.........................................................................................................................................................................................................................................................................................................................................................................................................................................................

* This lifeline is aimed to prevent user from falling. However, the system

itself is not suitable for working at height, it must also be used together

with CE certificated Safety Harness (EN 361, EN 358) shock absorber

lanyard (EN 355), hooks (EN 362) and fall arresters (EN 360)

* Operating Temperature Range Minimum -30’C to Maximum +70’C.

3- Raw material

This horizontal life line;

* Energy absorber is made of polyurethane.

* Anchor Brachate are made of 316 quality stainless steel.

* Pole anchor are made of ST 37 galvanized.

4- Anchor Point (EN 795/C:2012, CEN/TS 16415:2013)

* K-2010 Horizontal Life Line is suitable for 3 user at the same time.

(B-Dynamic Performans Version 2 - Direct installation on to the structure

with post anchor is suiatable for only 2 users.)

The anchor points of the horizontal lifeline is required to have a minimum

strength of 14 kN for use of 3 person. Breaking strenght of the structure

where the lifeline is goint to be installed should be reviewed in accordance

with Dynamic Performance Values.

4.1- Installation

* K-2010 Horizontal Lifeline must be installed by competent people who

have Working at Height Certificate and are trainined and authorized by

Kaya Safety. The responsiblity of whole system belongs to the company

that performed the installation.

* Please refer to K-2010 Horizontal Lifeline installation guide for correct

installation.

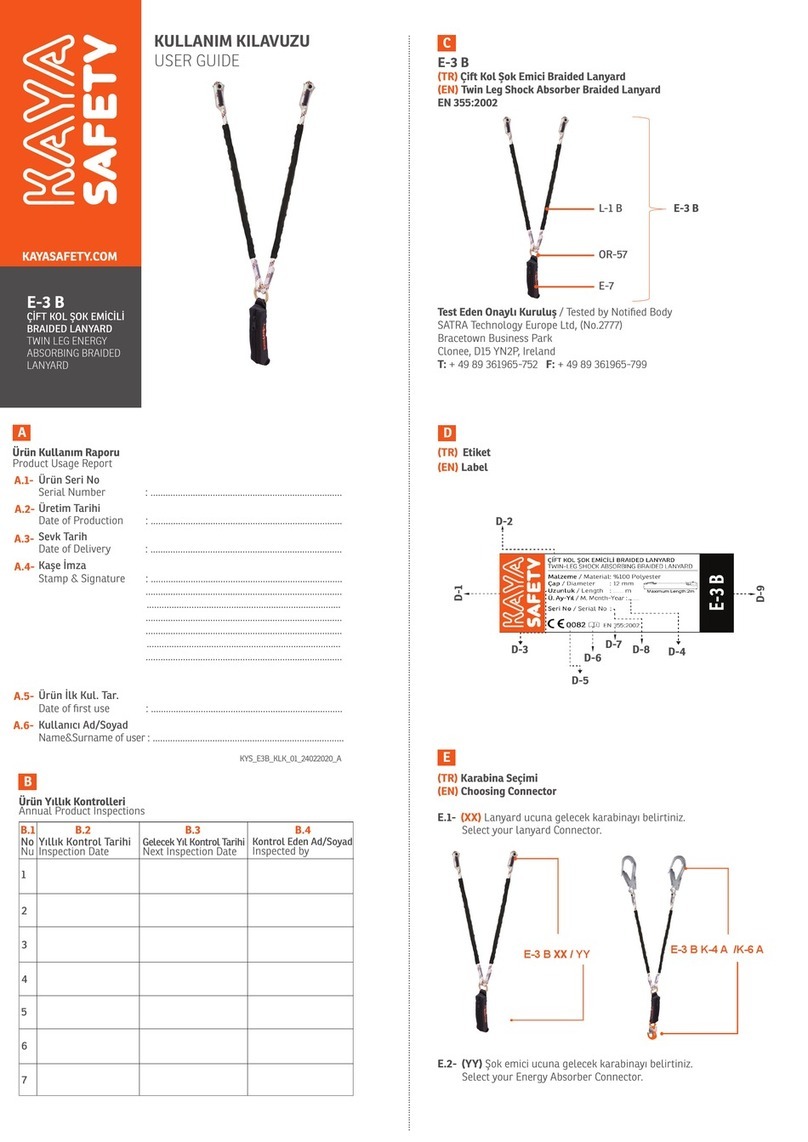

4.2. Using SRY-50 Slider

If the system is appropriate to use then SRY-50 Slidder is joint to the

system. SRY-50 slides on the line and so enables users to have a continuous

anchorage point. SRY-50 Slidder can be installed on and removed from any

point of the line.

In order to install SRY-50 onto the system;

* Open the latch of the SRY-50 and place it onto the line (Figure-1),

* Close latch of the SRY-50 (Figure-2),

* Place a K-14 Carabiner onto SRY-50 (Figure-3),

After attaching the SRY-50 onto the system, an appropriate PPE for working

at height must be used. Make sure that all the components are compatible

with whole system.

4.3 Using Lifeline

1- Warning sign must be checked by user before using the system to ensure

that the system is appropriate to use. Make sure that the date of the next

check of the system is not due, or it is not more than a year from the last

date of the check.

2- ,metsystserrallaffotrapasadesusienilefiLlatnoziroH0102-K

nehW

the impact force experienced by the user must be restricted to max of 6 kN.

