard 1 Rear Inboard 1

Blue/White 1 Rear Corners Rear Corners

Wire Color

(Major Color/Stripe) Pin#

Discrete Functions

(8 Wire Arrow Control)

Standard Functions

(4 Wire Arrow Control)

* - Reference page 11 for detailed explanation of functions

Note - Reference Switch table for explanation of what inputs are affected by

Active Low Switches

Functional Inputs

Fuctional inputs connect to your control head or

switching unit. Applying +12Vdc to any functional

input will activate it’s function (default-active high).

For more information, see switches explanantion on

second page.

Connector Pinning Chart

Controlled by Active Low Switch #2

Controlled by Active Low Switch #1

· When the switch is in the up position inputs connected to that switch are

active high. To activate an active high input, apply 12Vdc.

· When the switch is in the down position inputs connected to that switch

are active low. To activate the active low, apply ground (negative).

BREAKOUT BOX

DRAIN WIRE

BLACK 12 GA.

GROUND

40Amp FUSE

(Customer Supplied)

GROUND

POWER

CABLE

RED 12 GA.

RJ-45 CABLE

Active Low

Switch #1

Active Low

Switch #2

Red LED

Green LED

RED LIGHT

No Inputs Flashes Every 5 Secs.

Input Activated Steady On

Added Input Brief Flash

GREEN LIGHT

Command Rec’d Steady On Has good

(See below) connection

LOW POWER (STANDBY) MODE

If there is no input to the breakout box for

15 seconds, the lightbar will go into a

“standby” mode. The standby mode is a

low power mode that is used to extend

the life of your battery. The green light

will turn off when the lightbar enters

standby mode. The red light will flash

every five seconds showing that it has

power. The lightbar will awaken from the

standby mode if any input is activated on

the breakout box.

*note in standby mode each switch in the

down position will contribute to another

0.03A of standby current.

Page 12

FLASH PATTERN TABLE

BREAKOUT BOX HOOKUP:

Make sure the 24-pin connector and the RJ-45

connector are snapped in securely.

Follow the label for the wire color to connect to a

12Vdc source, which turns on that given light or

lights.

Make sure your wire connections are secured and

isolated from any other wire.

