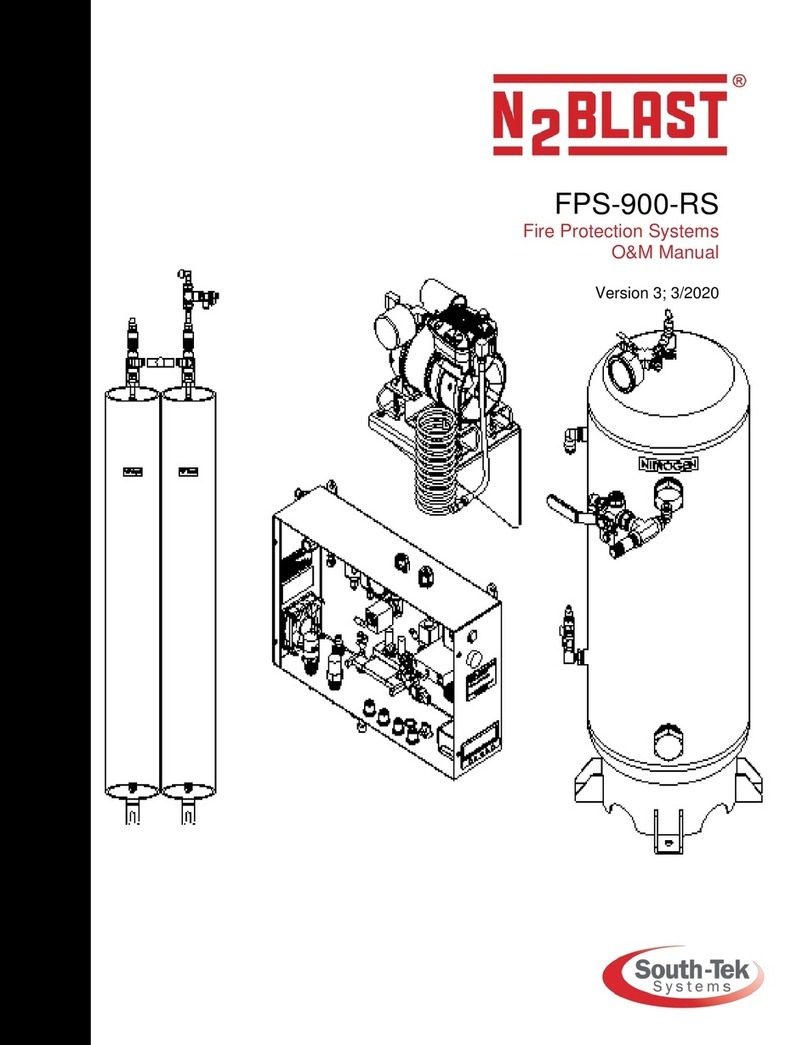

South-Tek Systems N2BLAST FPS-1650 User manual

FPS-1650

FPS-3250

FPS-5000

Fire Protection Systems

O&M Manual

Version 2; 03/2018

© 2020

The Leader in Nitrogen Generation Technology

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 2 of 32

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 3 of 32

TABLE OF CONTENT

1. INTRODUCTION ..................................................................................................................................... 6

1.1 General Purpose ............................................................................................................................. 6

1.2 About South-Tek Systems ............................................................................................................... 6

1.3 Audience ......................................................................................................................................... 6

1.4 Important Information ...................................................................................................................... 6

1.5 Limits Of Liability ............................................................................................................................. 7

1.6 Service Return Policy ...................................................................................................................... 7

2. SAFETY GUIDELINES ............................................................................................................................ 8

2.1 General ............................................................................................................................................ 8

3. RECEIVING, UNPACKING, AND STORAGE INSTRUCTIONS ............................................................ 10

3.1 Unpacking and Preparation ........................................................................................................... 10

4. SITE AND UTILITY REQUIREMENTS .................................................................................................. 11

4.1 Air Supply (for FPS-3250 and FPS-5000 Models Only) ................................................................ 11

4.2 Additional Piping and Hosings ....................................................................................................... 11

4.3 Electrical Requirements ................................................................................................................ 11