In order to do so the connection equipment used between safety harness

and Lifeline must be chosen correctly.

3- Your Lanyard or any other connection equipment must be connected

directly to SRY-50 Slider on the horizontal lifeline and to anchorage point

of Fall Arrest Harness indicated with ‘A’.

4- The angle of intermediate anchors of the lifline must be max of 15° and

turn corners must be 60°.

4.3.1 Use of Horizontal Lifeline with Retractable Fall Arrester or Guided

Type Fall Arrester with Flexible Anchor Line (EN 360, EN 353-2);

* The Retractable fall arrester (EN 360) must be compatiable to use with

Horizontal Lifeline. Kaya has tested, approved and certified below models

to use with K-2010 Horizontal Lifeline. For use of any other models, compatibilty

test needs to be performed with K-2010 Horizontal Lifeline and necessary

confirmation must be taken.Kaya is not responsble for the use of non-approved

models.

* Guided type fall arresters including a flexible anchor line (EN 353-2) can

not be used with K-2010 Horizontal Lifeline .

* When working with a retractable fall arrester on the Lifeline, depending

on the type of the model the safe fall distance must be calculated by based

on braking distance of the device. (Table-1)

4.4 Safe Fall Distance

Before working with K-2010 Horizontal Lifeline required fall clearance

must be calculated to reduce the risk of hitting the ground or any obstructions

at a lower level.

4.4.1 Safe Fall Distance - Working with Shock Absorber Lanyard (Figure -5)

Safe Fall Distance = X+A+B+C+D

X: Deflection occurred on Lifeline after fall (D1 values provided in tables

A and B must be considered based on type of lifeline, location and number

of use).

A: Length of Lanyard

B: Length of completely ripped out shock absorber

C: Height of Suspended Worker

D: Clearance to obstruction during fall arrest

4.4.2 Safe Fall Distance – Working with Retractable Fall Arrester (Figure-6)

Safe Fall Distance = X+B+C+D

X: Deflection occurred on Lifeline after fall (D1 values provided in tables

A and B must be considered based on type of lifeline, location and number

of use)

A: Distance of Retractable Fall Arrester to Anchorage Point

B: Lock up Distance of Retractable Fall Arrester (Choose from Table -1)

C: Height of Suspended Worker

D: Clearance to Obstruction during Fall Arrest

5. Supplementary Information Regarding Standard; EN 365

5.1 Rescue Plan

A worker who has been incapacitated by an injury or medical condition and

who is suspended by the full body harness must be rescued immediately.

So you must always have a rescue plan for such emergencies. Adequately

trained personnel and rescue equipment must be on hand for rescue.

5.2 Anchor Point

The anchor point of the system should preferably be located above the

user or should at least located at the waist level of the user. An attachment

point below this level will cause a serious injury or death. The anchor point

must conform to the requirements of the EN 795 standard and the minimum

strength of it must be12kN.

5.3 Various Situations

* A fall arrest harness is the only device allowed for supporting the body in

a fall arrest system.

* In a fall arrest system, it is essential to check the required clearance under.

the user before each use, to avoid any impact with the ground or an obstacle

in case of a fall.

* Make sure that the anchor point is correctly positioned, in order to limit

the risk and the height of a fall.

* When using multiple pieces of equipment together, a dangerous situation

can result if the safety function of one piece of equipment is affected by the

safety function of another piece of equipment.

* Users must be medically fit for activities at height. Warning: inert suspension

in a harness can result in serious injury or death.

* The instructions for use for each item of equipment used in conjunction

with this product must be respected.

* The instructions for use must be provided to users of this equipment in

the language of the country in which the product is to be used.

6 Control of Product and Validation

6.1 Before Each Use

Working at height equipment must be inspected before each use and/or

on a regular basis. Findings must be recorded on product control book.

Inspection must be performed based on following control criteria.

* If there is any deformation on system components

* If there is any corrosion on system components

* if system components are exposed to chemicals

If the product has one of the deviations above, it should be withdrawn from

service immediately. Defects found on the product should not be repaired;

manufacturer must be informed about it and user must proceed as per

manufacturer’s recommendation.

6.2 During Each Use

During performing the work at height if the equipment is connected with

another system, make sure that all pieces of equipment in the system are

correctly positioned with respect to each other.

7. Kaya General Information

7.1 Product Life

* There is no theoretical lifespan of metal components. Products must be

documented by at least one time per year to determine if the product is safe

to use. Kaya Safety is not responsible for the use of the product that has no

nnual periodic control.

* K-2020 Horizontal Lifeline is made of 316 Grade Stainless Steel. 316 grade

stainless steel is highly resistant to atmospheric corrosion. Depending on the

area of the use superficial rust spots can be seen on the product (Period may

shorten in industrial sites; iron powders and chemicals. Areas like close to

the sea; salty atmosphere). These superficial stains can be removed with an

appropriate maintenance program.

In all circumstances decision to continue to use the product can only be

made if annual periodic control has been performed and resulted positive

by manufacturer or a competent person authorized by manufacturer

If the product has one of the deviations below it should be withdrawn from

service immediately and should be destroyed to prevent further usage.

* It has suffered a heavy shock load or has had a load dropped onto it.

* If observed signs of corrosion on the product.

* if product was recorded not suitable for use during a control and if you

have any doubt about that.