1

2

3

4

Solid Arrow Plus, Slow

Solid Arrow, Slow

Individual Arrow, Fast

Chaser Arrow, Fast

Grow / Decay

Solid

Individual

2X Individual

Directional Bar Directional Function Patterns For

Left, Center Out, & Right Sequences

1

2

3

4

5

RoadRunner™

PowerPulse™

Q-Switch™

ETM™

Steady Burn

Alternating

Alternating

Variable

Simultaneous

Steady Burn

115

180

-

214

-

1.92

3.00

-

3.57

-

LED Takedown & Alley Flash Patterns

1

2

3

4

5

6

7

8

9

PowerPulse™ Alternating

PowerPulse™ Alternating

Quad Alternating

Warp Alternating

Hyper Scan

Super Scan

Power Flash

Thunder and Lightning

Center Out

Left/Right

Center Out

Adjacent

2X Individual Sweep

Pulsing + Sweep

Dual Rate Pulse/Alt

Dual Rate Alt/Pulse

Random

180

180

80

350

-

-

-

-

-

3.00

3.00

1.35

5.88

-

-

-

-

-

Directional Bar Warning Function Patterns

10

11

12

13

14

15

16

17

RoadRunner™

Warp

Warp

Inter-Cycle Flash

Inter-Cycle Flash

Inter-Cycle Flash

Inter-Cycle Flash

Inter-Cycle Flash

Alternating

Adjacent

Adjacent

Adjacent

Alternating

Alternating

Alternating

Alternating

115

350

350

-

-

-

-

-

1.92

5.88

5.88

-

-

-

-

-

Split Arrow Bars Also Have The Following Multi-color Patterns

LED Module Flash Patterns

#

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Pattern Name

Quint

Warp

Inter-Cycle Flash

Quad Flash

RoadRunner™

RoadRunner™

Slow Runner

Slow Runner

Q-Switch™

Single, Steady Burn

Quad, Steady Burn

Warp, Steady Burn

Nothing, Steady Burn

E-Pattern Single Flash

E-Pattern Double Flash

E-Pattern Single Flash

E-Pattern Double Flash

Warp 1,2,3

Warp 2,3,1

Warp 3,2,1

Steady Burn

Sequence

Alternating

Alternating

Alternating

Alternating

Alternating

Simultaneous

Alternating

Simultaneous

Variable

Steady Burn

Steady Burn

Steady Burn

Steady Burn

Alternating

Alternating

Simultaneous

Simultaneous

Variable

Variable

Variable

Steady Burn

fpm*

70

350

-

80

115

115

70

70

-

115

80

350

-

230

128

230

155

-

-

-

-

fps**

1.18

5.88

-

1.35

1.92

1.92

1.16

1.16

-

1.92

1.35

5.88

-

3.85

2.13

3.85

2.6

-

-

-

-

*fpm=Flashes per Minute

**fps=Flashes per Second

FLASH PATTERNS AND CONNECTOR

INSTRUCTIONS

LIGHTBAR CONTROLLER CONNECTOR INSTRUCTIONS

Light Output Groups

Orange

Brown

Red and Yellow

Green

Blue

Red and Yellow (2-wire)

Green (2-wire)

Blue (2-wire)

White

Small Connector

Input Group Control

Front Corners

Rear Corners

Front Inboard 1

Front Inboard 2

Front Inboard 3

Rear Inboard 1

Rear Inboard 2

Rear Inboard 3

Front Takedown Flash

Alley Flash

PURPOSE

8-WIRE CONTROL

NO ARROW

N/A

4 MOD ARROW

5 MOD ARROW

6 MOD ARROW

7 MOD ARROW

8 MOD ARROW

PASSENGER-SIDE EXIT

DRIVER-SIDE EXIT

SPLIT-COLOR ARROW MODULES

FULL ARROW MODULE

FOR TURN SIGNALS ON YELLOW OUTPUT

FOR TURN SIGNALS ON BLUE OUTPUT

EPL 9000 SWITCH SETTINGS

SW1

Off

Off

Off

Off

On

On

On

On

SW2

Off

Off

On

On

Off

Off

On

On

SW3

Off

On

Off

On

Off

On

Off

On

SW4

On

Off

SW5

On

Off

SW6

On

Off

Page 13

LIGHT MODULE WIRE HARNESS LOCATIONS

CONTROLLER AND WIRE HARNESS INSTRUCTIONS

Colors shown indicate color coded labels on

wiring harness.

White is used for all Take Down lights. Replace

color indicated on diagram with white labeled

wire.

SM=Small connector used on Alley lights only.

If modules are being replaced in the field make

sure they are reinstalled with single wire

connectors to FRONT of vehicle. See below.

Green

Single Wire

Red, Blue Double

Wire (Rear)

REPLACEMENT OF INBOARD, CORNER, TAKEDOWN AND ALLEY LED MODULES:

1. Disconnect main power.

2. Remove top cover by removing 6 sealed torx head screws.

3. Locate module and remove mounting screw. Pull module from lightbar.

4. Remove connector from rear of module by disengaging locking latch and pull

connector from back of module. (see illustration at right)