4.4 Site Specifications ......................................................................................................................... 11

5. PRODUCT INSTALLATION ................................................................................................................... 12

5.1 Installation (for FPS-1650) ............................................................................................................ 12

5.2 Panel Layout and Gas Connections .............................................................................................. 13

6. SYSTEM DESIGN ................................................................................................................................. 14

6.1 Key Features ................................................................................................................................. 14

6.1.1 Air Compressor (for FPS-1650 Only): .................................................................................. 14

6.1.2 Air Filters: ............................................................................................................................. 14

6.1.3 Programmable Logic Controller (Plc): .................................................................................. 14

6.1.4 Safety Relief Valves: ............................................................................................................ 14

6.1.5 Nitrogen Tank: ..................................................................................................................... 14

6.1.6 Automatic Cut-In and Cut-Out: ............................................................................................ 14

6.1.7 Patented Blastoff® Leak Detection: ...................................................................................... 15

6.2 Specifications ................................................................................................................................ 15

7. SYSTEM OPERATION .......................................................................................................................... 15

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 4 of 32

7.1 General .......................................................................................................................................... 16

7.2 Home Screen ................................................................................................................................ 16

7.3 Dashboard ..................................................................................................................................... 16

7.3.1 Smart-Trak® Sensor Graph .................................................................................................. 17

7.3.2 Sensor Data Log .................................................................................................................. 17

7.3.3 System Performance Log .................................................................................................... 17

7.3.4 Equipment Status Log ......................................................................................................... 18

7.3.5 N2 Leakage Log ................................................................................................................... 19

7.3.6 Bypass Log .......................................................................................................................... 19

7.4 Operation ....................................................................................................................................... 19

7.4.1 Bypass Alarm ....................................................................................................................... 20

7.4.2 Blastoff® Alarm ..................................................................................................................... 20

7.4.3 Compressor Issue Alarm ..................................................................................................... 20

7.4.4 Dryer Issue Alarm ................................................................................................................ 20

7.4.5 Filter Issue Alarm ................................................................................................................. 21

7.5 Graphs ........................................................................................................................................... 21

7.6 Alarms ........................................................................................................................................... 21

7.6.1 Filter Alarm ........................................................................................................................... 22

7.7 Product Information ....................................................................................................................... 22

7.8 System Settings ............................................................................................................................ 22

7.8.1 N2 Pressure Settings ............................................................................................................ 23

7.8.2 Sensosr Calibration ............................................................................................................. 23

7.8.3 Bypass Settings ................................................................................................................... 23

7.9 Maintenance .................................................................................................................................. 24

7.9.1 Valve Controls ...................................................................................................................... 24

7.9.2 Alarm Contacts .................................................................................................................... 25

7.9.3 Filter Maintenance ............................................................................................................... 25

7.10 Alarm Settings ............................................................................................................................. 25

7.10.1 General Alarm Settings ...................................................................................................... 26

7.10.2 O2 Purity Alarm Settings (Only Available with O2 Sensor) ................................................. 26

7.10.3 Blastoff® Alarm Settings ..................................................................................................... 26

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 5 of 32

7.10.4 N2 Pressure Alarm Settings ............................................................................................... 26

7.10.5 Bypass Alarm Settings ....................................................................................................... 26

7.10.6 Equipment Status Settings ................................................................................................ 27

7.11 Communication Settings ............................................................................................................. 27

7.11.1 Network Communication (PC) Screen ............................................................................... 27

7.11.2 Network Communications (PLC) Screen ........................................................................... 27

7.11.3 Network Communication Status ........................................................................................ 27

7.12 Factory Settings .......................................................................................................................... 27

8. START-UP PROCEDURES ................................................................................................................... 28

8.1 Start-Up Procedures ...................................................................................................................... 28

8.2 Checking For Leaks ...................................................................................................................... 29

8.2.1 To Determine if Leak is between Generator and Nitrorgen Tank: ....................................... 29

8.2.2 To Find Leak within Cabinet: ............................................................................................... 29

9. MAINTENANCE ..................................................................................................................................... 30

