3/21

Assembly and maintenance instructions railoc

Table of contents

0. General .................................................................................................................................................... 4

0.1 Intended use .......................................................................................................... 4

0.2 Preliminary remark ................................................................................................. 4

0.3 Liability and warranty ............................................................................................. 4

0.4 Safety instructions .................................................................................................. 4

1. Device description .................................................................................................................................. 5

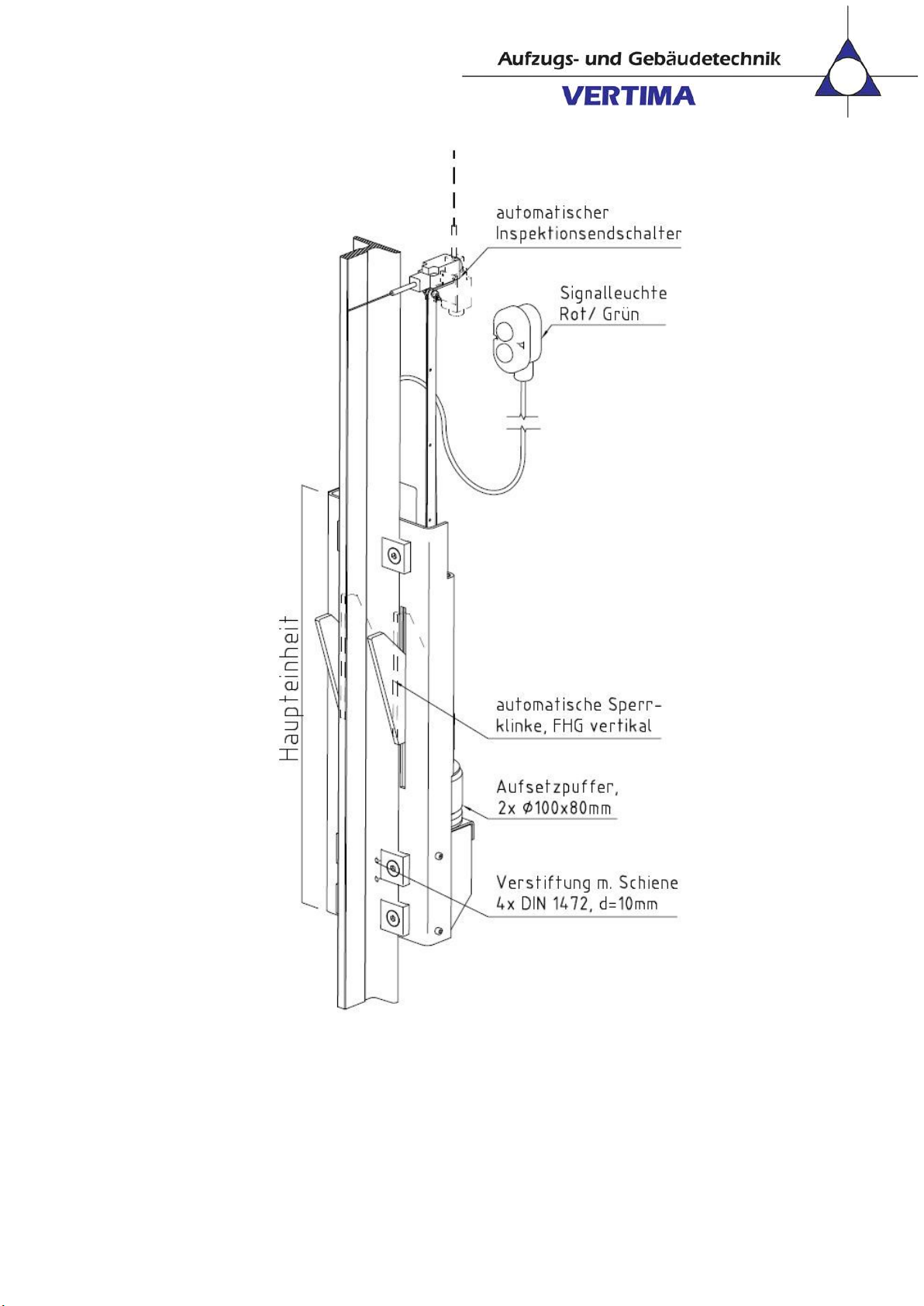

1.1 Design and scope of delivery ................................................................................. 5

1.2 Functionality ........................................................................................................... 6