5. Push module connector into module ensuring locking latch is seated properly.

6. Replace module and 2 screws that fasten module to base extrusion.

7. Restore power to bar and test new module to ensure functionality.

8. Replace top cover of bar with screws removed in step 2.

DRIVER

SIDE

PASSENGER

SIDE

FRONT

36” BAR

C

D

A

E

B

E

11 12 13 14

31 32 33 34

ORANGE

SM

BROWN

GREEN RED RED GREEN ORANGE

SM

BROWN

GREEN RED RED GREEN

42” BAR

C

D

A

E

B

E

11 12 13 14 15

31 32 33 34 35

ORANGE

SM

BROWN

BLUE GREEN RED GREEN BLUE ORANGE

SM

BROWN

BLUE GREEN RED GREEN BLUE

48” BAR

C

D

A

E

B

E

11 12 13 14 15 16

31 32 33 34 35 36

ORANGE

SM

BROWN

ORANGE

SM

BROWN

BLUE GREEN RED RED GREEN

BLUE GREEN RED RED GREEN

BLUE

BLUE

54” BAR

C

D

A

E

B

E

11 12 13 14 15 16 17

31 32 33 34 35 36 37

YELLOW

ORANGE

SM

BROWN

ORANGE

SM

BROWN

BLUE GREEN RED GREEN BLUE

BLUE GREEN RED GREEN BLUE

YELLOW

YELLOW

YELLOW

60” BAR

C

D

A

E

B

E

11 12 13 14 15 16 17 18

31 32 33 34 35 36 37 38

ORANGE

SM

BROWN

ORANGE

SM

BROWN

BLUE GREEN RED RED GREEN

BLUE GREEN RED RED GREEN

BLUE

BLUE

YELLOW

YELLOW

YELLOW

YELLOW

72” BAR

C

D

A

E

B

E

ORANGE

SM

BROWN

ORANGE

SM

BROWN

BLUE GREEN RED* RED* GREEN

BLUE BLANK RED* RED* BLANK

BLUE

BLUE

YELLOW

YELLOW

YELLOW

YELLOW

31 32 33 34 35 36 37 38 39 40

11 12 13 14 15 16 17 18 19 20

RED* RED*

RED* RED*

* DENOTES

DOUBLE WIRE

UNITS IN FRONT

ON 72” BAR

ONLY!

Page 14

PINNACLE TROUBLESHOOTING

NORMAL OPERATION

Under Normal operation with lightbar turned on the breakout box will have the Green and Red LED light on steady. When ever you change

an input to the lightbar the Red LED on the breakout box will flash then go back to steady.

When the lightbar is off (no inputs active) the Green LED on the breakout box will stay on for 15 seconds then go off putting the lightbar into

sleep (standby) mode. The Red LED will flash every 5 seconds to tell you there is power to the breakout box and it is waiting for an input to

turn on the lightbar.

NO OPERATION

No LED on or flashing on Breakout box; Check input power and ground to lightbar, check data cable for damage and/or

opens, check 5 amp fuse in electronic control box in lightbar.

Breakout box LED’s operating correctly; Check FH1 & FH2 fuse in electronic control box in lightbar

NO OR INCORRECT INBOARDS OR CORNERS LIGHTS (WARNING)

Breakout box LED’s operating correctly; Check FH1 fuse in electronic control box in lightbar

No steady Red LED on breakout box; Check 24-pin connector at breakout box (insure it is snapped in correctly), check

appropriate input to breakout box for output lights which should be on

No rear warning lights; Check dip switch SW5 setting for full (off) or split (on) arrow (on full you may not

get any warning) (after arrow dip switch changes main power must be cycled)

NO TAKEDOWNS OR ALLEYS LIGHTS

Breakout box LED’s operating correctly; Check FH2 fuse in electronic control box in lightbar

No steady Red LED on breakout box; Check 24-pin connector at breakout box (insure it is snapped in correctly), check

appropriate input to breakout box for output lights which should be on

INCORRECT OR NO ARROW OPERATION

Breakout box LED’s operating correctly; Check dip switches setting in electronic control box in lightbar (after arrow dip

switch changes main power must be cycled)

No steady Red LED on breakout box; Check 24-pin connector at breakout box (insure it is snapped in correctly), check

appropriate input to breakout box for output lights which should be on

Arrow direction incorrect; Change passenger/drivers side dip switch SW4 in electronic control box in lightbar

(after arrow dip switch changes main power must be cycled)

8-wire control not operating; Check dip switch setting SW1-3 (should be off, off, off) in electronic control box in

lightbar (after arrow dip switch changes main power must be cycled)

Split arrow not operating; Check dip switch SW5 (should be on) in electronic control box in lightbar (after

arrow dip switch changes main power must be cycled)

Page 15

REPLACEMENT PARTS

Inboard LED Assembly

Alley Light Assembly

Takedown/Worklight/

Assembly

Corner LED Assembly

Pre-empt Module

EPL PART # DESCRIPTION

PEPL9A0C Pinnacle Blank Alley Light - Clear Lens/No LEDs

PEPL9A1C-D Pinnacle Alley Light, 15° Forward Facing, Driver Side - Clear Lens/White LEDs

PEPL9A1C-P Pinnacle Alley Light, 15° Forward Facing, Passenger Side - Clear Lens/White LEDs