9.1 Air Pre-Filter (For FPS-1650 Units Only): ...................................................................................... 30

9.2 Air Filter Replacement ................................................................................................................... 30

10. KEY CONTACTS ................................................................................................................................. 31

11. FAQS ................................................................................................................................................... 31

11.1 Power Issues ............................................................................................................................... 31

11.2 Pressure Issues ........................................................................................................................... 31

11.3 Gas Leaks ............................................................................................................................. 31

APPENDIX A: WARRANTY ....................................................................................................................... 32

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 6 of 32

1. INTRODUCTION

1.1 General Purpose

This manual provides proper installation and use of South-Tek Systems N2BLAST® FPS-1650, FPS-

3250, and FPS-5000 only. South-Tek Systems is not responsible for damages when using this in

manners not approved by South-Tek Systems. The user(s) of this document should confer any

questions with a qualified South-Tek Systems representative on its commissioning and correct use.

Please contact South-Tek Systems with any question or concerns at:

South-Tek Systems, LLC

3700 U.S. Highway 421 North, Wilmington, NC, 28401

Tel: (888) 526-6284

Email: Info@southteksystems.com http://www.southteksystems.com/

The manual is based on the R&D performed by the South-Tek Systems Engineering.

WARNING: Read the manual in its entirety before installing or using the equipment.

1.2 About South-Tek Systems

South-Tek Systems, founded in 1997, is a nitrogen generator manufacturer designing nitrogen

generators for worldwide distribution. Why not produce nitrogen at your facility for a fraction of the cost

versus endlessly paying for bulk liquid or delivered gas cylinders? We make a full line of nitrogen

generator including:

• The N2GEN® Series Nitrogen generators for use in various industrial and lab applications.

50,000 SCFH unit.

• The BeerBlast™ - Mixed Gas Dispense System Increases profits, removes over or under

carbonation, and improves all-around taste and draft beer quality.

• The N2BLAST® - Corrosion Inhibiting System effectively arrests electrochemical, galvanic and

micro-biologically influenced corrosion (MIC) by introducing 99.9995% pure nitrogen into dry

and preaction sprinkler systems.

With purities ranging from 95% up to 99.999%, we provide nitrogen generators that are sure to suit

your needs. For more information about our complete nitrogen generator capabilities, please visit

www.southteksystems.com.

1.3 Audience

This manual is for Installer/Supervisory Staff. Read the entire manual before operating. Please contact

the local provider for any operation and maintenance questions before contacting the manufacturer.

1.4 Important Information

All personnel (and their supervisors) installing, operating, and maintaining the N2BLAST® must read

and fully understand this manual prior to installing, operating or performing maintenance.

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 7 of 32

The N2BLAST® produces nitrogen (N2) at a low flow rate, which quickly dissipates into the air. N2 gas

is not poisonous, but do not directly inhale, since high concentrations can cause asphyxiation. Install

the unit in a well ventilated room that is not sealed off from normal living space air changes.

All personnel involved with installation, operations, and maintenance of the N2-BLAST® must follow

safe working practices, including OHSA and local health/safety code regulations.

1.5 Limits of Liability

Buyer’s exclusive remedy for all claims shall be for damages, and seller’s total liability for any and all

losses and damages arising out of any cause whatsoever including, without limitation, defects in or

defective performance of the system, (whether such claim be based in contract, negligence, strictly

liability, other tort or otherwise) shall in no event exceed the purchase price of the system in respect

of which such cause arises or, at seller’s option, the repair or replacement of such; and in no event

shall seller be liable for incidental, consequential or punitive damages resulting from any such cause.

Seller shall not be liable for, and Buyer assumes all liability for, the suitability and the results of using

nitrogen by itself or in any manufacturing or other industrial process or procedure, all personal injury

and property damages connected with the possession, operation, maintenance, other use or resale of

the System. Transportation charges for the return of the System shall not be paid unless authorized

in advance by Seller.

NOTE: Any MODIFICATIONS made by the customer without the written consent of South-Tek

Systems will void the product’s warranty.