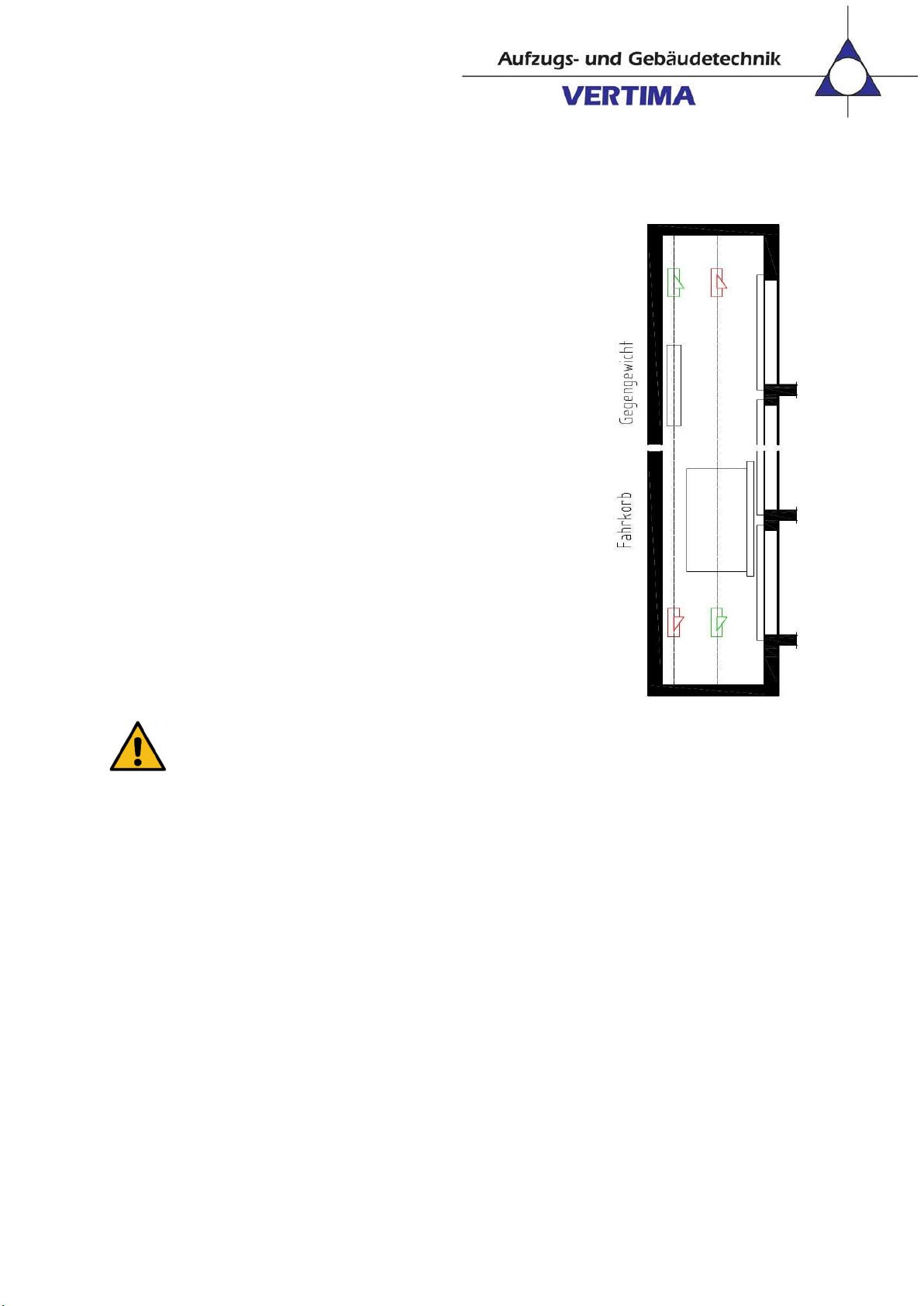

1.3 Mounting variants ................................................................................................... 8

1.4 External components and boundary conditions ..................................................... 9

1.5 General notes on function .................................................................................... 10

2. Assembly / installation......................................................................................................................... 11

2.1 Preparation .......................................................................................................... 11

2.2 Positioning the railoc ............................................................................................ 12

2.3 Mechanical assembly ........................................................................................... 12

2.4 Electrical installation............................................................................................. 13

2.5 Inspection and commissioning of the system after installation. ............................ 14

3. Railoc in operation ............................................................................................................................... 15

3.1 Test instruction ..................................................................................................... 15

3.2 Maintenance ........................................................................................................ 15

3.3 Repairs and disposal............................................................................................ 16

4. Annex ..................................................................................................................................................... 17

4.1 Principle description of the function of railoc ........................................................ 17

4.2 Circuit diagram ..................................................................................................... 18

4.3 Overview standard stops ...................................................................................... 19

4.4 Risk analysis (example) ....................................................................................... 20