PEPL9A2C Pinnacle Alley Light, Standard - Clear Lens/White LEDs

PEPL9BBHNS Pinnacle Breakout Box Harness, 12" Length

PEPL9BBHNL Pinnacle Breakout Box Harness, 36" Length

PEPL9CNTRL1 Pinnacle Motherboard, 12 volt

PEPL9CS12AA Pinnacle Corner Module - Amber Lens/Amber LEDs

PEPL9CS12AC Pinnacle Corner Module - Clear Lens/Amber LEDs

PEPL9CS12BB Pinnacle Corner Module - Blue Lens/Blue LEDs

PEPL9CS12BC Pinnacle Corner Module - Clear Lens/Blue LEDs

PEPL9CS12GC Pinnacle Corner Module - Clear Lens/Green LEDs

PEPL9CS12RC Pinnacle Corner Module - Clear Lens/Red LEDs

PEPL9CS12RR Pinnacle Corner Module - Red Lens/Red LEDs

PEPL9CS12WC Pinnacle Corner Module - Clear Lens/White LEDs

PEPL9HL6C Pinnacle Takedown/Work Light Module - Clear Lens/White LEDs

PEPL9L00A Pinnacle Blank Inboard Module - Amber Lens/ No LEDs

PEPL9L00B Pinnacle Blank Inboard Module - Blue Lens/ No LEDs

PEPL9L00C Pinnacle Blank Inboard Module - Clear Lens/ No LEDs

PEPL9L00R Pinnacle Blank Inboard Module - Red Lens/ No LEDs

PEPL9LLSAA Pinnacle Inboard Module - Amber Lens/Amber LEDs

PEPL9LLSAC Pinnacle Inboard Module - Clear Lens/Amber LEDs

PEPL9LLSBB Pinnacle Inboard Module - Blue Lens/Blue LEDs

PEPL9LLSBC Pinnacle Inboard Module - Clear Lens/Blue LEDs

PEPL9LLSGC Pinnacle Inboard Module - Clear Lens/Green LEDs

PEPL9LLSRC Pinnacle Inboard Module - Clear Lens/Red LEDs

PEPL9LLSRR Pinnacle Inboard Module - Red Lens/Red LEDs

PEPL9LLSWC Pinnacle Inboard Module - Clear Lens/White LEDs

PEPL9LLSFC Pinnacle Dual Color Arrow Module, Clear Lens – White/Amber

PEPL9LLSKC Pinnacle Dual Color Arrow Module, Clear Lens – Red/Amber

PEPL9LLSMC Pinnacle Dual Color Arrow Module, Clear Lens – Blue/Amber

PEPL9LLSPC Pinnacle Dual Color Arrow Module, Clear Lens – Green/Amber

PEPL9LLSZC Pinnacle Dual Color Arrow Module, Clear Lens – No LEDs/Amber

PEPL9LLSJC Pinnacle Dual Color Warning Module Clear Lens - Red/Blue

PEPL9LLSNC Pinnacle Dual Color Warning Module Clear Lens - Blue/Green

PEPL9RFGR Roof Wire Grommet for External Break Out Box on Pinnacle Lightbars

PETLJ00 External Breakout Box for ETL 5000 & Pinnacle Lightbars

PETLK00 Adjustable Height Mounting Bracket (1 bracket) for use w/ ETL 5000 & Pinnacle Lightbars

PETLK04 Low Profile Fixed Height Mounting Bracket (1 bracket) for use w/ ETL 5000 & Pinnacle Lightbars

PETLMX1 Hook Kit Extension for use w/ Adjustable Height Bracket on ETL 5000 & Pinnacle Lightbars

PETLM00 Permanent Mount Hardware for the Adjustable Height Bracket for use w/ ETL 5000 & Pinnacle Lightbars

PETLM(nn) Adjustable Height Bracket Hook Kit for ETL 5000 or Pinnacle Lightbars:*

PETLR00

Permanent Mount Hardware for the Low Profile Fixed Height Bracket for use w/ ETL 5000 & Pinnacle Lightbars

PEPL9GTT1C Pre-empt Module

PEPL9RFGR2 Roof Grommet

PEPL9GTTHN Harness

PEPL9LLH12(x)C Pinnacle High Diode Dual Color Rear Arrow Module

* SEE "HOOK KIT COMPATIBILITY CHART" FOR VEHICLE MODEL COMPATIBILITY

http://www.soundoffsignal.com/warnamber/lightbars/literature/HookKits_ETL5000.pdf

STANDARD REPLACEMENT PARTS

Page 16

CLEANING -

Keeping the lenses clean and scratch free will optimize the performance of the lightbar. To clean use a soft

cotton cloth and mild soapy water to clean dirt and insects off from the lenses. Never use window

cleaners or harsh chemicals on the lenses; this may cause failure of the lenses or reduce clarity resulting

in the reduction of light output.