1.6 Service Return Policy

Follow these procedures to return the system when performing site repairs is not possible:

• The owner must get a written Return Material Authorization number, which references the

model and serial number, from South-Tek Systems. South-Tek Systems will not accept any

items for service or credit without written authorization by South-Tek Systems.

• Returned all items with the original packaging material if possible. Package all items for safe

return to South-Tek Systems. South-Tek Systems will not be responsible for damages, which

occur in transit. Damages occurred from failing to adhere to these procedures will be the

customer’s responsibility. Contact South-Tek Systems for a return shipping address.

• Shipping charges must be prepaid on all returns.

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 8 of 32

2. SAFETY GUIDELINES

The following section outlines the basic safety considerations about installation and operation of the

N2BLAST® FPS-1650, FPS-3250, and FPS-5000. For other equipment used with the nitrogen

generator, such as air compressors, and dryers, refer to the manufacturer’s safety guidelines.

2.1 General

Using the FPS-1650, FPS-3250, and FPS-5000 correctly is important for safety and trouble-free

operation. Wrong use can cause damages to the system or can lead to incorrect gas supply. The

nitrogen generator produces nitrogen at a low flow rate, which quickly dissipates into the air. Nitrogen

is not poisonous, but do not directly inhaled, since high concentrations, can cause asphyxiation.

Install the unit in a well-ventilated room, unsealed off from normal living space air changes.

Read carefully and act accordingly before installing, operating, or repairing the unit:

• Operator must use safe working practices and rules when running the nitrogen generator.

• The owner is responsible for always keeping the unit in safe working conditions.

• Always use approved parts when performing maintenance and repairs. Make sure that

replacement parts meet or exceed the original parts’ specification.

• Only competent individuals, train and authorized, can install, operate, perform maintenance,

and repair.

• Isolate incoming and outgoing pressures to the generator, and depressurize the service or

repair section before performing any mechanical work, including changing the filters. Vent the

nitrogen generator’s exhaust gas outside or to a large, well-ventilated room to avoid

suffocation due to lack of oxygen.

• Wear safety glasses if the cabinet door is open while the machine is running.

• Use ear protection when the equipment is running.

WARNING: Components may experience pressure during operation. Pressurized gases are

dangerous and may cause injury or death if handled or used inappropriately.

• Never allow pressurized gas to exhaust from an unsecured hose. An unsecured hose may

present a whipping action, which can cause serious injury. If a hose burst during use,

immediately close all isolation valves if safe and turn off the unit.

• Never disable or bypass any safety relief valves.

• Always disconnect the nitrogen generator the supply power prior to performing electrical work.

NOTE: Always following local and site safety regulations in conjunction with this manual. Correct use

of the nitrogen generator is important for personal safety. Incorrect safety practices can cause damage

to the individual and equipment.

Follow safe working practices, OSHA, and local health and safety regulation when installing and

maintaining the N2BLAST® FPS-1650, FPS-3250, and FPS-5000.

WARNING: Read the manual before installing and operating the nitrogen generator to prevent

accidents and damages.

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 9 of 32

• Contact the supplier for questions not answered in this manual.

• Only use the FPS-1650, FPS-3250, and FPS-5000 as its designed purpose.

• Only qualified service-engineers may work on installation, maintenance and repairs.

Unqualified people should not work on the equipment.

• Do not tamper or experiment with the equipment or exceed the technical specifications

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 10 of 32

3. RECEIVING, UNPACKING, AND STORAGE INSTRUCTIONS

3.1 Unpacking and Preparation

The N2BLAST® FPS-1650, FPS-3250, and FPS-5000 will arrive in a wooden crate. Open the side

labeled “Open Side” to identify and verify all parts listed on the packing list are present and

undamaged. South-Tek Systems (STS) is not responsible for damages that occur during shipping and

handling of the N2BLAST®. Document any visual damages and report them to the responsible shipping

company, and then, contact STS at (888) 526-6284 to assess the damages.