The exterior of the lightbar also should be cleaned with mild soapy water and a soft cotton cloth.

MOUNTING INTEGRITY:

A review of bolt/hardware/mounting bracket integrity should be performed at the

beginning and end of each shift.

PRODUCT MAINTENANCE

NOTES

Page 17

WARRANTY & RETURN GOODS PROCEDURE

To review our Limited Warranty Statement & Return Policy for this or any SoundOff Signal product please visit our website at

www.soundoffsignal.com and select the “Warranty & Returns” link along the left column of our home page. If you have questions regarding this

product please contact Technical Services, Monday - Friday, 8 am to 5 pm at 1.800.338.7337, press #4 to skip the automated message. Questions

or comments that do not require immediate attention may be emailed to [email protected]. 1.800.338.7337. /

www.soundoffsignal.com / Thank you for trusting us with your safety!

Warranty Return Process

Please contact your SoundOff Signal Sales Representative, Customer Services staff or our Technical Department (800.338.7337) for a RMA#

(Return Merchandise Authorization) number.

The following information is required for issuance of the RMA#:

• Reason for returning the product*

• Address where replacement product is to be shipped*

• Telephone number where you may be reached*

• SoundOff Signal invoice number on which product was purchased**

• SoundOff Signal part number and serial number**

• E-mail address where RMA# should be e-mailed**

• Fax number where RMA# should be faxed**

SoundOff Signal will NOT accept returns without an RMA#. Each RMA# is good for only one (1) item and will expire (7) days after the date it

was issued. Products must be shipped back to SoundOff Signal and the RMA# clearly marked on the outside of the package near the shipping

label. Please use the following address on your shipping label:

ATTN.: RMA#

SoundOff Signal

3900 Central Parkway

Hudsonville, MI 49426

Please see reverse side for manufacturer warranty.

Warranty Exclusions

Shipping & Handling, labor and service fees are non-refundable. SoundOff Signal is not liable for any damage due to installation or personal injury as

a result of using SoundOff Signal product.

Warranty Forfeiture

Warranty will not be granted if the Warranty Return Policy & Procedure rules are not strictly followed. Physical damage resulting from customer

abuse will void warranty. Warranty will also be voided if any SoundOff Signal and/or manufacturer serial tags, product stickers, seals, or the like,

are removed, altered or tampered with. Returned product that is damaged by shipping via the RMA# procedure is not the responsibility of

SoundOff Signal.

* RMA# will not be given without this information.

** If available, please provide this information.

Document effective date on cover and below supersedes previously dated policies and statements.

There are no other warranties, expressed or implied, including, but not limited to, any implied merchantability or fitness for a particular use.

SoundOff Signal reserves the right to modify this warranty statement at any time; or to discontinue, modify, or upgrade any products of its

manufacture with design improvements without prior notice.

ISO-9001 Registered ©2009 SoundOff Signal Emergency Technology Inc. dba SoundOff Signal

Printed in the USA / All Rights Reserved / Specifications subject to change without notice.

PO Box 206 / 3900 Central Parkway / Hudsonville, MI 49426

toll free 800.338.7337 / office 616.896.7100 / order fax 616.896.1286 / www.soundoffsignal.com