Until Installation:

• Store the N2BLAST® in a dry and climate controlled (60-80° F) room

• Always keep N2BLAST® in an upright position or in box as shipped

• Read entire manual and make all connections (per instructions) before connecting power

• Keep all gas lines dry so moisture does not enter generator on hook-up

• Never place or stack objects on top of the N2BLAST®

Removing the nitrogen generator from the crate requires unbolting it from the crate. Carefully, lift the

unit out and set it on the floor. Use a floor jack to move it to the final location.

Note: For the FPS-1650, remove the 4 painted bolts below the cabinet to free up the compressor’s

vibration isolators.

Carefully, break down the crate and store in a safe location. Reuse the create if returning for factory

service.

Figure 1: Hardware Removal for FPS-1650 only

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 11 of 32

4. SITE AND UTILITY REQUIREMENTS

4.1 Air Supply (for FPS-3250 and FPS-5000 Models Only)

(Note: N2BLAST® FPS-1650 models have integrated compressor with acceptable air filtration.)

Keep the nitrogen generator’s air supply between 40-100° F (4-38° C) and a water dew point less than

40° F (4° C). Exceptions are available for custom designed units. Air supply that does not meet these

requirements may cause damages not covered by warranty. Other equipment, such as the air dryer

and pressure vessels, must meet minimum design specifications to function properly. Contact South-

Tek Systems or the local installer for any questions about air supply requirements.

The nitrogen generator’s incoming minimum and maximum air pressure is 100 PSIG and 125 PSIG,

respectively, unless otherwise configured. Set the incoming air pressure at the design air in pressure

to meet purity and flow specifications. Operation at other pressures may result in unwanted

performance and damages to the generator’s components. Air consumption depends on nitrogen

product purity and flow rate. Please consult South-Tek Systems for specific details.

4.2 Additional Piping and Hosings

Sourcing and installing piping and hosing components are by others. They must meet the max feed

air at system’s pressure, which can be up to 3 times the specified average feed air flow-rate. Consider

all incoming feed air flow-rate references on the nitrogen generator as average feed air unless

otherwise noted. If piping length from the air receiver is greater than 50 feet, consult with a piping

contractor for proper line size.

4.3 Electrical Requirements

The N2BLAST® FPS-1650, FPS-3250, and FPS-5000 requires 120-240VAC / 50-60hz / 1ph. The FPS-

1650 draws < 8A, the FPS-3250 and FPS-5000 draws < 5A. They have a built in 20A over-current

protection device and comes with a standard 3-prong US power cord for the electrical connection

(unless otherwise specified). They comes with UL 508A ICP certification, and the electrical schematic

are available upon request.

4.4 Site Specifications

Unless designed otherwise, install in a nonhazardous indoor location with temperatures between 40-

100°F (4°- 38°C). For ease of maintenance, troubleshooting, and minimizing pressure drop, install the

equipment in the same area. Leave enough space around the generator and other equipment for

routine maintenance.

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 12 of 32

5. PRODUCT INSTALLATION

5.1 Installation (for FPS-1650)

Install the N2BLAST® FPS-1650 on a hard, flat surface supporting 300+ lbs. To secure the unit to the

floor, use the four anchor bolt-holes on the support legs. Anchoring is not required, but follow site and

local codes for securing equipment.

The recommended clearance on the front and side is 36” for maintenance and 6” minimum on all sides

for ventilation. Keep in mind, the user touch screen is on left side and performing routine maintenance

is from the front door. Leave enough clearance room on the top of the cabinet for gas line connections.

The FPS-1650 has two ¼” OD drain ports on the

cabinet’s left side. The FPS-3250 and FPS-5000

has two ½” OD and one 3/8” OD drain tube on the

bottom of the cabinet. Plumb these drain lines

individually to the nearest site drain and leave

open to atmosphere for proper drainage.

See below for basic setup. Refer to the general

arrangement drawing for detail instructions

included with the installation package.

Figure 2: FPS Nitrogen Generator Drain Ports

Figure 3: FPS Nitrogen Generator Installation Setup

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 13 of 32

5.2 Panel Layout and Gas Connections

See figure below for panel layout and gas connections. Double-check all connection locations before

turning on or opening any valves.

Note: All N2BLAST® models come with ½” NPT Female connections unless otherwise stated.

External Components

Item#

Description

Service

1

½” FNPT Ball Valve

Air Inlet

2

½” FNPT Ball Valve

N2 Out

3

0-160 PSIG Pressure Gauge

Internal Storage Tank Pressure

4

¼” OD PTC Coupling

Filters Drain Line Connection

5

Unitronics Electrical Assembly

System Controller (PLC)

6

Power Entry Module, 20 AMP

System Main Power Connection

7

UL 508A Open Industrial Panel

Electrical Connections

8

UL 508A Open Industrial Panel Certification Label

9

Electrical Panel and Terminal Block Torque Specifications Label

10

Product Serial Number Label

11

Buzzer and Display Screen Warning Information Label

12

Nitrogen Generator Information Label

Figure 4: FPS Nitrogen Generator Dimensions and Connections

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 14 of 32

6. SYSTEM DESIGN

6.1 Key Features

The N2BLAST® FPS-1650, FPS-3250, and FPS-5000 key features:

• Air compressor (for FPS-3250 only)

• Safety Relief Valves

• Air Filters

• Automatic Pressure Cut-in/Cut-out

• Programmable Logic Controller (PLC)

• N2 Tank

• Pressure Swing Adsorption Beds

• STS Patented Blast Off®

6.1.1 Air Compressor (for FPS-1650 Only):

An oil-less internal air compressor has an engineered dampening system reducing vibration and

noise throughout the cabinet. The air compressor has a pre-filter to catch small particulates that

can cause damage. The recommended replacement for the pre-filter is 1000 run hours or 1-year,

whichever comes first. Dirtier environments may need more frequent changes. Consult with the

supplier for a different filter maintenance schedule if installing in a dirty environment.

6.1.2 Air Filters:

The generators have two filters between the compressed air and O2 separation beds - the

particulate and coalescing. The FPS-1650 has an air inlet pre-filter, and the FPS-3250 and FPS-

5000 will have an additional absorbing filter. The 5 micron particulate filter catches the bulk

particles, and the 0.1 micron coalescing catches the remaining smaller particles. Both filters feature

an auto-drain that drains any water buildup within the filter housing. These FPS-1650 drain lines

are on the cabinet’s lower left side. The FPS-3250 and FPS-5000 drain lines are on the cabinet’s

bottom. Connect these drain lines to a safe location. The FPS-3250 and FPS-5000 absorbing filter

does not require drain plumbing because it does not have an auto-drain.

6.1.3 Programmable Logic Controller (PLC):

An integrated PLC within the cabinet, features smart and efficient coding to maximize the

generator’s performance. It controls the valve timing and sequencing to move compressed gas

throughout the system. It also has a smart feature to go automatically into different “modes” based

on the current run stages. It comes with a touchscreen with many display options. (See Chapter 7:

System Operation for more about the program’s functionality).

6.1.4 Safety Relief Valves:

The installed ASME safety relief valves adds additional safety to protect component failures.

6.1.5 Nitrogen Tank:

A nitrogen tank inside the cabinet comes with ball valves, safety relief, and a gauge. The outlet gas

connects to an external manual ball valve for easy plug and play connection.

6.1.6 Automatic Cut-In and Cut-Out:

The generator starts and stops based on an analog signal to the PLC from the built-in pressure

transducer. Do not adjust the factory preset cut-in and out pressure without first consulting with

South-Tek Systems.

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 15 of 32

6.1.7 Patented Blastoff® Leak Detection:

The “BlastOff® Leak Detection” is a patented feature which sends an alarm if it detects a possible

gas leak. The alarm signal can be an audible, visual, and dry contact connection to the “Building

Management System’s (BMS)”. Power cycle the unit to reset the alarm, but avoid doing this multiple

times without finding the cause as it will shorten the generator’s life.