EPL9000 9.10

Table of contents

Other Soundoff Signal Dj Equipment manuals

Popular Dj Equipment manuals by other brands

Chauvet Professional

Chauvet Professional Maverick Storm 1 Wash user manual

Guangzhou Yingfeng Lighting Equipment

Guangzhou Yingfeng Lighting Equipment MHY10803 user manual

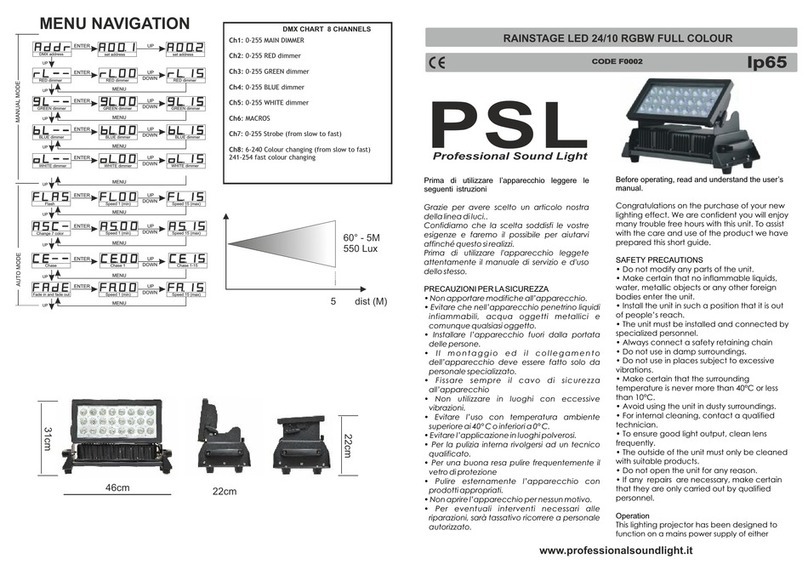

PSL

PSL RAINSTAGE LED 24/10 instructions

Strand

Strand Fresnelite 12081 operating instructions

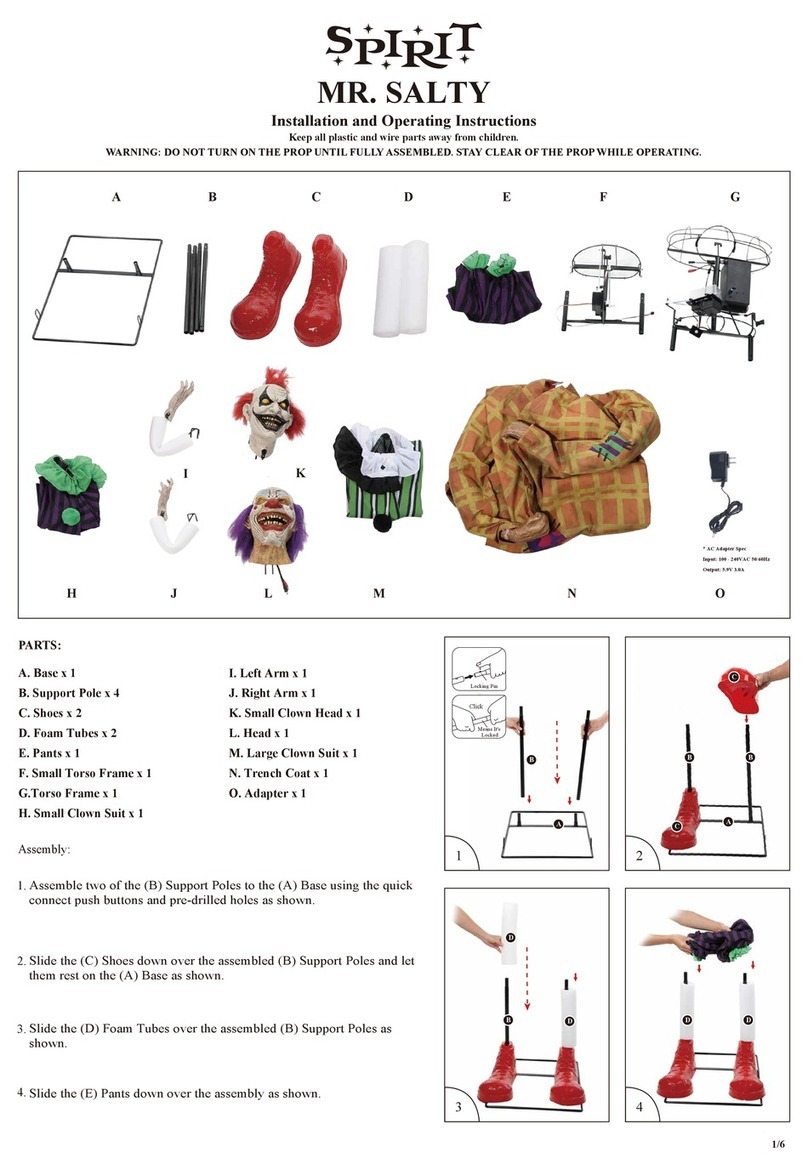

Spirit Halloween

Spirit Halloween Mr. Salty Installation and operating instructions

Flash professional

Flash professional P7100457 user manual