6.2 Specifications

N2Blast FPS-1650 and FPS-3250 Specifications

Nitrogen Purity

98.0+%

Installation

Floor standing

Display

Hours / Run / Standby / Filter Alarm / BlastOff®

N2 Storage Pressure

60-75 PSIG

Cabinet Port Connections

1/2” NPT Female

Electrical

120-240VAC / 50-60 Hz / 1Ph / FPS-1650 < 8 A, FPS-3250 < 5A

Compressor

(for FPS-1650 only) Integral / Oil-Free

Ambient Temp.

40° to 90°F

Noise Level (dbA)

< 80 dbA

Cabinet Dimensions

26” W x 18” D x 59” H

Weight

Approx: 265 lbs (FPS-3250

Table 1: FPS Nitrogen Generation Specifications

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 16 of 32

7. SYSTEM OPERATION

7.1 General

South-Tek Systems’ proprietary program controls the valve sequencing to produce nitrogen. The

design meets specifications of a fire protection system. Consult with South-Tek System for written

approval before performing any field changes or customization. Unauthorized changes voids all

warranties and may cause damages or malfunctions to the system.

This section describes the major control functions and

instrumentations associated with the nitrogen generators. All

programs are proprietary and password protected from the

factory. Do not alter any controls or instrumentations.

Changes without South-Tek Systems’ written consent voids

the performance specifications.

Note: This section does not included the controls for

supporting equipment, such as the compressor and dryer.

Please consult the original manufacturer’s manual for further

information.

7.2 Home Screen

The home screen displays menu that navigates the user to

different program screens. The first page allows access to the

following screens: Dashboard, Operation, Graphs, Alarms,

Production Info, and Next Screen. The “Next” screen allows

access to the following screens: Previous Screen, System

Settings, Maintenance, Alarm Settings, Communication

Settings, and Factory Settings. Printed on the manual’s

second page is the user password which allows access to

certain screens.

The home screen has a Start/Stop button to start and stop the generator. Hold the button for 1-second

to change state. The status indicator next to the Start/Stop button shows “Hold” for 1-second and then

change states from “Off” to “Running” or vice versa.

7.3 Dashboard

This screen provides the operator with the basic statistics of the

nitrogen generator. The large gauge on the screen displays the

nitrogen pressure in the nitrogen tank. Below the gauge is a

digital hour meter logging the overall run hours of the nitrogen

generator. The right side displays the “N2 Leakage Averages”.

It shows the last, current day, and monthly nitrogen leakage (in

SCFH) of the fire protection system.

The SMART-Trak® button navigates to another menu, and the

system status bar shows system status.

Figure 5: Home Screens

Figure 6: Dashboard Screen

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 17 of 32

7.3.1 SMART-Trak® Sensor Graph

The Smart-Trak button brings up the following other data tracking capabilities: Sensor Graphing,

Sensor and Data Log, System Performance Log, Equipment Status Log, N2 Leakage Log, and

Bypass Log. The user can scroll through the different choices using the left upper and lower arrows.

7.3.2 Sensor Data Log

This provides detail sensor data installed with the unit. The nitrogen pressure transducer comes

standard. Additional sensors includes - airflow meter, nitrogen flow meter, oxygen sensor, and air

in temperature sensor. The data log tracks current, average, max, and minimum when selecting

both the “Start” button and the nitrogen generator starts a new cycle. Press the “Stop” button to

stop logging, and press the “Reset” button to reset the data. The “SD Card” button brings up “Start"

micro SD card data logging option. To start the logging, press the “Start” button and press the

“Stop” button to stop the data collection. Before removing the micro SD card, press the “Eject”

button and wait until the status indicates that it is safe for removal.

7.3.3 System Performance Log

This feature tracks the system performance based on user input time. It continues to collect data

until the user turns off the logging. It collects the following data: Start Data, End Date, Total Run

hours, Total Cycles, Total Air Flow1, Total N2 Flow1, Air/N2 Ratio1, Average O2%1, Average O2

PPM1, Average Air Pressure1, and Average N2 Pressure.

Figure 7: SMART-Trak®

Figure 8: Sensor Data Logging

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 18 of 32

Note 1. The data collection is possible with optional sensors included. Contact South-Tek Systems

for further details.

Start the “System Performance Log” by going to the setup page. Enter the test duration and press

the “Start Performance Log” button (the icon will turn green). Reset the current data or entire

“System Performance Log” by pressing the “Reset” button. A confirmation screen pops up before

permanently deleting the data. An example of how the “System Performance Log” works: A “Test

Duration” of 7 days monitors and records data for 7 days. After 7 days, it logs the final values and

starts a new 7-day log. This cycle continues repeating itself every 7 days until stopping the “System

Performance Log”. This allows the user to compare historical data and monitor performance trends

of the system.

7.3.4 Equipment Status Log

The “Equipment Status Log” screen logs every equipment alarm instances (i.e. - air compressor,

dryer, or nitrogen generator alarm). It logs the date, time, and notes which equipment triggered an

alarm. Use the scrolling feature to scroll through the history. The data can be reset by pressing the

“Reset” button. A confirmation screen pops up before permanently deleting the data.

Figure 9: System Performance Log

Figure 10: Equipment Status Log

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 19 of 32

7.3.5 N2 Leakage Log

The “N2 Leakage Averages”, on the right of the screen shows three system leakage averages in

SCFH - last measured, current day, and current month. By pressing the “N2 Leakage Average

button”, it brings up more options to turn on/off the logging, view monthly log, and reset the data.

7.3.6 Bypass Log

The “Bypass Log” screen provides a log of every instances of

the system being in “Bypass” mode. It logs the date, time, and

duration of the bypass mode. Use the scrolling feature to scroll

through the history. The data can be reset by pressing the

“Reset” button. A confirmation screen pops up before

permanently deleting the data.

7.4 Operation

The following images display the “Off”, “Standby”, and “Running”. A status icon on each equipment

indicates the status. The check mark [P] indicates the equipment working properly where a warning

symbol [^] indicates an issue. Gas flow animation with small white blips travels along the appropriate

path (Air = Blue; N2 = Green). After initial alarm, all alarm screens will time-out and revert to this

operation screen. Gray piping with no animation mean no moving gas. The alarm triggered is displayed

in the upper right corner “Status Bar”.

Figure 2: N2 Leakage Log

Figure 3: Automatic Bypass Log

Figure 13: Operation Modes – Off, Standby, Running

The Leader in Nitrogen Generation Technology

Smart AMD O&M Manual

Version: 0; 1/2021

Page 20 of 32

7.4.1 Bypass Alarm

During the 30-minute fire protection piping system fill test, or if the

generator is not functioning correctly, the “Bypass Alarm” triggers.

This generator automatically switches over to the external air

compressor. This bypasses nitrogen production until the fire

protection piping system no longer demands the increased gas

flow. Press the red bell icon to temporarily silence the buzzer. The

generator will automatically return to normal nitrogen operation.

7.4.2 BLASTOFF® Alarm

The system activates a BlastOff® Alarm when it detects potential

leaks or nitrogen being overdrawn. The operation screen will

appear and with a status notification in the upper right corner

flashing “BlastOff”. Press the red bell icon to temporarily silence the

buzzer. Inspect and test the system for leaks and component

failures. Contact South-Tek System or your local installer for further

troubleshooting.

7.4.3 Compressor Issue Alarm

When the nitrogen generator detects an issue with the air

compressor, it will jump to the operation screen and display a

warning symbol on the air compressor. Press the red bell icon to

temporarily silence the buzzer. Check the air compressor for power,

line leaks, or other equipment failures in order to get the nitrogen

generator running properly again. Contact South-Tek System or the

local installer if further troubleshooting.

7.4.4 Dryer Issue Alarm

When the nitrogen generator detects an issue with the air dryer, it

will jump to the operation screen and display a warning symbol on

the air compressor. Press the red bell icon to temporarily silence the

buzzer. Check the air dryer for power, line leaks, or other equipment

failures in order to get the nitrogen generator running properly again.

Contact South-Tek System or the local installer if further

troubleshooting.

Figure 14: Bypass Mode

Figure 15: BlastOff Mode

Figure 16: Compressor Issue

Figure 17: Dryer Issue

This manual suits for next models

2

Table of contents

Other South-Tek Systems Safety Equipment manuals